Documente Academic

Documente Profesional

Documente Cultură

Project Titlesomechanges

Încărcat de

Lalit Goel0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări26 paginiak

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentak

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări26 paginiProject Titlesomechanges

Încărcat de

Lalit Goelak

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 26

EC-316

8085 MICROPROCESSOR PROJECT

REPORT

Submitted to: Submitted by:

Prof. D.V.Gadre Lalit Goel (75/EC/11)

Manshul Arora (78/EC/11)

Submitted on :

30/MAY/2014

Name of the Institute:

Netaji Subhas Institute of Technology (NSIT)

ACKNOWLEDGEMENT

We are taking this opportunity to express our profound gratitude and regards to Prof.

D.V.Gadre for his exemplary guidance, monitoring and constant encouragement

throughout the course of this project. His lucid explanation of the concepts helped us

to implement them practically in this project. The project allowed us to explore the

8085 microprocessor beyond the book. We would also like to thank our friend,

Malay Rautela, for helping us in times of need.

- Lalit Goel

- Manshul Arora

CONTENTS

S.No. Topic Page No.

1. Project Title 1

2. Objective 1

3. About the Project 1

4. Block Diagram 2

5. Components used 3

6. Tools used 4

7. Schematic 5

8. Board Layout 12

9. Project Code 15

10. Simplified Flow Chart 19

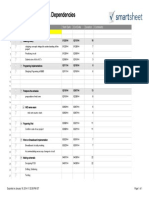

11. Proposed Timeline 20

12. Actual Timeline 21

13. References 23

1. Project Title: Keypad Code/Password Detector

2. Objective: The main aim of this project is to design a keypad password detector using 8085

microprocessor. The password is static and cannot be changed by the user.

3. About the Project:

In this project, a 4*4 matrix keypad is interfaced to the microprocessor system through a

MM74C922 keypad encoder IC. The user enters the 4-digit password through the keypad

whenever the Enter Password LED lights up. One button in the keypad is used as the

Submit Password button. When keypad buttons are pressed, the encoder generates an

RST7.5 interrupt to the microprocessor. The interrupt service routine determines which

digit is pressed and stores the corresponding data in RAM. Also, 4 LEDs glow to indicate

that 4 digits have been pressed. On pressing the Submit button, the stored password is

compared with the actual password. A green or red LED then glows to indicate whether the

password is correct or incorrect. The number of attempts is indicated by LED indicators and

after four unsuccessful attempts; the system gives a warning through a buzzer.

4. Block Diagram: A block diagram for the project in a broad sense is presented below:-

8085

P

Input

Through

4*4 Matrix

Keypad

MM74C922

Keyboard

Encoder

RAM

(32 kB)

EEPROM

(32 kB)

Outputs

using LEDs

and

buzzer

connected

to latches

5. Components used:

COMPONENTS QUANTITY MODEL

8085 (8-bit microprocessor) 1 8085AH

EPROM (32K X 8 bit) 1 27256

SRAM (32K X 8 bit) 62256

16 key Encoder 1 MM74C922

8 bit D latch bus driver 3 74HCT573N

Quad 2 input NOR gate 1 74HCT02N

Quad 2 input OR gate 1 74HCT32N

3 to 8 line

decoder/multiplexer active

low output

2 74HCT138N

Crystal

(Frequency = 4 MHz)

1 XTAL/S

Resistors 22 Resistors of different values

have been used with LEDs of

different colours. (Package

0204/7, 1/8 W)

Pull-up resistors=10 k

Pull down resistors = 680

Capacitors 15 Decoupling Capacitors = 0.1

F

Capacitor connected to crystal

= 22 pF

Capacitors after the power jack

= 10 F (electrolytic) and 0.1

F (ceramic)

Capacitors connected to

MM74C922 = 1 F and 0.1 F

Leds (3mm and 5mm) 13 LEDs of different colours have

been used, namely red, green,

blue and yellow

Power jack 1

Buzzer 1 F/QMBIII

6. Tools used:

Software tools:

1. EAGLE 6.4.0 for schematic and board layout

2. 8085 Simulator IDE by OshonSoft

3. UniPro software

Hardware Tools:

1. Soldering Iron

2. Solder

3. Multimeter

4. +5V DC Power Supply

5. UniPro Programmer

6. Cutter, Tweezer, Hand Files, etc.

7. Schematic:

8085 Basic Connections:

8085 is connected to RAM and EPROM using its data bus and one Latch for latching

the lower order adress from the multiplexed address and data bus.

The interrupts that were not required have been grounded through pull-down resistors.

The READY pin is set to logic 1 through a pull up resistor.

An LED has been attached to SOD pin and a push button has been attached to SID pin

for testing purposes.

Appropriate Reset circuitry has been used.

The memory read, memory write, I/O read and I/O write control signals have been

generated using a decoder as shown below:

A second decoder and 2-input NOR gates have been used to generate select signals for

two output ports.

Power supply:

The output from a +5V power supply is connected at CON1.

Capacitors are used to eliminate noise and generate a DC supply. Electrolytic capacitor

(10 F) is used to eliminate low-frequency noise, while ceramic capacitor (0.1 F) is

used to eliminate high frequency noise. Thus, a pure DC voltage is obtained. LED is

used to indicate the presence of power.

On further observing the circuit, it was realised that the voltage drop across the diode

varied with the current and hence, at the diode terminals on the board, a jumper wire

was connected instead of the diode.

Output Ports:

This is our output port 1 which consists of various LEDs and a buzzer connected to a latch.

The LEDs indicate the following function:

1 Enter password.

2 No. of password key pressed.

3 Correct and Incorrect password.

Similarly, the output port 2 contains an LED indicator which indictaes the number of

attempts left.

Latch is used for holding output data. Its enable pin is always grounded and its chip

select pin is selected through control signal as generated in control part.

Input through Keypad:

IC2 (MM74C922) is used to generate interrupt when a key is pressed from a keypad. When

a key is pressed its value is stored in some memory location and is used after some time for

comparison.

The MM74C922 keypad encoder implements all the logic necessary to interface a keypad

to a digital system. The encoder finds if any connections are being made in the keypad and

outputs four bits corresponding to the state of the keypad. One of the output bits, the "Data

Available" bit, is high when a button is being pressed and low when no button is being

pressed. The other four output bits are data bits which output a number depending on

which of the sixteen buttons is being pressed. Figure 1 shows a detailed diagram of how the

encoder is used. The eight inputs from the keypad are connected directly to the encoder.

The "Data Available" bit and the data bits are on the right side of the diagram.

The two capacitors located at the KBM and OSC pins of the encoder are used for

eliminating key bouncing. Figure 2 shows the debounce period versus the capacitor value

at the KBM input in microfarads. Using this graph, a capacitor value of 1 F was chosen.

This gives a sufficient debounce period that will eliminate all key bouncing but is not so

large that it requires the user to hold the button down a long time before the encoder

recognizes the input. Finding the value of the capacitor at the OSC pin is just a matter of

dividing the capacitance of the KBM capacitor by 10. Therefore, a capacitor with a value

of 0.1 F is used.

Figure 1: Diagram of Keypad and Keypad Encoder

7. Board Layout:

8. Project Code:

;Crystal Frequency 4 MHz

.ORG 0000H

JMP START1

.ORG 003CH

JMP ISR

START1: DI

LXI SP,0000H ;Initialising Stack Pointer

MVI C,04H ;Register C holds the number of attempts

CALL START2 ;Subroutine to initialise the required RAM locations and

;LED Indicator

CALL START3 ;Subroutine for initial setup

EI

NO_OPR: NOP

NOP

JMP NO_OPR ;Remains in the loop till interrupt occurs

ISR: DI

PUSH PSW

PUSH H

IN 02H ;Read Keypad

ANI 0FH

CPI 0FH ;Check if Submit button is pressed

JZ SUBMIT

STA 8000H ;Store the encoded data in a RAM location

MOV A,B

CPI 03H ;Check which digit is entered

JZ DIG_1

CPI 02H

JZ DIG_2

CPI 01H

JZ DIG_3

CPI 00H

JZ DIG_4

JMP RETURN

DIG_4: LDA 8000H ; To compare Digit 4Th of entered password with stored

STA 8004H. ; Digit of correct Password

MVI A,00000111B

OUT 00H

JMP DIG_DONE

DIG_3: LDA 8000H ; To compare Digit 3

rd

of entered password with stored

STA 8003H ; Digit of correct Password

MVI A,00001111B

OUT 00H

JMP DIG_DONE

DIG_2: LDA 8000H ; To compare Digit 2nd of entered password with stored

STA 8002H ; Digit of correct Password

MVI A,00011111B

OUT 00H

JMP DIG_DONE

DIG_1: LDA 8000H ; To compare Digit 1st of entered password with stored

STA 8001H ; Digit of correct Password

MVI A,00111111B

OUT 00H

JMP DIG_DONE

DIG_DONE: DCR B

RETURN: POP H

POP PSW

EI

RET

SUBMIT: LDA 8001H ;Submit button pressed

CPI 00H

JNZ WRONG

LDA 8002H

CPI 04H

JNZ WRONG

LDA 8003H

CPI 08H

JNZ WRONG

LDA 8004H

CPI 0CH

JNZ WRONG

RIGHT: MVI A,11111101B ;Password entered is correct

OUT 00H

HLT

WRONG: MVI A,11111011B ;Password entered is incorrect

OUT 00H

DCR C

CALL START2

MOV A,C

CPI 00H

JZ OVER

CALL DEL_5

CALL START3

POP H

POP PSW

EI

RET

OVER: MVI A,11111010B ;No. of attempts are over

OUT 00H

HLT

START2: PUSH PSW

MVI A,00H

STA 8000H

STA 8001H

STA 8002H

STA 8003H

STA 8004H

MVI B,03H

LXI H,TABLE

MOV A,L

ADD C

MOV L,A

JNC NO_ADJ

INR H

NO_ADJ: MOV A,M

OUT 01H

POP PSW

RET

START3: MVI A,01111111B

OUT 00H

RET

DEL_5: PUSH B ;Delay Subroutine

PUSH PSW

MVI D,02H

LOOP1: LXI B,0FFFFH

LOOP2: DCX B

MOV A,B

ORA C

JNZ LOOP2

DCR D

JNZ LOOP1

POP PSW

POP B

RET

TABLE: .DB 35H

.DB 15H

.DB 14H

.DB 04H

.DB 00H

;RESERVE .EQU 8000H

;RESERVE1 .EQU 8001H

;RESERVE2 .EQU 8002H

;RESERVE3 .EQU 8003H

;RESERVE4 .EQU 8004H

;P1 .EQU 0FH

;P2 .EQU 00H

;P3 .EQU 04H

;P4 .EQU 08H

;SUB_BUTTON .EQU 0CH

.END

9. Simplified Flow Chart:

START

Enter Password LED Glows

User enters the 4-digit password and Submit

button

READ KEYPAD

READ KEYPAD

Check whether

entered

password is

correct

PASSWORD is Incorrect

SWITCH ON RED LED

PASSWORD is Correct

SWITCH ON GREEN LED

END

DECREMENT THE LED INDICATOR BY

SWITCHING ON AN LED

CHECK WHETHER

WRONG

PASSWORD HAS

BEEN ENTERED

4 TIMES

ISSUE A WARNING

THROUGH BUZZER

10. Proposed Timeline:

Beginning Date End Date Duration Task

3

rd

February 20

th

February 18 days Studying the concepts

integral to the

understanding of the

project

Finalizing the circuit

Submission of the list of

ICs

21

st

February 7

th

March 15 days Preparation of Mid-

Semester Exam

Mid-Semester Exams

8

th

March 17

th

March 10 days Design the schematic

18

th

March 31

st

March 14 days Write the program

1

st

April 30

th

April 30 days Drilling, Soldering

Testing

Debugging

11. Actual Timeline:

Beginning Date End Date Duration Task

3

rd

February 20

th

February 18 days Studied the concepts

integral to the

understanding of the

project

Finalized the circuit

21

st

February 7

th

March 15 days Preparation of Mid-

Semester Exam

Mid-Semester Exams

15

th

March 31

st

March 17 days Designed a rough

schematic

Tested MM74C922

Keyboard Encoder on

Breadboard

Wrote the program

1

st

April 13

th

April 14 days Finalized the schematic

15

th

April 23

rd

April 8 days Board being

manufactured by

PCBPower

3

rd

May 13

th

May 10 days Soldering

SID/SOD Testing

working successfully

Debugging code

Main code testing

Working satisfactorily

except some minor

glitches

1. The month of January was dedicated to finding Project Idea and preparing Proposal.

2. Before the end of February, the circuit was finalized conceptually and work on schematic

had begun.

3. The schematic was finalized till 31

st

March.

4. We worked on the board file till 8

th

April and placed the order on 13

th

April (delivery

within 7 working days) after incorporating some more changes.

5. The board came on 23

rd

April as expected.

6. We completed soldering and tested the working of SID/SOD pins and output LEDs till

5

th

May.

7. From 7

th

May to 13

th

May, we tested the main code multiple times, incorporating some

changes each time. The project worked satisfactorily.

REFERENCES :

1. Microprocessor , Architecture, Programming , and Application with 8085 by

Ramesh Gaonkar.

2. http://en.wikipedia.org/wiki/Intel_8085

3. https://sites.google.com/site/imnishantg/projects

4. https://sites.google.com/site/colordetector8085/home/schematics

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- CamScanner ScansDocument8 paginiCamScanner ScansLalit GoelÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Itinerary 82994160-3347.HTMLDocument9 paginiItinerary 82994160-3347.HTMLLalit GoelÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- BudjetDocument40 paginiBudjetLalit GoelÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Smith ChartDocument41 paginiSmith ChartLalit GoelÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Arbitration and Conciliation (Amendment) Ordinance, 2015Document3 paginiThe Arbitration and Conciliation (Amendment) Ordinance, 2015Lalit GoelÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Control Lab Matlab PracticalskDocument12 paginiControl Lab Matlab PracticalskLalit GoelÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Itinerary 82994160-3347.HTMLDocument9 paginiItinerary 82994160-3347.HTMLLalit GoelÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- ViewDocument1 paginăViewLalit GoelÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- IjueeDocument1 paginăIjueeLalit GoelÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- ReadmeDocument1 paginăReadmeLalit GoelÎncă nu există evaluări

- Expt 7Document7 paginiExpt 7Lalit GoelÎncă nu există evaluări

- OpDocument1 paginăOpLalit GoelÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- OpDocument1 paginăOpLalit GoelÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- OpDocument1 paginăOpLalit GoelÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Cara Edit Pro 2.0Document5 paginiCara Edit Pro 2.0jafar sidiq100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- AasaDocument1 paginăAasaLalit GoelÎncă nu există evaluări

- GoiDocument2 paginiGoiLalit GoelÎncă nu există evaluări

- FilteringDocument1 paginăFilteringLalit GoelÎncă nu există evaluări

- Snoa 621 CDocument26 paginiSnoa 621 CLalit GoelÎncă nu există evaluări

- Dsudhsd SDSHD Ldkskdhs'dsdsgiudhs' HsuihdsDocument1 paginăDsudhsd SDSHD Ldkskdhs'dsdsgiudhs' HsuihdsLalit GoelÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Chapter 4Document25 paginiChapter 4Lalit GoelÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- MahabharatDocument1 paginăMahabharatLalit GoelÎncă nu există evaluări

- Basic Project With Gantt & DependenciesDocument1 paginăBasic Project With Gantt & DependenciesLalit GoelÎncă nu există evaluări

- LalaDocument1 paginăLalaLalit GoelÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- MahabharatDocument1 paginăMahabharatLalit GoelÎncă nu există evaluări

- LaladdDocument1 paginăLaladdLalit GoelÎncă nu există evaluări

- Fil HandlingDocument1 paginăFil HandlingLalit GoelÎncă nu există evaluări

- MahabharatDocument1 paginăMahabharatLalit GoelÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Quick Guide IEC V2 27 02 14Document3 paginiQuick Guide IEC V2 27 02 14federicosanchezÎncă nu există evaluări

- Fingerprint Lock Installation GuideDocument47 paginiFingerprint Lock Installation GuideJose Luis Quiroz OlivaÎncă nu există evaluări

- Tech Note 1010 - SQL Server Authentication and ArchestrA Network Account Restrictions When Installing Wonderware HistorianDocument8 paginiTech Note 1010 - SQL Server Authentication and ArchestrA Network Account Restrictions When Installing Wonderware Historianprofilemail8Încă nu există evaluări

- Week 1 Slides - AWS MoocDocument22 paginiWeek 1 Slides - AWS Moockaylia123Încă nu există evaluări

- Halcon 11 Brochure EnglishDocument20 paginiHalcon 11 Brochure EnglishSANKPLYÎncă nu există evaluări

- GE Multilin Feeder Management Relay 750man-A6Document336 paginiGE Multilin Feeder Management Relay 750man-A6Carlos Astorga DÎncă nu există evaluări

- C++ Formatted I/O GuideDocument13 paginiC++ Formatted I/O GuideridzuancomÎncă nu există evaluări

- Digital Forensic Analysis of A PlayStation 4 Hard Drive With Links To XRY Mobile ForensicsDocument35 paginiDigital Forensic Analysis of A PlayStation 4 Hard Drive With Links To XRY Mobile ForensicsLuke BarghÎncă nu există evaluări

- Master PDF Editor 3.4.00 - Mac Torrent Download PDFDocument16 paginiMaster PDF Editor 3.4.00 - Mac Torrent Download PDFCuong Nguyen Canh Huy0% (1)

- SmarTeam Design Express For CATIA Installation GuideDocument29 paginiSmarTeam Design Express For CATIA Installation GuidelceppetelliÎncă nu există evaluări

- What Different Selection Citeria For PLC Selection Criteria: AdvantagesDocument2 paginiWhat Different Selection Citeria For PLC Selection Criteria: AdvantagesMahesh ShendeÎncă nu există evaluări

- Xilinx Drivers GuideDocument12 paginiXilinx Drivers Guideecl_man100% (1)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Dislin-9 5 PDFDocument318 paginiDislin-9 5 PDFRamchandraÎncă nu există evaluări

- C StringsDocument31 paginiC StringsJoerald Montante Mongaya GrandeÎncă nu există evaluări

- Checklist AsetDocument8 paginiChecklist AsetcheanhoiÎncă nu există evaluări

- Fix Broken SudoDocument3 paginiFix Broken SudoadhomÎncă nu există evaluări

- TestingDocument32 paginiTestingemilfrancuÎncă nu există evaluări

- GE8151 Python Programming - Question Bank and Example ProgramsDocument13 paginiGE8151 Python Programming - Question Bank and Example ProgramsN.VivekananthamoorthyÎncă nu există evaluări

- JavascriptDocument23 paginiJavascriptNaveen KumarÎncă nu există evaluări

- Network Connection DiagramDocument14 paginiNetwork Connection DiagramPhạm Thanh SơnÎncă nu există evaluări

- MODBUS Communication Module for Planar4 SystemDocument4 paginiMODBUS Communication Module for Planar4 SystemGilberto Alejandro Tun BritoÎncă nu există evaluări

- NET Framework Class LibraryDocument77 paginiNET Framework Class LibraryAndrei SipoșÎncă nu există evaluări

- Raspberry Pi Begginer Guide 2020 Part 7Document10 paginiRaspberry Pi Begginer Guide 2020 Part 7New RegisterÎncă nu există evaluări

- LeadershipDocument11 paginiLeadershipHussain AhmedÎncă nu există evaluări

- LicenceManager User GuideDocument33 paginiLicenceManager User GuideStajic MilanÎncă nu există evaluări

- SUNMI T2 POS with Dual Displays and Facial RecognitionDocument1 paginăSUNMI T2 POS with Dual Displays and Facial RecognitionFiras A. MahadiÎncă nu există evaluări

- MIDGE DatasheetDocument2 paginiMIDGE DatasheetBrett AtkinsÎncă nu există evaluări

- Knowledge - LockboxDocument10 paginiKnowledge - LockboxHariprasad ManchiÎncă nu există evaluări

- Chapter 2. Introduction To Data ScienceDocument40 paginiChapter 2. Introduction To Data ScienceMeron EshetuÎncă nu există evaluări

- Huawei - Datacenter - Dump4Document15 paginiHuawei - Datacenter - Dump4Antonio Agustin Caceres FerreiraÎncă nu există evaluări