Documente Academic

Documente Profesional

Documente Cultură

SATR-J-6912 Rev 0 PDF

Încărcat de

Adel KlkDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SATR-J-6912 Rev 0 PDF

Încărcat de

Adel KlkDrepturi de autor:

Formate disponibile

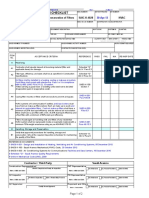

FAIL N/A RE-TEST DATE

ITEM

No.

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS

SAUDI ARAMCO ID/PID - 3/01/05 - REV A (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

FOUNDATION Fieldbus Segment Signal / Noise and

Impedance Testing (Installed Segment)

SATR-J-6912 1-Oct-05 INST

PLANT NO. EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

A Certification

A1

Specific tools and equipment shall be identified to make and perform

tests in the field with instructions for their use, calibration, and storage.

Schedule Q,

Att. IV, Sec.6.1.

A2

The CONTRACTOR shall identify, maintain, control, adjust, and calibrate

all tools, gauges, instruments and other measuring and testing devices

used for controlling quality.

Schedule Q,

Att. IV, Sec.6.1.

A3

Calibration shall be performed at established periods as specified in

the most stringent of SAUDI ARAMCO standards, other applicable

standards, or manufacturer recommendations; if no standards apply,

the calibration cycle shall not exceed six months.

Schedule Q,

Att. IV, Sec.6.1.

A4

CONTRACTOR shall provide backup equipment when the primary

equipment is being calibrated or tested.

Schedule Q,

Att. IV, Sec.6.1.

B1

Ensure that the field wiring is completed , terminated and that all field

spurs (but not the devices) are attached

SAES-J-904

Sec. 13

B. TEST PROCEDURE AND CHECK LIST

B3

Remove only the connector to the field wiring; it is not necessary to

remove the connector to the H1 card (DCS). Removing the connector to

the field wiring isolates the field wiring from the H1 card and power

supply, and enables you to make the resistance and capacitance

measurements in the pre-commissioning procedure. Important: Make

sure that bare hands do not come in contact with meter leads or

segment wiring.

SAES-J-904

Sec. 13

A5

CONTRACTOR personnel performing test and calibrations shall be

trained per applicable international or manufacturer requirements.

Schedule Q,

Att. IV, Sec.6.2.

B2

Remove the field bus segment cable(+,-, and shield) at terminal block

connector terminals (15,14&13) from the fieldbus power supply (H1-PS)

SAES-J-904

Sec. 13

B4

Measure resistance on the H1 segment conductors at the removed

Relcom terminal block connector coming in from the field and record

results on Network/ Segment Check out Form.

i) (+) signal conductor to (-) signal conduct

ii) (+) signal conductor to drain / shield wire

iii) (-) signal conductor to drain/shield wire

iv) (+) signal conductor to instrument ground bar

v) (-) signal conductor to instrument ground bar

vi) drain/shield wire to instrument ground bar

SAES-J-904

Sec. 13

Page 1 of 4

2. 100/250V Megger Tester

3. Oscilloscope

Test results are acceptable and in accordance with Saudi Aramco Engineering Standards and contractual requirements.

E. CONCLUSIONS

Test Records and Receipt documents are to be carefully presented in

original.

SAES-J-904

Sec. 13

Attachment 2 Recommended Torque Values for screw terminals

NOTES:

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

REMARKS:

ATTACHMENTS:

Attachment 1 NETWORK / SEGMENT CHECKOUT FORM

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

QC Inspector PID Representative

Technician Performing Test*

Saudi Aramco Contractor / Third-Party

PMT Representative

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

Name, Title, Department,

Company, Initials and

Date:

Work Verified Test Performed Successfully and Results are Acceptable:

Name, Initials and Date:

T&I Witnessed

B7

1. Digital

D. TEST RESULTS

E1

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), July 1993

4. SAES-J-904 FOUNDATION Fieldbus Systems, 31July 2004

2. Schedule Q -- Quality Requirements (Pro Forma Contract), November 2003

3. SA Pre-Commissioning Forms # J-015 Instrument and Control 10/97

QC Record Reviewed

indicates compliance with appropriate standards or performance in a specified manner.

QC Supervisor Proponent and Others

Name, Initials and Date:

Witnessed Test Work / Rework May Proceed

Name, Initials and Date:

QC Record Reviewed Work Verified T&I Witnessed

Y = YES N = NO F = FAILED *Person Responsible for Implementation of Test and Analysis of Results

QC Record Reviewed Work Verified

Name, Sign and Date:

Quality Record Approved:

Name, Organization,

Initials and Date:

T&I Witnessed

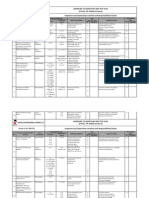

SAUDI ARAMCO ID/PID - 4/14/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

FOUNDATION Fieldbus Segment Signal / Noise and

Impedance Testing (Installed Segment)

SATR-J-6912 1-Oct-05 INST

C. TEST EQUIPMENT AND MATERIALS CRITERIA

ITEM

No.

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE

B5

N/A RE-TEST DATE

1. Use and Modify the attached forms based on requirements

SAES-J-904

Sec. 13

B6

Reconnect and torque test the previously disconnected field wiring

terminals. ( Attachment 2 gives recommended torque values) Measure

DC Voltage at the Relcom terminal block connector going to the field and

record results on Network/ Segment Checkout Form. (+) signal

conductor to (-) signal conductor on terminals 15, 13 and on 22 and 24

SAES-J-904

Sec. 13

Measure the capacitance on the H1 segment conductors at the removed

Relcom terminal block connector coming in from the field and record

results on Network/ Segment Check out Form.

i) (+) signal conductor to (-) signal conduct

ii) (+) signal conductor to drain / shield wire

iii) (-) signal conductor to drain/shield wire

iv) (+) signal conductor to instrument ground bar

v) (-) signal conductor to instrument ground bar

vi) drain/shield wire to instrument ground bar

PASS FAIL

Page 2 of 4

Attachment 1 NETWORK / SEGMENT CHECKOUT FORM

FOUNDATION Fieldbus Segment Signal / Noise and

Impedance Testing (Installed Segment)

INST SATR-J-6912 1-Oct-05

SAUDI ARAMCO ID/PID - 4/14/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

1.2

1.1

(-) to Shield Expected = Open Circuit > 20 M

1

(+) to Shield

Resistance Measurement at the H1 Network / Segment Conductors Coming in from the field.

(+) to (-) Signal

Expected 50 K ohm (increasing)

Expected = Open Circuit > 20 M

2

1.2

2.3

1.6

1.5

1.4

1.3

2.1

Expected = < 300nF

2.4

(-) to Shield Expected = < 300nF

(+) to Ground bar Expected = < 300nF

SAUDI ARAMCO - NETWORK / SEGMENT CHECK OUT FORM - A3

Project: --------------------------------------------------------------------------------------------------------- Plant Area--------------------------------------

Location :--------------------------------------------------------------------------------------------------------Service Area-----------------------------------

Segment No:----------------------------------------------------------------------------------------------------ID--------------------------------------------------

Cable Nos.( Trunk / Spur)----------------------------------------------------------------------------------Unit No.------------------------------------------

Drawing No.:

ITEM

No.

Actual Date ITEMS TO CHECK

2.2

Shield to Ground bar Expected = Open Circuit > 20 M

Capacitance Measurement at the H1 Network / Segment Conductors Coming in from the field

(+) to (-) Signal Expected = 1 F (0.8F to 1.2F)

(+) to Shield

REMARKS:

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

QC Record Reviewed Work Verified

QC Inspector PID Representative

Name, Title, Department,

Company, Initials and

Date:

Test Performed Successfully and Results are Acceptable:

Name, Initials and Date:

T&I Witnessed

Name, Initials and Date:

Witnessed Test Work / Rework May Proceed

Name, Initials and Date:

Work Verified

T&I Witnessed QC Record Reviewed Work Verified

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

QC Supervisor Proponent and Others

Name, Sign and Date:

Quality Record Approved:

Name, Organization,

Initials and Date:

T&I Witnessed QC Record Reviewed

(+) to Ground bar Expected = Open Circuit > 20 M

(-) to Ground bar Expected = Open Circuit > 20 M

2.5 (-) to Ground bar Expected = < 300nF

2.6 Shield to Ground bar Expected = < 300nF

3 DC Voltage Measurement at Fieldbus Power Supply / Conditioner

3.1 (+) to (-) Signal (Output) Expected = 18.6 - 19.4 VDC

(+) to (-) Signal (Input) Expected = 25 to 28 VDC

Page 3 of 4

SATR-J-6912 1-Oct-05

SAUDI ARAMCO ID/PID - 4/14/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

Attachment 2 Recommended Torque Values for Terminals - from www.EatonElectrical.com

FOUNDATION Fieldbus Segment Signal / Noise and

Impedance Testing (Installed Segment)

INST

Page 4 of 4

S-ar putea să vă placă și

- SATR-J-6911Rev 0 PDFDocument6 paginiSATR-J-6911Rev 0 PDFAdel KlkÎncă nu există evaluări

- SATR-J-6913 Rev 0 PDFDocument6 paginiSATR-J-6913 Rev 0 PDFAdel KlkÎncă nu există evaluări

- SATR-J-6501 - Rev 0 PDFDocument5 paginiSATR-J-6501 - Rev 0 PDFAdel KlkÎncă nu există evaluări

- SATR-J-6503 - Rev 0 PDFDocument5 paginiSATR-J-6503 - Rev 0 PDFAdel KlkÎncă nu există evaluări

- SAIC-P-3301 Rev 4Document2 paginiSAIC-P-3301 Rev 4sikandar1234Încă nu există evaluări

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 paginiSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 paginiSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkÎncă nu există evaluări

- Saudi Aramco Welding Consumables ChecklistDocument5 paginiSaudi Aramco Welding Consumables ChecklistAnsuman KalidasÎncă nu există evaluări

- SATR-J-6602 Rev 0 PDFDocument9 paginiSATR-J-6602 Rev 0 PDFAdel KlkÎncă nu există evaluări

- SATR-J-6601 Rev 0 PDFDocument4 paginiSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- SAIC-X-3001 Rev 2Document2 paginiSAIC-X-3001 Rev 2josephjohn2Încă nu există evaluări

- SAIC-J-6401 - Rev 0Document4 paginiSAIC-J-6401 - Rev 0Adel KlkÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 paginiSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 paginăSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapÎncă nu există evaluări

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pagini1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnÎncă nu există evaluări

- Satr S 4001Document1 paginăSatr S 4001mahdi_gÎncă nu există evaluări

- SATR-J-6505-Rev 0 PDFDocument5 paginiSATR-J-6505-Rev 0 PDFAdel KlkÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 paginiSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbDocument1 paginăSaudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbUzair AhmadÎncă nu există evaluări

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Document3 pagini1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 paginiSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinÎncă nu există evaluări

- Saudi Aramco CP Accessories InspectionDocument3 paginiSaudi Aramco CP Accessories InspectionaamirapiÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument3 paginiSaudi Aramco Inspection ChecklistDilshad AhemadÎncă nu există evaluări

- WELD SUMMARY TRACKINGDocument30 paginiWELD SUMMARY TRACKINGThamaraikani Mani100% (1)

- 26 Saic A 2009Document5 pagini26 Saic A 2009Naveed ShahÎncă nu există evaluări

- Saudi Aramco Hardness Testing Procedure ReviewDocument3 paginiSaudi Aramco Hardness Testing Procedure ReviewphilipyapÎncă nu există evaluări

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 paginiSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishÎncă nu există evaluări

- SATR-J-6512 - Rev 0 PDFDocument5 paginiSATR-J-6512 - Rev 0 PDFAdel KlkÎncă nu există evaluări

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 paginiSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroÎncă nu există evaluări

- Ssem 564 C27 SKM 01Document6 paginiSsem 564 C27 SKM 01Ahmed Mostafa Fadly MadyÎncă nu există evaluări

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Document49 paginiAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 paginiSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaÎncă nu există evaluări

- SAIC & SATR - InstrumentationDocument4 paginiSAIC & SATR - InstrumentationAdel KlkÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument21 paginiSaudi Aramco Inspection ChecklisthamidjoyiaÎncă nu există evaluări

- SATR-J - 6802 - Rev 0 PDFDocument3 paginiSATR-J - 6802 - Rev 0 PDFAdel KlkÎncă nu există evaluări

- Itp For SSDP Project Rev CDocument9 paginiItp For SSDP Project Rev CRachel FloresÎncă nu există evaluări

- SAIC-A-2009 Rev 7Document4 paginiSAIC-A-2009 Rev 7sajidazmi.amuÎncă nu există evaluări

- Saic P 3315Document2 paginiSaic P 3315Arshad ImamÎncă nu există evaluări

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 paginiSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalÎncă nu există evaluări

- SAIC-A-2023 Rev 0Document2 paginiSAIC-A-2023 Rev 0philipyapÎncă nu există evaluări

- SAIC-A-2015 Rev 2Document9 paginiSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Saudi Aramco System Lay-up ReportDocument2 paginiSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Saudi Aramco Leak Test ChecklistDocument1 paginăSaudi Aramco Leak Test ChecklistLegend AnbuÎncă nu există evaluări

- SAUDIPIPINGMATTRACEDocument9 paginiSAUDIPIPINGMATTRACEMAZHARULÎncă nu există evaluări

- ITP TableDocument3 paginiITP Tablearunrad100% (1)

- Leak test for water structuresDocument1 paginăLeak test for water structuresNoor Mohamed AzeezÎncă nu există evaluări

- Verify Saudi Aramco Test Equipment SafetyDocument6 paginiVerify Saudi Aramco Test Equipment SafetyEagle SpiritÎncă nu există evaluări

- SAIC-A-2024 Rev 2Document2 paginiSAIC-A-2024 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 paginăSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatÎncă nu există evaluări

- SAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingDocument3 paginiSAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingShaikh Mohd QaisarÎncă nu există evaluări

- 16 400 220 132KV C R PanelsDocument87 pagini16 400 220 132KV C R PanelsShatrughna SamalÎncă nu există evaluări

- ITP-000 Piping Fabrication (Exemple)Document5 paginiITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- 01-OSN 3500 Preliminary Acceptance Test Table V4.03Document15 pagini01-OSN 3500 Preliminary Acceptance Test Table V4.03maddymad52Încă nu există evaluări

- Satr H 2008Document2 paginiSatr H 2008Moghal AliÎncă nu există evaluări

- CSCS Rods & BracketsDocument66 paginiCSCS Rods & BracketsshuklahouseÎncă nu există evaluări

- Saudi Aramco Heat Exchanger ChecklistDocument1 paginăSaudi Aramco Heat Exchanger Checklistmubs997Încă nu există evaluări

- Satr A 2009Document2 paginiSatr A 2009Dilshad AhemadÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 paginiSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுÎncă nu există evaluări

- PRSN94Document18 paginiPRSN94Mula SrikantÎncă nu există evaluări

- Power Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageDocument7 paginiPower Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageAdel KlkÎncă nu există evaluări

- Inverter Topologies and Control Structure in Photovoltaic Applications: A ReviewDocument24 paginiInverter Topologies and Control Structure in Photovoltaic Applications: A ReviewKrishna PrasathÎncă nu există evaluări

- Low Voltage Ride ThroughDocument11 paginiLow Voltage Ride ThroughAdel KlkÎncă nu există evaluări

- Kelada, Buire JCGE22Document7 paginiKelada, Buire JCGE22Adel KlkÎncă nu există evaluări

- Inverter-Based Resource Performance Guideline NERCDocument97 paginiInverter-Based Resource Performance Guideline NERCSubhadeep PaladhiÎncă nu există evaluări

- Guide To Protection of Steel Against CorrosionDocument9 paginiGuide To Protection of Steel Against CorrosionAdel KlkÎncă nu există evaluări

- Network Design Manual v7.7Document194 paginiNetwork Design Manual v7.7somchak2000100% (3)

- Headlines DL - NERC 2013 Annual Report - Final - WebDocument31 paginiHeadlines DL - NERC 2013 Annual Report - Final - WebAdel KlkÎncă nu există evaluări

- Cooling Tower Thermal DesignDocument106 paginiCooling Tower Thermal Designxuense100% (4)

- PDS in ElectricalDocument16 paginiPDS in ElectricalPepe Garcia EstebezÎncă nu există evaluări

- Reactive Power and Fuel CalculationDocument10 paginiReactive Power and Fuel CalculationAdel KlkÎncă nu există evaluări

- 400-200 KV Substation DesignDocument62 pagini400-200 KV Substation DesignMousum91% (22)

- INFOSTEEL - Guide To Protection of Steel Against CorrosionDocument8 paginiINFOSTEEL - Guide To Protection of Steel Against CorrosionA87_navjÎncă nu există evaluări

- Design of EHV SubstationDocument66 paginiDesign of EHV SubstationMadanasekhar Tadimarri100% (1)

- CFB PresentationDocument48 paginiCFB PresentationSam100% (3)

- 3 Day1 - Plant Operation Modes RAF - HandoutDocument23 pagini3 Day1 - Plant Operation Modes RAF - HandoutAdel KlkÎncă nu există evaluări

- 3 3 GIZ17 XXX Presentation J HenkelDocument28 pagini3 3 GIZ17 XXX Presentation J HenkelAdel KlkÎncă nu există evaluări

- Transmission System Performance Analysis For High-Penetration Photovoltaics PDFDocument77 paginiTransmission System Performance Analysis For High-Penetration Photovoltaics PDFkm11kartalÎncă nu există evaluări

- Reactive Energy CompensationDocument38 paginiReactive Energy Compensationcyo3fffÎncă nu există evaluări

- Transmission LineDocument2 paginiTransmission LineAdel KlkÎncă nu există evaluări

- Transmission LineDocument2 paginiTransmission LineAdel KlkÎncă nu există evaluări

- 3 4 GIZ17 XXX Presentation Clemens HoffmannDocument20 pagini3 4 GIZ17 XXX Presentation Clemens HoffmannAdel KlkÎncă nu există evaluări

- 3 2 GIZ17 XXX Presentation Sandip SharmaDocument49 pagini3 2 GIZ17 XXX Presentation Sandip SharmaAdel KlkÎncă nu există evaluări

- 3 Fulfillment of Grid CodeDocument21 pagini3 Fulfillment of Grid CodeAdel KlkÎncă nu există evaluări

- Lesson Learned From Int - Wind Integration StudiesDocument109 paginiLesson Learned From Int - Wind Integration StudiesAdel KlkÎncă nu există evaluări

- Modeling and Control of Wind Power System PDFDocument212 paginiModeling and Control of Wind Power System PDFAdel Klk50% (2)

- Grid Code China Vs Amerca5Document50 paginiGrid Code China Vs Amerca5Adel KlkÎncă nu există evaluări

- 3 1 GIZ17 XXX Presentation Ernesto HuberDocument36 pagini3 1 GIZ17 XXX Presentation Ernesto HuberAdel KlkÎncă nu există evaluări

- NERC Balancing and Frequency Control 040520111Document53 paginiNERC Balancing and Frequency Control 040520111pongpumÎncă nu există evaluări

- Blackout PreventionDocument8 paginiBlackout PreventionAdel KlkÎncă nu există evaluări

- Exercises V1 Part2Document8 paginiExercises V1 Part2Ahmed AlgadriÎncă nu există evaluări

- 1gr-Fe Engine Control System4Document7 pagini1gr-Fe Engine Control System4mike chenÎncă nu există evaluări

- Power System Incident ReportDocument33 paginiPower System Incident ReportmentongÎncă nu există evaluări

- RPCP PDFDocument2 paginiRPCP PDFmhafizanÎncă nu există evaluări

- C POWER ACB Manual PDFDocument172 paginiC POWER ACB Manual PDFVishab Fred80% (5)

- Smith Chart BasicsDocument30 paginiSmith Chart Basicsfox7878Încă nu există evaluări

- Optical Communications (OC)Document22 paginiOptical Communications (OC)Bharat ChilamkuriÎncă nu există evaluări

- Reed's Vol 06 Basic Electrotechnology For Marine EngineersDocument570 paginiReed's Vol 06 Basic Electrotechnology For Marine EngineersXthesinos50% (2)

- Electricity and Magnetism TDA Writing RepsonseDocument2 paginiElectricity and Magnetism TDA Writing RepsonseAnonymous cAOc8lc5PRÎncă nu există evaluări

- Catalog 2009 enDocument356 paginiCatalog 2009 enIeremeiov VladimirÎncă nu există evaluări

- iG5A Troubleshooting ManualDocument45 paginiiG5A Troubleshooting ManualWidi PrasetyoÎncă nu există evaluări

- 15 Small Battery Certification PDFDocument11 pagini15 Small Battery Certification PDFdarkestmatterÎncă nu există evaluări

- How to perform basic calculations on an electronic calculatorDocument2 paginiHow to perform basic calculations on an electronic calculatorProduccion TAMÎncă nu există evaluări

- GXT SeriesDocument8 paginiGXT SeriesCésar S. Silva100% (2)

- Biological Effects of Magnetic Fields PDFDocument14 paginiBiological Effects of Magnetic Fields PDFPedro PereiraÎncă nu există evaluări

- PATROL - 601: Quad PirDocument2 paginiPATROL - 601: Quad PirAdrian DeoancaÎncă nu există evaluări

- Service Manual: SA-WVS200/WVS300Document12 paginiService Manual: SA-WVS200/WVS300myotezaÎncă nu există evaluări

- Wind Energy Turbine LayoutDocument15 paginiWind Energy Turbine LayoutjohnÎncă nu există evaluări

- Compact 20MHz Oscilloscope with Large Screen and Wide BandwidthDocument2 paginiCompact 20MHz Oscilloscope with Large Screen and Wide Bandwidthadak avijitÎncă nu există evaluări

- CitizensBand December1980 PDFDocument36 paginiCitizensBand December1980 PDFbobbyunlockÎncă nu există evaluări

- Detailed Lesson-WPS OfficeDocument7 paginiDetailed Lesson-WPS OfficeAl BayronÎncă nu există evaluări

- NTP35N15 Power MOSFET Features and SpecificationsDocument7 paginiNTP35N15 Power MOSFET Features and SpecificationsChristine GomezÎncă nu există evaluări

- MAN-07-007 MC-3 Series Instruction ManualDocument32 paginiMAN-07-007 MC-3 Series Instruction Manualmuamer.alajbegovicÎncă nu există evaluări

- Samsung Gt-p1000 Service Manual r1Document80 paginiSamsung Gt-p1000 Service Manual r1Alfred Vivien BossonÎncă nu există evaluări

- MXD1500 BrochureDocument2 paginiMXD1500 Brochurestato69100% (2)

- 3.26.2020 I2C Unbounded - Solve Your 2-Wire ChallengesDocument14 pagini3.26.2020 I2C Unbounded - Solve Your 2-Wire ChallengesMohsen haghighatÎncă nu există evaluări

- Electrostatic Notes-JEE NEETDocument41 paginiElectrostatic Notes-JEE NEETEunbyeolÎncă nu există evaluări

- Installation manual for Washer extractors W565H, W575H, W5105H, W5130H, W5180H, W5240H, W5300HDocument40 paginiInstallation manual for Washer extractors W565H, W575H, W5105H, W5130H, W5180H, W5240H, W5300HMarius Costan0% (1)

- Energy Meter Commissioning ChecklistDocument2 paginiEnergy Meter Commissioning ChecklistsalmanÎncă nu există evaluări