Documente Academic

Documente Profesional

Documente Cultură

Ferro Cement

Încărcat de

Vara PrasadDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ferro Cement

Încărcat de

Vara PrasadDrepturi de autor:

Formate disponibile

1

FERROCEMENT

1. INTRODUCTION

The term ferrocement is most commonly applied to a mixture of Portland cement and

sand reinforced with layers of woven or expanded steel mesh and closely-spaced small-diameter

steel rods rebar. It can be used to form relatively thin, compound curved sheets to make hulls for

boats, shell roofs, water tanks, etc. It has been used in a wide range of other applications

including sculpture and prefabricated building components. The term has been applied by

extension to other materials including some containing no cement and no ferrous material. These

are better referred to by terms describing their actual contents.

The term "ferrocement" was given to this product by its inventor in France, Joseph

Monier. At the time, (1850's) he wanted to create urns, planters, and cisterns without the expense

of kiln firing. In 1875 he created the first steel and concrete bridge. The outer layer was sculpted

in its wet state to mimic rustic logs, thereby also introducing Faux Bois concrete into practice.

(Recent trends have "ferrocement" being referred to as Ferro concrete or Reinforced concrete to

better describe the end product instead of its components. By understanding that aggregates

mixed with Portland cement form concrete, but many things can be called cement, it is hoped

this may avoid the confusion of many compounds or techniques that are not Ferro concrete.)

Ferro concrete has relatively good strength and resistance to impact. When used in house

construction in developing countries, it can provide better resistance to fire, earthquake, and

corrosion than traditional materials, such as wood, adobe and stone masonry. It has been popular

in developed countries for yacht building because the technique can be learned relatively

quickly, allowing people to cut costs by supplying their own labor. In the 1930s through 1950's,

it became popular in the United States as a construction and sculpting method for Novelty

architecture, examples of which created "dinosaurs in the desert", or a "giant pair of cowboy

boots and hat" for a service station.

2

1.1 CONSTRUCTION

The desired shape may be built from a multi-layered construction of mesh, supported by

an armature or grid, built with rebar and tied with wire. For optimum performance, steel should

be rust-treated, (galvanized) or stainless steel. (In early practice, in the desert, or for exterior

scenery construction, "sound building practice" was not considered or perhaps unknown as it

grew in some cases, from a folk craft tradition of masons collaborating with blacksmiths.) Over

this finished framework, an appropriate mixture (grout or mortar) of Portland cement, sand and

watered/or admixtures is applied to penetrate the mesh. During hardening, the assembly may be

kept moist, to ensure that the concrete is able to set and harden slowly and to avoid developing

cracks that can weaken the system. Steps should be taken to avoid trapped air in the internal

structure during the wet stage of construction as this can also create cracks that will form as it

dries. Trapped air will leave voids that allow water to collect and degrade (rust) the steel.

Modern practice often includes spraying the mixture at pressure, (a technique called Shotcrete,)

or some other method of driving out trapped air.

Older structures that have failed offer clues to better practices. In addition to eliminating

air where it contacts steel, modern concrete additives may include acrylic liquid "admixtures" to

slow moisture absorption and increase shock resistance to the hardened product or to alter curing

rates. These technologies, borrowed from the commercial tile installation trade, have greatly

aided in the restoration of these structures. Chopped glass or poly fiber can be added to reduce

crack development in the outer skin. (It should be noted that chopped fiber could inhibit good

penetration of the grout to steel mesh constructions. This should be taken into consideration and

mitigated, or limited to use on outer subsequent layers. Chopped fibers may also alter or limit

some wet sculpting techniques.)

1.2ECONOMICS

The economic advantage of Ferro concrete structures is that they are stronger and more

durable than some traditional building methods Depending on the quality of construction and the

climate of its location, houses may pay for themselves with almost zero maintenance and lower

insurance requirements. Water tanks could pay for themselves by not needing periodic

replacement, if properly constructed of Reinforced concrete.

3

Ferro concrete structures can be built quickly, which can have economic advantages. In

inclement weather conditions, the ability to quickly erect and enclose the building allows

workers to shelter within and continue interior finishing.

In India, Ferro concrete is used often because the constructions made from it are more resistant

to earthquakes. Earthquake resistance is dependent on good construction technique and

additional reinforcement of the concrete.

In the 1970s, designers adapted their yacht designs to the then very popular backyard

building scheme of building a boat using ferrocement. Its big attraction was that for minimum

outlay and costs, a reasonable application of skill, an amateur could construct a smooth, strong

and substantial yacht hull. A ferrocement hull can prove to be of similar or lower weight than a

fiber (fiberglass), aluminum, or steelhull.New methods of laminating layers of cement and steel

mesh in a mold may bring new life to ferrocement boat-building. A thorough examination of

Reinforced concrete and current practice would benefit the boat builder.

1.3 ADVANTAGES

The advantages of a well built Ferro concrete construction are the low weight,

maintenance costs and long lifetime in comparison with purely steel constructions. However,

meticulous building precision is considered crucial here. Especially with respect to the

cementitiouscomposition and the way in which it is applied in and on the framework, and how or

if the framework has been treated to resist corrosion.

When a Ferro concrete sheet is mechanically overloaded, it will tend to fold instead of

break or crumble like stone or pottery. So it is not brittle. As a container, it may fail and leak but

possibly hold together. Much depends on techniques used in the construction.

1.4 DISADVANTAGES

The disadvantage of Ferro concrete construction is the labor intensive nature of it, which

makes it expensive for industrial application in the western world. In addition, threats to

degradation (rust) of the steel components is a possibility if air voids are left in the original

construction, due to too dry a mixture of the concrete being applied, or not forcing the air out of

the structure while it is in its wet stage of construction, through vibration, pressurized spraying

techniques, or other means. These air voids can turn to pools of water as the cured material

4

absorbs moisture. If the voids occur where there is untreated steel, the steel will rust and expand,

causing the system to fail.

In modern practice, the advent of liquid acrylic additives and other advances to the grout

mixture, create slower moisture absorption over the older formulas, and also increase bonding

strength to mitigate these failures. Restoration steps should include treatment to the steel to arrest

rust, using practices for treating old steel common in auto body repair

2. APPLICATIONS OF FERROCEMENT

2.1 HOUSING APPLICATIONS

Ferrocement is considered as a suitable housing technology for developing countries

attested by the increasing number of easily built and comfortable ferrocement houses.

Ferrocement houses utilizing local materials such as wood, bamboo or bush sticks as equivalent

steel replacement have been constructed in Bangladesh, Indonesia and Papua New Guinea.

Precast ferrocement elements have been used in India, the Philippines, Malaysia, Brazil, Papua

New Guinea, Venezuela and the Pacific for roofs, wall panels and fences. In Sri Lanka, a

ferrocement house resistant to cyclones has also been developed and constructed. A pyramidal

dome over a temple in India and numerous spherical domes for mosques in Indonesia have been

constructed with ferrocement. The choice was dictated by low self-weight, avoidance of

formwork and availability of unskilled labor. In Israel, ferrocement is used to improve existing

houses. Precast corrugated roof units reinforced with local fibers comparable to asbestos cement

sheet and galvanized iron sheet are in used in Singapore, India, Indonesia, Peru and Zimbabwe.

Ferrocement Housing

5

Location: Bombay, India

Usage: Residential house

Parts in

Ferrocement:

CASTONE panels (Structural wall panels)

Cost: US$30/m. sqr.

Year of

Construction:

1980

Additional

Information:

Prefabricated panels, joining with nuts and bolts, stability of the structure is

achieved by box type configuration.

Name: Ferrocement Tenements

Location: Bombay, India

Usage: Low-cost housing

Parts in Ferrocement: CASTONE panels

Cost: US$32 - US$ 64 /m. sqr.

Year of Construction: 1980

Additional

Information:

360 units of one storey and 9260 units of two storey tenement houses

built.

Name: Ferrocement Housing

Location: Israel

Usage: Residential house

6

Dimensions: Covered area of 52 sq. meter

Cost:

US$310 per sq. meter (Composed to US$ 400 to US$ 500 per sq. meter for

concrete in 1982)

Additional

Information:

Temperature inside the house is cool and pleasant.

2.2 MARINE APPLICATION

Ferrocement has been adapted to traditional boat designs in Bangladesh, China, India,

Indonesia and Thailand due to timber shortages.In China, 600 ferrocement boat manufacturing

units produce annual capacity of 600,000 to 700,000 tonnages. Ferrocement boats are divided

into four categories according to usage: farming boats, fishing boats, transport boats and working

boats. In countries like Hong Kong, Korea, India, Malaysia, Philippines, Sri Lanka and Thailand,

ferrocement boats generally conform to western standards. In Hong Kong, India and Sri Lanka,

most of the ferrocement crafts constructed are used as mechanized fishing trawlers

In addition, the Southeast Asian Fisheries Development Center, Philippines, has used

ferrocement tanks for prawn broodstock and ferrocement buoys for a floatation system in the

culture of green mussels. This is the first large scale use of ferrocement for these purposes.

In Africa, ferrocement boatyards have been successfully established in Kenya, Sudan and

Malawi. The boatyards are now self supporting under the management of local staff trained by

the consultants. The objective of these boatyards is to provide rural fisherman opportunities to

explore the fishable grounds to increase their income. Ferrocement vessels have also been

constructed for Guinea Bessau.

7

2.3 AGRICULTURE APPLICATION

Agriculture provides the necessary resource bas for economic growth in developing

countries. The use of ferrocement technology can contribute towards solving some of the

production and storage problems of agricultural produce.Ferrocement has been used for grain

storage bins in Thailand, India and Bangladesh to reduce losses from attack by birds, insects,

rodents and molds.Thailo, a conical ferrocement bin; was designed and first constructed at the

Asian Institute of Technology (AIT), Bangkok, Thailand. Storage capacities range from one to

ten tons (1000 kg to 10000kg). This bin has proved to be structurally sound and construction has

provided adequate protection to the produce against rodent, insect and bird attacks. The bin costs

well within the means of the farmers. In Nigeria, the traditional timber thatch cub for food grain

storage has been improved with ferrocement. These bins are called "Ferrumbu".

The bin developed at the Structural Engineering Research Center (SERC), Roorkee, India, is

manufactured in the form of precast elements and assembled on site. In Bangladesh,

ferrocementsilos six to ten tons (6000 kg to 10000 kg) capacity reinforced with bamboo and two

layers of no. 20 gage hexagonal mesh on both sides of the bamboo have been proven

satisfactory. In Ethiopia, traditional underground pits are lined with ferrocement and provide

with an improved airtight lid, for a truly hermatic and waterproof storage chamber. The use of

ferrocement canal lining prevent seepage loss according to the research on the construction

techniques and behavior of ferrocement canal linings undertaken at AIT. Ferrocement canal

linings and aqueducts are now in use in China, Indonesia and Vietnam.

8

2.4 WATER AND SANITARY APPLICATION

Ferrocement can be effectively used for various water supply structures like well casings

for shallow wells, water tanks, sedimentation tanks, slow sand filters and for sanitation facilities

like septic tanks, service modules and sanitary bowls. Ferrocement water tanks of 20 to 2000

gallon capacity are mass produced in India. In Thailand and Indonesia, ferrocement and bamboo-

cement rainwater colloection tanks are being built on a self help basis by villagers under the

supervision of an apprapriate technology group to provide clean drinking water. Ferrocement

water tanks over multistory buildings in Singapore, Bangladesh and the Solomn Island. Bamboo-

cement well casings have been built in Indonesia to prevent contamination of the water.

Prefabricated service modules have been developed and constructed in the Solomn Islands and

India. A service module is a unit which provides water supply for drinking and washing toghethe

with toilet facilities. Ferrocement septic tanks have been in used in Thailand, India, Indonesia,

Philippines and Papua New Guinea while ferrocement toilet bowls have been developed and

constructed in Thailand and Bangladesh.

2.5 RURAL ENERGY APPLICATION

Biogas and solar energy are two alternate sources of energy for the rural areas in which

ferrocement can be of use in their production. Biogas can be used for cooking, lighting and

refrigeration. In Thailand and India, biogas digesters and biogas holders have been constructed

with ferrocement which lead to a considerable cost reduction. Ferrocement has also been used as

digester lining when bricks are not economically available. More ferrocement biogas digesters

will promote conservation of timberlands and it will encourage farmers to raise livestock

providing additional income to the family.

2.6 MISCELLANEOUS APPLICATION

Ferrocement is proving to be a technology that can respond to the diverse economic,

social and cultural needs of man.Ferrocement has been used to strengthen older structures, a

medium for sculpture and for many other types of structures. Ferrocement as a medium for

sculpture proves its versatility and the unlimited dimension to which it can be used. Ferrocement

in art is an exciting development and it open new horizons.

9

3. CONSTITUENT MATERIALS

1. Cement

2. Fine Aggregate

3. Water

4. Admixture

5. Mortar Mix

6. Reinforcing mesh

7. Skeletal Steel

8. Coating

4. FERRO CEMENT JARS:

Ferrocement consists of a thin sheet of cement mortar which is reinforced with a cage made of

wire mesh and steel bars. Because ferrocement is structurally more effectient than masonry, the

thickness of the walls of the container are as low as 10 to 15 mm. Ferrocement components can

be casted in any shape using suitable moulds. The technology is extremely simple to implement,

and even semi-skilled workpersons can learn it with ease. Ferrocement requires only a few easily

available materials - cement, sand, galvanized iron (GI) wire mesh, and mild steel (MS) bars - in

small amounts compared to masonry and RCC.

4.1 POT SHAPED CONTAINER

The process of construction of a pot shaped Ferro cement container is quite simple. The

only materials required are hessian cloth, chaff (waste from agricultural produce), GI wire mesh,

MS bars, cement and sand.

4.1.2Preparation of mould:

The hessian cloth is first stitched into a sack resembling the shape of a container. It is

then filled with chaff that is compacted in layers. Dry leaves or dry grass can also be used in

place of chaff. Once the sack is filled with the filler material, it is beaten into the required shape

by a wooden bat.

10

Source: Catch water

4.1.3Laying of reinforcement:

A GI wire mesh (22-26 gauge - see table) is tied around the mould leaving sockets at

suitable locations for inlet, over flow and cleaning pipes. Tying 6 mm diameter MS bars at wide

intervals both horizontally and vertically strengthens the reinforcement cage.

4.1.4 Preparation of cement mortar for plastering:

Cement mortar of suitable proportion (see table) is prepared, having water content equal

to 0.45 times the volume of cement.

Capacity of

containerLitres

Thickness of the

walls

Ratio Cement: sand

Thickness of GI wire

(guage)

400 10 1:3 26

600 10 1:3 24

900 12 1:2:5 24

1500 15 1:2:5 22

11

4.1.5 Plastering:

The mortar is plastered in two layers along the wall thickness, the second layer being

applied 24 hours after the first. The Ferro cement wall normally has a thickness of 10 to 15 mm,

depending on the volume of the container. The cement mortar is applied ensuring a minimum

clearance (cover) 3 mm between the reinforcement mesh and the outer surfaces of the wall.

4.1.6 Removal of mould:

The mould of the container is removed 24 hours after casting of the wall is completed, by

removing the filler material. The container can be brought into use after 10 days of wet curing.

4.2 Ferrocement Tank using Skeletal Cage:

4.2.1 Phases of construction

i Selection of site

iiMarking for circular foundation:

Choose the diameter of foundation (Df) for required storage capacity from the table

Capacity of storage

tank (litres)

5,000 and 6,000 7,000 and 8,000 9,000 and 10,000

Df 2.40 m 2.70 m 3.00 m

iii Excavation for foundation

iv Compacting the excavated pit

v Placing cement concrete in foundation:

Prepare Plain Cement Concrete of 1:4:8 mix ( 1 cement: 4 sand: 8 stone aggregate of 40mm size)

vi Erection of mould/ Preparation of elements of skeletal cage

12

a. Preparation of Elements of Skeletal Cage:

Source: Action for food Production and United Nations Children's Fund, Rooftop rainwater harvesting systems

Skeletal cage is an assembly of 4 types of elements (of different shapes) made from mild steel

rods. They are

'U' shaped elements

'L' shaped elements

'' shaped elements

'O' shaped elements

Dimensions of elements for tank capacities 5,000 litres to 10,000 litres

Element No. Dimensions Capacity of Storage Tank (in litres)

5,000 6,000 7,000 8,000 9,000 10,000

U 2 H 1.8 2.1 1.9 2.1 1.9 2.1

W1 2.05 2.05 2.35 2.35 2.65 2.65

4 H 1.8 2.1 1.9 2.1 1.9 2.1

L W2 0.82 0.82 0.95 0.95 1.05 1.05

8 H 1.8 2.1 1.9 2.1 1.9 2.1

L W3 0.5 0.5 0.6 0.6 0.65 0.65

D1 9Nos 11Nos 10Nos 11Nos 10Nos 11Nos

2.05 2.05 2.35 2.35 2.65 2.65

1 D2 1.25 1.25 1.41 1.41 1.60 1.60

1 D3 0.62 0.62 0.71 0.71 0.84 0.80

b. Assembling the elements:

Place the two 'U' shaped rods vertically over the foundation, perpendicular to each other

13

Place the outer, middle and inner rings over the two 'U' shaped rods, coinciding with the

circular marking and tie the intersections with binding wires

Place and tie 4 'L' shaped elements on the center marking of each quarter, each rod

extending upto the inner most ring

Place and tie 8 '' shaped elements on the remaining markings, each element extending to

the middle ring

Place and tie all the rings of diameter 'D1" over the vertical reinforcement at a uniform

spacing of 20 cm

For providing cylindrical shape to the skeletal cage, fix cross bars at the top of skeletal

cage and ie with ropes, 3-4 vertical rods to wooden pegs pegged to the ground.

c. Tying of mesh over skeletal cage

Select the reinforcement mesh that suits the capacity of the tank from the table below:

Capacity of Tank (Lt) 5,000 & 6,000 7,000 & 8,000 9,000 & 10,000

Specification of wire

mesh

Chicken wire mesh of

22 gauge and 12 mm

(1/2") opening

Chicken wire mesh of

20 gauge and 25 mm

(1") opening

Chicken wire mesh of

20 gauge and 25 mm

(1") opening

Source: Action for food Production and United Nations Children's Fund, Rooftop rainwater harvesting system

Tie the mesh with binding wire to the skeletal cage at all intersections of elementsProvide a

tucking length of 30 cm (1 foot) at the base Project the mesh 10 cm above the top of the skeletal

cage Cut the skeletal cage and insert pipe fixtures such as overflow pipe, drain pipe and tap at

appropriate places as given in table

Over flow pipe 10 cm below the top of cage

Drain pipe 5 cm above the foundation

Tap 10 cm above the foundation

viii. Plastering the tank's outside wall

14

Prepare cement slurry (cement mixed with water) and add anti-rust agent (chrometrioxide

tablets)

Apply one coat of cement slurry (mix of cement and water) over the mesh using a

painting brush

Prepare cement mortar of depending on capacity of tank

Apply the first coat of cement mortar on the outer surface at a thickness of 1 cm. Care has

to be taken to fill the space between the two layers completely. This could be done by

using a GI sheet, slightly curved in shape to be held close to the skeletal cage from inside

by a person, while cement mortar is applied by another from outside

Leave 10 cm of mesh projected above the cage unplastered in order to join the skeletal

dome to the tank

After two hours, apply a second coat of mortar of a thickness of 1 cm.

ix. Plastering the tank's inside wall

After two hours of outside plastering, apply cement slurry to the inner surface of the tank

wall

Prepare cement mortar of 1: 3 mix and add waterproof compound in liquid form

Apply first coat of cement mortar of 1 cm thickness on the inner surface, starting from

bottom of the tank moving laterally and progressing towards the top

After two hours, apply second coat of mortar to attain a total wall thickness of 2 cm

Apply cement slurry as final coat on outer and inner surfaces of tank and smoothen using

coir brush

x. Removal of mould

xi. Casting of tank floor:

Sprinkle cement slurry over the foundation concrete

Prepare plain cement concrete of 1:2:4 mix ( 1 cement: 2 sand: 4 stone aggregate of 12

mm size), pour it over the base and compact to a thickness of 50 mm (2 inch)

Finish the floor base using cement mortar keeping the slope towards the drain pipe

Finish the wall and base joints (inner and outer) with cement mortar

Twelve hours after setting the tank floor, add waterproof compound (liquid form) with

cement slurry and apply it over inside surface of the tank and smoothen with coir brush.

15

xii. Curing the tank

Cure the tank for 14 days by pouring water thrice a day or covering the tank with wet

gunny bags

In coastal areas, after curing for 14 days, apply rust proof paint over the outer surface of

tank wall

xiii. Construction of roof for the tank

An assembly of mild steel elements is prepared as a skeletal frame for the roof. Chicken

wire mesh is tied over it and plastered in cement mortar

The roof is provided with two openings. One is an opening of diameter 35 cm for

accommodating the filter container. Another is a manhole with a 60 cm opening. The

opening for the filter will be on one side of the roof. The manhole is provided at the

centre of dome

5. COST EFFECTIVENESS OF FERRO-CEMENT STRUCTURES

The type of economic system.

Type of applications.

Relative cost of labor.

Capital and local tradition of construction procedure.

Doesnt need heavy plant or machinery.

Low cost of construction material

16

LIST OF PICTURES

Fig1: Typical cross section of Ferro-cement structure

Fig2:REINFORCING MESH

17

Fig3: Residential and Public Buildings

Fig4: Industrial Structures

18

Fig5: Transportation Structures

CONCLUSION

Ferro-cement come into wide spread use only in the last two decades and still in its infancy.

Sufficient design information is available and adequate field experience has been acquired to

enable safe design and construction of many types of Ferro-cement structures.

Whether it can economically compete with alternate materials depends on the type and location

of application. For industrially developed countries, Ferro-cement seems economical for medium

storage tank, roofshells, boat, tank and the ease of forming complicated shapes and lighter

weight of Ferro-cement can be safely exploited.

S-ar putea să vă placă și

- FlyashDocument50 paginiFlyashThai Hai LyÎncă nu există evaluări

- Water Retaining Conc RepairDocument48 paginiWater Retaining Conc Repairanele_amisÎncă nu există evaluări

- Recent Progress in Concrete-Polymer CompositesDocument10 paginiRecent Progress in Concrete-Polymer Compositesswathi1105Încă nu există evaluări

- Chloride ResistanceDocument37 paginiChloride ResistanceCarlos Augusto Sánchez Rondón100% (1)

- Mineral and Chemical Admixtures: Advanced Concrete Technology CE 612Document23 paginiMineral and Chemical Admixtures: Advanced Concrete Technology CE 612Kasturi BhuyanÎncă nu există evaluări

- Behaviour On Geopolymer Mortar Using Granulated Blast Furnace SlagDocument5 paginiBehaviour On Geopolymer Mortar Using Granulated Blast Furnace SlagMauricio David Ruiz OdarÎncă nu există evaluări

- BS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesDocument19 paginiBS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesRaviranjan kumarÎncă nu există evaluări

- Carbonation of Flyash ConcretDocument6 paginiCarbonation of Flyash ConcretAnshul SoniÎncă nu există evaluări

- Project:: Use of Metakaoline and Alccofine As A Admixture in ConcreteDocument52 paginiProject:: Use of Metakaoline and Alccofine As A Admixture in ConcreteAnonymous wlbOBqQWDÎncă nu există evaluări

- PPT2 - POLYMER CONCRETE-the Construction Material of Xxi CenturyDocument20 paginiPPT2 - POLYMER CONCRETE-the Construction Material of Xxi CenturyChandu ReddyÎncă nu există evaluări

- Aerated Concrete Production Using Various Raw MaterialsDocument5 paginiAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Introduction of Cement: When Was Cement Begin?Document11 paginiIntroduction of Cement: When Was Cement Begin?مايف سعدونÎncă nu există evaluări

- Comparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementDocument5 paginiComparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementesatjournalsÎncă nu există evaluări

- Reactive Powder Concrete Done By, C.Sugashini, B. Kanchana, RA. AkshayaDocument35 paginiReactive Powder Concrete Done By, C.Sugashini, B. Kanchana, RA. AkshayaAkshaya RohiniÎncă nu există evaluări

- Mechanical Strength and Water Resistance of Magnesium Oxysulfate CementDocument11 paginiMechanical Strength and Water Resistance of Magnesium Oxysulfate CementArlen Gutierrez100% (1)

- GFRCDocument4 paginiGFRCrahulchandokÎncă nu există evaluări

- Slef Cleaning Concrete PDFDocument9 paginiSlef Cleaning Concrete PDFP Guru RajuÎncă nu există evaluări

- Translucent ConcreteDocument22 paginiTranslucent ConcreteRicha ShahÎncă nu există evaluări

- Cellular Light Weight ConcreteDocument35 paginiCellular Light Weight ConcreteUTP gamingÎncă nu există evaluări

- Astm C1688-08Document3 paginiAstm C1688-08Sergio Vidal ArcosÎncă nu există evaluări

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 paginiFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireÎncă nu există evaluări

- Construction Materials and TestingDocument61 paginiConstruction Materials and TestingAliñabo RoqueÎncă nu există evaluări

- Cement Types - Portland Cement Association (PCA)Document3 paginiCement Types - Portland Cement Association (PCA)Eddy EffendiÎncă nu există evaluări

- P K Mehta - Advancement in Con. Tech - 090405Document8 paginiP K Mehta - Advancement in Con. Tech - 090405Narayan SinghaniaÎncă nu există evaluări

- Cracks in ConcereteDocument37 paginiCracks in ConceretePradeepLokhandeÎncă nu există evaluări

- Experimental Study On Flexural Behaviour of Reinforced Geopolymer Concrete Beam With Steel FiberDocument43 paginiExperimental Study On Flexural Behaviour of Reinforced Geopolymer Concrete Beam With Steel Fiberkarthiksamp100% (1)

- SeminarDocument21 paginiSeminarsoukhya100% (1)

- Chapter 2 Clays and BricksDocument50 paginiChapter 2 Clays and BricksPiolo Lim AvenidoÎncă nu există evaluări

- Banthia - Fibre-Reinforced Concrete PDFDocument29 paginiBanthia - Fibre-Reinforced Concrete PDFPriyanka BasuÎncă nu există evaluări

- Article 3 - Applications and Properties of Fibre Reinforced ConcreteDocument9 paginiArticle 3 - Applications and Properties of Fibre Reinforced Concretesara.marrok17Încă nu există evaluări

- Specification For Blended Cement Sri Lanka PDFDocument34 paginiSpecification For Blended Cement Sri Lanka PDFhasanÎncă nu există evaluări

- Concret CementDocument29 paginiConcret CementKamal Hameed Al-taiy100% (1)

- A Review Paper On Graphene Modified CementDocument9 paginiA Review Paper On Graphene Modified CementZunnun Bari PialÎncă nu există evaluări

- The Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesDocument9 paginiThe Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesPrakash100% (1)

- White GRC - Glass Fibar Reinforced ConcreteDocument4 paginiWhite GRC - Glass Fibar Reinforced ConcreteProjÎncă nu există evaluări

- ABC Tile Adhesive Heavy DutyDocument1 paginăABC Tile Adhesive Heavy DutyMark GoducoÎncă nu există evaluări

- Nanotechnology in Concrete - A ReviewDocument12 paginiNanotechnology in Concrete - A ReviewYongliang Liu100% (1)

- 12.basalt Fibers - ProjectDocument8 pagini12.basalt Fibers - ProjectSahil GandhiÎncă nu există evaluări

- ConcreteDocument23 paginiConcreteHein ZanÎncă nu există evaluări

- Bulding Materials IIIDocument29 paginiBulding Materials IIIKaushik JayaveeranÎncă nu există evaluări

- Experimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionDocument14 paginiExperimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionAditya SutarÎncă nu există evaluări

- Comparative Study of Different Calcined Waste Shells As Partial Replacement To Cement in MortarDocument1 paginăComparative Study of Different Calcined Waste Shells As Partial Replacement To Cement in MortarBillie Ian B. Salamante Jr.Încă nu există evaluări

- Concrete Technology Lec#01 ConcreteDocument2 paginiConcrete Technology Lec#01 ConcretefaizanÎncă nu există evaluări

- CLC Brick ProductionDocument14 paginiCLC Brick ProductionKrishna YarlagaddaÎncă nu există evaluări

- Effect of Fineness of SandDocument8 paginiEffect of Fineness of SandRamBinodSharmaÎncă nu există evaluări

- Tile Adhesives - Kenya StandardDocument19 paginiTile Adhesives - Kenya StandardChrisÎncă nu există evaluări

- LSM Data Sheet Tarmac August 16 1Document7 paginiLSM Data Sheet Tarmac August 16 1Azhar ShaikhÎncă nu există evaluări

- Concrete: From Grey To GreenDocument12 paginiConcrete: From Grey To GreenOmar Marghani SalmaÎncă nu există evaluări

- W.P.T. - Penetron ChemicalsDocument30 paginiW.P.T. - Penetron ChemicalsguptasonsonÎncă nu există evaluări

- Building Materials Final Solution After Cor.Document64 paginiBuilding Materials Final Solution After Cor.TarunÎncă nu există evaluări

- Our Products - Republic CementDocument6 paginiOur Products - Republic CementDean MendozaÎncă nu există evaluări

- Study and Experimentation of Autoclaved Aerated Concrete by Using Fly AshDocument5 paginiStudy and Experimentation of Autoclaved Aerated Concrete by Using Fly AshInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Final PDF frc1-2Document23 paginiFinal PDF frc1-2Sherif FodaÎncă nu există evaluări

- Roller Compacted Concrete (RCC) in PavementsDocument15 paginiRoller Compacted Concrete (RCC) in PavementsAlhilali ZiyadÎncă nu există evaluări

- Hydrated LimeDocument1 paginăHydrated Limeavmurugan87100% (1)

- Stabilization of Weak Subgrade For Road Using Fly Ash and Rice Husk AshDocument5 paginiStabilization of Weak Subgrade For Road Using Fly Ash and Rice Husk Ashumi shakilaÎncă nu există evaluări

- Portland Cement Rebar: FerrocementDocument4 paginiPortland Cement Rebar: FerrocementnandhuÎncă nu există evaluări

- Introduction of FerrocementDocument28 paginiIntroduction of FerrocementLokesh MeenaÎncă nu există evaluări

- Copper Flashings And Weatherings - A Practical HandbookDe la EverandCopper Flashings And Weatherings - A Practical HandbookÎncă nu există evaluări

- Recruitment To The Post of Officers in Grade A' (RDBS)Document28 paginiRecruitment To The Post of Officers in Grade A' (RDBS)Rajat Yadav YaduvanshiÎncă nu există evaluări

- Earthquake Resistant Design of StructuresDocument43 paginiEarthquake Resistant Design of Structuresajitgijare100% (1)

- Civil Engineering 2121Document96 paginiCivil Engineering 2121Vara PrasadÎncă nu există evaluări

- Cement and Steel Rates For The Month of February 2012Document1 paginăCement and Steel Rates For The Month of February 2012Guru PrasadÎncă nu există evaluări

- Estimate: Tribal Welfare DepartmentDocument7 paginiEstimate: Tribal Welfare DepartmentVara PrasadÎncă nu există evaluări

- Cement and Steel Rates For The Month of March 2012Document1 paginăCement and Steel Rates For The Month of March 2012Guru PrasadÎncă nu există evaluări

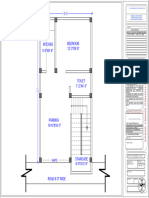

- Standard DetailsDocument14 paginiStandard DetailsGayan IndunilÎncă nu există evaluări

- FLAT BAR DesignDocument8 paginiFLAT BAR DesignTerry CheukÎncă nu există evaluări

- Cutting List RoofingDocument2 paginiCutting List RoofingCzarinaCanarAguilarÎncă nu există evaluări

- On Bubble Deck SlabDocument16 paginiOn Bubble Deck SlabDaman100% (1)

- Modal and Harmonic Analysis of A Cantilver Beam With Differrent Cross-SectionsDocument6 paginiModal and Harmonic Analysis of A Cantilver Beam With Differrent Cross-SectionsTJPRC PublicationsÎncă nu există evaluări

- 507 33 Powerpoint-Slides Ch17 DRCSDocument60 pagini507 33 Powerpoint-Slides Ch17 DRCSArun Goyal100% (3)

- DR - Nurul ImamDocument11 paginiDR - Nurul Imamnadimalam78692Încă nu există evaluări

- Concrete Pipe DrawDocument10 paginiConcrete Pipe Drawdhiraj KumarÎncă nu există evaluări

- EXPERIMENT 3: Deflection of Simply Supported Beam and Cantilever Beam Cantilever BeamDocument7 paginiEXPERIMENT 3: Deflection of Simply Supported Beam and Cantilever Beam Cantilever BeamZol Has100% (1)

- Generate Column Interaction DiagramDocument88 paginiGenerate Column Interaction DiagramSaad SekkateÎncă nu există evaluări

- Sheel Roof: Vaibhav.b.p 3PD14AT034Document1 paginăSheel Roof: Vaibhav.b.p 3PD14AT034vaibhavÎncă nu există evaluări

- Flexural Design of Prerstress Members (Examples) : Case C: Limit Zone For Tendon CentroidDocument6 paginiFlexural Design of Prerstress Members (Examples) : Case C: Limit Zone For Tendon CentroidRaja AliÎncă nu există evaluări

- Chapter 2.0 - Structural AnalysisDocument31 paginiChapter 2.0 - Structural Analysisfaraeiin57Încă nu există evaluări

- L12 Bolt Connection 2Document17 paginiL12 Bolt Connection 2Kidus KidaneÎncă nu există evaluări

- Local Buckling and Section ClassificationDocument7 paginiLocal Buckling and Section ClassificationMohammed Junaid ShaikhÎncă nu există evaluări

- Introduction To RCCDocument17 paginiIntroduction To RCCdasapathri jahnaviÎncă nu există evaluări

- Model GP Building EstimateDocument153 paginiModel GP Building Estimate8790922772Încă nu există evaluări

- Steel Joint Design (Flexible End Plate)Document6 paginiSteel Joint Design (Flexible End Plate)Wazini D. IzaniÎncă nu există evaluări

- PSD Task 2 NotesDocument16 paginiPSD Task 2 Notesmuhfil MuhfilÎncă nu există evaluări

- All Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingDocument6 paginiAll Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingSudarshan PatilÎncă nu există evaluări

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 paginăRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Foam Concrete LiteratureDocument14 paginiFoam Concrete LiteratureAnil Purohit100% (1)

- Mivan Shuttering - QuotationDocument5 paginiMivan Shuttering - Quotationmahesh pandeyÎncă nu există evaluări

- Structural Design Detailing and Construc PDFDocument40 paginiStructural Design Detailing and Construc PDFIbnuyusoff77Încă nu există evaluări

- Test Result of Concrete Cube Quality Control Laboratory, Road Div SiwanDocument2 paginiTest Result of Concrete Cube Quality Control Laboratory, Road Div SiwanB k RajÎncă nu există evaluări

- Unrestrained BeamDocument3 paginiUnrestrained BeamGanesh Konar100% (1)

- Conplast WLDocument2 paginiConplast WLady999Încă nu există evaluări

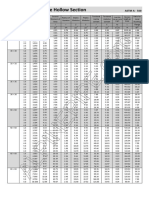

- Astm A500 SHS 1Document4 paginiAstm A500 SHS 1Wong JowoÎncă nu există evaluări

- Item No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkDocument6 paginiItem No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkmayaÎncă nu există evaluări

- Behavior of Members Subjected To Axial LoadsDocument21 paginiBehavior of Members Subjected To Axial LoadsAhmad Faraz JuttÎncă nu există evaluări