Documente Academic

Documente Profesional

Documente Cultură

Gear Pump Article

Încărcat de

Geoffrey AllenDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gear Pump Article

Încărcat de

Geoffrey AllenDrepturi de autor:

Formate disponibile

External Gear Pump Overview

External gear pumps are a popular pumping principle

and are often used as lubrication pumps in machine

tools, in fluid power transfer units, and as oil pumps in

engines.

External gear pumps can come in single or double

(two sets of gears) pump configurations with spur

(shown), helical, and herringbone gears. Helical and

herringbone gears typically offer a smoother flow

than spur gears, although all gear types are relatively smooth. Large-capacity

external gear pumps typically use helical or herringbone gears. Small external

gear pumps usually operate at 1750 or 3450 rpm and larger models operate at

speeds up to 640 rpm. External gear pumps have close tolerances and shaft

support on both sides of the gears. This allows them to run to pressures beyond

3,000 PSI / 200 BAR, making them well suited for use in hydraulics. With four

bearings in the liquid and tight tolerances, they are not well suited to handling

abrasive or extreme high temperature applications.

Tighter internal clearances provide for a more reliable measure of liquid passing

through a pump and for greater flow control. Because of this, external gear

pumps are popular for precise transfer and metering applications involving

polymers, fuels, and chemical additives.

How External

Gear Pumps

Work

External gear pumps are similar

in pumping action to internal

gear pumps in that two gears

come into and out of mesh to produce flow. However, the external gear pump

uses two identical gears rotating against each other -- one gear is driven by a

motor and it in turn drives the other gear. Each gear is supported by a shaft with

bearings on both sides of the gear.

1. As the gears come out of mesh, they create expanding volume on the inlet

side of the pump. Liquid flows into the cavity and is trapped by the gear teeth as

they rotate.

2. Liquid travels around the interior of the casing in the pockets between the

teeth and the casing -- it does not pass between the gears.

3. Finally, the meshing of the gears forces liquid through the outlet port under

pressure.

Because the gears are supported on both sides, external gear pumps are quiet-

running and are routinely used for high-pressure applications such as hydraulic

applications. With no overhung bearing loads, the rotor shaft can't deflect and

cause premature wear.

Advantages

High speed

High pressure

No overhung bearing loads

Relatively quiet operation

Design accommodates wide

variety of materials

Disadvantages

Four bushings in liquid area

No solids allowed

Fixed End Clearances

Applications

Common external gear pump applications include, but are not limited to:

Various fuel oils and lube oils

Chemical additive and polymer metering

Chemical mixing and blending (double pump)

Industrial and mobile hydraulic applications (log splitters, lifts, etc.)

Acids and caustic (stainless steel or composite construction)

Low volume transfer or application

Materials Of Construction / Configuration

Options

As the following list indicates, rotary pumps can be

constructed in a wide variety of materials. By

precisely matching the materials of construction

with the liquid, superior life cycle performance will

result.

External gear pumps in particular can be

engineered to handle even the most aggressive

corrosive liquids. While external gear pumps are

commonly found in cast iron, newer materials are

allowing these pumps to handle liquids such as sulfuric acid, sodium

hypochlorite, ferric chloride, sodium hydroxide, and hundreds of other corrosive

liquids.

Externals (head, casing, bracket) - Iron, ductile iron, steel, stainless steel,

high alloys, composites (PPS, ETFE)

Internals (shafts) - Steel, stainless steel, high alloys, alumina ceramic

Internals (gears) - Steel, stainless steel, PTFE, composite (PPS)

Bushing - Carbon, bronze, silicon carbide, needle bearings

Shaft Seal - Packing, lip seal, component mechanical seal, magnetically-

driven pump

http://www.pumpschool.com/principles/external.asp#Advantages

2014, Pump School

School Policy

Sponsored by Viking Pump, Inc.

How to Maintain Gear Pumps

By Chris Hoke, eHow Contributor

A composite external gear

pump performs well in

corrosive liquid applications.

Gear pumps use positive displacement to force water through the pump.

A gear pump is a positive displacement pump that uses two meshing gears to pump

both low and high viscosity liquids. The two gears draw liquid into the enclosed

housing through the inlet, trap the liquid between the gear teeth and then propel the

liquid through the outlet. Gear pumps may require occasional maintenance for optimal

performance, the frequency of which is best based on past performance. Maintenance

on most gear pumps can be accomplished without removing the driving component

and plumbing.

Instructions

1

Remove the gear pump casing screws with the Phillips screwdriver. The screw

configuration may vary based on the manufacturer and may require the use of a flat-

bladed screwdriver or hexagonal wrench to remove the screws. Consult your pump

manual for the correct tool.

2

Remove the pump casing. Gear pumps that have not seen regular maintenance for an

extended length of time may not open easily by hand. In these cases, insert the edge of a

flat-bladed screwdriver into the seam in the case's housing and gently apply pressure

until the casing comes apart.

3

Check for wear on the tips of the gear teeth. A new gear pump has a clearance of between

0.005 inch and 0.007 inch between the gear teeth and the gear chamber wall, just

enough to insert a piece of thin wrapping paper. More clearance than that indicates wear

due to scrubbing against the gear chamber wall, which can occur when the pump heats

up and the metal gears expand outward, or can be the result of bearing wear.

4

Examine all of the bearings for signs of wear. Severely worn bearings are egg-shaped and

allow the gears to move around within the gear chamber. If bearings are worn, they

should be replaced using a bearing puller, which is a device that uses a collet to remove

bearings from inside of the bearing bore. New bearings should then be greased and

replaced. Alternately, the entire bearing assembly can be replaced on some models of

gear pumps.

5

Inspect the pin that holds the gears onto their shafts. This pin prevents the gears from

coming loose, and if they are sheared off they will cause the pump to stop working

completely. The pin can be sheared off if a foreign object enters the pump and jams the

gears or if a bearing becomes worn enough to stop rotation within the pump. If the pin is

damaged or sheared off, replace the pin and thoroughly clean the inside of the gear

chamber.

6

Examine the pump cover for bulges. Extreme pressure inside the pump, as well as a

powerful blow to the drive shaft that enters the pump, can cause bulges in the pump

cover, which allow liquid to bypass the pumping process (called slippage). If bulges are

found, the damaged pump cover should be replaced by removing the screws that hold it

in place and installing a new pump cover.

7

Check the pump for signs of general wear caused by improper use. If the gear pump has

been used to pump an abrasive liquid, the shaft may have visible scouring marks.

Likewise, if the gear pump has been used to pump certain chemicals not compatible with

the metals that make up the components of the pump, the gears and shafts will bear

etching and deterioration may be present. Thoroughly rinse the inside of the gear

chamber, removing the chemicals and abrasive fluids. In severe cases where the gear

pump has been used to pump chemicals and abrasives for an extended period, the pump

components may not be salvageable and will require replacing.

Read more: http://www.ehow.com/how_6323303_maintain-gear-pumps.html#ixzz339B0y300

S-ar putea să vă placă și

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDe la EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiÎncă nu există evaluări

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDe la EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallEvaluare: 4 din 5 stele4/5 (8)

- 3412C Emcp Ii+ PDFDocument4 pagini3412C Emcp Ii+ PDFLolo Khaled67% (3)

- Denso Engine Management SystemsDocument184 paginiDenso Engine Management SystemsNiculae Noica100% (1)

- Vehicle Crash Worthiness CompleteDocument388 paginiVehicle Crash Worthiness Completemuscogiuri100% (3)

- Rotary Pumps: Internal Gear PumpDocument15 paginiRotary Pumps: Internal Gear PumpanbuvrpÎncă nu există evaluări

- Gear PumpsDocument15 paginiGear PumpsPrince ShanÎncă nu există evaluări

- Selecting Positive Displacement PumpsDocument4 paginiSelecting Positive Displacement PumpsArindam GhosalÎncă nu există evaluări

- Screw Pump: Presented By: Padon, Mric Kimjim JDocument24 paginiScrew Pump: Presented By: Padon, Mric Kimjim JJohn A. CenizaÎncă nu există evaluări

- Positive Displacement PumpsDocument5 paginiPositive Displacement PumpsGabriel Andrés Barcha Angulo100% (1)

- Positive Displacement PumpDocument43 paginiPositive Displacement Pumpvenkeeku100% (2)

- Gear Pump PDFDocument21 paginiGear Pump PDFAli HassanÎncă nu există evaluări

- Troubleshooting PumpDocument54 paginiTroubleshooting PumpM.nour El-din100% (3)

- Motor k21 ServicioDocument223 paginiMotor k21 ServicioGersom García García100% (2)

- Mitsubishi mt2100 210 2500 250 Parts Catalogue Engine Opt PDFDocument64 paginiMitsubishi mt2100 210 2500 250 Parts Catalogue Engine Opt PDFbtxps5100% (1)

- Pumps Selection and Sizing and TroubleshootingDocument131 paginiPumps Selection and Sizing and TroubleshootingMujadid KhawajaÎncă nu există evaluări

- Pump Selection GuideDocument2 paginiPump Selection Guidem_najmanÎncă nu există evaluări

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesDe la EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesEvaluare: 5 din 5 stele5/5 (1)

- Vertical Sump PumpDocument6 paginiVertical Sump Pumpsahildhingra100% (1)

- Don'T Forget The Cat E-Trim Codes and Files: Avoid Costly RepairsDocument2 paginiDon'T Forget The Cat E-Trim Codes and Files: Avoid Costly Repairsguayanecitro100% (1)

- DOOSAN DL300A WHEELED LOADER Service Repair Manual PDFDocument45 paginiDOOSAN DL300A WHEELED LOADER Service Repair Manual PDFdfjjskemmdm86% (7)

- Himsen NewDocument20 paginiHimsen NewMaksym KlymenkoÎncă nu există evaluări

- EAF Energy ModelDocument10 paginiEAF Energy Modelcimav100% (2)

- Pump Learning Guide1Document171 paginiPump Learning Guide1password2013Încă nu există evaluări

- Id FD PaDocument17 paginiId FD PaSara LopezÎncă nu există evaluări

- Pull and Push Up of PropDocument11 paginiPull and Push Up of Propsandeep_yadav_530% (1)

- What's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsDocument4 paginiWhat's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsTapas ChaudhuriÎncă nu există evaluări

- West Seno The First Deepwater Field in Indonesia A Strategy To Optimize Reserves Tatang Heri Robert Mathers R. Andrew MccartyDocument15 paginiWest Seno The First Deepwater Field in Indonesia A Strategy To Optimize Reserves Tatang Heri Robert Mathers R. Andrew MccartyREandoÎncă nu există evaluări

- Positive - Disp PumpsDocument33 paginiPositive - Disp PumpscmahendrÎncă nu există evaluări

- Internal External Gear PumpsDocument15 paginiInternal External Gear PumpsAndreDericiÎncă nu există evaluări

- Gear PumpDocument7 paginiGear PumpMuhammad QayyumÎncă nu există evaluări

- Gear PumpsDocument7 paginiGear PumpsPrince ShanÎncă nu există evaluări

- Gear Pump Design: Using AGMA MethodDocument28 paginiGear Pump Design: Using AGMA Method20M130 - MUKUNTH A GÎncă nu există evaluări

- Poitive Displacment Type Pump SelectionDocument4 paginiPoitive Displacment Type Pump Selectionmanpreetsodhi08Încă nu există evaluări

- External Gear Pump PrinciplesDocument3 paginiExternal Gear Pump PrinciplesJam BabÎncă nu există evaluări

- Diff Types of PD PumpsDocument6 paginiDiff Types of PD PumpsdhakshuÎncă nu există evaluări

- Gear Pump OperationDocument7 paginiGear Pump Operationahmed el sayedÎncă nu există evaluări

- External Gears: Dinesh Bakthavatsalam 20192297 4M-I September 30, 2005Document7 paginiExternal Gears: Dinesh Bakthavatsalam 20192297 4M-I September 30, 2005vasanthavananÎncă nu există evaluări

- Pumps - Hassan ElBanhawiDocument20 paginiPumps - Hassan ElBanhawijesus_manrique2753Încă nu există evaluări

- Hydraulic Cylinder AppDocument5 paginiHydraulic Cylinder AppwanradhiahÎncă nu există evaluări

- Screw PumpsDocument4 paginiScrew PumpsElia MekdadÎncă nu există evaluări

- Intruab 2)Document8 paginiIntruab 2)ahmad pidotÎncă nu există evaluări

- Gear Pump Operation and Maintenance: Mike SondaliniDocument2 paginiGear Pump Operation and Maintenance: Mike Sondaliniagrocel_bhv5591Încă nu există evaluări

- Parts of A PumpDocument5 paginiParts of A Pumpanmn123100% (1)

- Definition of PumpDocument14 paginiDefinition of Pumpimate77Încă nu există evaluări

- Elements D'une Pompe en AnglaisDocument4 paginiElements D'une Pompe en AnglaismerouaneinconuÎncă nu există evaluări

- Pushrods The Key To PerformanceDocument4 paginiPushrods The Key To PerformanceJerson T. AltovarÎncă nu există evaluări

- Pros and Cons - Horizontal Split Case PumpsDocument5 paginiPros and Cons - Horizontal Split Case Pumpsjarryd100% (1)

- Zenith Pumps: B-Series Gear PumpsDocument20 paginiZenith Pumps: B-Series Gear Pumpskosmc123Încă nu există evaluări

- Seminar Types of PumpDocument21 paginiSeminar Types of Pump05 Dhiraj AldarÎncă nu există evaluări

- Hydraulic Shock Absorber in VehicleDocument23 paginiHydraulic Shock Absorber in VehicleGopal GuptaÎncă nu există evaluări

- Chapter One Introduction To Pump Pump DefinitionDocument44 paginiChapter One Introduction To Pump Pump DefinitionyoungÎncă nu există evaluări

- Chapter One Introduction To Pump Pump DefinitionDocument44 paginiChapter One Introduction To Pump Pump DefinitionyoungÎncă nu există evaluări

- Fluid Flow Note Chapter 7Document57 paginiFluid Flow Note Chapter 7Fareez IzwanÎncă nu există evaluări

- Advantages DisadvantagesDocument3 paginiAdvantages DisadvantagesUmesh AhirraoÎncă nu există evaluări

- UNIT 1 (G) IhpDocument60 paginiUNIT 1 (G) Ihpsantosh alguleÎncă nu există evaluări

- Advantages and Disadvantages of Screw Pumps PaperDocument6 paginiAdvantages and Disadvantages of Screw Pumps PaperRenato Orosa100% (1)

- Rotary Pumps: By: Luiz Angelo L. Villegas & Alrich Jetro S. CantagoDocument15 paginiRotary Pumps: By: Luiz Angelo L. Villegas & Alrich Jetro S. CantagoJohn A. CenizaÎncă nu există evaluări

- Steering Gear Selection and Installation ManualDocument37 paginiSteering Gear Selection and Installation ManualHaris StavrouÎncă nu există evaluări

- PumpsDocument38 paginiPumpsbernabasÎncă nu există evaluări

- Pump Working PrinciplesDocument7 paginiPump Working PrinciplesamirulbznÎncă nu există evaluări

- PRTMN 11Document23 paginiPRTMN 11Bambang IrawanÎncă nu există evaluări

- Positive Displacement Pumps (PD)Document9 paginiPositive Displacement Pumps (PD)Anson LowkieÎncă nu există evaluări

- Bombas CentrifugasDocument34 paginiBombas CentrifugasMauro MuñozÎncă nu există evaluări

- Pump Unit Control Valves ActuatorsDocument17 paginiPump Unit Control Valves ActuatorsVetrivezhan PsivamÎncă nu există evaluări

- Gear Pump QuestionsDocument2 paginiGear Pump QuestionsChandramohan MuruganÎncă nu există evaluări

- Tuthill - C Series Service ManualDocument22 paginiTuthill - C Series Service ManualbenkaouhaÎncă nu există evaluări

- YWE P250 ManualDocument21 paginiYWE P250 ManualNuriffah Izzah100% (1)

- A Beginners Guide To Progressive Cavity PumpsDocument4 paginiA Beginners Guide To Progressive Cavity PumpsGaurav SinghÎncă nu există evaluări

- Splash Protection - SOLASguidelines ChII-2-15.2Document8 paginiSplash Protection - SOLASguidelines ChII-2-15.2Marco Aurélio SchelesÎncă nu există evaluări

- (Lurgi) : I S Gypsunl Ready No-W?Document42 pagini(Lurgi) : I S Gypsunl Ready No-W?Zeus4321Încă nu există evaluări

- Incomplete CombustionDocument5 paginiIncomplete CombustionDineshkumarÎncă nu există evaluări

- MCQs - EAM - Unit 4Document11 paginiMCQs - EAM - Unit 4Sayee DeshpandeÎncă nu există evaluări

- Ferguson TE20, To20, To30 Service Manual - Copia-Páginas-1-47Document47 paginiFerguson TE20, To20, To30 Service Manual - Copia-Páginas-1-47Facundo Santiago MuletÎncă nu există evaluări

- Basic RefineryDocument17 paginiBasic RefineryKhairatun NisaÎncă nu există evaluări

- PRESENTATION - Electric Powered Air Blower Controlled Charcoal StoveDocument30 paginiPRESENTATION - Electric Powered Air Blower Controlled Charcoal StovederecÎncă nu există evaluări

- Proton Exchange MembraneDocument22 paginiProton Exchange MembraneHanifan Lidinillah100% (1)

- Gastech-Conf-Brochure FINAL JAN 2011Document20 paginiGastech-Conf-Brochure FINAL JAN 2011KIRANJOSHIÎncă nu există evaluări

- Basics of Distillation: V. K. KapoorDocument62 paginiBasics of Distillation: V. K. Kapoorstardeepakrati100% (1)

- Exxon East Area GX TopsideDocument2 paginiExxon East Area GX TopsidetyuÎncă nu există evaluări

- Natural ReNatural Resources and Associated Problemssources and Associated ProblemsDocument24 paginiNatural ReNatural Resources and Associated Problemssources and Associated ProblemsAnkur PoddarÎncă nu există evaluări

- Unconventional Oil and Gas PotentialDocument85 paginiUnconventional Oil and Gas PotentialAngelina RandaÎncă nu există evaluări

- Expanse Al 600Document4 paginiExpanse Al 600raza102Încă nu există evaluări

- TAD740GE: Volvo Penta Genset EngineDocument2 paginiTAD740GE: Volvo Penta Genset Engineجمال ابو الفضلÎncă nu există evaluări

- Sizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)Document1 paginăSizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)ekabudiartiÎncă nu există evaluări

- Hidromotori PDFDocument40 paginiHidromotori PDFDarkoÎncă nu există evaluări

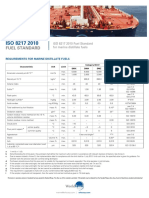

- ISO 8217 2010 Tables 1 Amp 2 1Document2 paginiISO 8217 2010 Tables 1 Amp 2 1Prashant Kumar SinghÎncă nu există evaluări