Documente Academic

Documente Profesional

Documente Cultură

Coal Gasification & SynGas DRI Process Overview

Încărcat de

telegenicsDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Coal Gasification & SynGas DRI Process Overview

Încărcat de

telegenicsDrepturi de autor:

Formate disponibile

Coal Gasification

&

SynGas based DRI

Presented by

Rajesh J ha

Executive Director

J indal Steel & Power Limited

Orissa, India

1

Back ground

India is third largest producer of coal in the

world*

India has fourth largest reserve of coal in

the world**

Non Coking Coal reserves are 233.8Billion

Tons(~87%)

Coking Coal Reserves are 33.4(~13%)

Billion Tons

Typically Indian coal has high ash content

(15-45%) & low calorific value

* Source: www.worldcoal.org (International Energy Agency)

** Source: www.worldcoal.org

2

Source : Coal Ministrys Annual Report

3

Indias Share of World DRI Prodn.

2008

4

India

Source: www.spongeironindia.in

5

Total India DRI Production 2008

21.2 Million Tons

14.79 Million tons Coal Based

70%

6.41 Million tons Gas based

6

Iron Oxide is converted into Iron in two

ways

(a) Blast Furnace/ Smelting reduction Route

(b) Direct Reduced Iron (DRI) route.

Smelting Reduction has shown some

limited success - COREXFINEX

High ash Indian coal suitability ?

In India Metallurgical Coal reserves are

limited. For going in Blast Furnace route,

required coking coal needs to be

imported very volatile n expensive

7

What To Do ???

a) India has abundant high quality iron ore

b) Scarcity of Natural Gas

c) India has abundant non Coking coal.

d) Non coking coal is to be used efficiently

Coal Gasification ???

8

Alternatives

There are two prevalent ways of

producing Direct Reduced Iron (DRI).

(a) Rotary kiln based

(b) Gas based

In both the processes non-coking

coal can be used.

9

Rotary Kiln DRI Vs Gas based DRI

S No Rotary Kiln based DRI Gas based DRI

1 Prone to Pollution. Clean Technology.

2 Plant size 50 500 TPD 1200 -6000 TPD

3 Low Capital cost Investment required is comparatively higher

4 Energy requirement is high Energy requirement is atleast 20% less than that

of rotary Kiln

5 Not suitable for making quality steel (for flat

products)

Product suits making good quality steel

6 DRI fines (-3mm) generated is ~30-40% Losses

in SMS are more due to high % of fines

DRI fines (-5mm) ~5% Losses in SMS are less

due to low % of fines

7 Sulfur in the Coal partly attached to DRI and

partly going to atmosphere as SO2 causes

environmental pollution

Sulfur content in DRI is in the range of 0.003-

0.01%

10 Carbon in the range of 0.1 0.3% Carbon in the range of 1.5-2.5%.

11 Metallization 86-90% Metallization 92-94%

10

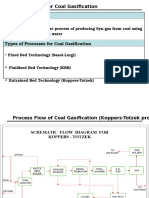

Examine Coal Gasification

11

Table 12. Some important features of different

Coal Gasification process

FEATURES Fixed Bed Fluidized Bed Entrained Bed

Lurgi FBDB Winkler Shell Texaco

1. a) Pressure , Kg/ cm2 10-30 Atm 30-40 40-80

b) Temperature deg C 1200 1100 1600 1600

c) Gas-outlet Temp, deg C 675 ~850 1370 1320

2 Type of Coal and caking coals All ranks except

coking coal

Low rank coal All types All types

3 Feed coal size , mm 6-50 0-9.5 -200 mesh 0-0.5

4 Moisture in feed coal , wt% up to 18 <5 No limit

5 Maximum ash content tried,

wt%

up to 40 up to 25 up to 25

6 Ash withdrawal Dry Powder Dry Powder Molten

Slag

Molten Slag

7 Dry gas composition , vol%

CO 18-20 34-36 65-66 55-57

H2 39-41 40-42 30-32 33-35

CH4 10-12 3-4 0.4 <0.1

CO2 28-30 19-20 1-2 10-12

S ' Compounds ~0.5 ~0.5 0.4 0.3

N2 and others ~0.5 1 1 0.6

8 H2 / CO ratio in gas 2.1 1.25 0.48 0.65

9 Calorific value of gas , kcal /

Nm3

2600-2900 2640 2980 2700

10 Cold Gas efficiency , % >85 80-83 76-77

11 Carbon Conversion , % 93-99 >93 >99

12

WHY SASOL-LURGI GASIFICATION

Well demonstrated, Proven Technology, Low

risk. 101 Gasifiers in operations.

Suited to wide variety of low grade , high ash

content coal up to 40 %

Robust and mature technology, high reliability

and on line availability factors. ( 90 to 92 % )

13

High Carbon efficiency ( i.e. 95 % )

High cold gas efficiency = 85 % because of

counter current operation.

Oxygen consumption is low

14

Most suitable for steel industry, as it contains

gas H2: CO = 1.6: 1.8 and CH4 of 10 to 12 %

which is a requirement of steel industry.

Ash fusion temp of Indian Coal is high. Hence

dry bottom ash is preferred.

No coal drying & grinding. So less energy

consumption and not hazardous.

Valuable Co-Products like tar, oil, phenol,

ammonia are produced.

15

Syngas Composition vs Reformed Gas

S No Component MIDREX HYL

Reformer

COREX Syngas ZR

Scheme

1 H2 55 73 19 51 50

2 CO 33.5 15 38 31 15

3 CH4 3.1 5 1 9 25

4 CO2 2.6 1 35 6 3

5 H2O 5 5 3 1.5 4

6 N2 0.8 1 4 1.5 3

7 H2/CO 1.64 5 0.5 1.65 3.33

Above table shows the composition of the Reducing Gas that is being used by various

processes. Syngas from Coal Gasification looks to be quite usable.

16

Inputs Specific Consumption

Unit Natural gas Syngas

Iron ore t/ t 1.42-1.44 1.42-1.44

(Screened-3.2-mm, dry basis)

Natural gas Gcal/ t 2.4 -

Syngas* Gcal/ t - 2.2

Electricity kwh/ t 115 115

Oxygen Nm3/ t 15 15

Water m3 1.5-1.8 1.5-1.8

Steam at 4.5 bar

For Co2 removal in syngas kg/ t - 700

Labour man hrs/ t 0.11-0.17 0.11-0.17

Maintenance US$ 3.5 3.0

17

Process Route

Gasifier

Air

Separation

Plant

Gas Cleaning &

Conditioning

CO

2

Removal

Gas Heater

Scrubber

Shaft Furnace

O

2

Coal

Heavy Fuel Oil

Pet Coke

Naptha

Reducing

Gas

Recycle

Gas

Iron Ore

DRI/HBI

Gasification plant Direct Reduction Plant

18

Figure 2. Energiron process

19

Sasol- Lurgi gasifier can use high ash coal

(34-36% ash).

269 t/ hr of coal produces 225 000 NM3/ hr

of syn gas.

Adequate volume for 2.5 MTPA DRI plant

This technology is being implemented at

J SPL, Angul (Orissa) for 4 MTPA DRI plant.

20

Figure 1. Coal gasification process block diagram

21

Following tests were conducted on Coal sources to

determine the suitability for Gasification

Purposes:

Proximate Analysis

Ultimate Analysis

Co2 Gasification reactivity

Particle size distribution

Ash melting properties and ash composition

Caking Properties under 30 kg/ cm2

22

Thermal Fragmentation

Mechanical Fragmentation

Fisher Assay

Total Sulphur

Heating Value

Rank of the coal.

23

Table 2: Particle size distribution on sample

as received (Mass% -Fraction Retained)

Fraction (mm) Talcher 1 Talcher 2

37.5 9.7 3.0

26.5 39.0 42.5

19 25.4 30.8

13.2 11.8 11.7

9.5 5.9 4.5

6.7 3.4 2.5

4.75 1.5 1.3

3.35 0.9 0.9

2.36 0.6 0.7

1.7 0.3 0.5

-1.7 0.3 1.8

-0.5 1.2 0

24

Table 3: Proximate analysis

(air dried basis-mass %)

Sample Talcher 1 Talcher 2

% Moisture 7.5 6.4

%Volatile

matter

26.3 26.2

% Fixed

carbon

31.9 31.6

% Ash 34.3 35.8

Co2 reactivity/ hr 50% burn off - 5.9

25

Table 5. Fisher assay (mass %)

Sample Talcher

(composite)

% Tar (as received) 6.5

% Tar (dry basis)^A 7.3

% Char* (as received) 77.6

% Water (as received) 10.3

% gas (as received) 5.6

26

Table 6. Ash fusion properties

Sample Initial

deformation

(

o

C)

Hemispherical

(

o

C)

Flow

(

o

C)

Talcher 1 1530 1590 +1600

Talcher 2 1500 1580 +1600

Higher Ash Fusion Temp Low H2/CO ratio

27

Table 7. Ash Analysis (mass %)

Sample Talcher 1 Talcher 2

SiO2 66.6 66.7

Al2O3 25.0 25.4

Fe2O3 2.4 1.8

P2O5 1.0 1.0

TiO2 1.4 1.4

CaO 1.8 1.2

MgO 0.9 0.8

K2O 1.7 1.7

Na2O 0.3 0.3

SO3 0.2 0.1

28

Caking properties

Talcher coal of the size -19+2.36mm under

pressure of inert atmosphere shows no caking

tendency.

29

Thermal & Mechanical Fragmentation

The thermal & mechanical fragmentation tests

were conducted on a composite sample.

The thermal degradation of the Talcher Coal at

atmospheric pressure was 20%.

The mechanical fragmentation of the Talcher

coal was determined as 32.7%.

30

Table 8. Ultimate analysis & heating value

Sample Talcher

C Mass

%

DAF

76.4

H 5.3

N 1.9

S 0.7

O(by difference) 15.7

Lower calorific

value(air dried)

MJ / kg

17.3

Higher calorific

value(Dry basis)

MJ / kg

17.5

31

Inorganic and Organic Sulphur distribution

Sample Total Sulphur Mineral

Sulphur

Organic

sulphur

Talcher 1 0.46 0.08 0.38

Talcher 2 0.45 0.11 0.34

Table 9. Forms of Sulpher (mass% as received basis)

.

32

Table 10.

Petrographic Composition

Sample PETROGRAPHIC COMPOSITION

(MASS %)

Vitrinite Liptinite Total

Inertnite

Visible

minerals

Talcher 49.8 2.2 15.4 32.6

33

Classification of Coal According To Rank

---------0.25----------0.4------------0.6------------4.0---------

Lignite Sub-bituminous Bituminous Anthracite

Talcher Coal Rank was found to be - 0.37

34

Process flow at J indal Steels

Angul Project

Coal

Gasification

Gas based

DRI

EAF

Slab Caster

Hot Strip

Mill

Plate Mill

35

Blast

Furnace

2

nd

Step

Right technological fit

Lower cost base of raw material

Market linkage at strategic process interface.

Utilization of complete coal basket

Conclusion

36

Thank You

37

Thermal Fragmentation: It is measured by placing a sample with

a specific predetermined size distribution into a pre heated

muffle oven at 100

o

C under atmospheric pressure. The coal is

then heated to 700

o

C (final temperature) at a rate of

+/ - 12

o

C/ min. The experiments are conducted under nitrogen

with a reaction time of 60 minutes at the final temperature. The

percentage thermal fragmentation of coal is given as a

percentage decrease in Sauter Diameter. The smaller the

percentage decrease, the better the themal stability.

38

% Thermal Fragmentation= d

p

before test d

p

after test x 100

d

p

before test

Sauter Mean Diameter (SMD, d

32

or D[3,2]) is a common

measure in fluid dynamics as a way to estimate the average

particle size. It was originally developed by German scientist, J .

Sauter in the late 1920s. It is defined as the diameter of a

sphere that has the same volume/ surface area ratio as a

particle of interest. Several methods have been devised to obtain

a good estimate of the SMD

39

Cold Gas efficiency: Heating value of (CO + H2 + C2 to C6) x 100

Heating value of Coal

Carbon Efficiency: Carbon Converted x 100

Carbon input by Coal

40

1) South Africa: 80 Gasifiers

2) USA: 14 Gasifiers

3) China: 7 Gasifiers

Total : 101 Gasifiers

41

DRI vs Hot Metal (BF route) comparision

S No DRI Hot Metal

1 Iron Ore and non-coking coal are

available abundantly in India

Coking Coal is to be imported

2 Pellet Plant and Coal Gasification

plants are required

Sinter plant and Coke Oven plant are

required

3 Cost of production Cost of Production

4 Investment required for making

liquid steel

Investment required for making liquid

steel

5 Conversion cost of DRI to liquid

steel

Conversion cost of Hot Metal to liquid

steel

6 Overall production cost from Iron

Ore / Coal to Liquid steel

Overall production cost from Iron Ore

/ Coal to Liquid steel

7 Overall investment for Iron Ore /

Coal to Liquid steel

Overall investment for Iron Ore / Coal

to Liquid steel

42

Process Scheme for Syn Gas + DRI

43

Ash fusion properties and Ash composition

Ash fusion properties and Ash composition: Ash fusion

properties and ash composition are given in Table-6 &

Table-7. Tests are conducted under oxidizing conditions at

a temperature of 1600C.Ash fusion temperature of Talcher

coal is significantly high with coal displaying high ash

melting point as a result a low H2:CO ratio gas can

naturally be produced. This increases the carbon efficiency

by lowering the CO2 content in the product gas.

In Talcher coal SiO2 & Al2O3 contents are on higher side

and CaO &Fe2O3 contents are relatively on lower side.

44

Table 11. The effect of coal quality on Gasifier performance

S.No Parameter Importance

1 Moisture Influences gasifier efficiency

Determines if process must be dry or slurry

fed

2 Volatile Matter Determines the extent & rate of gasification

reactions

3 Heating value Determines plant dimensions

Influences generation capacity

4 Ash content Lowers system efficiency

Increases slag production & disposal cost

5 AFT ( Ash Fusion

Temp)

Influences melting ability of the coal Ash

(must be solid below performance

temperature)

6 Slag viscosity

1400

o

C

Influences smooth slag flow between packed

bed particles (viscosity must be sufficiently

low)

7 Char reactivity Influences the extent of carbon conversion

8 Sulur May cause corrosion of heat exchanger

surfaces

9 Nitrogen Contributes to NO

X

emissions.

10 Chlorine May form HCL which can poison gas cleaning

system catalysts

May form HCL which can cause chloride

stress corrosion.

45

S-ar putea să vă placă și

- Environmental Issues Management: C P C BDocument79 paginiEnvironmental Issues Management: C P C BGanesh N KÎncă nu există evaluări

- Producers Gas PlantsDocument13 paginiProducers Gas PlantsHalil İbrahim KüplüÎncă nu există evaluări

- Dri PDFDocument4 paginiDri PDFhablimasyahidÎncă nu există evaluări

- Sponge Iron PlantDocument23 paginiSponge Iron Plantashu_update100% (2)

- Boiler Data (Texmoco BoilersDocument6 paginiBoiler Data (Texmoco Boilersamitdharne100% (1)

- Vacuum Pumps Common Problems and TroubleshootingDocument18 paginiVacuum Pumps Common Problems and TroubleshootingAV kayanÎncă nu există evaluări

- Sulphur Acid Plant Modelling (PFD Detailed) PDFDocument5 paginiSulphur Acid Plant Modelling (PFD Detailed) PDFCristian GómezÎncă nu există evaluări

- LE Manufacturing PFHE Brochure Update RZ VIEW Tcm19-406598Document9 paginiLE Manufacturing PFHE Brochure Update RZ VIEW Tcm19-406598Toth IstvanÎncă nu există evaluări

- Manufacturing Phosphoric Acid Process DesignDocument54 paginiManufacturing Phosphoric Acid Process DesignPawan SuvarnaÎncă nu există evaluări

- Sulphuric Acid PlantsDocument16 paginiSulphuric Acid PlantsSekar.SÎncă nu există evaluări

- Esteem - The Fired Heater CompanyDocument49 paginiEsteem - The Fired Heater CompanymonugeniÎncă nu există evaluări

- The Basic Flowsheet of Melamin BASF ProcessDocument2 paginiThe Basic Flowsheet of Melamin BASF ProcessMochamad Adi Saputro100% (1)

- Advanced Centrifugal Casting Alloys For Dri ProcessesDocument12 paginiAdvanced Centrifugal Casting Alloys For Dri ProcessesDavid RodriguesÎncă nu există evaluări

- 12108040-Zinc Extraction in Contrast With ISP Process PDFDocument20 pagini12108040-Zinc Extraction in Contrast With ISP Process PDFSachin MourÎncă nu există evaluări

- Ammonia Based DesulferizationDocument36 paginiAmmonia Based Desulferizationlibid_rajÎncă nu există evaluări

- Insulating Fire Brick ProductsDocument3 paginiInsulating Fire Brick Productsshuyang zhang100% (1)

- P 3 2 e 12 150dpi19 5772 PDFDocument12 paginiP 3 2 e 12 150dpi19 5772 PDFkeyur1109Încă nu există evaluări

- Operation of The First HIsmelt Plant in ChinaDocument8 paginiOperation of The First HIsmelt Plant in ChinaJJÎncă nu există evaluări

- Coal GasificationDocument72 paginiCoal GasificationguymailyÎncă nu există evaluări

- Mathematical Model of Magnetite Oxidation in A Rotary Kiln FurnaceDocument6 paginiMathematical Model of Magnetite Oxidation in A Rotary Kiln Furnacedavibraga8041Încă nu există evaluări

- Thermax BoilerDocument48 paginiThermax BoilerSandeep Kumar100% (3)

- Bayers Process ReactionsDocument23 paginiBayers Process Reactionsgullipalli srinivasa raoÎncă nu există evaluări

- Q245R PDFDocument2 paginiQ245R PDFAnonymous 9zykaX6T100% (1)

- TENOVA Brochure Secondary MetallurgyDocument24 paginiTENOVA Brochure Secondary Metallurgyuck65Încă nu există evaluări

- Pre-Feasibility R E P O R T: Ammonia / Urea Fertilizer ProjectDocument37 paginiPre-Feasibility R E P O R T: Ammonia / Urea Fertilizer ProjectAyman RiyadhÎncă nu există evaluări

- Implementing a Feed Gas Saturation System to Improve Reformer EfficiencyDocument8 paginiImplementing a Feed Gas Saturation System to Improve Reformer EfficiencyDavid PierreÎncă nu există evaluări

- Coal Gasification PDFDocument8 paginiCoal Gasification PDFmrizalygani99Încă nu există evaluări

- Proposal For Coal GasificationDocument7 paginiProposal For Coal GasificationDeepakGawasÎncă nu există evaluări

- Coke Formation Mechanisms and Coke Inhibiting Methods in Pyrolysis FurnacesDocument15 paginiCoke Formation Mechanisms and Coke Inhibiting Methods in Pyrolysis Furnaceskarl liÎncă nu există evaluări

- COMPRIT F50G-6 gunning mixDocument2 paginiCOMPRIT F50G-6 gunning mixNic RicÎncă nu există evaluări

- Purifying Hydrocarbons for Hydrogen ProductionDocument12 paginiPurifying Hydrocarbons for Hydrogen ProductionrajuÎncă nu există evaluări

- Fives CryogenieDocument17 paginiFives CryogenieA RÎncă nu există evaluări

- 1 (A) Thermodynamics of Iron MakingDocument18 pagini1 (A) Thermodynamics of Iron MakingDafi GhifariÎncă nu există evaluări

- 60% Alumina Dense Castable for 1600°C ServiceDocument1 pagină60% Alumina Dense Castable for 1600°C ServiceRAVI KIRAN CHALLAGUNDLAÎncă nu există evaluări

- HZL Project ReportDocument13 paginiHZL Project ReportsiddÎncă nu există evaluări

- Coke Oven Gas Purification and Cooling ProcessDocument3 paginiCoke Oven Gas Purification and Cooling Processshishir18Încă nu există evaluări

- Refractory IndustryDocument39 paginiRefractory IndustryAnsu Mishra100% (2)

- The Sulphur CompanyDocument20 paginiThe Sulphur CompanyNenadÎncă nu există evaluări

- Coal Gasification Comparison for Methanol ProductionDocument19 paginiCoal Gasification Comparison for Methanol ProductionRafael DamarÎncă nu există evaluări

- Ausmelt SmeltingDocument6 paginiAusmelt SmeltingMarcelo SerranoÎncă nu există evaluări

- Hydrogen and Syngas Production and Purification TechnologiesDe la EverandHydrogen and Syngas Production and Purification TechnologiesÎncă nu există evaluări

- New Resume SunilDocument5 paginiNew Resume SunilAnish Kumar DhirajÎncă nu există evaluări

- Superalloys For High Temperatures-A Primer: How and When To Use This ChapterDocument9 paginiSuperalloys For High Temperatures-A Primer: How and When To Use This ChapterSuriyachai NiamsornÎncă nu există evaluări

- Jamalganj UCG ProspectDocument23 paginiJamalganj UCG ProspectArup Kumar BiswasÎncă nu există evaluări

- Whytheat K-Data SheetDocument1 paginăWhytheat K-Data SheetAbhinay SuratkarÎncă nu există evaluări

- Iron Making TechnologyDocument53 paginiIron Making TechnologyAwas Ada UdinÎncă nu există evaluări

- UreaDocument86 paginiUreaAdi Ahmad100% (1)

- Heat Resistant Alloy HK40 Data SheetDocument2 paginiHeat Resistant Alloy HK40 Data SheethawyegÎncă nu există evaluări

- Process Flow Diagram - Nitric AcidDocument1 paginăProcess Flow Diagram - Nitric AcidAsma NasserÎncă nu există evaluări

- Blast Furnace Stove Refractory Findings and Innovative SolutionsDocument12 paginiBlast Furnace Stove Refractory Findings and Innovative SolutionsBalaji B HÎncă nu există evaluări

- Reduction Kinetics of Iron Ore PelletsDocument43 paginiReduction Kinetics of Iron Ore PelletsDivyesh Parmar100% (1)

- CoalDocument23 paginiCoalhinaÎncă nu există evaluări

- ENERGIRON Direct Reduction Technology - Economical Flexible and Environmentally FriendlyDocument28 paginiENERGIRON Direct Reduction Technology - Economical Flexible and Environmentally FriendlyAgustine Setiawan100% (1)

- Coal UtilizationDocument50 paginiCoal UtilizationNoviandryÎncă nu există evaluări

- Boiler PreservationDocument35 paginiBoiler PreservationANKUSH YOGIÎncă nu există evaluări

- Blast Furnace IronmakingDocument83 paginiBlast Furnace IronmakingKumar Varun100% (1)

- 1 s2.0 0196890494900868 MainDocument7 pagini1 s2.0 0196890494900868 MainDana MateiÎncă nu există evaluări

- Contact ProcessDocument19 paginiContact ProcessLeela Santosh KumarÎncă nu există evaluări

- Media Release RIL Q3 FY21 22012021Document40 paginiMedia Release RIL Q3 FY21 22012021Anvesh DontulaÎncă nu există evaluări

- 44650Document5 pagini44650Anonymous xpdTqvÎncă nu există evaluări

- The Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997Document29 paginiThe Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997telegenicsÎncă nu există evaluări

- Hand Book On Succession Process and A Guide To The FamilyDocument65 paginiHand Book On Succession Process and A Guide To The FamilytelegenicsÎncă nu există evaluări

- TOCICO-Baptista, Humberto Modern TOC Distribution (Workshop) v1Document54 paginiTOCICO-Baptista, Humberto Modern TOC Distribution (Workshop) v1telegenicsÎncă nu există evaluări

- III.4.1.6 Interplanetary Travel-1-2Document12 paginiIII.4.1.6 Interplanetary Travel-1-2telegenicsÎncă nu există evaluări

- Steps Cios Can Take To Drive Business Model InnovationDocument10 paginiSteps Cios Can Take To Drive Business Model InnovationtelegenicsÎncă nu există evaluări

- Capital Compounders2Document17 paginiCapital Compounders2telegenicsÎncă nu există evaluări

- Potential Multibagger 2.0Document4 paginiPotential Multibagger 2.0telegenicsÎncă nu există evaluări

- Tocilizumab in Hospitalized Patients-Nejmoa2028700Document14 paginiTocilizumab in Hospitalized Patients-Nejmoa2028700telegenicsÎncă nu există evaluări

- Indian Steel IndustryDocument28 paginiIndian Steel Industrykeanu100% (1)

- Development of A Buffer Monitoring DashboardDocument47 paginiDevelopment of A Buffer Monitoring DashboardtelegenicsÎncă nu există evaluări

- EY Indian Steel Strategy To Ambition PDFDocument21 paginiEY Indian Steel Strategy To Ambition PDFManu GCÎncă nu există evaluări

- 50 Examples of Corporations That Failed To InnovateDocument108 pagini50 Examples of Corporations That Failed To InnovateSumar SonoÎncă nu există evaluări

- Steps Cios Can Take To Drive Business Model InnovationDocument10 paginiSteps Cios Can Take To Drive Business Model InnovationtelegenicsÎncă nu există evaluări

- Media Release RIL Q3 FY21 22012021Document40 paginiMedia Release RIL Q3 FY21 22012021Anvesh DontulaÎncă nu există evaluări

- Use Cases: IG Petro, Tata Steel, Mahindra, ITC, Titan, ABB, AirbusDocument55 paginiUse Cases: IG Petro, Tata Steel, Mahindra, ITC, Titan, ABB, AirbustelegenicsÎncă nu există evaluări

- The Strategy & Tactic Tree: Reliable Rapid ResponseDocument69 paginiThe Strategy & Tactic Tree: Reliable Rapid ResponsetelegenicsÎncă nu există evaluări

- Neewee Intro Solution 2021-04-06 HCHDocument79 paginiNeewee Intro Solution 2021-04-06 HCHtelegenicsÎncă nu există evaluări

- Neewee Intro Solution 2021-04-06 HCHDocument79 paginiNeewee Intro Solution 2021-04-06 HCHtelegenicsÎncă nu există evaluări

- Ru Iron and Steel Industry Report Eng PDFDocument25 paginiRu Iron and Steel Industry Report Eng PDFBharath RajÎncă nu există evaluări

- KingsvillaDocument8 paginiKingsvillatelegenicsÎncă nu există evaluări

- Overview of The Steel and Iron Ore Market 2020Document26 paginiOverview of The Steel and Iron Ore Market 2020telegenicsÎncă nu există evaluări

- Teacher Survey Learning Loss Is Global and SignificantDocument10 paginiTeacher Survey Learning Loss Is Global and SignificanttelegenicsÎncă nu există evaluări

- Tocilizumab in Hospitalized Patients-Nejmoa2028700Document14 paginiTocilizumab in Hospitalized Patients-Nejmoa2028700telegenicsÎncă nu există evaluări

- ELibri May 2021 - Fairy Tales BookshelfDocument1 paginăELibri May 2021 - Fairy Tales BookshelftelegenicsÎncă nu există evaluări

- 29 Cities. Curfew Order 27.04.21Document4 pagini29 Cities. Curfew Order 27.04.21telegenicsÎncă nu există evaluări

- SAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandoutDocument26 paginiSAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandouttelegenicsÎncă nu există evaluări

- SAP S4HANA Webcast Series - EN - Session - 05 - Methods - and - Tools - HandoutDocument49 paginiSAP S4HANA Webcast Series - EN - Session - 05 - Methods - and - Tools - HandouttelegenicsÎncă nu există evaluări

- SAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandoutDocument26 paginiSAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandouttelegenicsÎncă nu există evaluări

- IR CompressorDocument30 paginiIR CompressorkingofngayeÎncă nu există evaluări

- PC400 400LC-8R PDFDocument8 paginiPC400 400LC-8R PDFAsmar FixÎncă nu există evaluări

- G20 Business Letter We Mean Business CoalitionDocument26 paginiG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoÎncă nu există evaluări

- Iapa ManualDocument275 paginiIapa ManualJabi JabzzÎncă nu există evaluări

- Komatsu Hydraulic Excavator Pc850se 8 Shop ManualDocument20 paginiKomatsu Hydraulic Excavator Pc850se 8 Shop Manualleon100% (41)

- Plantilla WPS (GMAW-MIG) Junta VDocument1 paginăPlantilla WPS (GMAW-MIG) Junta Vjhojan garciaÎncă nu există evaluări

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 paginiPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- Pelton TurbineDocument5 paginiPelton Turbinegauravarora93Încă nu există evaluări

- TestDocument22 paginiTestAbdul WaheedÎncă nu există evaluări

- Vibration Isolation Selection GuideDocument5 paginiVibration Isolation Selection GuidearifzakirÎncă nu există evaluări

- 64 Meeting January 7-8, 2013Document42 pagini64 Meeting January 7-8, 2013ymadhukumarÎncă nu există evaluări

- Monbat 12V200AhDocument1 paginăMonbat 12V200AhMaria MuresanÎncă nu există evaluări

- Straight Differential Expansion - DMXDocument4 paginiStraight Differential Expansion - DMXJurun_BidanshiÎncă nu există evaluări

- Heat Exchanger (Oil To Water) Installation Information: Description: Power RequirementsDocument4 paginiHeat Exchanger (Oil To Water) Installation Information: Description: Power Requirements413666436qq.comÎncă nu există evaluări

- Field Joint CoatingDocument7 paginiField Joint CoatingTeodor EzaruÎncă nu există evaluări

- ABB String Inverters: PVS-50/60-TLDocument4 paginiABB String Inverters: PVS-50/60-TLBianca OlaruÎncă nu există evaluări

- Nasdaq Aaon 2002Document26 paginiNasdaq Aaon 2002gaja babaÎncă nu există evaluări

- External Corrosion of PipeDocument0 paginiExternal Corrosion of Pipejafarimehdi17Încă nu există evaluări

- Switch and Types of Switch: What Is A Switch?Document5 paginiSwitch and Types of Switch: What Is A Switch?Swagat PradhanÎncă nu există evaluări

- FertiOne Manual (30.11.15)Document36 paginiFertiOne Manual (30.11.15)YacineÎncă nu există evaluări

- Instr 12205 Elements Transmitters Transducers DisplacersDocument103 paginiInstr 12205 Elements Transmitters Transducers DisplacersKumar SomasundaramÎncă nu există evaluări

- Draft MP Net Metering Policy - 4.11Document11 paginiDraft MP Net Metering Policy - 4.11Anand PuntambekarÎncă nu există evaluări

- Air Compressor Presentation 1.1Document20 paginiAir Compressor Presentation 1.1ROBERTO FELIX RUEDASÎncă nu există evaluări

- Упражнения на отработку Second ConditionalDocument6 paginiУпражнения на отработку Second ConditionalНаргиля ГаджиеваÎncă nu există evaluări

- Regulator Capacitor Manual PDFDocument8 paginiRegulator Capacitor Manual PDFKyle StairÎncă nu există evaluări

- Rotak: Downloaded From Manuals Search EngineDocument18 paginiRotak: Downloaded From Manuals Search EngineOvidiu BrinzanÎncă nu există evaluări

- Screw Compressors: Models: VEDocument42 paginiScrew Compressors: Models: VEVoştinar IoanÎncă nu există evaluări

- FI 48 Rigid Glasswool Sheets and Acoustic BlanketDocument2 paginiFI 48 Rigid Glasswool Sheets and Acoustic BlanketJimWest69Încă nu există evaluări

- Engine Construction and OperationDocument31 paginiEngine Construction and OperationRohit NewarÎncă nu există evaluări

- History of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Document584 paginiHistory of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Artisan Ideas75% (4)