Documente Academic

Documente Profesional

Documente Cultură

Structural and Crane Load Design Criteria For Building Systems

Încărcat de

aiyubi2100%(1)100% au considerat acest document util (1 vot)

672 vizualizări13 paginicrane

Titlu original

Structural and Crane Load Design Criteria for Building Systems

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentcrane

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

672 vizualizări13 paginiStructural and Crane Load Design Criteria For Building Systems

Încărcat de

aiyubi2crane

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 13

Structural and Crane Load Design Criteria

For Steel Building Systems

Structural and Crane Load Design Criteria

For Steel Building Systems

CSSBI B15A 10

October 2010

Canadian Sheet Steel

Building Institute

652 Bishop St. N., Unit 2A

Cambridge, Ontario N3H 4V6

Tel.: (519) 650-1285

Fax: (519) 650-8081

www.cssbi.ca

C a n a d i a n S h e e t S t e e l B u i l d i n g I n s t i t u t e

CSSBI B15A 10

October 2010

Structural and Crane Load Design Criteria For Steel Building Systems

One of the objects of the CSSBI and its members is the development of standards that promote

safety, performance and good practice. This bulletin is published as a guide for designers,

specifiers and users of Steel Building Systems (SBS) and as a reference for building code officials

and other authorities.

The material presented herein has been prepared for the general information of the reader and

care has been taken to ensure that this Bulletin is a reasonable interpretation of the applicable

code requirements. While the material is believed to be technically correct and in accordance

with recognized practice at the time of publication, it does not obviate the need to determine its

suitability for a given situation. Neither the CANADIAN SHEET STEEL BUILDING INSTITUTE nor its

Members warrant or assume liability for the suitability of this bulletin for any general or particular

application.

Buildings Incorporating Steel Building Systems: Responsibilities of the Parties Involved, CSSBI B8-06,

Canadian Sheet Steel Building Institute, Cambridge, ON

Crane Supporting Steel Structures: Design Guide, 2

nd

Edition, Canadian Institute of Steel

Construction, Markham, ON, 2009

National Building Code of Canada 2005, National Research Council of Canada, Ottawa, ON

Copyright October 2010

by CANADIAN SHEET STEEL BUILDING INSTITUTE

All rights reserved. This publication, nor any part thereof, may be reproduced in any

form without the Written permission of the publisher.

ISBN 978-1-895535-62-4

Preface

Reference Documents

CSSBIII B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

The objective of this bulletin is to present the structural and crane loading requirements in a

format that is easy to understand. The structural loads are taken from the 2005 National Building

Code of Canada. The focus is on Steel Building Systems, however, the loading criteria are

applicable to most low rise building construction.

The National Building Code of Canada is a model document used by the provinces and territories

of Canada in the preparation of their own building codes, which are the governing legislation for

building construction. For specific designs, the loading criteria presented in this Bulletin should

be checked against the requirements of the applicable building code.

A. STRUCTURAL LOADS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A1: Live Loads due to Use and Occupancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A2: Mezzanine Live Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A3: Collateral and Dead Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

B. CRANE LOAD DESIGN CRITERIA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B1: Crane Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B2: Crane Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B3: Top Running Cranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B4: Deflections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B5: Crane Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B6: Loads on Frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B7: Load Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B8: Crane Beam Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B9: Load Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B10: Crane Beam Corbels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B11: Crane Load Design Criteria Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction

Table of Contents

II

CSSBI1 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

The National Building Code of Canada outlines the minimum loads for which a building is to be

designed to support. These loads are categorized as: Live, Dead and Environmental (snow, wind

and earthquake).

A1: Live Loads due to Use and Occupancy

Live Loads are the expected variable loads on the building structure due to the intended use and

occupancy. Crane loads and the pressure of liquids in containers are considered as Live Loads.

The National Building Code of Canada specifies a minimum magnitude of Live Loads to cover the

effect of ordinary load concentrations that may occur on the element being considered.

On roof surfaces, the minimum Live Load of 1 kPa (0.8 kPa for buildings in the Low Importance

Category) represents the load during construction. Post construction, this load represents,

maintenance workers and their equipment. On interior surfaces such as elevated floors, the Live Load

is specified based on the occupancy or usage of the area(e.g. assembly areas, storage areas or libraries).

For loads on surfaces not specifically defined in the National Building Code of Canada the designer of

the structure (as defined in CSSBI B8) is responsible for defining the applicable load.

Examples of Live Load based on use and occupancy are:

Arenas, Churches, Gymnasia, other areas of similar use 4.8 kPa

Fixed seating Churches and Theaters, Classrooms 2.4 kPa

Equipment areas and service rooms 3.6 kPa

A2: Mezzanine Live Loads

Mezzanine means an intermediate floor assembly between the floor and ceiling of any room or

storey and includes an interior balcony. (Ref. NBCC-05, 1.4.1.2, Division A)

Live Loads on mezzanines are based on the use and occupancy of the area. Where there is a

corridor on the mezzanine floor the design load shall be the intended use of the room being

served by the corridor. Where a mezzanine is to have multiple uses the design Live Load will be

the greater load of the intended uses.

A3: Collateral and Dead Loads

Dead Load consists of the accumulation of the permanent self weight and collateral loads. Permanent

weight is the sumof the self weight of the structural elements and all the weight of other material

elements that would always exist throughout the life of the structure (e.g. insulation and lights).

Collateral load is the weight of any additional loads that may be in specific parts of the building, but

may not be in all of the building (e.g. sprinklers, air handling units and other mechanical units). Listed

beloware several items or materials that would typically be considered as collateral loads

Sprinklers 0.24 kPa

Light ductwork 0.15 kPa

Acoustic ceiling tiles 0.10 kPa

Light aggregate plaster ceiling 0.19 kPa

Common glass window and framing 0.38 kPa

Glass Skylights and framing 0.58 kPa

A. Structural Loads

1

CSSBI2 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

When designing the structural members for uplift loads (i.e. roof sheets, purlins and frames), the

counter acting collateral loads are not included in the design. The collateral load is included when

they act in the same direction as the dead load.

B1: Crane Types

Steel Building Systems can support several different types of crane systems when required. The

typical crane types are Top Running, Under Hung and Jib cranes and are usually electric powered.

Cranes can be provided in several styles based on the required capacity, span and service class.

Top Running cranes are supported by the crane bridge end trucks bearing on rails that are

supported on top of their crane beams. These cranes have the greatest variation in capacity, span

and service class and usually span the full width of the framing supports.

Under Hung cranes are supported by using a suspension type support which is connected to the

bottom of a frame. The crane wheels are supported from the bottom flange of the crane beams

which act as a crane rail and usually only span a portion of the column to column span of the

structure. They are usually a small capacity of crane.

2

B. Crane Load Design Criteria

Figure B1: Top Running Crane

CSSBI3 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

Jib cranes are specialty cranes for a specific

location and utility. They consist of a fixed length

horizontal boom that can rotate about the

supporting column. They are commonly used in

areas of staged production to transfer work from

station to station. Jib cranes are usually attached

to a column flange allowing a rotation of more

than 180 degrees. Considering the rotation of

the load, Bi-axial bending usually governs the

design of the supporting column.

3

Figure B2: Under Hung Crane

Figure B3: Jib Crane

CSSBI4 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

B2: Crane Service

Cranes are classified based on their frequency of operation called a Duty Cycle varying from Class

A to F. A Class A crane is for more infrequently used moderate cranes and a Class F is for a heavy

duty continuous severe service. The service of the crane is based on the quantity of partial and

full lifts during a specified period of operation and does not limit the capacity of the crane.

Cranes that are usually supported by SBS buildings are often top running cranes of Class C. SBS

buildings that support cranes greater than C must be evaluated based on the additional

requirements set forth by the CISC Crane-Supporting Steel Structures: Design Guide.

B3: Top Running Cranes

Top running cranes are the most common type of crane that a SBS building can be designed to

support. The capacity of the crane is based on the magnitude of the Lifted Load. The Lifted Load,

Span and Service define the crane member sizes, girder type and configuration. Single Girder

cranes with a capacity of 10 tons usually span up to 50. Double Girder cranes with a capacity of 25

tons usually span up to 65. Box Girder cranes usually are required on longer spans.

The function of a crane is to move the lifted load horizontally and longitudinally in the building.

The lifted load is usually supported with a hook, which is cabled to a hoist. The hoist is supported

by a trolley which moves the horizontally along the crane bridge. The crane bridge is connected

to a number of crane trucks at each end depending on the capacity and span. The crane trucks

can have 2, 4 or 8 wheels based on the capacity of the crane. The wheels ride along a crane rail

which is supported by runway beams. The sketch in Figure B4 illustrates the basic crane

components and some of the defined distances.

The crane span is defined as the horizontal distance from center to center of the crane wheel

supports. The horizontal crane coverage is defined as the crane span less the left side hook

approach and right side hook approach. Side clearances are measured from the center of the

supporting rail to the face of the supporting column and are required for operation, safety, and

wheel maintenance.

4

Figure B4 Crane Components and Definitions

CSSBI5 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

The hook height is the distance from the datum to the highest position of the hook. The crane

must be able to travel within the building avoiding obstructions in the building such as lights,

equipment and the structural framing. The vertical clearance is measured from the top of the

crane rail to the underside of the structure. This clearance is based on the size of the crane bridge,

location of the hoist and trolley, rail and a safety allowance.

B4: Deflections

Serviceability requirements of the crane system and crane supporting structural system are

outlined in the CSA-S16 Design of Steel Structures. Unfactored crane loads without impact are

used to calculate the deflections. The permissible vertical deflection limit for runway beams is

L/600 for class A, B, and C cranes, L/800 for class D, and L/1000 for classes E and F. The permissible

horizontal deflection limit of runway beams is L/400. The permissible lateral deflection of the

crane supporting structural system is based on unfactored crane loads, or unfactored 1 in 10

wind loads, and shall not exceed 50mm for cab operated cranes. The permissible lateral deflection

of the structure is CH/240 for class A, B and C cranes, and CH/400 for class D, E and F cranes, where

CH is measured from the base to the top of the crane rail. There is an exception for frames

supporting pendant-operated cranes, which has a limit of CH/100.L is the center to centre

distance between crane runway beam supports.

B5: Crane Data

Crane Data for the design of crane systems is to be provided by the manufacturer of the crane to

the designer of the crane supporting system. Listed below is the minimum required crane

information to be used in the design of crane supporting systems.

Quantity of Cranes

New or Existing Crane

Capacity (tons or tonnes)

Class

Span

Power source (hand geared or electric)

Total weight of crane, weight of trolley and hoist

MaximumWheel load

Spacing, Diameter and Number of wheels

Vertical and Horizontal clearances

Hook approach

Special impact factors or serviceability requirements

B6: Loads on Frames

The sketch in Figure B5 shows the cross section of a steel building system with the associated

crane loads. The sketch in Figure B6 shows the longitudinal loads applied to the building by the

crane.

5

(without impact)

CSSBI6 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

B7: Load Directions

The vertical crane live loads are applied to the top of the rail at the centerline of the crane beams.

The weight of the crane beam is applied at the top of the corbel bracket. The vertical loads are

applied eccentric to the supporting frame column when a corbel attached to the column is used.

The horizontal and longitudinal crane loads are considered as live loads. They are applied at the

top of the crane rail as illustrated in Figure B7.

6

Figure B5 - Building Section Showing Loads

Figure B6 Building Longitudinal Loads

CSSBI7 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

B8: Crane Beam Loads

The design of the Crane Beam is to include all the loads imposed on the beam, which include the

self weight of the beam, rail, all accessories, the loads induced from the crane and the lifted load.

The design of the crane runway beams is to include the impact factor. The Impact Factor is

applied to the lifted load and the weight of the crane including the trolley and hoist. For example,

an electrically operated crane has an impact factor of 1.25; whereas pendant operated cranes

have an impact factor of 1.10.

Crane beams are usually designed as simple span beams. Structural analysis of the beam is

required to determine the location of the maximum design moments and shears due to the

crane traveling along the length of the crane beam.

B9: Load combinations

Load combinations are specified in the National Building Code of Canada. The crane loads are

considered to be live loads.

Consideration of the magnitude and direction of the crane must be taken into account when

loading the frame. One combination is to include the maximum vertical loads on one side of the

bridge with the horizontal loads going in one direction and then a combination with the

horizontals going in the opposite direction. Frames should always be designed with the

maximum load on one side and the minimum load on the other.

Multiple cranes can impact the quantity of load combinations greatly, especially for multi-span

frames. For vertical loads, all combinations of maximum/minimum loads for each crane must be

checked; all cranes are loaded simultaneously. This is not necessary for lateral and longitudinal

loads, since there is a very low probability of multiple cranes imposing full lateral (or longitudinal)

loads at the same time. Similarly, the vertical impact load is not required for all cranes

simultaneously. Refer to the CISC Crane-Supported Steel Structure Design Guide for suggested load

combinations for various situations.

7

Figure B7 Building Crane Loads

Note: Impact factor also applies for crane beam connection, fatigue check requirement for stress

reversal on top flange, tension flange and welds at stiffeners.

CSSBI8 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

B10: Crane BeamCorbels

The design of the crane runway beam supporting corbel is to include the impact factor and

fatigue loading. The design of the crane beam corbel is to include all the loads imposed on the

corbel from the crane beam. Simple span crane beams impose loads in one direction. Continuous

crane beam design causes stress reversals on the corbel.

B11: Crane Load Design Criteria Example

Building Size: 30m clear span building x 42m long x 9m high

7 - 6m bays

Crane Data: 1 new 10 tonne, Class C, electric operated crane

Crane span: to be determined

Crane weight: 11500 Kg

Trolley weight: 630 Kg

Hoist weight: combined with trolley

Maximum wheel load: 81.3 KN (without impact)

Number of wheels: 2 per end truck

Wheel spacing: 4980 mm

Vertical clearance: 1295 mm

Horizontal clearance: 203 mm

Crane approach: 1016 mm

Crane is electrically operated, and is not pendant operated

Code specified serviceability requirements

Determine the Crane Span:

The crane span is the building width, less the structure depth, less the horizontal clearances, and

is illustrated in Figure B8.

Building Width = BWD = 30000 mm

Assumed Frame Width = AFWD = 1070 mm

Horizontal Clearance = HCD = 203 mm

Crane span = SPD = BWD 2 (AFWD + HCD)

SPD = 30000 2(1072 + 203) = 27450 mm

8

CSSBI9 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

Calculate the Crane Loads:

Lifted Crane Load = LCL = 10 tonnes = 97.90 KN

Crane Weight = CW = 112.87 KN

Trolley and Hoist Weight = THW = 6.19 KN

When the lifted load is hoisted and is as far to the left as physically possible, it is at the closest

position to the left support. This is equal to the crane approach. The crane approach is the smaller

distance of the left or right side approach.

Crane Approach = CAD = 1016 mm

The Maximum Load Factor for this span based on the side approach is

MXLF = (SPD CAD) /SPD = (27450 1016 )/ 27450 = 0.96

The Minimum Load Factor for this span based on the side approach is

MNLF = 1 MXLF = 1 0.96 = 0.04

There are 2 wheels per truck and 2 trucks per crane for a total of 4 wheels for this crane.

Wheels per Truck = TrW = 2

Total number of Wheels = TTrW = 4

The calculated Wheel Loads are:

MaximumWheel Load = MXWL = CW/TTrW + MXLF ( THW + LCL ) / TrW

MXWL = 112.87 / 4 + 0.96 ( 6.19 + 97.90 ) / 2 = 78.18 KN

MinimumWheel Load = MNWL=CW/ TTrW + MNLF ( THW + LCL ) / TrW

MNWL = 112.87 / 4 + 0.04 ( 6.19 + 97.90 ) / 2 = 30.30 KN

The sum of all wheel loads is 2 ( 78.18) + 2 ( 30.30) = 216.96 KN

Check the sum of the lifted load + the crane, trolley and hoist weight.

112.87 + 6.19 + 97.90 = 216.96 KN

9

Figure B8 Crane Span

CSSBI10 B15A-10

NBC 2005 Structural and Crane Load Design Criteria For Steel Building Systems

The maximum load of the crane on any one frame will be when a crane wheel is directly in line

with the frame centerline as illustrated in Figure B9.

The distance between frames is the bay size, BAYD = 6000 mm

The Wheel Spacing = WSD = 4980 mm

Truck Wheel Factor = TWF = ( 2 WSD/ BAYD)

= 2 4980/6000 = 1.17

Vertical Frame Load:

Maximum Live Load:

MXVFL = MXWL * TWF = 78.18 * 1.17 = 91.47 KN

Minimum Live Load:

MNVFL = MNWL * TWF = 30.30 * 1.17 = 35.45 KN

Assume the crane beam, rail and accessories weighs 7 KN per 6m bay

Horizontal Load:

The horizontal load is 20% of the sum of the lifted load, weight of the trolley and hoist weight

applied at the top of the rail and is equally divided between each side of the crane.

The horizontal load will then be distributed to each frame proportional to the relative stiffness

and support conditions.

CLHL = CRHL = ( 0.20 ( THW + LCL ) /2 ) TWF

= ( 0.20 ( 6.19 + 97.90 ) /2 ) 1.17 = 12.18 KN

Longitudinal Load:

The longitudinal load is to be 10% of the maximum wheel load (on driving wheels) at the top of the rail.

CLLL = CRLL = 0.10 ( MaximumWheel Load ) * Number of Wheels

= 0.10 ( 81.3 ) * 2 = 16.26 KN

10

Figure B9 Configuration Causing Maximum Crane Load on a Frame

S-ar putea să vă placă și

- Investigation of the Chirajara Bridge CollapseDe la EverandInvestigation of the Chirajara Bridge CollapseÎncă nu există evaluări

- Masonry Design ExamplesDocument13 paginiMasonry Design ExamplesRoger FonsecaÎncă nu există evaluări

- Building Inspection Report (Sample Report)Document39 paginiBuilding Inspection Report (Sample Report)Syamimi AlwaniÎncă nu există evaluări

- Software verification of wide flange beam bending capacitiesDocument7 paginiSoftware verification of wide flange beam bending capacitiesAntonius AjalahÎncă nu există evaluări

- Canam Steel DeckDocument168 paginiCanam Steel DeckAnonymous 8hx6hKN3Încă nu există evaluări

- Through Bolt Connection PDFDocument197 paginiThrough Bolt Connection PDFAkhil VNÎncă nu există evaluări

- Tower Design-Chapter 2-Pile Caps Design-Nada ZarrakDocument37 paginiTower Design-Chapter 2-Pile Caps Design-Nada ZarrakNadaZarrakÎncă nu există evaluări

- Design Recommendations For Steel Deck Floor SlabsDocument32 paginiDesign Recommendations For Steel Deck Floor Slabswayzane100% (1)

- Table 1 of Road Note 27 PDFDocument1 paginăTable 1 of Road Note 27 PDFFlavioMuhaleÎncă nu există evaluări

- Meet The Experts - Steel JoistsDocument2 paginiMeet The Experts - Steel Joistsseth_gzbÎncă nu există evaluări

- Zamil Steel PDFDocument12 paginiZamil Steel PDFAshishÎncă nu există evaluări

- MiTeK Gable End and BracingDocument4 paginiMiTeK Gable End and BracingSam LeungÎncă nu există evaluări

- Almas-Tower Structural DesignDocument12 paginiAlmas-Tower Structural DesignBalaji PalaniÎncă nu există evaluări

- Reinforced Concrete Slab DesignDocument70 paginiReinforced Concrete Slab DesignLeandro Madeira100% (1)

- Labone Office Complex Structural Design Report Rev 01 PDFDocument99 paginiLabone Office Complex Structural Design Report Rev 01 PDFBoris Escubio100% (1)

- Steel JoistDocument20 paginiSteel JoistMahfuzur RahmanÎncă nu există evaluări

- Design of Industrial Crane Building Frame and Structural ComponentsDocument42 paginiDesign of Industrial Crane Building Frame and Structural ComponentsAizaz ShaikhÎncă nu există evaluări

- Appendix ADocument42 paginiAppendix Ayliu8877100% (1)

- CIDECT Design Guide 1 2008 - CLDocument142 paginiCIDECT Design Guide 1 2008 - CLChiong Lee100% (1)

- Assignment 1 GRAD 2019Document4 paginiAssignment 1 GRAD 2019RamonErnestoICÎncă nu există evaluări

- Microsoft Word - Design Station Purlins & Girts-Rev3Document31 paginiMicrosoft Word - Design Station Purlins & Girts-Rev3khairul4008Încă nu există evaluări

- Scaffolding: Presented by AglaiaDocument15 paginiScaffolding: Presented by AglaiaMuhammad AmmarÎncă nu există evaluări

- Lintel BeamDocument3 paginiLintel BeamVarinder SinghÎncă nu există evaluări

- Cold Formed SteelDocument66 paginiCold Formed Steelarkirthi1175Încă nu există evaluări

- BS8110 Simply Supported Slab DesignDocument8 paginiBS8110 Simply Supported Slab DesignRavish RavindraÎncă nu există evaluări

- Hollow Core Planks Application and Design GuideDocument46 paginiHollow Core Planks Application and Design Guidemixi1978100% (1)

- Sherman - Extended Shear TabsDocument148 paginiSherman - Extended Shear TabsRohan KarandeÎncă nu există evaluări

- Fischer THB INT 110640 082013Document445 paginiFischer THB INT 110640 082013arunks4uÎncă nu există evaluări

- Seismic Design of Industrial StructuresDocument73 paginiSeismic Design of Industrial StructuresBang Success100% (1)

- Part 6 Analysis and Design of Purlins W PDFDocument17 paginiPart 6 Analysis and Design of Purlins W PDFCalvin TehÎncă nu există evaluări

- CrossLam CLT CA Design Guide 1Document32 paginiCrossLam CLT CA Design Guide 1lavignenoeÎncă nu există evaluări

- Metal StairsDocument6 paginiMetal Stairssks_242Încă nu există evaluări

- Structural Steel Design Fabrication and Construction 00Document60 paginiStructural Steel Design Fabrication and Construction 00Dedy KristiantoÎncă nu există evaluări

- Serviceability MBMADocument2 paginiServiceability MBMAabdulloh_99100% (1)

- CW ManualDocument281 paginiCW ManualShamim Ahsan Zubery100% (2)

- Steel Roof Truss DesignDocument29 paginiSteel Roof Truss DesignKiki Setiawan75% (4)

- Staircase Control BLDG Calc (Copy)Document4 paginiStaircase Control BLDG Calc (Copy)Mon LeeÎncă nu există evaluări

- Seismic Evaluation of Existing Buildings and Strengthening TechniquesDocument12 paginiSeismic Evaluation of Existing Buildings and Strengthening TechniquesSujan ShresthaÎncă nu există evaluări

- Design of High-Rise BuildingsDocument23 paginiDesign of High-Rise BuildingsBehairy Ahmed0% (1)

- Tedds Engineering Library (AU)Document79 paginiTedds Engineering Library (AU)CSEC Uganda Ltd.Încă nu există evaluări

- Deep Beam Flexure and Shear DesignDocument40 paginiDeep Beam Flexure and Shear DesignPragya Roy95% (39)

- Reinforced Concrete Column Combined Footing Analysis DesignDocument19 paginiReinforced Concrete Column Combined Footing Analysis DesignHaseeb Ahmed100% (1)

- Moment Distribution Method ExplainedDocument37 paginiMoment Distribution Method ExplainedSuleiman Yusuf JibrilÎncă nu există evaluări

- ROOF TRUSS DESIGN AND MAINTENANCE GUIDEDocument36 paginiROOF TRUSS DESIGN AND MAINTENANCE GUIDETaufiq PrihantoroÎncă nu există evaluări

- Steel DeckDocument38 paginiSteel Deckrabih87100% (1)

- Table of Contents Pti 6thDocument5 paginiTable of Contents Pti 6thDuy Linh NguyễnÎncă nu există evaluări

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- The Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionDe la EverandThe Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionÎncă nu există evaluări

- Structures Failures Reasons and MitigationDe la EverandStructures Failures Reasons and MitigationÎncă nu există evaluări

- Structural and Crane Load Design CriteriaDocument13 paginiStructural and Crane Load Design CriteriaMontoya SantiagoÎncă nu există evaluări

- NBC 2005 Snow, Wind and Earthquake Load Design Criteria For Steel Building SystemsDocument46 paginiNBC 2005 Snow, Wind and Earthquake Load Design Criteria For Steel Building SystemsArif RiyadÎncă nu există evaluări

- Untitled Attachment 00050Document109 paginiUntitled Attachment 00050Amr HassanÎncă nu există evaluări

- Taddy House AnalysisDocument138 paginiTaddy House AnalysisShane Talan MagtagñobÎncă nu există evaluări

- NBCC 2015: Design Load Criteria For Steel Building SystemsDocument61 paginiNBCC 2015: Design Load Criteria For Steel Building SystemsalbertoxinaÎncă nu există evaluări

- Bes A002 2005Document11 paginiBes A002 2005Deputy Chief Engineer TransgridÎncă nu există evaluări

- Precast Balanced Cantilever BridgeDocument139 paginiPrecast Balanced Cantilever Bridgeوائل محمد محمودÎncă nu există evaluări

- 2006 Structural Seismic Design Manual 1Document32 pagini2006 Structural Seismic Design Manual 1Julio Rafael Terrones Vásquez100% (1)

- (International Code) Seismic Design Manual - IEBC 2009Document36 pagini(International Code) Seismic Design Manual - IEBC 2009MIKHA20140% (3)

- Two Storied Shed-2 - (30-08-21)Document116 paginiTwo Storied Shed-2 - (30-08-21)MD SohagÎncă nu există evaluări

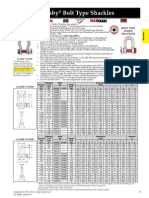

- Kukmc 0378 UsDocument2 paginiKukmc 0378 Usaiyubi2Încă nu există evaluări

- Kukmc 0377 UsDocument2 paginiKukmc 0377 Usaiyubi2Încă nu există evaluări

- Kukmc 0376 UsDocument12 paginiKukmc 0376 Usaiyubi2Încă nu există evaluări

- 200 60 IndustrialDocument8 pagini200 60 Industrialaiyubi2Încă nu există evaluări

- Heavy duty fifth wheel couplings JSK 38 C-1-2Document2 paginiHeavy duty fifth wheel couplings JSK 38 C-1-2aiyubi2Încă nu există evaluări

- Kukmc 0375 UsDocument4 paginiKukmc 0375 Usaiyubi2Încă nu există evaluări

- Kukmc 0328 UsDocument8 paginiKukmc 0328 Usaiyubi2Încă nu există evaluări

- Hose Clamps and Ferrules for Assembly of Different FittingsDocument6 paginiHose Clamps and Ferrules for Assembly of Different Fittingsaiyubi2Încă nu există evaluări

- Kukmc 0328 UsDocument8 paginiKukmc 0328 Usaiyubi2Încă nu există evaluări

- Kukmc 0258 UsDocument2 paginiKukmc 0258 Usaiyubi2Încă nu există evaluări

- 400-20 (Meter Manual)Document28 pagini400-20 (Meter Manual)edwinramonÎncă nu există evaluări

- MS100-00 (M-MA Series Meter Specs)Document6 paginiMS100-00 (M-MA Series Meter Specs)aiyubi2Încă nu există evaluări

- Acf Fastener HandbookDocument84 paginiAcf Fastener Handbookninjanear2012100% (2)

- DODGE Torque-Arm Speed Reducer Feature BenefitDocument4 paginiDODGE Torque-Arm Speed Reducer Feature Benefitaiyubi2Încă nu există evaluări

- Repair Manual JSK 38Document38 paginiRepair Manual JSK 38aiyubi2Încă nu există evaluări

- A-344, A-347 Master LinkDocument1 paginăA-344, A-347 Master LinkAekJayÎncă nu există evaluări

- Fifthwheel - JOST JSK 38CDocument2 paginiFifthwheel - JOST JSK 38Caiyubi2100% (2)

- C-Line - Front & Back CoversDocument4 paginiC-Line - Front & Back Coversaiyubi2Încă nu există evaluări

- CROSBY Master Link & Shackles - MetricDocument2 paginiCROSBY Master Link & Shackles - Metricaiyubi2Încă nu există evaluări

- DRIV-LOK Press Fit FastenersDocument28 paginiDRIV-LOK Press Fit Fastenersaiyubi2Încă nu există evaluări

- Blind FastenersDocument7 paginiBlind Fastenersaiyubi2Încă nu există evaluări

- Coel Catalogue 2006 1Document58 paginiCoel Catalogue 2006 1Danilo MontesanoÎncă nu există evaluări

- Wire Rope ThimblesDocument1 paginăWire Rope Thimblesaiyubi2Încă nu există evaluări

- CROSBY Master Link & Shackles - MetricDocument2 paginiCROSBY Master Link & Shackles - Metricaiyubi2Încă nu există evaluări

- Crosby G-2130Document1 paginăCrosby G-2130AekJayÎncă nu există evaluări

- Tranz Couplings CatalogDocument4 paginiTranz Couplings Catalogaiyubi2Încă nu există evaluări

- Crosby Mckissick Sheaves CatalogDocument29 paginiCrosby Mckissick Sheaves Catalogaiyubi2Încă nu există evaluări

- APEX U-Joint CatalogDocument28 paginiAPEX U-Joint Catalogaiyubi2Încă nu există evaluări

- A-344 & A347 Welded Master Link - ImperialDocument1 paginăA-344 & A347 Welded Master Link - Imperialaiyubi2Încă nu există evaluări

- Universal JointsDocument10 paginiUniversal JointsshashanksekharÎncă nu există evaluări

- Commerce PROJECT For CLASS 11Document21 paginiCommerce PROJECT For CLASS 11jasdeep85% (67)

- Nuclear Power in The United KingdomDocument188 paginiNuclear Power in The United KingdomRita CahillÎncă nu există evaluări

- Print Bus 100 CH 13 - QuizletDocument2 paginiPrint Bus 100 CH 13 - QuizletMac TorejaÎncă nu există evaluări

- Commercial Real Estate Case StudyDocument2 paginiCommercial Real Estate Case StudyKirk SummaTime Henry100% (1)

- 1982 SAMAHAN ConstitutionDocument11 pagini1982 SAMAHAN ConstitutionSAMAHAN Central BoardÎncă nu există evaluări

- Class 32 Infill Exemption CriteriaDocument3 paginiClass 32 Infill Exemption CriteriaDaniel JimenezÎncă nu există evaluări

- Form 1 Sentence Indication Practice Direction: Number ... of 2016 Request For Sentence Indication (Direction 3.3 Procedure')Document3 paginiForm 1 Sentence Indication Practice Direction: Number ... of 2016 Request For Sentence Indication (Direction 3.3 Procedure')Gail HoadÎncă nu există evaluări

- QSPOT571423: Create Booking Within 24 HoursDocument2 paginiQSPOT571423: Create Booking Within 24 HoursNaimesh TrivediÎncă nu există evaluări

- Property ValuationDocument2 paginiProperty Valuationprazol112233Încă nu există evaluări

- Tax RTP May 2020Document35 paginiTax RTP May 2020KarthikÎncă nu există evaluări

- Marking Guide for Contract Administration ExamDocument7 paginiMarking Guide for Contract Administration Examრაქსშ საჰაÎncă nu există evaluări

- Kenya Methodist University Tax Exam QuestionsDocument6 paginiKenya Methodist University Tax Exam QuestionsJoe 254Încă nu există evaluări

- Islamic Mangement Vs Conventional ManagementDocument18 paginiIslamic Mangement Vs Conventional Managementlick100% (1)

- Itin1263560672051514255713 PDFDocument2 paginiItin1263560672051514255713 PDFmoha salaÎncă nu există evaluări

- Assignment No 1. Pak 301Document3 paginiAssignment No 1. Pak 301Muhammad KashifÎncă nu există evaluări

- Deuteronomy SBJT 18.3 Fall Complete v2Document160 paginiDeuteronomy SBJT 18.3 Fall Complete v2James ShafferÎncă nu există evaluări

- BPT Bulletproof Standards SmallDocument1 paginăBPT Bulletproof Standards Smallalex oropezaÎncă nu există evaluări

- The FALSE POPE - Saint HildegardDocument2 paginiThe FALSE POPE - Saint HildegardJoseph Dwight100% (1)

- Eepc Foreign TradeDocument3 paginiEepc Foreign Tradepeerspot.me3Încă nu există evaluări

- The Revolt of 1857: Causes, Nature, Importance and OutcomesDocument8 paginiThe Revolt of 1857: Causes, Nature, Importance and OutcomesMaaz AlamÎncă nu există evaluări

- Comprehension and Essay Writing Junior Judicial Assistant Delhi High Court 2012Document2 paginiComprehension and Essay Writing Junior Judicial Assistant Delhi High Court 2012varaki786Încă nu există evaluări

- Mullane vs. Central Hanover Bank & Trust Co., Trustee, Et AlDocument20 paginiMullane vs. Central Hanover Bank & Trust Co., Trustee, Et AlAngelica LeonorÎncă nu există evaluări

- Shakespeare and The Middle Ages 2009 PDFDocument310 paginiShakespeare and The Middle Ages 2009 PDFgianiÎncă nu există evaluări

- SSS v. Favila, GR No. 170195, March 28, 2011Document1 paginăSSS v. Favila, GR No. 170195, March 28, 2011MonicaCelineCaroÎncă nu există evaluări

- Compromise AgreementDocument2 paginiCompromise AgreementPevi Mae JalipaÎncă nu există evaluări

- Mila Exam LegalDocument2 paginiMila Exam LegalSarmila ShanmugamÎncă nu există evaluări

- DepEd Mandaluyong City outlines COVID-19 work arrangementsDocument18 paginiDepEd Mandaluyong City outlines COVID-19 work arrangementsRenante SorianoÎncă nu există evaluări

- What Is Leave Travel Allowance or LTADocument3 paginiWhat Is Leave Travel Allowance or LTAMukesh UpadhyeÎncă nu există evaluări

- Routing Slip: Document Tracking SystemDocument8 paginiRouting Slip: Document Tracking SystemJeffrey Arligue ArroyoÎncă nu există evaluări

- Faculty - Business Management - 2023 - Session 1 - Pra-Diploma Dan Diploma - Eco211Document16 paginiFaculty - Business Management - 2023 - Session 1 - Pra-Diploma Dan Diploma - Eco2112021202082Încă nu există evaluări