Documente Academic

Documente Profesional

Documente Cultură

IISC Bangalore - Materials Engineering Courses-2013-14

Încărcat de

Sri PuduTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IISC Bangalore - Materials Engineering Courses-2013-14

Încărcat de

Sri PuduDrepturi de autor:

Formate disponibile

Scheme of Instruction Page 200

MATERIALS ENGINEERING

M. E. PROGRAMME

MATERIALS ENGINEERING

(Duration : 2 Years)

64 credits

Hard core: 8 credits

MT 202 3:0 Thermodynamics and Kinetics

MT 241 3:0 Structure and Characterisation of Materials

MT 243 0:2 Laboratory Experiments in Metallurgy

Soft core: Any three out of the following eight courses

MT 209 3:0 Defects in Materials

MT 220 3:0 Microstructural Design and Development of Engineering Materials

MT 231 3:0 Interfacial Phenomena in Materials Processing

MT 245 3:0 Transport Processes in Process Metallurgy

MT 252 3:0 Science of Materials Processing

MT 253 3:0 Mechanical Behaviour of Materials

MT 260 3:0 Polymer Science and Engineering - I

Proj ect: 32 Credi ts

MT 299 0:32 Dissertation Project

Electives - 15 Credits: At least 9 credits must be taken from the courses offered by the

Department.

MT 201 (JAN) 3:0

Phase Transformations

Overview of phase transformations, nucleation and growth theories, coarsening, precipitation,

spinodal decomposition, eutectoid, massive, disorder-to-order, martensitic transformations.

crystal interfaces and microstructure. topics in the theory of phase transformations: linear

stability analysis, elastic stress effects, sharp interface and diffuse interface models of

microstructural evolution.

C Sri vastava

Prerequisites: Basic courses on crystallography, thermodynamics, phase diagrams and

diffusion.

Porter. D.A., and Easterling, E. E, Phase Transformations in Metal and Alloys, Van Nostrand, 1981.

J ena, A. K., and Chaturvedi, M., Phase Transformations in Materials, Prentice-Hall, 1993.

Khachaturyan, A. G., Theory of Structural Transformation in Solids, J ohn Wiley, 1983.

Reed-Hill, R. E., and Abbaschian R., Physical Metallurgy Principles, P.W.S-Kent, 1992.

MT 202 (AUG) 3:0

Thermodynami cs and Kinetics

Classical and statistical thermodynamics, Interstitial and substitutional solid solutions,

solution models, phase diagrams, stability criteria, critical phenomena, disorder-to-order

transformations and ordered alloys, ternary alloys and phase diagrams, Thermodynamics of

point defects, surfaces and interfaces. Diffusion, fluid flow and heat transfer.

T A Abi nandanan

Lupis C.H.P., Chemical Thermodynamics of Materials, Elsevier Science, 1982.

Scheme of Instruction Page 201

Shewmon P., Diffusion in Solids, 2

nd

Edition, Wiley, 1989.

Adamson A.W. and Gast A.P., Physical Chemistry of Surfaces (Sixth Edition), J ohn Wiley, 1997.

MT 206 (JAN) 3:0

Texture and Grai n Boundary Engi neering

Concepts of texture in materials, their representation by pole figure and orientation

distribution functions. Texture measurement by different techniques. Origin and development

of textures during materials processing stages: solidification, deformation, annealing, phase

transformation, coating processes and thin film deposition. Influence of texture on

mechanical and physical properties. Texture control in aluminium industry, automotive grade

and electrical steels, magnetic and electronic materials. Introduction to grain boundary

engineering and its applications.

S SUWAS

M. Hatherly and W.B. Hutchinson, An Introduction to Textures in Metals (Monograph No. 5), The Institute of Metals,

London.

V. Randle and O. Engler, Introduction to Texture Analysis: Macrotexture, Microtexture and orientation mapping,

Gordon and Breach Science Publishers.

F.J . Humphreys and M. Hatherly, Recrystallisation and Related Phenomenon, Pergamon Press.

P.E.J . Flewitt, R.K. Wild, Grain Boundaries.

MT 208 (AUG) 3:0

Diffusion in Solids

Fick's first and second law, Interdiffusion, Intrinsic diffusion and Integrated diffusion

coeffiecient, Relation with tracer diffusion coefficient, Growth Kinetics, Matano-Boltzmann

analysis, History and development of the Kirkendall effect, Darken analysis, Stable, unstable

and multiple Kirkendall planes. Concept of velocity diagram construction, Role of the

Kirkendall effect on morphogenesis, Physico-chemical approach.

A PAUL

P. Shewmon: Diffusion in Solids

MT 209 (JAN) 3:0

Defects in Materials

Review of defect classification and concept of defect equilibrium. Review of point defects in

metallic, ionic and covalent crystals. Dislocation theory - continuum and atomistic.

Dislocations in different lattices. Role of anisotropy. Dislocation kinetics. Interface

thermodynamics and structure. Overview of grain boundaries, interphase boundaries,

stacking faults and special boundaries. Interface kinetics: migration and sliding. Defect

interactions: point defect-dislocation interaction, dislocation-interface interactions,

segregation, etc.. Overview of methods for studying defects including computational

techniques

S Karthikeyan

W.D. Kingery, H.K. Bowen and D.R. Uhlmann. Introduction to Ceramics, 2

nd

ed., J ohn Wiley and Sons, 1976

D. Hull and D. J . Bacon, Introduction to dislocations, 4th ed., Butterworth-Heinemann, 2001.

D.A. Porter and K.E. Easterling: Phase Transformation in Metals and Alloys, 2

nd

ed. Chapman and Hall, 1992.

R.W. Balluffi, S.M. Allen, W.C. Carter: Kinetics of Materials, 1

st

ed. Wiley-Interscience, 2005.

J .P. Hirth and J .L. Lothe: Theory of Dislocations, 2nd ed., Krieger, 1982.

A. P. Sutton and R. W. Balluffi: Interfaces in Crystalline Materials, 1st ed., Oxford Univ. Press, 1995.

MT 218 (AUG) 2:1

Modeling and Simulation i n Materials Engineering

Importance of modeling and simulation in Materials Engineering. The modeling processs.

Analytical and numerical approaches. Numerical solution of ODEs and PDEs. Atomistic

modeling ab-initio techniques and molecular dynamics. Monte Carlo methods Kinetic MC

and simulated annealing. Mesoscale modeling microstructure modeling methods, phase

Scheme of Instruction Page 202

field technique, dislocation dynamics, computational crystal plasticity. Introduction to multi

scale modeling schemes. Review and overview of materials modeling methods capabilities,

limitations and applications. Labs on Molecular dynamics, Monte Carlo method, Dislocation

dynamics and Phase field techniques

S Karthikeyan and T A Abinandanan

A.B. Shiflet and G.W. Shiflet, Introduction to Computational Science: Modeling and Simulation for the Sciences,

Princeton University Press, 2006.

D.C. Rapaport: The Art of Molecular Dynamics Simulation, Cambridge Univ. Press, 1995.

K. Binder, D. W. Heermann: Monte Carlo Simulation in Statistical Physics, Springer, 1997.

R. Phillips, Crystal, Defects and Microstructures Modeling across scales, Cambridge Univ. Press, 2001.

K.G.F J anssens, D. Raabe, E. Kozeschnik, M.A. Miodownik, B. Nestler: Computational Materials Engineering: An

Introduction to Microstructure Evolution, Elsevier Academic press, 2007.

A. P. Sutton and R. W. Balluffi: Interfaces in Crystalline Materials, 1st ed., Oxford Univ. Press, 1995.

MT 220 (JAN) 3:0

Mi crostructural Design and Development of Engi neeri ng Materials

This course will build on the fundamentals of phase stability, transformations, processing,

solid state physics, and mechanical behavior to describe how engineering materials can be

tailored to achieve desired properties through the control of composition, processing and

microstructure. Two broad classes of materials will be covered. Thermo-structural materials

will include aluminium and magnesium alloys, titanium and nickel base alloys, steels,

composites, shape memory alloys and amorphous alloys. Functional materials will include

hard and soft magnetic materials, families of semiconductors, optical materials and electronic

ceramics. Common applications for these materials and current technological challenges and

trends will be also be highlighted.

Subodh Kumar, D Banerjee, U Ramamurty

Lutjering G. and Williams J .C., Titanium, Springer, New York

Reed R.C., The Superalloys: Fundamentals and Applications, Cambridge University Press, UK.

Bhadeshia, H.K.D.H. and Honeycombe R., Steels: Microstructure and Properties, Butterworth-Heinemann,

UK.

Polmear I.J . ,Light Alloys: From Traditional Alloys to Nanocrystals, 4

th

ed, Butterworth-Heinemann, UK.

Hummel R.E., Electronic Properties of Materials, Springer, New York.

Hull D. and Clyne T.W., An Introduction to Composite Materials, Cambridge University Press.

MT 231 (JAN) 3:0

Interfaci al Phenomena in Material s Processing

Materials and surfaces, Adsorption from solution, Thermodynamics of adsorption - surface

excess and surface free energy, Gibbs equation, adsorption isotherms, wetting, contact

angle, Young's equation, Monolayer and interfacial reactions, Electrical phenomena at

interfaces, electrochemistry of the double layer, electrokinetics, flocculation, coagulation and

dispersion, Polymers at interfaces, Emulsions. Applications in Materials Processing.

S Subramanian

Matrijivic E (Ed.), Surface and Colloid Science, Plenum, New York, 1982.

Adamson A.W., Physical Chemistry of Surfaces, Wiley Interscience, New York, 1996.

Laskowski J .S. and Rolston J (Ed.), Colloid Chemistry in Mineral Processing, Elsevier, New York, 1992.

MT 235 (AUG) 3:0

Corrosi on Technology

Basic electrochemical principles governing corrosion. Types and mechanisms of corrosion.

Advances in corrosion engineering and control.Anodic and Cathodic control-Biocorrosion,

mechanisms and microbiological aspects. Corrosion under sub-soil and sea water

Scheme of Instruction Page 203

conditions- Marine biofouling and biocorrosion with respect to industrial conditions. Methods

of abatement.

K A Natarajan

Fontana, M.G., Corrosion Engineering, 3rd Edition, McGraw-Hill, N.Y., 1978.

Borenstein, Microbiologically influenced corrosion handbook.

MT 241 (AUG) 3:0

Structure and Characterization of Material s

Bonding and crystal structures, Stereographic projection, Point and space groups, Defects in

crystals, Schottky and Frenkel defects, Charged defects, Vacancies and interstitials in non

stoichiometric crystals, Basics of diffraction theory, X-ray powder diffraction and its

applications, Electron diffraction and Electron microscopy.

R Ranj an

A. R. West, Solid State Chemistry and its Applications, J ohn Wiley

B. D. Cullity, Elements of x-ray Diffraction.

A. Kelly and G. W. Groves, Crystallography and Crystal Defects, Longman

M. D. Graef and M. E. Henry, Structures of Materials, Cambridge

MT 243 (AUG) 0:2

Laboratory Experiments in Metallurgy

Experiments in Metallographic techniques, heat treatment, diffraction mineral beneficiation,

chemical and process metallurgy, and mechanical metallurgy.

Faculty

MT 245 (AUG) 3:0

Transport Processes in Process Metall urgy

Basic and advanced idea of fluid flow, heat and mass transfer. Integral mass, momentum and

energy balances. The equations of continuity and motion and its solutions. Concepts of

laminar and turbulent flows. Concept of packed and fluidized bed. Non-wetting flow, Natural

and forced convection. Unit processes in process metallurgy. Application of the above

principles in process metallurgy.

G S Gupta

J . Szekely and N.J . Themelis, Rate Phenomena in Process Metallurgy, Wiley, New York, 1971

G.H. Geiger and D R Poirier: Transport Phenomena in Metallurgy, Addison-Wesley, 1980.

D.R. Gaskell: Introduction to Transport Phenomena in Materials Processing, 1991.

R.B. Bird, W.E. Stewart and E.N. Lightfoot: Transport Phenomena, J ohn Wiley International Edition, 1960

F.M. White: Fluid Mechanics, McGraw Hill, 1994

Various research papers

MT 248 (JAN) 3:0

Modelling and Computational Methods in Metallurgy

Basic principles of physical and mathematical modelling. Similarity criteria and dimensional

analysis. Detailed study of the modelling of various metallurgical processes such as blast

furnace, induction furnace, ladle steelmaking, rolling, carburizing and drying. Finite Difference

method. Solution of differential equations using various numerical techniques. Convergence

Scheme of Instruction Page 204

and stability criteria. Assignments will be based on developing computer code to solve the

given problem.

G S Gupta

Prerequisite: Knowledge of transport phenomena, programming language

J . Szekely and N.J . Themelis, Rate Phenomena in Process Metallurgy, Wiley, New York, 1971

B. Carnahan, H.A. Luther and J .O. Wilkes: Applied Numerical Methods, J ohn Wiley, NY, 1969.

Various research papers

MT 250 (AUG) 3:0

Introduction to Material s Science and Engineering

Compulsory for ME. students who do not have BE Metallurgy Compulsory for research

students without materials background

Bonding, types of materials, basics of crystal structures and crystallography.

Thermodynamics, thermochemistry, unary systems. Methods of structural characterisation.

Thermodynamics of solid solutions, phase diagrams, defects, diffusion. Solidification. Solid-

solid phase Transformations. Mechanical behaviour: elasticity, plasticity, fracture.

Electrochemistry and corrosion. Band structure, electrical, magnetic and optical materials.

Classes of practical material systems: metallic alloys, ceramics, semiconductors, composites

V Jayaram

W.D. Callister: Materials Science & Engineering, Wiley (India) 2007

MT 252 (AUG) 3:0

Sci ence of Materials Processing

Fundamentals of Materials Processing: Deformation processing. Fundamentals and

application of plasticity, Yielding, Operations specially conditioned by friction. Flow instability,

drawability, anisotropy. Thermally activated processes, dynamic recovery and

recrystallization, Modeling of materials processing. Applications of deformation processing.

Processing methods involving consolidation and sintering of powders.

Structural size and its importance, bulk nanostructured materials by severe plastic

deformation (SPD), Unique features of SPD and properties. Nanostructured materials

prepared by solid state processing, properties, benefits and application of nanocrystalline

microstructures in structural materials.

S Suwas

W.A. Backofen, Deformation processing: Addision Wesley.

Processing of Metals and Alloys: Materials Science and Technology series, eds. R.W. Cahn and P. Haasan, Wiley

VCH.

Nanostructured Materials by Severe Plastic Deformation: eds. M. Zahetbuer and R.Z. Valiev, Spinger Verlag.

MT 253 (AUG) 3:0

Mechanical Behaviour of Materials

Theory of Elasticity. Theory of Plasticity Review of elementary dislocation theory.

Deformation of single and polycrystals. Temperature and strain rate effects in plastic flow -

strain hardening, grain size strengthening, solid solution strengthening, order hardening,

precipitation hardening, dispersion strengthening. Strengthening by martensitic

transformation, creep, fatigue and fracture.

Subodh Kumar

Kelly, A and Nicholson R.B. (Eds.), Strengthening methods in crystals.

G.E. Dieter, Mechanical Metallurgy, McGraw-Hill, London (1988).

Scheme of Instruction Page 205

MT 255 (JAN) 3:0

Solidi fication Processing

Advantage of solidification route to manufacturing, the basics of solidification including fluid

dynamics, solidification dynamics and the influence of mould in the process of casting. Origin

of shrinkage, linear contraction and casting defects in the design and manufacturing of

casting, continuous casting, Semi-solid processing including pressure casting, stir casting and

thixo casting. Welding as a special form of manufacturing process involving solidification.

Modern techniques of welding, the classification of different weld zones, their origin and the

influence on properties and weld design. Physical and computer modeling of solidification

processes and development of expert systems. New developments and their possible impact

on the manufacturing technology in the future with particular reference to the processes

adaptable to the flexible manufacturing system.

K Chattopadhyay

J . Campbell, Casting, Butterworth - Haneman, London, 1993

M.C. Flemings, Solidification Processing , McGraw Hill, 1974.

MT 256 (JAN) 3:0

Fracture

Review of elastic and plastic deformation. Historical development of fracture mechanics.

Thermodynamics of fracture including Griffith theory. Linear elastic fracture mechanics. Irwin

and Dugdale extensions. Stability of cracks. Crack resistance curves and toughening of brittle

materials. Ductile failure. J -integral. Indentation failure. Environmental aspects of failure.

Cyclic Fatigue. Methods to measure toughness. Fracture in thin films and interfaces.

Toughening in hierarchical structures

V Jayaram

Fracture of Brittle Solids. B.R.Lawn. Cambridge University Press (1993).

Mechanical Behaviour of Materials. Thomas H. Courtney. McGraw Hill (1990).

Engineering Fracture Mechanics. David Broek. Sijthoff and Nordhoff. The Netherlands (1978).

Deformation & Fracture of Engineering Materials. Richard Hertzberg. J ohn Wiley (1996).

MT 257 (JAN) 3:0

Finite El ement Analysis for Materials Engineers

Introduction to fundamental equations of elasticity and plasticity. introduction to tensor

notations. Modelling of a physical problem using FEA.. fundamentals of FEA. such as

meshing (uniform. non-uniform. 1-D. 2-D). stiffness matrix. mapping. interpolation. Rayleigh

Ritz method. Galerkin method. Gauss-Legendre method. residual methods. Solving linear and

non-linear structural. thermal and electrical problems using a commercial FEA software.

Concepts of crystal plasticity and anisotropy in FEA.

Praveen Kumar

Robert D. Cook. David S. Malkus. Michael E. Plesha and Robert J . Witt. Concepts and Applications of Finite

Element Analysis

MT 260 (AUG) 3:0

Pol ymer Science and Engineering I

Introduction. Polymer classification. structure. Various techniques of synthesis and their

kinetics. Structure and molecular weight determination. Chemistry and applications of

commercial plastics. Thermodynamics and solution properties. solid state properties.

viscoelasticity and rubber elasticity. Polymer processing and rheology.

P C Ramamurthy and M Giridhar

Scheme of Instruction Page 206

Odian. G.. Principles of Polymerization. McGraw Hill. 2ndEd.. 1981.

Dotson. N. A.. Galvan. R.. Laurence. R. L..Tirrell. M.. Polymerization Process Modeling. Wiley. 1995.

Billmeyer. F. W., Textbook of Polymer Science. J ohn Wiley & Sons. 1984.

MT 261 (JAN) 3:0

Pol ymer Science and Engineering II

Fundamentals of polymers. Electroactive polymers. Device physics: Crystal structure, Energy

band diagram, Charge carriers, Heterojunctions, Diode characteristics. Device fabrication

techniques like Solution, Evaporation. Devices like Organic photovoltaic device, Organic Light

emitting device, Polymeric sensors. Stability of organic devices.

P C Ramamurthy

Handbook of Conducting Polymers (Third Edition) Conjugated Polymers: Theory, Synthesis, Properties and

Characterization, Edited by Terje A. Skotheim and J ohn R. Reynolds, CRC Press.

Handbook of Conducting Polymers (Third Edition) Conjugated Polymers: Processing and Applications Edited by

Terje A. Skotheim and J ohn R. Reynolds, CRC Press.

Organic Photovoltaics Mechanisms, Materials, and Devices by Sam-Shajing Sun

Niyazi Serdar Sariciftci. CRC Press.

Semiconductor Physics and Devices Basic Principles Donald A. Neamen, McGraw

Hill publications.

MT 262 (JAN) 3:0

Concepts in Pol ymer Blends and Nanocomposites

Introduction to polymer blends and composites, nanostructured materials and

nanocomposites, Polymer-polymer miscibility, factors governing miscibility, immiscible

systems and phase separation, Importance of interface on the property development,

compatibilizers and compatibilization, Blends of amorphous & semi-crystalline polymers,

rubber toughened polymers, particulate, fiber reinforced composites. Nanostructured

materials like nano clay, carbon nanotubes, graphene etc. and polymer nanocomposites.

Surface treatment of the reinforcing materials and interface/interphase structures of

composites / nanocomposites. Various processing techniques like solution mixing, melt

processing. Unique properties of blends, composites/nanocomposites in rheological,

mechanical, and physical properties and applications

S Bose

Paul D. R. and Newman S., Polymer Blends, Vol 1&2 Academic Press, 2000

Utracki L. A., Polymer Alloys and Blends, Hanser, 2000

Chung C., Introduction to Composites, Technomic, Lancaster, PA. 1998.

Summerscales J . and Short D., Fiber Reinforced Polymers, Technomic. 1988

T.J . Pinnavia and G.W. Beall (eds.), Polymer-Clay Nanocomposites, Wiley, New York 2000.

Ajayan P. M., Schadler L. S., Braun P. V., Nanocomposite Science &Technology, Wiley-VCH, Weinheim, 2003.

MT 271 (AUG) 3:0

Introduction to Bi omateri al s Sci ence and Engineering

This course will introduce basic concepts of biomaterials research and development including

discussion on different types of materials used for biomedical applications and their relevant

properties. Contents: Surface engineering for biocompatibility; Protein adsorption to materials

surfaces; Blood compatibility of materials; Immune response to materials; Corrosion and wear

of implanted medical devices; Scaffolds for tissue engineering and regenerative medicine;

Concepts in drug delivery; Regulatory issues and ethics.

K Chatterj ee

Ratner et al: Biomaterials science: An introduction to materials in medicine, 2nd edition, Elsevier Academic Press

Current Research Literature

Scheme of Instruction Page 207

MT 299 0:32

Dissertation Project

The M.E. Project is aimed at training the students to analyse independently any problem

posed to them. The project may be a purely analytical piece of work. a completely

experimental one or a combination of both. In a few cases. the project can also involve a

sophisticated design work. The project report is expected to show clarity of thought and

expression. critical appreciation of the existing literature and analytical and/or experimental or

design skill.

FACULTY

S-ar putea să vă placă și

- Emcm-001 AjDocument459 paginiEmcm-001 Ajcristianpetricean100% (2)

- Tank and Pressure Vessel MaintenanceDocument30 paginiTank and Pressure Vessel MaintenancePandu Satrio100% (2)

- Notes On Quantum MechanicsDocument397 paginiNotes On Quantum MechanicsBruno Skiba100% (3)

- Passed Report - Glass - 17.5mmDocument29 paginiPassed Report - Glass - 17.5mmsaravqwerty100% (1)

- Metallized PlasticDocument388 paginiMetallized PlasticLuận NgôÎncă nu există evaluări

- Syllabus Copy (I-VIII) Semester Vtu MechDocument44 paginiSyllabus Copy (I-VIII) Semester Vtu Mech''-Anoop Jm-''80% (5)

- Cooling Tower Noise Control Silencers Reduce SoundDocument37 paginiCooling Tower Noise Control Silencers Reduce SoundUllas EK100% (1)

- Preparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsDocument13 paginiPreparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsRoshan KejariwalÎncă nu există evaluări

- 2008 Mech PDFDocument82 pagini2008 Mech PDFmotuandgoluÎncă nu există evaluări

- Constitutive Equations for Engineering Materials: Elasticity and ModelingDe la EverandConstitutive Equations for Engineering Materials: Elasticity and ModelingEvaluare: 5 din 5 stele5/5 (2)

- TN NewDocument6.322 paginiTN Newdeva nesan83% (6)

- Mechanics of Material Interfaces: Proceedings of the Technical Sessions on Mechanics of Material Interfaces Held at the ASCE/ASME Mechanics Conference, Albuquerque, New Mexico, June 23-26, 1985De la EverandMechanics of Material Interfaces: Proceedings of the Technical Sessions on Mechanics of Material Interfaces Held at the ASCE/ASME Mechanics Conference, Albuquerque, New Mexico, June 23-26, 1985Încă nu există evaluări

- Literature Review On Cement Industry WHRDocument24 paginiLiterature Review On Cement Industry WHRnihal attarÎncă nu există evaluări

- M.Tech. Metallurgical and Materials Engineering Scheme and SyllabiDocument17 paginiM.Tech. Metallurgical and Materials Engineering Scheme and SyllabiSachith Praminda RupasingheÎncă nu există evaluări

- First YearDocument23 paginiFirst YearsaratknairÎncă nu există evaluări

- MSE PG CoursesDocument65 paginiMSE PG CoursesMirtunjay KumarÎncă nu există evaluări

- Mtech Mme Materials Science 2012 13Document19 paginiMtech Mme Materials Science 2012 13Anonymous sENwj8nwqÎncă nu există evaluări

- Web Site: - : Centurion University of Technology & Management ODISHA-761211, INDIADocument29 paginiWeb Site: - : Centurion University of Technology & Management ODISHA-761211, INDIAJames OrtegaÎncă nu există evaluări

- MET311E Physical MetallurgyDocument2 paginiMET311E Physical MetallurgySaúl L Hdez TÎncă nu există evaluări

- BTECH Syllabus-1Document31 paginiBTECH Syllabus-1AJIT PRASAD 12- C. Roll-04Încă nu există evaluări

- Synopis 2Document4 paginiSynopis 2chima melfordÎncă nu există evaluări

- HJKKJKDocument79 paginiHJKKJKDeepak ChandranÎncă nu există evaluări

- NIT Manipur Syllabus PDFDocument11 paginiNIT Manipur Syllabus PDFzilangamba_s4535Încă nu există evaluări

- Courses - Materials Engineering IIScDocument19 paginiCourses - Materials Engineering IIScsatishkumarvÎncă nu există evaluări

- BS Chemistry Syllabus Final 2021-25 ..Document71 paginiBS Chemistry Syllabus Final 2021-25 ..Faisal IrfanÎncă nu există evaluări

- R13 B.Tech I Year SyllabusDocument2 paginiR13 B.Tech I Year Syllabusమత్సా చంద్ర శేఖర్Încă nu există evaluări

- FRM Course Syl Lab Us Ip DownloadDocument2 paginiFRM Course Syl Lab Us Ip DownloadYatish PujaraÎncă nu există evaluări

- PHY110 Engineering Physics Course OverviewDocument2 paginiPHY110 Engineering Physics Course Overviewdineesha siddelaÎncă nu există evaluări

- Advanced Program in Material Science and EngineeringDocument9 paginiAdvanced Program in Material Science and Engineeringmai4ka-1Încă nu există evaluări

- SyllabusDocument85 paginiSyllabusAkshit GuptaÎncă nu există evaluări

- ECE Sem 1 SyllabusDocument10 paginiECE Sem 1 SyllabusDaksh SharmaÎncă nu există evaluări

- AM Material ScienceDocument4 paginiAM Material ScienceTushar Mani AgarwalÎncă nu există evaluări

- BTech Mech SyllabusDocument19 paginiBTech Mech Syllabusmadansiyag3Încă nu există evaluări

- BS Chemistry Syllabus Final 2022-26Document71 paginiBS Chemistry Syllabus Final 2022-26Usman RafiqueÎncă nu există evaluări

- Metallurgy SyllabusDocument43 paginiMetallurgy SyllabusSrinivasulu PuduÎncă nu există evaluări

- M.Tech Structural Engineering 1st Semester CurriculumDocument103 paginiM.Tech Structural Engineering 1st Semester CurriculumTanmaya Kumar SahooÎncă nu există evaluări

- Core Mathematics, Physics, Language Skills, and Management SyllabusDocument3 paginiCore Mathematics, Physics, Language Skills, and Management SyllabusJitendra VishnoliaÎncă nu există evaluări

- Material Science and Metallurgy Course OverviewDocument203 paginiMaterial Science and Metallurgy Course OverviewNISHAANTH S 1861462Încă nu există evaluări

- Ag 205Document61 paginiAg 205Leonardo NanjarÎncă nu există evaluări

- CH 101 Chemistry (3 1 0 8)Document5 paginiCH 101 Chemistry (3 1 0 8)sunita mahapatraÎncă nu există evaluări

- Mse 212Document6 paginiMse 212Ana Emily PrentissÎncă nu există evaluări

- Cse PSG Semester 1Document77 paginiCse PSG Semester 1Hari HrithikÎncă nu există evaluări

- VJTI Syllabus 28-08-2008Document560 paginiVJTI Syllabus 28-08-2008Abhinav MauryaÎncă nu există evaluări

- Syllabus - BE EEE (Regular) ('15)Document92 paginiSyllabus - BE EEE (Regular) ('15)Venkat PrakashÎncă nu există evaluări

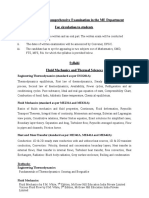

- Structure of The Comprehensive Examination in The ME Department For Circulation To StudentsDocument4 paginiStructure of The Comprehensive Examination in The ME Department For Circulation To StudentspraveenÎncă nu există evaluări

- Structure and Properties of Metals: Quantitative Microstructure AnalysisDocument11 paginiStructure and Properties of Metals: Quantitative Microstructure AnalysisVasundhara SaxenaÎncă nu există evaluări

- AMIE Section A Diploma Stream SyllabusDocument7 paginiAMIE Section A Diploma Stream SyllabusJames WolfeÎncă nu există evaluări

- Semester I: 15L101 Calculus and Its Applications 3 2 0 4Document97 paginiSemester I: 15L101 Calculus and Its Applications 3 2 0 4sathishkumar.vÎncă nu există evaluări

- Gujarat Technological University Semester II Maths IIDocument9 paginiGujarat Technological University Semester II Maths IIskishan4uÎncă nu există evaluări

- Robotics Engineering Syllabus PDFDocument93 paginiRobotics Engineering Syllabus PDFhariprasath0% (1)

- List of B. Tech. Electives PH 451: Plasma Physics 3-0-0-6Document8 paginiList of B. Tech. Electives PH 451: Plasma Physics 3-0-0-6SujithÎncă nu există evaluări

- Gtu Be Civil First YearDocument14 paginiGtu Be Civil First YearHR Divya RanaÎncă nu există evaluări

- Applied Physics & Engineering DrawingDocument20 paginiApplied Physics & Engineering DrawingVivek ParmarÎncă nu există evaluări

- MEC5017Document2 paginiMEC5017PethurajÎncă nu există evaluări

- Chemistry Final6Document4 paginiChemistry Final6MohitÎncă nu există evaluări

- Large Deformations of Solids Physical Basis and Mathematical ModellingDocument500 paginiLarge Deformations of Solids Physical Basis and Mathematical Modellingking sunÎncă nu există evaluări

- 2022-23 AP SyllabusDocument2 pagini2022-23 AP SyllabusThrishaÎncă nu există evaluări

- GATE Syllabus For Materials ScienceDocument4 paginiGATE Syllabus For Materials SciencecrsolankeÎncă nu există evaluări

- RB1: Introduction To Nanotechnology by Charles P Poole and Frank J. OwensDocument5 paginiRB1: Introduction To Nanotechnology by Charles P Poole and Frank J. OwensyeateshwarriorÎncă nu există evaluări

- C12HDocument129 paginiC12Hkhudhayer1970Încă nu există evaluări

- B. Tech. in Metallurgical & Materials Engineering VNITDocument29 paginiB. Tech. in Metallurgical & Materials Engineering VNITShameekaÎncă nu există evaluări

- List of QuestionsDocument2 paginiList of Questionstripathi522003Încă nu există evaluări

- Electron and Positron Spectroscopies in Materials Science and Engineering: Materials Science and TechnologyDe la EverandElectron and Positron Spectroscopies in Materials Science and Engineering: Materials Science and TechnologyOtto BuckÎncă nu există evaluări

- Muni RajuDocument1 paginăMuni RajuSri PuduÎncă nu există evaluări

- Srinivasulu PDocument4 paginiSrinivasulu PSri PuduÎncă nu există evaluări

- HHDocument260 paginiHHSri PuduÎncă nu există evaluări

- Courses For The January-2014 Semester - Materials EngineeringDocument4 paginiCourses For The January-2014 Semester - Materials EngineeringSri PuduÎncă nu există evaluări

- Books and Authors - Questions and Answers Test GKBA2Document3 paginiBooks and Authors - Questions and Answers Test GKBA2Sri PuduÎncă nu există evaluări

- Lecture 1Document9 paginiLecture 1Richa TripathiÎncă nu există evaluări

- Principles of Metallurgical Thermodynamics - CRC Press BookDocument1 paginăPrinciples of Metallurgical Thermodynamics - CRC Press BookSri Pudu0% (3)

- Books and Authors - Questions and Answers Test GKBA3Document3 paginiBooks and Authors - Questions and Answers Test GKBA3Sri PuduÎncă nu există evaluări

- Books and Authors - Questions and Answers Test GKBA1Document3 paginiBooks and Authors - Questions and Answers Test GKBA1Sri PuduÎncă nu există evaluări

- NPTEL Materials Characterization CourseDocument5 paginiNPTEL Materials Characterization CourseSri PuduÎncă nu există evaluări

- InterviewCallLetter 14104707Document1 paginăInterviewCallLetter 14104707Sri PuduÎncă nu există evaluări

- Nptel Phase 2 - CoursesDocument2 paginiNptel Phase 2 - CoursesSri PuduÎncă nu există evaluări

- (Paper) SBI PO SOLVED EXAM PAPER 2008 - General Awareness & Computer Knowledge - UPSCPORTAL - India's Largest Community For IAS, CSAT, Civil Services Exam AspirantsDocument14 pagini(Paper) SBI PO SOLVED EXAM PAPER 2008 - General Awareness & Computer Knowledge - UPSCPORTAL - India's Largest Community For IAS, CSAT, Civil Services Exam AspirantsSri PuduÎncă nu există evaluări

- Quantum Mechanics: Eigenvalue ProblemsDocument11 paginiQuantum Mechanics: Eigenvalue ProblemsSri PuduÎncă nu există evaluări

- Cover Letter for JRF in Metallurgy at NIT WarangalDocument2 paginiCover Letter for JRF in Metallurgy at NIT WarangalSri PuduÎncă nu există evaluări

- Fundamentals of Molecular Physics by P.B Sindhu... Excellent BookDocument531 paginiFundamentals of Molecular Physics by P.B Sindhu... Excellent BookSri PuduÎncă nu există evaluări

- Cover Letters To Get You Hired - FastwebDocument4 paginiCover Letters To Get You Hired - FastwebSri PuduÎncă nu există evaluări

- CVs and Cover Letters - Example CVs - Prospects - AcDocument3 paginiCVs and Cover Letters - Example CVs - Prospects - AcSri PuduÎncă nu există evaluări

- Best Books For SBI PO Exam 2014 - Toppers Choice - Government Jobs - Recruitment 2014-2015 - IBPS - SSC - UPSC - Railway EtcDocument6 paginiBest Books For SBI PO Exam 2014 - Toppers Choice - Government Jobs - Recruitment 2014-2015 - IBPS - SSC - UPSC - Railway EtcSri PuduÎncă nu există evaluări

- CSIR Physical Sciences June 2009 Paper 2Document2 paginiCSIR Physical Sciences June 2009 Paper 2Sri PuduÎncă nu există evaluări

- Combined Geo-Scientist 2014 - Physics SyllabusDocument8 paginiCombined Geo-Scientist 2014 - Physics SyllabusSrinivasulu PuduÎncă nu există evaluări

- Melvin SeemanDocument10 paginiMelvin SeemanSri PuduÎncă nu există evaluări

- Phase Diagrams and MicrostructuresDocument3 paginiPhase Diagrams and MicrostructuresSri PuduÎncă nu există evaluări

- PHD BrouchreDocument5 paginiPHD BrouchreilurohitÎncă nu există evaluări

- Appendix B Indexed XRD DataDocument1 paginăAppendix B Indexed XRD DataSri PuduÎncă nu există evaluări

- Books VerificationDocument2 paginiBooks VerificationSri PuduÎncă nu există evaluări

- Appendix ADocument10 paginiAppendix ASri PuduÎncă nu există evaluări

- References Final 1Document8 paginiReferences Final 1Sri PuduÎncă nu există evaluări

- Q1 Day 1-3 Enrichment ActivitiesDocument3 paginiQ1 Day 1-3 Enrichment ActivitiesAngelica N. HilarioÎncă nu există evaluări

- Letlok Tube Fitting Catalog 2017Document94 paginiLetlok Tube Fitting Catalog 2017chipulinoÎncă nu există evaluări

- Reference: Frank MonaghanDocument20 paginiReference: Frank MonaghanIeeeChannaÎncă nu există evaluări

- Aerospace: Hi-Shear CorporationDocument1 paginăAerospace: Hi-Shear CorporationJose Miguel Atehortua ArenasÎncă nu există evaluări

- Fatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxDocument18 paginiFatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxSWAPNIL PATILÎncă nu există evaluări

- Test Certificate DetailsDocument2 paginiTest Certificate Detailsshrikant bhirudÎncă nu există evaluări

- 778-Full Length Article-2037-1-10-20210622Document15 pagini778-Full Length Article-2037-1-10-20210622francis bautistaÎncă nu există evaluări

- Concrete Discharge Time (ASCC)Document1 paginăConcrete Discharge Time (ASCC)V. ManilalÎncă nu există evaluări

- Cube TestDocument15 paginiCube TestFAHIEMAH ZAHRA YAAKUBÎncă nu există evaluări

- Suva R-507Document2 paginiSuva R-507Eliott Noe Rumiche ChungaÎncă nu există evaluări

- Structural Engineering Design CriteriaDocument13 paginiStructural Engineering Design Criteriadstv2005Încă nu există evaluări

- Model KCB-Temperarture Gauge (Bimetal) - CommentedDocument3 paginiModel KCB-Temperarture Gauge (Bimetal) - CommentedAkhil JoseÎncă nu există evaluări

- Differential Scanning Calorimetry: G.W. H. Höhne, W. Hemminger, H.-J. FlammersheimDocument4 paginiDifferential Scanning Calorimetry: G.W. H. Höhne, W. Hemminger, H.-J. FlammersheimMiguel Angel Magaña FuentesÎncă nu există evaluări

- Trident Tank-Butyl Bladder Pressure TankDocument4 paginiTrident Tank-Butyl Bladder Pressure TankcurlyjockeyÎncă nu există evaluări

- Design and Fabrication of Thermoelectric CoolerDocument12 paginiDesign and Fabrication of Thermoelectric CoolerwalkerÎncă nu există evaluări

- Head loss calculation for Souq Waqif car parking projectDocument1 paginăHead loss calculation for Souq Waqif car parking projectKarthy GanesanÎncă nu există evaluări

- Catalog 3800 Quick Coupling ProductsDocument229 paginiCatalog 3800 Quick Coupling ProductsANKUSH PARMARÎncă nu există evaluări

- 1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A BeamDocument7 pagini1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A Beamprieten20006936Încă nu există evaluări

- TWPH Rev - 5Document1 paginăTWPH Rev - 5pravinmishra1245Încă nu există evaluări

- Recycling Pavement.1Document10 paginiRecycling Pavement.1Prabu DhanusuÎncă nu există evaluări

- Metz 19Document2 paginiMetz 19dirafly3566Încă nu există evaluări

- Input:: Depth of Failure Surface or Tunnel Below SlopeDocument1 paginăInput:: Depth of Failure Surface or Tunnel Below SlopemartinmuguruzaÎncă nu există evaluări

- Dudley Renovation Exploded DiagramsDocument2 paginiDudley Renovation Exploded DiagramsStudioAPLAÎncă nu există evaluări