Documente Academic

Documente Profesional

Documente Cultură

2 / " Mechanical Temperature, Pressure & Vacuum Gauges: Installation

Încărcat de

oopsadhitTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2 / " Mechanical Temperature, Pressure & Vacuum Gauges: Installation

Încărcat de

oopsadhitDrepturi de autor:

Formate disponibile

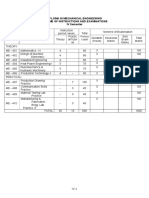

Vacuum Hose

Nylon Tubing

Adapter

1

8" NPT Adapter

1

4" NPT Adapter

Connect to

12V Lighting

Grommet

T-Fitting

For vacuum

gauges

For pressure

gauges

NOTE: Some late model vehicles use electronic sensors in their pressure and

temperature senders for engine control functions. Before removing original

sender, we recommend that you contact your automotive dealer to be sure no

critical functions will be disrupted. When installing a new pressure gauge, use

a "T" fitting to keep the warning light operational. This allows you to monitor

the pressure and still have a warning light to indicate emergency conditions.

1. Gauge can be mounted in-dash in a 2

5

/8" diameter hole or in Auto Meter

gauge mounting cups 3201 or 3202. Mounting cup is included with the

Black Fuel Saver & Chrome Fuel Saver Vacuum Gauges.

2. Drill

3

/8" diameter holes and install rubber grommets provided where

pressure or vacuum line passes through sheet metal (such as firewall).

3. Attach nylon pressure line to fitting on back of gauge using adapter nut,

ferrule, and sealing nut as shown in diagram above. Route line through

grommets to engine compartment. Connect line to pressure outlet on engine

by using

1

/8" adapter (

1

/4" if necessary), ferrule, and sealing nut for boost

and pressure gauges, or

1

/8" adapter and "T" fitting for vacuum gauges.

NOTE: Do not over tighten sealing nut. Tighten

1

/4 turn beyond snug.

4. Make sure line is routed from moving parts or hot engine components.

Where a potential hazard exists, it is recommended that a quality braided

stainless steel pressure line be used (3227 or 3228). Start engine and

inspect installation for any leaks.

5. Snap the light socket assembly in the gauge. Connect the white wire to

the dash lighting circuit or other 12 volt light source. Connect the black

wire to a good ground.

Ferrule

Sealing Nut

Use Teflon Sealing Tape

or Sealing Compound

where symbol indicates.

NOTE: When using braided

stainless steel line, tie down line

to avoid excessive vibration.

Pressure & Vacuum

For high pressure models 4424 (0-400 PSI) and

4425 (0-600 PSI) use only braided stainless

steel line.

For Model 4426 Brake Pressure, see back.

Sealed Tubing

Temperature

Sensor

Engine

Water

Passage

Sealing Nut

Grommet

1

2" NPT Mounting Nut

(For

3

8" NPT Use No. 2263)

NOTE: Some late model vehicles use electronic sensors in their pressure and

temperature senders for engine control functions. Before removing original

sender, we recommend that you contact your automotive dealer to be sure

no critical functions will be disrupted. When installing a new pressure gauge,

it is beneficial to use a "T" fitting to keep the warning light operational. This

allows you to monitor the pressure and still have a warning light to indicate

emergency conditions.

1. Gauge can be mounted in-dash in a 2

5

8" dia. hole in Auto Meter gauge

mounting panels or in Auto Meter gauge mounting cups 3203 or 3204.

2. Cut a

7

8" hole in firewall and route temperature sensor at end of gauge

tubing through hole. Slit the rubber grommet and position in hole so

gauge tubing is held firmly in place. If a gauge mounting cup is used,

install additional grommet in back of cup in same manner.

3. Insert and tighten mounting nut in the

1

2" pipe threaded outlet on

engine. (For engines with

3

8" outlet use Auto Meter no. 2263.) Insert

sensor in the mounting nut and carefully tighten with sealing nut. Apply

an anti-seizure compound-graphite to avoid seizure of the temperature

sensor to the sealing nut.

NOTE: Do not over tighten sealing nut. A

1

4 turn beyond snug should be sufficient.

Make sure gauge tubing is routed away from hazardous moving parts or hot

engine components. The Oil Temperature gauges and Transmission

Temperature gauges usually require drilling a hole and welding the Auto

Meter no. 2261 steel weld fitting in the oil or transmission pan. Check for

adequate internal clearance for the temperature sensor. Install temperature

sender as described above.

4. To use remote transmission temperature adapter, install an Auto Meter no.

2286 for

3

/8" tubing or no. 2287 for

5

/16" tubing in transmission line leading

from transmission using compression and NPT fittings provided.

5. Start engine and inspect installation for any leaks.

6. Snap in light socket assembly and connect to dash lighting circuit or

other 12 volt source.

Temperature Gauges

Installation

Installation

Use Teflon Sealing Tape

or Sealing Compound

where symbol indicates.

Connect to

12V Lighting

Apply anti-seizure

compound-graphite.

Side View

Top View

I M P O R T A N T

WEAR

SAFETY GLASSES

(*Models 4424 and 4425 must

use only braided stainless steel)

INSTALLATION INSTRUCTIONS

2

5

/8" MECHANICAL TEMPERATURE,

PRESSURE & VACUUM GAUGES

Instr. No. 2650-100V

IMPORTANT: Should you ever need to

remove the temperature sensor, loosen the

sealing nut without allowing the mounting

nut to rotate. Remove temperature sensor

and mounting if necessary. Failure to follow

this procedure may break capillary tubing

internally, thus, voiding warranty.

Models: For the Black

Fuel Saver & Chrome Fuel

Saver Vacuum Gauges, or

when using optional 3201

or 3202 mounting cup.

Star washer must

be placed between

mounting base and

cup strap.

Connect to

12V Lighting

Right

angle

adapter

Grommets

12 MONTH LIMITED WARRANTY

Auto Meter Products, Inc. warrants to the consumer that all Auto Meter High Performance products will be free from defects in material and workmanship for a period of twelve (12) months from date of the

original purchase. Products that fail within this 12 month warranty period will be repaired or replaced at Auto Meter's option to the consumer, when it is determined by Auto Meter Products, Inc. that the

product failed due to defects in material or workmanship. This warranty is limited to the repair or replacement of parts in the Auto Meter instruments. In no event shall this warranty exceed the original

purchase price of the Auto Meter instruments nor shall Auto Meter Products, Inc. be responsible for special, incidental or consequential damages or costs incurred due to the failure of this product. Warranty

claims to Auto Meter must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied

warranties shall be limited in duration to the said 12 month warranty period. Breaking the instrument seal, improper use or installation, accident, water damage, abuse, unauthorized repairs or alterations voids

this warranty. Auto Meter Products, Inc. disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by Auto Meter.

SERVICE

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. Please

specify when you need the product back. If you need it back immediately mark the outside of the box "RUSH REPAIR," and Auto Meter will service product within two days

after receiving it. ($10.00 charge will be added to the cost of "RUSH REPAIR.") If you are sending product back for Warranty adjustment, you must include a copy (or original)

of your sales receipt from the place of purchase.

FOR SERVICE SEND TO: AUTO METER PRODUCTS, INC. 413 W. Elm St., Sycamore, IL 60178 USA (815) 895-8141

For Email: service@autometer.com

Sealed Tubing

Connect to

12V Lighting

Rotate large grommet at back of cup as

necessary to allow tubing to exit as

straight as possible out back of cup.

Shown i n 3203 or

3204 Mounting Cup

Grommet

Optional Cup Mounting

1. If you are not familiar with proper brake system bleeding procedure,

do not install this gauge. Have a qualified mechanic do it for you.

2. Install gauge in 2

5

8" dia. dashboard hole or use under dash panels.

Secure gauge with the mounting bracket provided. NOTE: If mounting

gauge other than in-dash or under dash, mounting provisions may have

to be determined by the installer.

3. Secure bleed screw, bleed screw bushing, and brake line fitting to the tee

provided with the gauge as shown above.

4. Secure the tee assembly from Step 3 to the gauge port. Be sure not to

over tighten as this can cause the movement to loosen in the case.

5. Install a tee at the brake system location suitable for your application.

6. Install steel double flare brake line between gauge and tee.

7. Connect WHITE light wire to the dash lighting circuit or other 12V source.

Connect the BLACK light wire to a suitable ground.

8. Bleed your gauge and brake system using standard brake bleeding

procedure. If you are not familiar with proper brake system bleeding

procedure, do not install this gauge. Have a qualified mechanic do it.

Brake Pressure

Bleed Tubing

Bleed Screw

Mounting

Bracket

Bleed Screw

Bushing

Tee 1/8"-27 NPTF

Brake Line Fitting

Sleeve

Nut

Double Flare Steel

Brake Line To Tee

In Brake System

1/8" NPTF (Male)

XSAE 37or 45

Male Flare

Temperature Pressure & Vacuum

Use Teflon Sealing Tape

or Sealing Compound

where symbol indicates.

2650-100V 5/7/01

Model: 4426

-4AN fitting with wrench flat.

(use caution, do not to over tighten)

WARNING:

ONLY double flared brake line may be used to install this gauge. All fittings

you use must have a minimum working pressure of 2000 PSI.

2001 Auto Meter Products Inc.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Aci 447R-18 PDFDocument36 paginiAci 447R-18 PDFdodiÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Application Engineering BulletinDocument2 paginiApplication Engineering BulletinCesar G.Încă nu există evaluări

- 1400SRM0046 (06 2017) Uk en PDFDocument46 pagini1400SRM0046 (06 2017) Uk en PDFCosmin GîrleanuÎncă nu există evaluări

- Science 6 Q3 Module 8 WK 8 - v.01 CC-released-07Mar2021Document20 paginiScience 6 Q3 Module 8 WK 8 - v.01 CC-released-07Mar2021zangÎncă nu există evaluări

- List Equipment Pltu Pangkalan Susu 2x200mwDocument7 paginiList Equipment Pltu Pangkalan Susu 2x200mwDanny SurbaktiÎncă nu există evaluări

- Product Recommendation Hyundai County County D4AF (2004 and After)Document3 paginiProduct Recommendation Hyundai County County D4AF (2004 and After)Jose CachipatoÎncă nu există evaluări

- 05-1 N T4 Hydraulic Section Rev1Document128 pagini05-1 N T4 Hydraulic Section Rev1Fútbol y más100% (1)

- Numbering File SystemsDocument15 paginiNumbering File SystemsefendiÎncă nu există evaluări

- 72 Olympique (Owners Manual)Document40 pagini72 Olympique (Owners Manual)JacobnMarie LaaksoÎncă nu există evaluări

- SaeDocument8 paginiSaeahmadÎncă nu există evaluări

- SBTET AP C-14 SYLLABUS DME IV SemesterDocument36 paginiSBTET AP C-14 SYLLABUS DME IV Semesterthirukumar50% (2)

- AccessTUNER Calibration & Tuning Guide Worksheet For Subarus v2.07Document8 paginiAccessTUNER Calibration & Tuning Guide Worksheet For Subarus v2.07Marcelo Tapia MaureiraÎncă nu există evaluări

- Paper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFDocument11 paginiPaper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFbigsteve9088Încă nu există evaluări

- Selva - Expert'STips, Cleaning Mechanical MovementsDocument2 paginiSelva - Expert'STips, Cleaning Mechanical MovementsFeelxxÎncă nu există evaluări

- CEPSA Lubricants WindpowerDocument5 paginiCEPSA Lubricants WindpowerVaida Man KanÎncă nu există evaluări

- Noc18 Ce23 Assignment2 PDFDocument4 paginiNoc18 Ce23 Assignment2 PDFrichard kwofieÎncă nu există evaluări

- 8-6 Fits and AllowancesDocument15 pagini8-6 Fits and AllowancesshivendrakumarÎncă nu există evaluări

- Pipe Fittings Surface AreaDocument1 paginăPipe Fittings Surface AreasajoÎncă nu există evaluări

- Ball Mill Heat Balance ExplanationDocument4 paginiBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- Transmotauto 2015Document107 paginiTransmotauto 2015zoragiÎncă nu există evaluări

- Yamaha Ek25bmhDocument230 paginiYamaha Ek25bmhjorge gerÎncă nu există evaluări

- Uav Introduction 4Document10 paginiUav Introduction 4Vijayanandh RÎncă nu există evaluări

- Standards For The Mobility Requirements of Military VehiclesDocument19 paginiStandards For The Mobility Requirements of Military VehiclesSekwah HawkesÎncă nu există evaluări

- MATERIALS AND CONSTRUCTION ArunachalamDocument6 paginiMATERIALS AND CONSTRUCTION Arunachalamdharanya sivabalanÎncă nu există evaluări

- Notes - Measurement of Air ConsumptionDocument7 paginiNotes - Measurement of Air ConsumptionAnil Frivolous Abstemious100% (2)

- 2011 Land Rover Range Rover SpecsDocument4 pagini2011 Land Rover Range Rover Specssportutilityvehicle100% (1)

- NEO Steel Chimney DesignDocument8 paginiNEO Steel Chimney DesignAnil Pradeep100% (1)

- Vibration FinalDocument20 paginiVibration FinaljaysamÎncă nu există evaluări

- En J02.DAI.73 Daikin RZAG N Technical Data RZAG NV1 Data BookDocument51 paginiEn J02.DAI.73 Daikin RZAG N Technical Data RZAG NV1 Data BookTheEngineer - المهندسÎncă nu există evaluări

- Amal Float 691 622069 PDFDocument2 paginiAmal Float 691 622069 PDFjvdkjdlkkÎncă nu există evaluări