Documente Academic

Documente Profesional

Documente Cultură

Esa SP 1173 PDF

Încărcat de

stoufsaxoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Esa SP 1173 PDF

Încărcat de

stoufsaxoDrepturi de autor:

Formate disponibile

(a)

(b)

Figure 2: Specimen

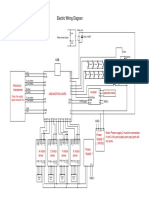

1 - (a) Photograph of top side; (b) Photograph of solder side; (c) and (d) the electrical

circuit for conventionally manually soldered double-sided pcbs

60

(a)

(b)

Figure 3: Specimen 2 - (a) Photograph of assembled mlb supporting chip carriers and

chip capacitors; (b) electrical monitoring circuit

61

Figure 4: Close-up view of enamel wires used to maintain a constant stand-off height of

0.3 mm. Photograph of Specimen 2 shows the solder joint castellations

immediately after vapour-phase soldering and cleaning

62

Figure 5: Appearance of (a) epoxy and (b)

polyimide pcb comb patterens

63

figures

64

Figure 6: Conathane EN I 1 - Coating removed by tip of soldering iron at 300C. A

disagreeable odour was continually released as the coating became soft. It was

possible, albeit with some difficulty, to remove small chips of coating with an orange

stick (wooden probe). Adjacent coating was partially lifted

Figure 7: Solithane 113 - Hot air was needed to heat coating locally to about 100C and

it was then possible to prise of the coating with an orange stick

conformal coatings for future spacecraft

Figure 8: Uralane 5750 LV - Local hot-air heating was required to heat the coating to

100C. this coating was difficult to remove

Figure 9: CV 1144-0 - Coating was easy to remove with the aid of an orange stick at

ambient temperature. There was minimal lifting of adjacent coating

figures

Figure 10: Mapsil 213 - The coating was easily removed with the aid of an orange stick

at ambient temperature. Care had to be taken to avoid lifting adjacent coating (worst

case visible in photograph)

Figure 11: Sylgard 184 - Coating was quite easy to remove at room temperature with

the aid of an orange stick, but lifting of adjacent area of coating was difficult to avoid

figures

conformal coatings for future spacecraft

Figure 12: Scotchcast 280 - A soldering iron tip at 300C was required to heat and

slightly soften this coating. It was then possible to remove very small pieces with an orange

stick. The coating hardened rapidly and application of heat caused the release of an

unpleasant odour

figures

Figure 13: Illustrations of method for removing leadless chip carriers from pcb 68

82

conformal coatings for future spacecraft

Figure 14: Conathane EN 11 - Coating was melted with a soldering iron at 300C.

Unpleasant odour was released. The coating was difficult to remove with the aid of an

orange stick. Lifting and removing a chip carrier required nine seconds

Figure 15: Solithane 113 - Hot air at 100C was needed to soften the coating, which was

then peeled off with an orange stick. Lifting and removal of a chip carrier required

six seconds

figures

Figure 16: Uralane 5750 LV - The coating is quite hard even when heated to 100C

with hot air. Removal of a chip carrier required seven seconds

Figure 17: CV 1144-0 - The coating was quite easy to remove at ambient

temperature. Removal of a chip carrier required five to six seconds

figures

conformal coatings for future spacecraft

Figure 18: Mapsil 213 - The coating was easily removed at ambient temperature.

Removal of a chip carrier required five to six seconds

Figure 19: Sylgard 184 - Clean removal of all coating at room temperature was a little

more difficult. Removal of a chip carrier required five to six seconds

figures

Figure 20: Scotchcast 280 - Only with a soldering iron at 300C was it possible to

remove this coating. Complete removal of material from the pcb was very difficult.

Removal of a chip carrier required nine seconds

conformal coatings for future spacecraft

Figure 21: Orange-peel appearance and wide-mouthed cracking after 1000 thermal

cycles (Transistor, Solithane 113)

Figure 22: Top view of wedge-wedge bonded 38m diameter aluminium wire after

800 thermal cycles. The original form of the wire was a symmetrical loop. Thermal

mismatch has produced twists and kinks in the wire that are typical of all wires

encapsulated in Solithane, Conathane or Scotchcast. The wire fracture surfaces

(arrowed) on this Solithane sample exhibit necking and a reduced wire cross-sectional

area of approx. 50%

figures

con

formal coatings for future spacecraft

Figure 23: Microsection of a typical glass-bodied diode, confirming that the thick

conformal coating had encased the lower part of this component and its leads. The stand-

off height, e, is 0.9mm. After 1000 thermal cycles, the large cyclic strains produced

by the expanding and contracting coating have cracked the plated through hole soldered

joint and wedged up the component to reduce the height of the stud connection leads

on the underside of this pcb

figures

Figure 24: Optical (left-hand side) and SEM images of extensively damaged solder

joint. The ratcheting effect of the coating during each thermal cycle has pulled the lead

towards the component side of the board. Sample is Diode CR3, coated with

Scotchcast, after 1000 thermal cycles. Electrical continuity is maintained within the

plated through hole

figures

conformal coatings for future spacecraft

Figure 25: SEM views of stud-leaded Transistor Q2 coated with Uralane following

1000 thermal cycles (J lead)

Figure 26: Optical (left-hand side) and SEM views of microsectioned Transistor Q2 lead

J shown in Figure 25. Crack propagati on has not entered the plated through hole region and

is confined to the stud fillet. Cracking is not present at the transistor side of the joint or

in the vicinity of the entrapped gas pocket.

79

conformal coatings for future spacecraft

Figure 27: SEM views of stud-leaded Transistor Q2 coated with Uralane following

1000 thermal cycles (L lead). This is the same component as that shown in Figure 25.

figures

80

Figure 28: Optical (left-hand side) and SEM views of microsectioned Transistor Q2 lead L

shown in Figure 27. Cracks have propagated completely through this solder joint to

produce an electrical open circuit after 600 thermal cycles (micrograph made after 1000

cycles)

conformal coatings for future spacecraft

Figure 29: SEM views of lead on Resistor R4, coated with CV 1144, aft er 1000

thermal cycles. Very little surface movement has occurred

figures

Figure 30: Leadless chip carrier coated with Scotchcast, device Z 5 (see Fig. 3 for

location on polyimide pcb) after 1000 thermal cycles.

Overall view (a) shows some detachment of Scotchcast from upper side face of

ceramic package and some delamination from pcb surface (arrows). The castellations 2

and 3 are detailed at x40 magnification (b and c) but, even with the best inspection

optics, the fillets of these soldered joints cannot be seen to contain cracks which

account for the electrical open circuits

tr

Figure 31: Optical micrographs made parallel to a row of solder joint castillations

(shown as section XX in Figure 30). Scotchcast after 1000 cycles. All castellations

contain cracked soldered joints

84

< --- Crack location is at level of

metallised base of the castellation

(c) x 130

figures

86

(a) General transverse view through cracked joint, also showing physical construction of

the multilayer polyimide board with copper-coated molybdenum inner layer. The

Scotchcast surrounds the package (arrows) and fills the stand-off volume (x 32)

(b) Detail of the irregular crack path. Zones of maximum shear strain have an

enlarged tin-lead grain structure. This is castellation No. 3 (x64)

figures

88

(c) Similar picture of the irregular crack path. Zones of maximum shear strain have an

enlarged tin-lead grain structure. This is castellation No. 3 (X64)

Figure 32: Microsection made progressively across the solder fillets shown in Figure 30

(section YY). Every joint was electrically open circuit, but because these defects do not

emerge as wide-mouthed cracks they are not visible through the Scotchcast coating

during inspection at high magnification

tr

Figure 33: Leadless chip carrier coated with Conathane EN 11. Visual appearance (a)

shows slight surface roughness of fillets, but microsections (SEM images b and c)

confirm that no cracks were initiated during exposure to 1000 thermal cycles.

tr

(a) Optical image of capacitor

(b) Optical view of microsectioned capacitor showing stand-off height to be 200 m.

Note: Scotchcast has separated from upper (arrowed) part of solder fillet and has

flowed in to fill the space beneath the component. The tin-lead microstructure has

recrystallised in zones of high shear strain (see following SEM images).

Magnification: X60

figures

conformal coatings for future spacecraft

Figure 34: Ceramic chip capacitor (Specimen 2, C2) coated with Scotchcast, shows no

electrical discontinuities after 1000 thermal cycles. The SEM images show surface

roughening of fillets and some microcracks inside the solder (in zones of large grain

size).

S-ar putea să vă placă și

- Industrial Chemistry of Oxides for Emerging ApplicationsDe la EverandIndustrial Chemistry of Oxides for Emerging ApplicationsÎncă nu există evaluări

- Chapter 9 - Electron Beam WeldingDocument14 paginiChapter 9 - Electron Beam WeldingrafikdmeÎncă nu există evaluări

- Laser Technology: Applications in Adhesion and Related AreasDe la EverandLaser Technology: Applications in Adhesion and Related AreasÎncă nu există evaluări

- Sheet 2Document2 paginiSheet 2افكار متنوعهÎncă nu există evaluări

- Fabrication of PMOS TransistorsDocument11 paginiFabrication of PMOS TransistorsNash Anderson50% (4)

- UACE Physics Paper 2 2019Document7 paginiUACE Physics Paper 2 2019Gadget TechnologyÎncă nu există evaluări

- Some Aspects of Srray Losses in Large Power Transformers: Institut Koncar, Bastijanova BB, 10002 Zagreb, CroatiaDocument6 paginiSome Aspects of Srray Losses in Large Power Transformers: Institut Koncar, Bastijanova BB, 10002 Zagreb, CroatiaManu JagdishÎncă nu există evaluări

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document10 paginiInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasÎncă nu există evaluări

- Annexure 4.2-End Term Exam Q-Paper TemplateDocument2 paginiAnnexure 4.2-End Term Exam Q-Paper TemplateDr. Vivek SrivastavaÎncă nu există evaluări

- Annexure 4.2-End Term Exam Q-Paper TemplateDocument2 paginiAnnexure 4.2-End Term Exam Q-Paper TemplateDr. Vivek SrivastavaÎncă nu există evaluări

- Annexure 4.2-End Term Exam Q-Paper TemplateDocument2 paginiAnnexure 4.2-End Term Exam Q-Paper TemplateDr. Vivek SrivastavaÎncă nu există evaluări

- 220 - 800 EBG O Terminating InstructionDocument17 pagini220 - 800 EBG O Terminating InstructionMario DaniloÎncă nu există evaluări

- AADyomin - Optics N Laser Engineer - 08Document6 paginiAADyomin - Optics N Laser Engineer - 08drsharizal77Încă nu există evaluări

- Electron - Specimen Interactions Specimen Preparation Electron MicroscopesDocument49 paginiElectron - Specimen Interactions Specimen Preparation Electron MicroscopesarulmuruguÎncă nu există evaluări

- 01ec304 Vlsi 1Document20 pagini01ec304 Vlsi 1ShelÎncă nu există evaluări

- Layout Solns 3Document12 paginiLayout Solns 3VIKRAM KUMARÎncă nu există evaluări

- Gym Area Boq For Nri Club HouseDocument5 paginiGym Area Boq For Nri Club HouseSantosh ThakurÎncă nu există evaluări

- Met-2023 (PDF) - SQDocument34 paginiMet-2023 (PDF) - SQYair Yint AungÎncă nu există evaluări

- ME5507 Tutorial Questions On 13th NovDocument8 paginiME5507 Tutorial Questions On 13th NovSulaiman ObaidÎncă nu există evaluări

- Georgia - 3D Toroidal Air-Core Inductor With Through-Wafer Interconnect For On-Chip IntegrationDocument4 paginiGeorgia - 3D Toroidal Air-Core Inductor With Through-Wafer Interconnect For On-Chip IntegrationChandra ShettyÎncă nu există evaluări

- 3 Chaper 3 InsulatorsDocument7 pagini3 Chaper 3 InsulatorsKrishna SinghÎncă nu există evaluări

- Advanced Manufacturing ScienceDocument3 paginiAdvanced Manufacturing Sciencemukesh3021Încă nu există evaluări

- ME30604 Nontraditional Manufacturing ProcessesDocument3 paginiME30604 Nontraditional Manufacturing Processesshubham jaiswalÎncă nu există evaluări

- Revised de of Electric Fencing of Mansa JailDocument8 paginiRevised de of Electric Fencing of Mansa JailSumit gargÎncă nu există evaluări

- Transformer Design 2bDocument13 paginiTransformer Design 2bCaloy FelicianoÎncă nu există evaluări

- T1-T7Q Ee2005 NtuDocument10 paginiT1-T7Q Ee2005 NtuamosmarongshengÎncă nu există evaluări

- Physics Paper 1-Spm 2010Document9 paginiPhysics Paper 1-Spm 2010Phy LabÎncă nu există evaluări

- Higt Temp Failure Case LanceDocument2 paginiHigt Temp Failure Case LanceDevin Trianda PutraÎncă nu există evaluări

- PCBDesign Tutorial Rev ADocument70 paginiPCBDesign Tutorial Rev Asyafruddinr_68006517Încă nu există evaluări

- Carry Heat Away From Power Modules PCBsDocument8 paginiCarry Heat Away From Power Modules PCBsAmir Hooshang Ghadymi MahaniÎncă nu există evaluări

- Solenoid Coils For Switching and Proportional ValvesDocument8 paginiSolenoid Coils For Switching and Proportional ValvesGrid LockÎncă nu există evaluări

- Typical Bill For A 2x15MVA Transformer Substation ConstructionDocument6 paginiTypical Bill For A 2x15MVA Transformer Substation ConstructionRajeshYadav100% (1)

- Tutorial 3 (Cable and Sizing of Conductors) ESB S2 2013 Student VersionDocument5 paginiTutorial 3 (Cable and Sizing of Conductors) ESB S2 2013 Student VersionNajiyah SalehÎncă nu există evaluări

- Gujarat Technological UniversityDocument4 paginiGujarat Technological Universitythe grayÎncă nu există evaluări

- Electro Chemical MachiningDocument10 paginiElectro Chemical Machiningdev2945Încă nu există evaluări

- 9EH EoC Test 2013 No SolsDocument11 pagini9EH EoC Test 2013 No SolsDanny EtieveÎncă nu există evaluări

- Pavement DesignDocument4 paginiPavement DesignharshavkumarÎncă nu există evaluări

- Uace Physics Paper 2 2002Document6 paginiUace Physics Paper 2 2002Ainebyoona ChriscentÎncă nu există evaluări

- Bushings For PT MY2014Document36 paginiBushings For PT MY2014Shung Tak ChanÎncă nu există evaluări

- University of Mauritius Faculty of Engineering: Paper No Examination Second Semester 2002 / 2003 DateDocument5 paginiUniversity of Mauritius Faculty of Engineering: Paper No Examination Second Semester 2002 / 2003 DateJeetun RuveenÎncă nu există evaluări

- ME2151Document6 paginiME2151Delroy JqÎncă nu există evaluări

- Cdna09628enc 001Document62 paginiCdna09628enc 001siderurgiaÎncă nu există evaluări

- University of MauritiusDocument8 paginiUniversity of MauritiusKeshav GopaulÎncă nu există evaluări

- R7 210304 Mechanics of SolidsDocument2 paginiR7 210304 Mechanics of SolidssivabharathamurthyÎncă nu există evaluări

- Electrification of Earth Bund Singur 08.07.2020Document27 paginiElectrification of Earth Bund Singur 08.07.2020mahipal287100% (1)

- EE328 Sheet 1Document6 paginiEE328 Sheet 1Maha ZadaÎncă nu există evaluări

- Bus Duct DesignDocument24 paginiBus Duct Designhani_pilevar3778Încă nu există evaluări

- Mechanics of Solids PDFDocument8 paginiMechanics of Solids PDFprashanthreddy26Încă nu există evaluări

- Advanced Machining Processes and NanofabricationDocument27 paginiAdvanced Machining Processes and NanofabricationShirish PathakÎncă nu există evaluări

- ME30604 Nontraditional Manufacturing ProcessesDocument3 paginiME30604 Nontraditional Manufacturing Processesshubham jaiswalÎncă nu există evaluări

- Previous Years GATE Questions Sub: Production Technology (Welding)Document12 paginiPrevious Years GATE Questions Sub: Production Technology (Welding)KAUSTUB CHAUHANÎncă nu există evaluări

- Uace Physics Paper 2 2001Document6 paginiUace Physics Paper 2 2001Ainebyoona ChriscentÎncă nu există evaluări

- KMPR Photo Resist For Fabrication of Thick Micro StructuresDocument4 paginiKMPR Photo Resist For Fabrication of Thick Micro StructuresVictoria HicksÎncă nu există evaluări

- PMRDA BOQ Inquiry With ScopeDocument8 paginiPMRDA BOQ Inquiry With ScopeAkd DeshmukhÎncă nu există evaluări

- Electromechanical Systems Ee-352 Instructor: DR Mashood Nasir Spring 2018-19 Assignment 1 Due Date: 8 February, 2019Document4 paginiElectromechanical Systems Ee-352 Instructor: DR Mashood Nasir Spring 2018-19 Assignment 1 Due Date: 8 February, 2019Shiza ShakeelÎncă nu există evaluări

- Presstres MidDocument2 paginiPresstres MidTarun KumarÎncă nu există evaluări

- 9A21504 Aerospace Vehicle Structures IIDocument8 pagini9A21504 Aerospace Vehicle Structures IIsivabharathamurthyÎncă nu există evaluări

- Engineering Failure Analysis: Y .V. NawancyDocument7 paginiEngineering Failure Analysis: Y .V. Nawancyqueno1Încă nu există evaluări

- Ee 1403 - Design of Electrical ApparatusDocument3 paginiEe 1403 - Design of Electrical ApparatussubhazÎncă nu există evaluări

- Me 1993Document4 paginiMe 1993Asad MohammadÎncă nu există evaluări

- Lecture 27: Mixers. Gilbert Cell: Mixers Shift The Frequency Spectrum of An Input SignalDocument9 paginiLecture 27: Mixers. Gilbert Cell: Mixers Shift The Frequency Spectrum of An Input Signalsurajka1Încă nu există evaluări

- 50L3400UDocument16 pagini50L3400UJustin NgÎncă nu există evaluări

- E2209wf - Monitor - 44 - 51Document51 paginiE2209wf - Monitor - 44 - 51Davi TavaresÎncă nu există evaluări

- Audio CompressionDocument9 paginiAudio CompressionIshaan EvenidaÎncă nu există evaluări

- Different Types of Fuses and Its ApplicationsDocument10 paginiDifferent Types of Fuses and Its ApplicationsAhmet MehmetÎncă nu există evaluări

- Rev.3 7/12/2014 Becker 1432 Modification To Accept Auxiliary Input Without TapeDocument1 paginăRev.3 7/12/2014 Becker 1432 Modification To Accept Auxiliary Input Without TapeRadu Baciu-Niculescu100% (1)

- Power Electronics-2 MarksDocument12 paginiPower Electronics-2 Marks20EUEE053- MADHUBALAN.SÎncă nu există evaluări

- Electronic Measurements A Practical Approach (Farzin Asadi, Kei Eguchi) - CompressedDocument172 paginiElectronic Measurements A Practical Approach (Farzin Asadi, Kei Eguchi) - CompressedManafu GregorÎncă nu există evaluări

- VoIP Network Design ChecklistDocument3 paginiVoIP Network Design ChecklistJonathan AkisanmiÎncă nu există evaluări

- A - Introduction B - Organisation C - Championships Program D - Technical E - Awards F - Matters Not Covered by These Rules AppendixDocument12 paginiA - Introduction B - Organisation C - Championships Program D - Technical E - Awards F - Matters Not Covered by These Rules AppendixAlex BerezinÎncă nu există evaluări

- Diode and Its TypesDocument4 paginiDiode and Its TypesSaqib IqbalÎncă nu există evaluări

- Measurements and Instrumentation (ELE 3202)Document4 paginiMeasurements and Instrumentation (ELE 3202)JithinÎncă nu există evaluări

- VR-3000 - VR3000-S - Error - Codes SW 2.54Document2 paginiVR-3000 - VR3000-S - Error - Codes SW 2.54gÎncă nu există evaluări

- Computer Organization & ArchitectureDocument49 paginiComputer Organization & Architecture03Abhishek SharmaÎncă nu există evaluări

- Instruction Manual and Experiment Guide: Electricity System 1Document75 paginiInstruction Manual and Experiment Guide: Electricity System 1alfabicaÎncă nu există evaluări

- Installation and Operating Manual of v3 v4 v6 v7Document29 paginiInstallation and Operating Manual of v3 v4 v6 v7Trency FernandesÎncă nu există evaluări

- Microwind 3.5 BRDocument2 paginiMicrowind 3.5 BRJonathan Arley Torres CastañedaÎncă nu există evaluări

- Ad146 ManualDocument38 paginiAd146 ManualCharityÎncă nu există evaluări

- Re-716ss-Rev-02 29 3 21enDocument2 paginiRe-716ss-Rev-02 29 3 21enmohammed.ibn.hassaanÎncă nu există evaluări

- Im3 User ManualDocument149 paginiIm3 User Manualאם איי ביומדיקס MA BIOMEDICS LTDÎncă nu există evaluări

- VCN500 Video Cloud Node BrochureDocument1 paginăVCN500 Video Cloud Node BrochureMarcelo GarciaÎncă nu există evaluări

- Powrer Data Sheet20131011Document5 paginiPowrer Data Sheet20131011sondk2Încă nu există evaluări

- OSI OverviewDocument14 paginiOSI OverviewhekÎncă nu există evaluări

- Verbal, Logical and QuantsDocument30 paginiVerbal, Logical and QuantsNaveen ChaubeyÎncă nu există evaluări

- Fiber - Infrastructure - Newsletter MeridianDocument9 paginiFiber - Infrastructure - Newsletter MeridianYandhi SuryaÎncă nu există evaluări

- Kbpc3504 Full Bridge RectifierDocument2 paginiKbpc3504 Full Bridge Rectifierrudey18Încă nu există evaluări

- 1734 EP24dcDocument3 pagini1734 EP24dca29ankitÎncă nu există evaluări

- Simocode Pro CDocument2 paginiSimocode Pro CHowk RiosÎncă nu există evaluări

- Transistor Circuit NotesDocument15 paginiTransistor Circuit NotesKim KeatÎncă nu există evaluări

- Mach3 Electric Wiring DiagramDocument1 paginăMach3 Electric Wiring DiagramSimasArmonas100% (1)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDe la EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceEvaluare: 4 din 5 stele4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Laws of UX: Using Psychology to Design Better Products & ServicesDe la EverandLaws of UX: Using Psychology to Design Better Products & ServicesEvaluare: 5 din 5 stele5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDe la EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneEvaluare: 4.5 din 5 stele4.5/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsDe la EverandDesign for How People Think: Using Brain Science to Build Better ProductsEvaluare: 4 din 5 stele4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsDe la EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsEvaluare: 4 din 5 stele4/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDe la EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersEvaluare: 4 din 5 stele4/5 (13)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDe la EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableÎncă nu există evaluări

- 507 Mechanical Movements: Mechanisms and DevicesDe la Everand507 Mechanical Movements: Mechanisms and DevicesEvaluare: 4 din 5 stele4/5 (28)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

- Understanding Automotive Electronics: An Engineering PerspectiveDe la EverandUnderstanding Automotive Electronics: An Engineering PerspectiveEvaluare: 3.5 din 5 stele3.5/5 (16)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesDe la EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesEvaluare: 3 din 5 stele3/5 (1)

- Design Recipes for FPGAs: Using Verilog and VHDLDe la EverandDesign Recipes for FPGAs: Using Verilog and VHDLEvaluare: 2 din 5 stele2/5 (1)