Documente Academic

Documente Profesional

Documente Cultură

Compressors

Încărcat de

parvin.fDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Compressors

Încărcat de

parvin.fDrepturi de autor:

Formate disponibile

Compressors

COMPRESSORS

Khalafallah 07/09

COMPRESSORS

/

235

Compressors

PURPOSES OF COMPRESSION

1. To transmit power, as in a compressed

air system for operating pneumatic

tools;

Khalafallah 07/09

/25

tools;

2. To provide air for combustion;

3. To transport and distribute gas, as in

natural gas pipelines and city gas

distribution systems;

Compressors

PURPOSES OF COMPRESSION

4. To circulate a gas through a process

or a system; and,

Khalafallah 07/09

/25

5. To produce and maintain reduced

pressure levels for many purposes.

Compressors

METHODS OF COMPRESSION

1. Trap consecutive quantities of gas in

some type of enclosure, reduce the

volume, thus increasing the pressure,

Khalafallah 07/09

/25

volume, thus increasing the pressure,

then push the compressed gas out of

the enclosure.

Compressors

METHODS OF COMPRESSION

2. Trap consecutive quantities of gas in

some type of enclosure, reduce the

volume, thus increasing the pressure,

Khalafallah 07/09

/25

volume, thus increasing the pressure,

then push the compressed gas out of

the enclosure.

Compressors

METHODS OF COMPRESSION

3. Compress the gas by the mechanical

action of rapidly rotating impellers or

bladed rotors that impart velocity and

Khalafallah 07/09

/25

bladed rotors that impart velocity and

pressure to the flowing gas (velocity is

further converted into pressure in

stationary diffusers or blades).

Compressors

METHODS OF COMPRESSION

4. Entrain the gas in a high velocity jet of

the same or another gas and convert

the high velocity of the mixture into

Khalafallah 07/09

/25

the high velocity of the mixture into

pressure in a diffuser.

Compressors

Types Of Compressors

Positive-Displacement

(Intermittent Flow)

Khalafallah 07/09

/25

Rotary Reciprocating

Sliding-vane Straight-lobe

Liquid-Piston Helical-lobe

Compressors

Types Of Compressors

Dynamic

(Continuous Flow)

Khalafallah 07/09

/25

Turbo compressor

Ejector

Centrifugal

Axial Flow Mixed Flow

Compressors

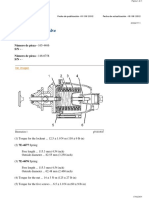

Khalafallah 07/09

/25

Single-stage reciprocating

compressor

Rotary (sliding Vane)

compressor

1-Casing 2- rotor 3-Vane 4-Intake;

5-discharge nozzle

Compressors

Khalafallah 07/09

/25

Two-stage centrifugal

compressor.

Axial-flow compressor (seven-stage).

1-rotating blades ; 2-compreasor

rotor, 3-stator blades

Compressors

SOME DEFINITIONS AND UNITS OF

MEASUREMENTS

The user of compression equipment

is interested primarily in the

Khalafallah 07/09

/25

is interested primarily in the

quantity of gas handled between the

initial and final pressure and

temperature conditions and in the

power required.

Compressors

Pressure is expressed as a force (weight) per

unit of the area exposed to the pressure.

Pressure is usually measured by a gauge that

registers the difference between the pressure

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

1-Pressure

Khalafallah 07/09

/25

registers the difference between the pressure

in a vessel and the current atmospheric

pressure. It is usual to express pressure in:

Pounds/sq. in (psi)

Kilograms/sq. cm (kg/cm2)

Kilopascals (kPa)

Bar (10

5

Pa)

Compressors

The International Atmosphere is defined as the

weight of the column of air existing above the

earth's surface at45lat. and sea level. It is

equivalent to 14.696 psi or 1.0333

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

1-Pressure

Khalafallah 07/09

/25

equivalent to 14.696 psi or 1.0333

Kg/cm2(1.0133 bar) and is usually expressed

as ata meaning atmospheres absolute.

Compressors

A gas is said to be under vacuum when its

pressure is below atmospheric. Vacuum is

usually measured by a differential gauge that

shows the difference in pressure between that

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

2- Vacuum

Khalafallah 07/09

/25

shows the difference in pressure between that

in the system and the atmosphere. The

measured pressure is a gauge pressure and it

is usually expressed as mm Hg Vac, in Hg Vac

or psi Vac....

Compressors

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

2- Vacuum

Subtracting the vacuum reading from the

atmospheric pressure will give an absolute

pressure which is accurate. This may be

expressed as: in Hg abs., mm Hg abs., psi

Khalafallah 07/09

/25

expressed as: in Hg abs., mm Hg abs., psi

abs...... The term torr means one mm Hg abs.

It is infrequently used.

Compressors

Atmospheric pressure

Vacuum

gauge pressure

absolute pressure

Khalafallah 07/09

/25

absolute zero pressure

absolute pressure

Compressors

The compressor designer must determine the

actual volume of gas to be handled at the

inlet of most types of compressors.

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

3-Volume

Khalafallah 07/09

/25

Volume flow rates may be expressed in:

Cu ft/min (cfm)

Standard Cu ft/min (Scfm)

Millions of Cu ft/24hr (MMCF/D)

Cubic meters/Sec (m

3

/s)

Compressors

In the US, the usual standard is 14.696 psia

and 60F. Europeans normally use one ata and

0C. MMCFD, called Million Cu ft per day is

originated in the natural gas pipeline industry

which it usually refers to volume at 14.4 pisa

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

3-Volume

Khalafallah 07/09

/25

which it usually refers to volume at 14.4 pisa

and inlet temperature.

Volume or weight rates are often given as dry

(no water vapor). Specified conditions should

include a flat statement that the relative

humidity is zero, 100% or some in between

figure (partially saturated).

Compressors

The compressor engineer must determine the

energy flow during compression, not only to

properly size the driver needed, but to

provide cooling media as required. Units used

SOME DEFINITIONS AND UNITS OF MEASUREMENTS

4-Power

Khalafallah 07/09

/25

provide cooling media as required. Units used

are well-defined and as listed below are really

rates:

Horsepower (hp)

Kilowatt (kW)

Compressors

Khalafallah 07/09

/25

Comparison between characteristics of different compressor types

Compressors

Khalafallah 07/09

/25

Comparison of power characteristics of different compressor types

Compressors

Khalafallah 07/09

/25

Compressors

Khalafallah 07/09

/25

Compressors

Advantages of Positive Displacement- and Turbo-Compressors

Positive Displacement Turbocompressors

Advantages available for small and

large capacities

good rangeability

usually high efficiency

suitable for light and

heavy gases

large capacities

Steady flow

relatively small dimensions

for large capacities

little maintenance

Khalafallah 07/09

/25

heavy gases

high reliability

no oil contamination

no valves

low maintenance cost

low wear

low noise

no severe vibration

problems

light foundation

Compressors

Disadvantages of Positive Displacement- and Turbo-Compressors

Positive Displacement Turbocompressors

Disadvantages much maintenance

required

low reliability

often noisy

often severe vibration

problems

not suitable for small

capacities

limited rangeability

(surge/stonewall)

efficiency much

dependent upon good

Khalafallah 07/09

/25

problems

requires heavy foundation

not suitable for very large

capacities

dependent upon good

design and on operating

point

high compression ratio

difficult to obtain

less suitable for light

gases

Compressors

THERMODYNAMIC LAWS THERMODYNAMIC LAWS

The First Lawof Thermodynamics

This states that energy cannot be created

or destroyed during a process ( such as

Khalafallah 07/09

/24

or destroyed during a process ( such as

compression and delivery of a gas ),

although it may change from one form of

energy to another. In other words,

whenever a quantity of one kind of energy

disappears, an exactly equivalent total of

other kinds of energy must be produced

Compressors

THERMODYNAMIC LAWS THERMODYNAMIC LAWS

The Second Law of Thermodynamics

This is more abstract and can be stated

several ways.

Khalafallah 07/09

/24

1. Heat cannot, of itself, pass from a

colder to a hotter body.

2. Heat can be made to go from a body at

lower temperature to one at higher

temperature only if external work is

done.

Compressors

THERMODYNAMIC LAWS THERMODYNAMIC LAWS

3. The available energy of the isolated

system decreases in all real

processes.

The Second Law of Thermodynamics

Khalafallah 07/09

/24

processes.

4. Heat or energy (like water), of itself,

will flow only downhill.

Compressors

THERMODYNAMIC LAWS THERMODYNAMIC LAWS

The Second Law of Thermodynamics

In thermodynamics a measure of the

unavailability of energy has been devised

and is known as entropy .

Khalafallah 07/09

/24

and is known as entropy .

It is defined by the differential equation:

T

dQ

ds =

Compressors

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

An ideal or perfect gas is one to which

the laws of Boyle, Charles, and Amonton

apply. To the best of our knowledge there

Khalafallah 07/09

/24

apply. To the best of our knowledge there

are no such gases, but these laws are

used and corrected by compressibility

factors based on experimental data.

Compressors

The Perfect Gas Formula

Starting with Charles' and Boyle's Laws, it is

possible to develop the formula for a given

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

possible to develop the formula for a given

weight of gas.

pv=R

o

T

In this very useful form, R

o

is known as the

Universal Gas Constant.

Compressors

Partial Pressures

Vapor pressure created by one pure liquid

will not affect the vapor pressure of a

second pure liquid, when the liquids are

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

second pure liquid, when the liquids are

insoluble and non reacting and the liquid

sand/or vapors are mixed within the

same system.

Compressors

Partial Pressures

There is complete indifference on the

part of each component to the existence

of all others. The total vapor pressure for

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

of all others. The total vapor pressure for

the mixture is the sum of the vapor

pressures of the individual components.

This is Dalton's law and each individual

vapor has a partial pressure as

differentiated from the total pressure of

the mixture.

Compressors

Relative Humidity

Relative humidity is a term frequently

used to represent the quantity of

moisture (water vapor) present in a

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

moisture (water vapor) present in a

mixture although it uses partial pressures

in so doing. It is expressed as:

Pa

Pv

temperture mixture exisiting of pressure vapor saturated

pressure vapor partial actual

RH

100

100

(%)

=

Compressors

Specific Humidity

Specific humidity, used in calculations

on certain types of compressors, is a

totally different term. It is the ratio of

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

totally different term. It is the ratio of

the weight of water vapor to the weight

of dry air and is usually expressed as

pounds (or grains) of moisture per pound

of dry air.

Compressors

Specific Humidity

Wa

Wv

SH =

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

Pa

Pv

Pv P

Pv

SH

also

622 . 0 622 . 0

=

=

Where Pa is partial air pressure

Compressors

Degree of Saturation

The degree of saturation denotes the

actual relation between the weight of

moisture existing in a space and the

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

moisture existing in a space and the

weight that would exist if the space

saturated.

Pv P

Ps P

RH

saturated SH

actual SH

saturation of Degree

=

100

(%)

Compressors

Compressibility

All gases deviate from the perfect or

ideal gas laws to some degree. In some

cases the deviation is rather extreme. It

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

cases the deviation is rather extreme. It

is necessary that these deviations be

taken into account in many compressor

calculations to prevent compressor and

driver sizes being greatly in error.

Compressors

Compressibility

The ideal gas equation is therefore

modified to:

Ideal or Perfect Gas Laws Ideal or Perfect Gas Laws

Khalafallah 07/09

/24

pv=ZR

o

T

OR OR

Z = pv /R

o

T

Compressors

Two basic compression cycles or

processes are applicable to both

positive displacement and dynamic

compressors.

Compression Cycles

Khalafallah 07/09

/24

compressors.

Isothermal compression occurs when

the temperature is kept constant as

the pressure increases.

Compressors

This requires continuous removal of the

heat of compression.

Compression follows the formula:

Compression Cycles

Khalafallah 07/09

/24

Compression follows the formula:

P

1

V

1

= P

2

V

2

= Constant

Compressors

Adiabatic compression is obtained when

there is no heat added to or removed from

the gas during compression.

Compression Cycles

Khalafallah 07/09

/24

the gas during compression.

Compression follows the formula:

P

1

V

1

k

= P

2

V

2

k

= Constant

Compressors

Dynamic units, however, generally use the

polytropic cycle where the pV relationship

is:

Compression Cycles

Khalafallah 07/09

/24

is:

P

1

V

1

n

= P

2

V

2

n

= Constant

Compressors

P

r

e

s

s

u

r

e

Isothermal

Polytypic uncooled

(Dynamic)

Adiabatic (k)

Polytypic cooled

Khalafallah 07/09

/24

Compression cycles

Volume

Polytypic cooled

(Reciprocating)

Compressors

Compressor staging

All basic compressor elements regardless of

type, have certain limiting operating

conditions. When any limitation is involved

it becomes necessary to multistage the

Khalafallah 07/09

/24

it becomes necessary to multistage the

compression process; that is, do it in two

or more steps. Each step will utilize at

least one basic element designed to

operate in series with the other elements

of the machine.

Compressors

Compressor staging

1. Discharge temperature - all types;

The limitations vary with the type of

compressor, but the most important include

Khalafallah 07/09

/24

1. Discharge temperature - all types;

2. Pressure rise (or differential) - dynamic

units and most positive-displacement

types;

3. Compression ratio - dynamic units;

Compressors

Compressor staging

3.Effect of clearance - reciprocating

units (this ties in also with compression

ratio); and,

4.Desirability of saving power.

Khalafallah 07/09

/24

4.Desirability of saving power.

Compressors

Compressor staging

A reciprocating compressor usually requires

a separate cylinder for each stage with

intercooling of the gas between stages.

Khalafallah 07/09

/24

In a reciprocating unit, all cylinders are

commonly combined into one unit assembly

and driven from a single crankshaft.

Compressors

Compressor staging

Rotary positive-displacement compressors

can, in some instances, combine two stages

in one casing, but more often use two

separate machines properly sized for their

Khalafallah 07/09

/24

separate machines properly sized for their

individual requirement, with cooling

between stages. They will often have a

common driver and a common base plate.

Compressors

Positive Displacement

Compressors

Khalafallah 07/09

/66

Compressors

Compressors

Positive-displacement units are those in which

successive volumes of gas are confined within a

closed space and elevated to a higher pressure.

Khalafallah 07/09

/66

closed space and elevated to a higher pressure.

Two methods are used to compress gas. These

methods are :

Compressors

1. Trap consecutive quantities of gas in some

type of enclosure, reduce the volume, thus

increasing the pressure, then push the

compressed gas out of the enclosure.

Khalafallah 07/09

/66

2. Trap consecutive quantities of gas in some

type of enclosure, carry it without volume

change to the discharge opening, compress

the gas by backflow from the discharge

system, then push the compressed gas out of

the enclosure.

Compressors

The principle types of positive displacement

compressors are:

Reciprocating compressors are positive-displacement

machines in which the compressing and displacing

element is a piston having a reciprocating motion

Khalafallah 07/09

/66

element is a piston having a reciprocating motion

within a cylinder.

Rotary positive-displacement compressors are

machines in which compression and displacement

is effected by the positive action of rotating

elements.

Compressors

Sliding-vane compressors are rotary

positive-displacement machines in which

axial vanes slide radialy in a rotor

eccentrically mounted in a cylindrical casing.

Gas trapped between vanes is compress and

Khalafallah 07/09

/66

Gas trapped between vanes is compress and

displaced.

Liquid-piston compressors are rotary positive-

displacement machines in which water or

other liquid is used as the piston to compress

and displace the gas handled.

Compressors

Two-impeller straight-lobe compressors

are rotary positive-displacement machines in which

two straight mating lobed impellers trap gas and

carry it from intake to discharge. There is no

internal compression.

Khalafallah 07/09

/66

internal compression.

Helical- or spiral-lobe compressors are

rotary positive-displacement machines in which

two intermeshing rotors, each with a helical form,

compress and displace the gas.

Compressors

The basic reciprocating compression element

is a single cylinder compressing on only one

side of the piston (single-acting). A unit

compressing on both sides of the piston

1. THE RECIPROCATING COMPRESSOR

Khalafallah 07/09

/66

compressing on both sides of the piston

(double-acting) consists of two basic single-

acting elements operating in parallel in one

casting.

Compressors

The reciprocating compressor uses automatic

spring loaded valves that open only when the

proper differential pressure exists across the

valve. Inlet valves open when the pressure in

1. THE RECIPROCATING COMPRESSOR

Khalafallah 07/09

/66

valve. Inlet valves open when the pressure in

the cylinder is slightly below the intake

pressure. Discharge valves open when the

pressure in the cylinder is slightly above the

discharge pressure

Compressors

Compressor Classification Compressor Classification Compressor Classification Compressor Classification

Heavy-duty compressor Moderate duty compressor

Vertical or Y-type trunk piston

Cross head type

Khalafallah 07/09

/66

Vertical or Y-type trunk piston

Lubricated air cooled

Operating at high speed (high operating temperature)

Cross head type

Operating at low speeds

Compressors

Khalafallah 07/09

/66

Two-stage compressor designs with pressure stage

in individual cylinders

Compressors

Khalafallah 07/09

/66

Reciprocating compressor ;

schematic and indicator diagram.

compressor indicator diagram

showing cylinder clearance.

Compressors

Khalafallah 07/09

/66

Effect of compression ratio on

compressor capacity

Two-stage uniflow differential-

piston compressor

Compressors

Khalafallah 07/09

/66

Two-stage uniflow compressor. Theoretical indicator

diagram

Compressors

Khalafallah 07/09

/66

Two-stage single acting

differential-piston compressor

Two-stage single acting

differential-piston compressor.

Theoretical indicator diagram

Compressors

Khalafallah 07/09

/66

Three-stage differential-piston compressor

Three-stage differential-piston compressor

split in the first stage

six-stage differential-piston compressor

Compressors

Khalafallah 07/09

/66

Indicator functional diagram

1-Compressor cylinder;2-Compressor piston ;3-rectifiying mechanism; 4-

indicator cylinder ; 5-indicator diagram; 6-reducing gear; 7- indicator

driver; 8- indicator driver cords; 9- indicator pen

Compressors

Khalafallah 07/09

/66

Compressor indicator diagrams

Reciprocating compressor discharging into a given pipe line.

Characteristic curves for different rotative speeds.

Compressors

Six-stage angle

compressor

Khalafallah 07/09

/66

Compressors

Khalafallah 07/09

/66

Five-stage vertical

reciprocating compressor

Compressors

Khalafallah 07/09

/66

Two-stage opposed air compressor

Compressors

Khalafallah 07/09

/66

Plane of a four-cylinder, horizontal-opposed, heavy-duty compressor

(200 to more than 12000 HP)

Compressors

Khalafallah 07/09

/66

Compressors

Disk piston

Differential piston of three-stages

compressors

Khalafallah 07/09

/66

compressors

Compressors

Khalafallah 07/09

/66

Stuffing box with split metal packing rings

Compressors

Khalafallah 07/09

/66

Stuffing box with flexible metal packing rings

Compressors

Plate valve with

two annular slots

Khalafallah 07/09

/66

Disk valve of low-capacity

compressor

Compressors

Khalafallah 07/09

/66

Low-pressure uniflow valve design. principle of

operation

Compressors

Khalafallah 07/09

/66

Conventional water-cooled compressor cylinder

Compressors

Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor

The effect of added clearance is often use as a means of

capacity control. To obtain low clearance and a high

volumetric efficiency VE the designer finds that it

necessary to limit the size and number of valves. This

Khalafallah 07/09

/66

necessary to limit the size and number of valves. This

may tend to lower the efficiency of compression and

raise the horsepower. If a double-acting cylinder is

considered there are two clearance pockets in each end

four in all.

Compressors

Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor

There are five control steps. These are sized so that the

VE of either end with only one pocket open to the

cylinder is about half the fill load VE while with two

open; the VE is reduced to zero. Pockets may be

Khalafallah 07/09

/66

open; the VE is reduced to zero. Pockets may be

opened and closed manually or automatically. Full 3/4

1/2 1/4 and no load indicating diagrams for the double-

acting cylinder arc determined as indicated in Fig. 12.

corresponding pockets in low and high pressure

cylinders are opened or closed at the same time.

Compressors

Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor Clearance Control of Reciprocating Compressor

When clearance control is used to prevent driver

overload under variable pressure conditions the

pocket or pockets are often manually operated

Khalafallah 07/09

/66

Compressors

Typical Hand Operated

Inlet Valve Unloader for

high pressure valves

Khalafallah 07/09

/66

Compressors

Typical fixed volume

clearance pocket

Khalafallah 07/09

/66

Compressors

Variable volume

clearance pocket

Khalafallah 07/09

/66

Compressors

Khalafallah 07/09

/66

The operation of five-step clearance control

Compressors

Khalafallah 07/09

/66

Compressor capacity regulation

by suction throttling

Automatic system for capacity regulation

by suction throttling.

Compressors

Khalafallah 07/09

/66

Capacity regulation by holding the inlet valve

open. schematic

Compressors

Khalafallah 07/09

/66

Capacity regulation by holding the

inlet valve open.

Variable-clearance capacity control.

indicator diagram

Compressors

2. ROTARY COMPRESSORS

2.1 Sliding Vane Rotary Compressors

The rotary sliding-vane compressor has as its

basic element the cylindrical casing with its heads

and rotor assembly . When running at design

pressure, the theoretical indicator card is

Khalafallah 07/09

/66

pressure, the theoretical indicator card is

identical to the reciprocator. There is one

difference of importance, however. The

reciprocating unit has spring-loaded valves that

open automatically on small pressure differentials

between the outside and inside of the cylinder

Compressors

ROTOR WITH NON-METALLIC SLIDING

VANES.

GAS IS GRADUALLY COMPRESSED AS

POCKETS GET SMALLER.

Khalafallah 07/09

/66

AS ROTOR TURNS GAS IS TRAP- IN

POCKETS FORMAED BY VANES.

COMPRESSED GAS IS PUSHED OUT

THROUGH DISCHARGE PORT

Compressors

A. One used for stationary service is fitted for

standard lubrication is water jacketed and uses

water-cooled intercoolers on multistage unit.

This compressor has a narrow range of

capacity and pressure. The machine is built

in two types:

Khalafallah 07/09

/66

water-cooled intercoolers on multistage unit.

B. One has a combination lubrication and cooling

system (a radiation type oil cooler) and a water-

cooled exchanger) consisting of a flood of oil to

the machine at all times.

Compressors

The stationary water-cooled unit

2. ROTARY COMPRESSORS

2.1 Sliding Vane Rotary Compressors

The larger single-stage machines are offered only for the

lower pressures. Figure 14 presents a section of two-stage

Khalafallah 07/09

/66

lower pressures. Figure 14 presents a section of two-stage

unit with an intercooler. Single-stage boosters can be

supplied for working pressures up to 400 psig.

Compressors

When used as single-stage vacuum pumps unit sizes go to

approximately 686 mm Hg vacuum. Two-stage vacuum

pumps can be supplied for 759 mm Hg vacuum and three-

The stationary water-cooled unit

Khalafallah 07/09

/66

pumps can be supplied for 759 mm Hg vacuum and three-

stage for an even higher vacuum (lower absolute pressure).

Speeds for this type of compressor ranges between 575 and

1750 rpm depending on size

Compressors

These These These These units units units units can can can can be be be be fitted fitted fitted fitted for for for for outdoor outdoor outdoor outdoor

installation installation installation installation or or or or for for for for use use use use in in in in a aa a duty duty duty duty atmosphere atmosphere atmosphere atmosphere. .. .

The The The The discharge discharge discharge discharge and and and and intake intake intake intake have have have have high high high high frequency frequency frequency frequency

Characteristics

The stationary water-cooled unit

Khalafallah 07/09

/66

The The The The discharge discharge discharge discharge and and and and intake intake intake intake have have have have high high high high frequency frequency frequency frequency

pulsation pulsation pulsation pulsation. .. .

The The The The units units units units are are are are used used used used primarily primarily primarily primarily for for for for air air air air and and and and can can can can

handle handle handle handle other other other other dry dry dry dry gases gases gases gases or or or or gases gases gases gases containing containing containing containing

liquid liquid liquid liquid. .. .

40/48

Compressors

Khalafallah 07/09

/66

A ROTARY VANE COMPRESSOR

Compressors

Lubricated units

This This This This type type type type for for for for ratings ratings ratings ratings of of of of 125 125 125 125 HP HP HP HP and and and and higher higher higher higher takes takes takes takes 6 66 6

to to to to 20 20 20 20 % %% % more more more more power power power power than than than than the the the the reciprocating reciprocating reciprocating reciprocating

compressor compressor compressor compressor per per per per cfm cfm cfm cfm compressed compressed compressed compressed. .. . For For For For this this this this reason reason reason reason it it it it

The stationary water-cooled unit

Khalafallah 07/09

/66

compressor compressor compressor compressor per per per per cfm cfm cfm cfm compressed compressed compressed compressed. .. . For For For For this this this this reason reason reason reason it it it it

is is is is more more more more recently recently recently recently for for for for the the the the lower lower lower lower pressure pressure pressure pressure ranges ranges ranges ranges. .. .

water water water water cooled cooled cooled cooled vane vane vane vane type type type type rotates rotates rotates rotates may may may may generally generally generally generally be be be be

classed classed classed classed as as as as heavy heavy heavy heavy duty duty duty duty compressors compressors compressors compressors suitable suitable suitable suitable for for for for long long long long

periods periods periods periods at at at at fill fill fill fill load load load load. .. .

Compressors

Khalafallah 07/09

/66

The The operating operating cycle cycle of of aa two two- -impeller impeller straight straight- -lobe lobe rotary rotary compressor compressor

Compressors

Khalafallah 07/09

/66

Illustrative sections of a typical helical Illustrative sections of a typical helical- -lobe rotary compressor lobe rotary compressor

Compressors

A two A two A two A two- -- -impeller straight impeller straight impeller straight impeller straight- -- -lobe positive lobe positive lobe positive lobe positive

displacement compressor element consists of a displacement compressor element consists of a displacement compressor element consists of a displacement compressor element consists of a

casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or

The Two-Impeller Straight-Lobe Compressor

Khalafallah 07/09

/66

casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or casing containing duplicate symmetrical rotors or

impellers usually having a figure eight cross impellers usually having a figure eight cross impellers usually having a figure eight cross impellers usually having a figure eight cross

section. Some have three lobes. These intermesh, section. Some have three lobes. These intermesh, section. Some have three lobes. These intermesh, section. Some have three lobes. These intermesh,

are kept in phase by external timing gears, and are kept in phase by external timing gears, and are kept in phase by external timing gears, and are kept in phase by external timing gears, and

rotors in opposite directions. The term rotors in opposite directions. The term rotors in opposite directions. The term rotors in opposite directions. The term cycloidal cycloidal cycloidal cycloidal

often is used for this type even though the often is used for this type even though the often is used for this type even though the often is used for this type even though the

impellers may have other than cycloidal form impellers may have other than cycloidal form impellers may have other than cycloidal form impellers may have other than cycloidal form

Compressors

The Two-Impeller Straight-Lobe Compressor

There There There There is is is is no no no no compression compression compression compression or or or or reduction reduction reduction reduction of of of of gas gas gas gas

volume volume volume volume during during during during the the the the turning turning turning turning of of of of the the the the rotors rotors rotors rotors. .. . The The The The

rotors rotors rotors rotors merely merely merely merely move move move move the the the the gas gas gas gas from from from from the the the the inlet inlet inlet inlet to to to to the the the the

Khalafallah 07/09

/66

rotors rotors rotors rotors merely merely merely merely move move move move the the the the gas gas gas gas from from from from the the the the inlet inlet inlet inlet to to to to the the the the

discharge discharge discharge discharge. .. . Compression Compression Compression Compression is is is is by by by by back back back back flow flow flow flow into into into into the the the the

casing casing casing casing from from from from the the the the discharge discharge discharge discharge line line line line at at at at the the the the time time time time the the the the

discharge discharge discharge discharge port port port port is is is is uncovered uncovered uncovered uncovered. .. . I II I Displacement Displacement Displacement Displacement of of of of

the the the the compressed compressed compressed compressed gas gas gas gas into into into into the the the the discharge discharge discharge discharge system system system system

then then then then takes takes takes takes place place place place. .. . There There There There are are are are no no no no valves valves valves valves. .. .

Compressors

Khalafallah 07/09

/66

Steps in compression by a typical helical-lobe rotary compressor

Compressors

Diagram Diagram A A - The chamber of lobe A is full of gas at inlet

pressure and further intake will soon stop. Lobe B is

delivering gas at discharge pressure.

Diagram Diagram B B - Lobe A has closed the intake but has not yet

passed the edge of the discharge port. Lobe B is still

discharge.

Khalafallah 07/09

/66

Diagram Diagram CC - Lobe A has passed the discharge port

permitting discharge gas to flow into the chamber,

compressing the gas therein. The other side of Lobe A is

starting the intake cycle. Lobe B is still discharging.

Diagram Diagram DD - Lobe A is still discharging on one side and

filling its other chamber with intake gas. Lobe B has

completed intake for its second chamber and is about pass

the discharge port.

Compressors

Helical-Lobe Rotary Compressors

This machine is a two-rotor positive displacement

rotary unit compressing gas between the

intermeshing helical lobes and the rotor chambers of

the housing. The basic elements is the housing with

its enclosed rotor assemblies. The lobes on the two

Khalafallah 07/09

/66

its enclosed rotor assemblies. The lobes on the two

rotors are not identical. The male , or driven, rotor (

main rotor ) has a form that fits into the pocket of the

female, or gate, rotor. About 85 to 90 percent of the

power is used by the main rotor, the gate requiring

only 10 to 15 percent of the total power at the most.

Compressors

Helical-Lobe Rotary Compressors

There are two types, one using timing gears to

properly phase the two rotors at all times. This kind

requires no lubrication and sealing is by close

Khalafallah 07/09

/66

clearances. The second type uses a flood of oil

through the machine to lubricate and seal and to

cool the compressed gas. In this style, the timing

gears may, at times, be omitted.

Compressors

Reciprocating Compressor

Sizing

Khalafallah 07/09

/66

Sizing

Compressors

Reciprocating Compressor Sizing

Once the suction and discharge pressures, the suction

gas temperature, the required flow rate and the gas

composition are determined, a compressor can be

selected to do the job.

The selection will depend on the relative importance of

Khalafallah 07/09

/66

The selection will depend on the relative importance of

efficiency, reliability and cost, but certain principles will

always apply.

Compressors for a wide range of applications tend to

run with about the same piston speed. That is

compressors with a long stroke tend to run slower than

those with a short stroke. Further, short stroke

compressors tend to be of lighter construction with

lower allowable loads.

Compressors

For the best efficiency and reliability at the expense

of increased cost, a piston speed at the low end of

the normal range will be used.

The compressor speed and the stroke will then be

Khalafallah 07/09

/66

The compressor speed and the stroke will then be

determined by the horsepower requirement. A low

horse power application will require a light, low

stroke, high speed compressor. A high horse power

application will require a heavy, long stroke, low

speed compressor. If possible, larger compressors

are directly coupled to the driver. Thus the speed

range of available drivers may influence the selection

of the compressor.

Compressors

The number of stages must then be selected. One

consideration here is the allowable discharge

temperature; another is the pressure ratio capability

of the available cylinders as determined by their

fixed clearance; another is efficiency. If the

calculated discharge temperature using one stage is

Khalafallah 07/09

/66

calculated discharge temperature using one stage is

too high, obviously more stages are needed. During

preliminary sizing, the isentropic discharge

temperature can be used, but if a certain number of

stages creates a marginal situation, the discharge

temperature should be estimated more accurately.

As a first estimate, it can be assumed that equal

pressure ratios are used for all stages.

Compressors

In practice it is often good to take a higher pressure

ratio in the low pressure ratio stages and unload the

more critical higher pressure stages a little.

In almost all multi-stage applications the gas will be

cooled between stages. In this case, increasing the

number of stages, up to a limit, will increase the

efficiency of the compressor. This is because with

Khalafallah 07/09

/66

efficiency of the compressor. This is because with

intercooling, the compression more closely

approximates an isothermal compression with

resulting lower power requirement. An alternative

way of looking at this is on a pressure volume

diagram. The work required to compress the gas is

given by the area of the pressure vs volume

diagram.

Compressors

The figure shows a single-

and a two-stage

compression for a given

application. The diagram

for single stage

compression is 1-2-3-4-1.

For two-stage

compression, it is 1-5-6-7-

Khalafallah 07/09

/66

compression, it is 1-5-6-7-

3-8-4-1. As the interstage

gas is cooled (5-6), its

volume decreases. The

work done as given by the

areas of the diagrams is

obviously less in the two-

stage case than in the

single-stage case.

Effect of multistaging

Compressors

Further, if any liquids are condensed out of the gas

in the intercoolers, the liquids must be separated

from the gas and the mass of gas compressed

from that interstage to the final discharge is

reduced with a further resulting power reduction.

Khalafallah 07/09

/66

reduced with a further resulting power reduction.

However as stages are added, the number of

compressor valves the gas must flow through in

series, and the amount of interstage piping and

coolers increase.

Compressors

If too many stages are used, the pressure losses in

the valves and piping will offset the gains from

intercooling and the efficiency will be reduced.

The cost of a compressor to do a given task usually

increases as the number of stages is increased

Khalafallah 07/09

/66

increases as the number of stages is increased

because of the additional compressor cylinders,

coolers and piping.

In a few applications, there will be side streams

where gas either enters or leaves the process at

fixed pressures. These requirements may determine

the interstage pressures used.

Compressors

Once the number of stages is selected, the

cylinders for each stage can be selected. Usually a

selection will be made from cylinder designs

available. Knowing the inlet conditions and the

required capacity, and with the speed and stroke

already selected, the required cylinder bore can be

Khalafallah 07/09

/66

already selected, the required cylinder bore can be

estimated. The available cylinders can then be

checked to see which, if any, meet the

requirements.

The following must be checked. First, the pressure

rating of the cylinder must be adequate to be safe

at the design and any upset conditions.

Compressors

The cylinder rating should be higher than the relief

valve setting. Second, the frame load, rod load and

degrees of reversal must be within the rating for the

frame components. Third, the capacity calculated

with the minimum cylinder clearance allowing for all

Khalafallah 07/09

/66

with the minimum cylinder clearance allowing for all

losses must meet the requirements. Fourth, the

power requirement of this cylinder must not exceed

the power rating per throw of the frame

components. If all these requirements are met, a

suitable cylinder has been chosen. Additional

optimization may be needed to determine

Compressors

Additional optimization may be needed to

determine the best possible cylinder for this

application. If no cylinder can be found to meet

the requirements, then either a new cylinder must

be designed, a frame rated for a higher frame load

or horsepower per throw must be selected, or two

Khalafallah 07/09

/66

or horsepower per throw must be selected, or two

or more, smaller cylinders must be chosen to run

in parallel to meet the required flow. Note that if

smaller cylinders are used, the frame load and the

power per throw will be reduced.

Compressors

It is usual for smaller cylinders to be available in

higher pressure ratio versions, so all the

requirements can usually be met by using

multiple cylinders per stage.

The basic compressor sizing is then complete,

but must be checked at alternate design or upset

Khalafallah 07/09

/66

but must be checked at alternate design or upset

conditions. Additional factors such as the out-of-

balance force transmitted from the compressor to

the foundation, the potential for harmful torsional

vibrations in the crankshaft and drive train,

optimization of the compressor layout, efficiency,

and cost will be considered before the design is

finalized.

Compressors

Reciprocating compressors are categorized

primarily by the frame. Each style of frame has an

optimum horsepower range and speed range. Each

frame style also has an array of cylinders, varying in

Methods of Rating

Reciprocating Compressors

Khalafallah 07/09

/66

frame style also has an array of cylinders, varying in

bore diameter and pressure rating, that are

designed for compatibility with the frame.

The primary considerations that limit the choice

of compressor style, presented somewhat in order

of relative importance, are:

Compressors

Number of services and/or stages;

Inlet volume capacity;

Discharge pressure;

Inlet pressure;

Physical characteristics of the gas including ratio

of heat capacity, molecular weight, and

Khalafallah 07/09

/66

of heat capacity, molecular weight, and

compressibility;

Inlet temperature;

Anticipated allowable down-time;

Type of motive power available.

Other factors such as chemical corrosiveness,

chemical toxicity, available foundation space, or

special oil-contamination limitations may also take on

varying degrees of importance.

Compressors

A preliminary calculation of the horsepower can be

arrived using the first six parameters listed above.

Allowances must be made for the mechanical

efficiency and the compression efficiency. At this

point, the design engineer must rely on model

availability data from manufacturers. The

Khalafallah 07/09

/66

availability data from manufacturers. The

anticipated maximum horsepower will place the

service in a range of frame styles. However,

consideration of the seventh parameter, allowable

downtime, will narrow the range considerably.

Higher speed units, although less expensive, will

tend to have shorter run times between service

periods than slower speed units.

Compressors

The selection of a frame style from any individual

manufacturer will fix the range of compatible

cylinders that are available. Each cylinder has a

specific internal diameter and a maximum working

pressure. The total piston displacement of the

cylinder being considered is determined by the

internal area of the cylinder, the size of the piston

Khalafallah 07/09

/66

internal area of the cylinder, the size of the piston

rod, the stroke (piston travel distance allowed by the

crankshaft), and the rotational speed of the

crankshaft.

Consideration of piston displacements, which must

be greater than the CFM of the intended service,

together with the cylinder pressure ratings will

narrow the range of cylinders for the application.

Compressors

Consideration must also be given to the "rod

load" or "pin load" rating of the compressor

frame. This must be compared to the maximum

force imposed by the differential pressure on the

cylinders, since this force is transmitted down the

piston rod and/or connecting rod and onto the

Khalafallah 07/09

/66

piston rod and/or connecting rod and onto the

running gear and bearings within the frame.

When the range of cylinders has been narrowed

to this point, a closer approximation of the gas

handling capabilities of a cylinder may be

obtained by an evaluation of the volumetric

efficiency.

Compressors

Evaluation of the volumetric efficiency requires a

knowledge of the cylinder clearance volume, which

is commonly expressed as a percentage of the

piston displacement. In most cases, the clearance

designed into a cylinder will be between 3 and 16%.

Precise evaluation of the volumetric efficiency also

Khalafallah 07/09

/66

Precise evaluation of the volumetric efficiency also

requires information concerning the pressure losses

at the inlet valves, as well as empirical data

concerning the rate at which a particular gas slips

past the piston rings, rod packing, and cylinder

valves. Reliance on the manufacturer's method of

calculation is, of course, necessary for guaranteed

performance.

Compressors

There are several items regarding the application

of reciprocating compressors that must be

considered. If these items are neglected, they may

cause a great deal of concern when the inevitable

problem occurs.

Application Notes

Khalafallah 07/09

/66

Reciprocating compressors are not fond of liquids

of any sort, particularly when delivered with the

inlet gas stream. For any application a good sized

suction drum with drain provision is in order. It

may be a part of the pulsation control if properly

done.

Compressors

If the stream is near saturation or has a

component near saturation, consideration should

be given to using a horizontally oriented cylinder

configuration, with the discharge nozzle on the

bottom side of the cylinder. While on the subject of

condensation, for the same gas near saturation,

cylinder cooling must be monitored and controlled

Khalafallah 07/09

/66

cylinder cooling must be monitored and controlled

to prevent gas condensation inside the cylinder.

It would appear obvious for startup, and in some

cases full time operation, that a suction strainer or

filter is mandatory. The reason for the strainer is to

keep junk and pipe scale out of the compressor.

Compressors

Fines from pipe scale and rust will make short

work of the internal bore of a cylinder and are not

all that good for the balance of the components. In

some severe cases cylinders have been badly

damaged in a matter of a few weeks. The strainer

should be removable in service for cleaning,

Khalafallah 07/09

/66

should be removable in service for cleaning,

particularly when it is intended for permanent

installation. Provision must be made to monitor

the condition of the strainer. Much frustration has

been expended because a compressor was

overheating or losing capacity and no one knew if

the strainer had fouled or blinded.

Compressors

The discharge temperature should be limited to

300F as recommended by API 618. Higher

temperatures cause problems with lubricant

coking and valve deterioration. In non-lube service

the ring material is also a factor in setting the

temperature limit. While 300F doesn't seem all

that hot, it should be remembered that this is an

Khalafallah 07/09

/66

that hot, it should be remembered that this is an

average outlet temperature, whereas the cylinder

will have "hot" spots exceeding this temperature.

Finally, planning may save money and time if

process changes are foreseeable. For instance,

capacity increase, or an increase in molecular

weight due to a catalyst change, results in

decreased volumetric flow.

Compressors

Although the cylinders must be sized for

economical operation at the present rate, the

frame can be sized for future applications. When

the future conditions become a reality, the

Khalafallah 07/09

/66

the future conditions become a reality, the

cylinders can be changed while keeping the

same frame. This saves the investment cost and

delivery time of a complete new compressor

without the penalty of over-sizing and its

inherent inefficient operation.

Compressors

BASIC THEORY OF

TURBOCOMPRESSORS

Khalafallah 07/09

/87

TURBOCOMPRESSORS

Compressors

BASIC THEORY

Turbo-compressors belong to the group of

compressors which are based on the dynamic

principle where kinetic energy is imparted by a

rotating impeller to a gas in order to keep it

Khalafallah 07/09

/87

rotating impeller to a gas in order to keep it

continuously flowing, while a suitable diffuser

converts this kinetic energy into pressure energy.

When the gas flow with respect to the shaft is in the

radial direction, the compressor is called centrifugal

or radial compressor.

Compressors

When the main direction of flow is parallel to the

shaft, the compressor is called axial flow compressor.

The basic theory of both types of turbo compressors

is the same and is based on Eulers turbine equation

Khalafallah 07/09

/87

is the same and is based on Eulers turbine equation

which will be derived for a general case of flow and

then for a radial stage in the following.

Compressors

C2

C1

C1

C2

F

m

o

C

u2

C

r2

C

r2

Khalafallah 07/09

/87

C1

R

+

m

o

C

u1

C

r1

r1

r2

F= m

o

(

2

-

1

)

T= m

o

(

2

.

2

1

.

1

)

Compressors

Khalafallah 07/09

/87

Flow through a radial impeller

Compressors

( )

( )

1 1 2 2

/

u u

o

U C U C m P W

r C r C m T

= =

=

(1)

(2)

Khalafallah 07/09

/87

( )

( )

1 2

1 1 2 2

/

u u

u u

C C U W

U C U C m P W

=

= = (2)

(3)

For axial stages

Compressors

Comparing equations (2) and (3), it is clear that

the work in a radial stage could be bigger than the

work in an axial stage and consequently the radial

stage gives a pressure ratio higher than the axial

one.

Khalafallah 07/09

/87

AFFINITY LAWS

These consider the effect of size and speed

on performance :

Volume flow rate N D

Specific work N

2

D

2

Power N

3

D

5

Compressors

Gas Pressure Ratio

Neglecting heat loss,

o o p

C

T

C

T c

T T c w

1

2

2

2

1 2

) (

(

(

|

|

|

|

+

|

|

|

|

+ =

=

Khalafallah 07/09

/87

( )

p

u u

p

c

C U C U

C C

T

T

C

T

C

T c

1 1 2 2

2

2

1

2

1

2

1

1

2

2

2 2

2 2

+

|

|

\

|

+

=

(

|

|

\

+

|

|

\

+ =

Compressors

( ) ( )

3 2

2

2

1

1

2 2

1

1 1 2 2

2

2

1

2

1

1 2

C C

ho ho

C U C U C C

T c

P P

n

n

u u

p

=

(

(

+ + =

(4)

Khalafallah 07/09

/87

The compression process through a compressor stage

is illustrated on the h-s chart :

2 2

3

2

3

2

2

2

C

T c

C

T c

p p

+ = +

(5)

Compressors

Khalafallah 07/09

/87

H-s diagram for a compressor

Compressors

( )

( )

( )

1

1 2

1 2

) 1 (

1

o p

o o

o s o

is

C U C U

T c

h h

h h

k

k

(6)

Khalafallah 07/09

/87

( )

1

1

1 1 2 2

1 1 2 2

1

(

(

=

k

k

o p

u u is

u u

T c

C U C U

C U C U

(7)

Compressors

PERFORMANCE OF CENTRIFUGAL

COMPRESSORS

IDEAL PERFORMANCE

The ideal characteristics of centrifugal compressors

depends essentially on the impeller exit angle 2.

Khalafallah 07/09

/87

depends essentially on the impeller exit angle 2.

The relation between specific work and

dimensionless flow rate is a straight line

relationship.

Compressors

At the design point, the minimum energy loss takes

place. At off design conditions the energy loss will be

higher. So, the shape of characteristic curve deviates

from the straight line relation ship.

Taking into consideration effect of leakage loss the

curve is shifted to the lift.

Khalafallah 07/09

/87

curve is shifted to the lift.

Surge effects will limit the relation ship at a certain

minimum value which represents the stability limit of

operation.

Choking limits flow rate to a certain maximum value

(on the right hand side of the performance curve -

stone wall).

Compressors

Khalafallah 07/09

/87

Performance of compressors

Compressors

CENTRIFUGAL COMPRESSORS

Khalafallah 07/09

/87

CENTRIFUGAL COMPRESSORS

Compressors

The centrifugal compressor has a limited stable

operating range. This may affect the economics of

operation at part load. The minimum capacity may vary

from 45 to 90% of rated capacity.

For commercial machines, an exit volume of

approximately 300 to 400 CFM from the last impeller is

Characteristics of Centrifugal Compressors

Khalafallah 07/09

/87

For commercial machines, an exit volume of

approximately 300 to 400 CFM from the last impeller is

generally considered the lower limit. These units

usually operate at 20,000 rpm or lower, with the trend

upward. They are well suited for direct connection to

steam-or gas-turbine drivers which permit variable-

speed control.

Compressors

Other features of these compressors include:

- high availability, they frequently operate;

without shutdown for 2 or 3 years;

- less maintenance and attendance costs as

Characteristics of Centrifugal Compressors

Khalafallah 07/09

/87

- less maintenance and attendance costs as

compared with reciprocators;

- require small and relatively inexpensive

foundations;

- have greater volume capacity per unit of building

space;

- bearings and seals can be designed so that no oil

can enter the gas stream.

Compressors

CASING TYPE

APPROXIMATE MAXIMUM RATINGS

Pressure Capacity-inlet Power

PsiG KpaG CFM m

3

/min BHP kW

A. Sectionalized

usually multistage

10 69 20,000 566 600 448

CLASSIFICATION CENTRIFUGAL COMPRESSORS

Khalafallah 07/09

/87

usually multistage

10 69 20,000 566 600 448

B. Horizontally split

Single stage (double suction)

Multistage

15

1,000

103

6,900

650,000

200,000

18,408

5,664

10,000

35,000

7,640

26,110

C. Vertically split

Single stage (double suction)

Overhung Pipeline

Multistage

30

1,200

5,500+

207

8,275

37,900

250,000

25,000

20,000

7,080

708

566

10,000

20,000

15,000

7,460

14,920

11,190

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Multi-stage centrifugal compressor with intercooling

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

Classification of Centrifugal Compressors

Sectionalized units are an assembly of similar sections, as

many sections are used as required to obtain the desired

number of stages. Casings are of fabricated steel or cast iron.

Such machines are simple and require limited supervision

and maintenance.

1-Sectionalized casing

Khalafallah 07/09

/87

and maintenance.

This design is used extensively in supplying air for

combustion in furnaces, ovens, as well as in pneumatic

conveying of materials, agitation and aeration, and many

miscellaneous applications requiring relatively low pressure

and small volumes.

Sectionalized units are normally built to standard sizes and

ratings.

Compressors

2-Horizontally split casing

Classification of Centrifugal Compressors

This is the preferred construction for the larger multistage

units and for some single stage machines, both within

pressure limitations.

The casing is usually of cast construction (iron or steel).

Khalafallah 07/09

/87

The casing is usually of cast construction (iron or steel).

Other materials may be used where necessary. The interior,

including shaft, impellers, bearings, and seals is readily

accessible for inspection and repair by removal of the top

half.

These units are used for a wide range of air and gas

applications and are well suited to process service.

Compressors

Classification of Centrifugal Compressors

3-Vertically split casing

This is available in three distinct single-stage (double suction)

and multistage designs.

The single stage design includes:

1.Low pressure with impeller overhung on motor shaft

2.Impeller overhung on a shaft carried by compressor

Khalafallah 07/09

/87

2.Impeller overhung on a shaft carried by compressor

bearings.

3. High pressure booster compressor (pipeline-type).

The multistage designs include:

1. Single shaft.

2. Multiple shaft for optimum speeds and efficiency.

Compressors

- Impellers

Impellers may be classed as open, semiclosed

and closed. The open and semiclosed impellers

may be cast, milled from a forging, or built by

welding.

Major Centrifugal Compressor Details

Khalafallah 07/09

/87

welding.

- Diaphragms

- lnterstage packings

- Journal & thrust bearings

- Balancing drum

- Shaft seals

- Gas cooling

Compressors

Three general methods are used to control

centrifugal compressors with variations and

refinements within each method. Control may be

designed to maintain constant inlet or discharge

pressure, inlet volume or inlet gas weight. These

methods include:

Methods of Control

Khalafallah 07/09

/87

pressure, inlet volume or inlet gas weight. These

methods include:

1. Variable speed steam turbine, variable speed

motor and hydraulic or magnetic coupling.

2. Blow off of unwanted output (to atmosphere or

recirculated).

3.Throttle intake, butterfly valve or inlet guide

vanes.

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

AXIAL COMPRESSORS AXIAL COMPRESSORS AXIAL COMPRESSORS AXIAL COMPRESSORS

Khalafallah 07/09

/87

Compressors

Axial Axial Axial Axial compressors compressors compressors compressors within within within within the the the the industrial industrial industrial industrial field field field field fit fit fit fit

principally principally principally principally into into into into the the the the low low low low- -- - and and and and moderate moderate moderate moderate- -- - pressure, pressure, pressure, pressure,

large large large large- -- -capacity capacity capacity capacity range range range range. .. . Compression Compression Compression Compression ratios ratios ratios ratios on on on on air air air air vary vary vary vary

between between between between 2 22 2 and and and and 5 55 5, ,, , with with with with a aa a maximum maximum maximum maximum of of of of about about about about 7 77 7 for for for for a aa a

large large large large unit unit unit unit in in in in one one one one casing casing casing casing. .. . Special Special Special Special designs designs designs designs for for for for higher higher higher higher

Khalafallah 07/09

/87

between between between between 2 22 2 and and and and 5 55 5, ,, , with with with with a aa a maximum maximum maximum maximum of of of of about about about about 7 77 7 for for for for a aa a

large large large large unit unit unit unit in in in in one one one one casing casing casing casing. .. . Special Special Special Special designs designs designs designs for for for for higher higher higher higher

ratios ratios ratios ratios are are are are available, available, available, available, but but but but are are are are not not not not generally generally generally generally applied applied applied applied

industrially industrially industrially industrially. .. .

Compressors

Some Some Some Some of of of of the the the the more more more more important important important important applications applications applications applications include include include include

supplying supplying supplying supplying air air air air for for for for: :: :

- -- - Gas Gas Gas Gas turbine turbine turbine turbine combustion combustion combustion combustion

- -- - Wind Wind Wind Wind tunnels tunnels tunnels tunnels

- -- - Blast Blast Blast Blast furnaces furnaces furnaces furnaces

Khalafallah 07/09

/87

- -- - Blast Blast Blast Blast furnaces furnaces furnaces furnaces

- -- - Air Air Air Air separation separation separation separation plants plants plants plants

- -- - Steam Steam Steam Steam boiler boiler boiler boiler pressurized pressurized pressurized pressurized forced forced forced forced draft draft draft draft

- -- - Agitation Agitation Agitation Agitation of of of of sewage sewage sewage sewage

- -- - Ventilation Ventilation Ventilation Ventilation

- -- - combustion combustion combustion combustion air air air air for for for for oil oil oil oil refinery refinery refinery refinery processes processes processes processes

Compressors

They They They They are are are are used used used used to to to to handle handle handle handle other other other other gases gases gases gases in in in in the the the the

following following following following applications applications applications applications: :: :

- -- - Catalytic Catalytic Catalytic Catalytic cracking cracking cracking cracking

- -- - Atomic Atomic Atomic Atomic reactor reactor reactor reactor gas gas gas gas cooling cooling cooling cooling

- -- - Petrochemical Petrochemical Petrochemical Petrochemical manufacture manufacture manufacture manufacture

Khalafallah 07/09

/87

- -- - Petrochemical Petrochemical Petrochemical Petrochemical manufacture manufacture manufacture manufacture

- -- - Natural Natural Natural Natural gas gas gas gas boosting boosting boosting boosting

The The The The capacities capacities capacities capacities now now now now being being being being handled handled handled handled in in in in axial axial axial axial compressors compressors compressors compressors of of of of

the the the the industrial industrial industrial industrial type type type type vary vary vary vary from from from from 25 25 25 25, ,, ,000 000 000 000 to to to to above above above above 1 11 1, ,, ,000 000 000 000, ,, ,000 000 000 000

inlet inlet inlet inlet CFM CFM CFM CFM ( (( (700 700 700 700 to to to to 28 28 28 28, ,, ,000 000 000 000 m mm m

3 33 3

/min) /min) /min) /min). .. .

Pressures Pressures Pressures Pressures are are are are generally generally generally generally well well well well below below below below 100 100 100 100 psig psig psig psig ( (( (690 690 690 690 kPag), kPag), kPag), kPag),

but but but but may may may may be be be be as as as as high high high high as as as as 500 500 500 500 psig psig psig psig ( (( (3450 3450 3450 3450 kPag) kPag) kPag) kPag). .. .

Compressors

The The The The axial axial axial axial- -- -flow flow flow flow compressor compressor compressor compressor is is is is usually usually usually usually made made made made up up up up of of of of

several several several several stages stages stages stages. .. . Each Each Each Each stage stage stage stage comprises comprises comprises comprises a aa a set set set set of of of of rotating rotating rotating rotating

blades blades blades blades and and and and stationary stationary stationary stationary blades, blades, blades, blades, both both both both being being being being circular circular circular circular two two two two- -- -

dimensional dimensional dimensional dimensional cascades cascades cascades cascades of of of of blades blades blades blades. .. . The The The The rotating rotating rotating rotating blades blades blades blades

are are are are attached attached attached attached to to to to rotor rotor rotor rotor disks disks disks disks or or or or a aa a drum drum drum drum and and and and the the the the stationary stationary stationary stationary

Axial-flow Compressor Stage

Khalafallah 07/09

/87

are are are are attached attached attached attached to to to to rotor rotor rotor rotor disks disks disks disks or or or or a aa a drum drum drum drum and and and and the the the the stationary stationary stationary stationary

blades blades blades blades are are are are rigidly rigidly rigidly rigidly fixed fixed fixed fixed in in in in the the the the compressor compressor compressor compressor casing casing casing casing. .. .

The The The The first first first first stage stage stage stage of of of of a aa a compressor compressor compressor compressor may may may may be be be be built built built built with with with with or or or or

without without without without inlet inlet inlet inlet guide guide guide guide vanes vanes vanes vanes. .. . The The The The last last last last stage stage stage stage is is is is always always always always

provided provided provided provided with with with with straightener straightener straightener straightener blades, blades, blades, blades, the the the the function function function function of of of of which which which which

is is is is to to to to remove remove remove remove swirl swirl swirl swirl from from from from the the the the flow flow flow flow and and and and to to to to reduce reduce reduce reduce energy energy energy energy

losses losses losses losses at at at at discharge discharge discharge discharge. .. .

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Compressors

Khalafallah 07/09

/87

Axial Axial Axial Axial- -- -flow Compressor Stage flow Compressor Stage flow Compressor Stage flow Compressor Stage

Compressors

Khalafallah 07/09

/87

Blade Cascade of an Axial Blade Cascade of an Axial Blade Cascade of an Axial Blade Cascade of an Axial- -- -flow Compressor Stage flow Compressor Stage flow Compressor Stage flow Compressor Stage

Compressors

The The The The compressor compressor compressor compressor employs employs employs employs sleeve sleeve sleeve sleeve bearings bearings bearings bearings. .. . The The The The axial axial axial axial thrust thrust thrust thrust

is is is is taken taken taken taken by by by by a aa a thrust thrust thrust thrust bearing bearing bearing bearing on on on on the the the the driver driver driver driver side side side side. .. . The The The The intake intake intake intake

and and and and discharge discharge discharge discharge covers covers covers covers the the the the casing casing casing casing are are are are made made made made detachable detachable detachable detachable for for for for

ease ease ease ease of of of of manufacture manufacture manufacture manufacture. .. . The The The The inlet inlet inlet inlet and and and and outlet outlet outlet outlet shaft shaft shaft shaft seals seals seals seals are are are are of of of of

the the the the staggered staggered staggered staggered type type type type. .. .

Examples of Compressor Design Examples of Compressor Design Examples of Compressor Design Examples of Compressor Design

Khalafallah 07/09

/87

the the the the staggered staggered staggered staggered type type type type. .. .

The The The The next next next next slide slide slide slide gives gives gives gives an an an an idea idea idea idea of of of of the the the the construction construction construction construction of of of of a aa a

stationary stationary stationary stationary axial axial axial axial flow flow flow flow compressor compressor compressor compressor. .. . The The The The compressor compressor compressor compressor design design design design

features features features features a aa a constant constant constant constant diameter diameter diameter diameter rotor rotor rotor rotor and and and and a aa a tapered tapered tapered tapered casing casing casing casing. .. . Air Air Air Air

is is is is taken taken taken taken and and and and discharged discharged discharged discharged in in in in a aa a crosswise crosswise crosswise crosswise direction direction direction direction through through through through

nozzles nozzles nozzles nozzles made made made made integral integral integral integral with with with with the the the the underside underside underside underside of of of of the the the the casing casing casing casing left left left left

and and and and right right right right halves halves halves halves. .. .