Documente Academic

Documente Profesional

Documente Cultură

910012408023

Încărcat de

M.Saravana Kumar..M.E0 evaluări0% au considerat acest document util (0 voturi)

20 vizualizări10 paginiMolten metal is poured into the bottom half of the pre-heated die. The upper half closes the die and applies pressure during the solidification process. Both ferrous and non-ferrous materials can be produced using this method.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMolten metal is poured into the bottom half of the pre-heated die. The upper half closes the die and applies pressure during the solidification process. Both ferrous and non-ferrous materials can be produced using this method.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

20 vizualizări10 pagini910012408023

Încărcat de

M.Saravana Kumar..M.EMolten metal is poured into the bottom half of the pre-heated die. The upper half closes the die and applies pressure during the solidification process. Both ferrous and non-ferrous materials can be produced using this method.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 10

INTRODUCTION

Squeeze casting, also known as liquid metal forging,

is a combination of casting and forging process.

The molten metal is poured into the bottom half of the

pre-heated die.

As the metal starts solidifying, the upper half closes

the die and applies pressure during the solidification

process.

Both ferrous and non-ferrous materials can be

produced using this method.

MATERIALS

ALUMINIUM:

Aluminium is a very light metal with a specific weight of 2.7

g/cm. For example, the use of aluminium in vehicles reduces dead-

weight and energy consumption while increasing load capacity. Its

strength can be adapted to the application required by modifying the

composition of its alloys.

STEEL:

Steel is a common material for building and forming. It makes

up the frames of cars, and it's used to make a variety of machine parts.

However, steel comes in a number of varieties, and one of these types

is called low-carbon steel, which has different properties than those of

other types of steel.

LITERATURE SURVEY

C.S. Goh , K.S. Soh , P.H. Oon , B.W. Chua(2009)

Effect of squeeze casting parameters on the

mechanical properties of AZ91Ca Mg alloys.

A study on the effect of squeeze casting parameters

on the mechanical properties of AZ91 Mg alloy with

2 wt.% Ca incorporated was conducted.

A good combination of tensile and macro hardness

properties was obtained with better mechanical

properties.

E. Hajjari a,M. Divandari b, A.R.Mirhabibi(2009)

The effect of applied pressure on fracture surface and

tensile properties of nickel coated continuous carbon

fiber reinforced aluminum composites fabricated by

squeeze casting.

Reinforcing aluminum with carbon fibers, offers a

high potential for increasing the specific strength and

specific youngs modulus of these types of

composites. Therefore, carbon fiber reinforced

aluminum components are of great interest for the

potential aerospace and automotive applications.

D. Mandala, B.K.Duttab, S.C.Panigrahib(2007)

Effect of wt% reinforcement on microstructure and mechanical

properties of Al2Mg base short steel fiber composites.

Al2Mg alloy composites with varying wt% of copper-coated

short steel fiber reinforced were prepared through liquid

process vortex method. Steel fibers were coated with copper

by electroless deposition method. It is observed that density,

hardness and porosity increased with increasing wt% of fibers.

There is a significant improvement in strength and hardness

with addition of fibers.

Liu Lei,Li Weiwei, Tang Yiping, Shen Bin, Hu

Wenbin(2008)

Friction and wear properties of short carbon fiber

reinforced aluminum matrix composites.

The friction and wear properties of short carbon

fibers (SCFs) reinforced aluminum matrix composite

were studied.

The incorporation of SCF in Al alloy improved the

wear resistance greatly.

METHODOLOGY

The methodology for the reinforcement of steel in aluminium is as

follows.

Reinforcement of steel in aluminium

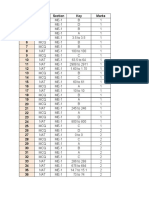

Selection of parameters

Samples casted by squeeze casting & Gravity die casting

Testing for mechanical & metallurgical properties

REFERENCE

Effect of squeeze casting parameters on the

mechanical properties of AZ91Ca Mg alloys C.S.

Goh , K.S. Soh , P.H. Oon, B.W. Chu.

The effect of applied pressure on fracture surface and

tensile properties of nickel coated continuous carbon

fiber reinforced aluminum composites fabricated by

squeeze casting E. Hajjari, M. Divandari, A.R.

Mirhabibi.

Effect of wt% reinforcement on microstructure and

mechanical properties of Al2Mg base short steel

fiber composites D. Mandala, B.K. Duttab, S.C.

Panigrahi.

THANK YOU

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- UC3842 Inside SchematicsDocument17 paginiUC3842 Inside Schematicsp.c100% (1)

- MT-1 Full NotesDocument56 paginiMT-1 Full NotesM.Saravana Kumar..M.EÎncă nu există evaluări

- Strength of Materials - Unit 2 - Week 1Document3 paginiStrength of Materials - Unit 2 - Week 1M.Saravana Kumar..M.EÎncă nu există evaluări

- Best Polysilicon Technologies Russ HamiltonDocument15 paginiBest Polysilicon Technologies Russ HamiltonBenYi Chou100% (1)

- Small Bulk LPG Storage at Fixed Installations Technical GuidanceDocument3 paginiSmall Bulk LPG Storage at Fixed Installations Technical GuidanceavlaavlaÎncă nu există evaluări

- General Chemistry Course OutlineDocument3 paginiGeneral Chemistry Course OutlineShairuz Caesar Briones DugayÎncă nu există evaluări

- 2 & 3 - Institutional Vision, Mision, PO, PSO, PEODocument4 pagini2 & 3 - Institutional Vision, Mision, PO, PSO, PEOM.Saravana Kumar..M.EÎncă nu există evaluări

- Details Dr. V KhalkarDocument1 paginăDetails Dr. V KhalkarM.Saravana Kumar..M.EÎncă nu există evaluări

- Effective Engineering Teaching in PracticeDocument4 paginiEffective Engineering Teaching in PracticeM.Saravana Kumar..M.EÎncă nu există evaluări

- Latha MathavanDocument3 paginiLatha MathavanM.Saravana Kumar..M.EÎncă nu există evaluări

- IAT2 Key PDFDocument8 paginiIAT2 Key PDFM.Saravana Kumar..M.EÎncă nu există evaluări

- M.saravana Kumar Updated Co StatementDocument5 paginiM.saravana Kumar Updated Co StatementM.Saravana Kumar..M.EÎncă nu există evaluări

- NDT Syallbus Anna University ScribdDocument2 paginiNDT Syallbus Anna University ScribdM.Saravana Kumar..M.EÎncă nu există evaluări

- Scholar List MechDocument152 paginiScholar List MechM.Saravana Kumar..M.EÎncă nu există evaluări

- Engineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsDocument4 paginiEngineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.EÎncă nu există evaluări

- Engineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesDocument4 paginiEngineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesM.Saravana Kumar..M.EÎncă nu există evaluări

- Design Subject SyallbusDocument8 paginiDesign Subject SyallbusM.Saravana Kumar..M.EÎncă nu există evaluări

- Laws of Thermodynamics - Unit 3 - Week 2 PDFDocument3 paginiLaws of Thermodynamics - Unit 3 - Week 2 PDFM.Saravana Kumar..M.EÎncă nu există evaluări

- Solution - Assignment - Laws of Thermodynamics - 3rd WeekDocument5 paginiSolution - Assignment - Laws of Thermodynamics - 3rd WeekM.Saravana Kumar..M.EÎncă nu există evaluări

- WEEK 1 SolutionsDocument5 paginiWEEK 1 SolutionsM.Saravana Kumar..M.EÎncă nu există evaluări

- Laws of Thermodynamics - Unit 3 - Week 2Document3 paginiLaws of Thermodynamics - Unit 3 - Week 2M.Saravana Kumar..M.EÎncă nu există evaluări

- Mechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsDocument5 paginiMechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsM.Saravana Kumar..M.EÎncă nu există evaluări

- Engineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesDocument4 paginiEngineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesM.Saravana Kumar..M.EÎncă nu există evaluări

- Strength of Materials - Unit 6 - Week 5Document3 paginiStrength of Materials - Unit 6 - Week 5M.Saravana Kumar..M.EÎncă nu există evaluări

- Engineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsDocument5 paginiEngineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.EÎncă nu există evaluări

- ME-1 Section MCQ and NAT Type Exam ResultsDocument2 paginiME-1 Section MCQ and NAT Type Exam ResultsM.Saravana Kumar..M.EÎncă nu există evaluări

- DTS 06Document18 paginiDTS 06M.Saravana Kumar..M.EÎncă nu există evaluări

- Strength of Materials - Unit 3 - Week 2Document4 paginiStrength of Materials - Unit 3 - Week 2M.Saravana Kumar..M.EÎncă nu există evaluări

- Mechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressDocument4 paginiMechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressM.Saravana Kumar..M.EÎncă nu există evaluări

- Laws of Thermodynamics - Unit 5 - Week 4Document3 paginiLaws of Thermodynamics - Unit 5 - Week 4M.Saravana Kumar..M.EÎncă nu există evaluări

- Abrasive Jet MachiningDocument12 paginiAbrasive Jet MachiningM.Saravana Kumar..M.EÎncă nu există evaluări

- Syllabi GATE2017 PDFDocument73 paginiSyllabi GATE2017 PDFAnkit Kumar AJÎncă nu există evaluări

- Anna University Manufacturing Technology1 Previous Year Question Papers CollectionDocument20 paginiAnna University Manufacturing Technology1 Previous Year Question Papers CollectioneurekaÎncă nu există evaluări

- Gate PlanDocument1 paginăGate PlanM.Saravana Kumar..M.EÎncă nu există evaluări

- AmpsentryDocument6 paginiAmpsentryMarcos C.Încă nu există evaluări

- EMT and Transmission Lines ReviewDocument2 paginiEMT and Transmission Lines Reviewrupesh guptaÎncă nu există evaluări

- Electric BrewingDocument5 paginiElectric BrewingxmacabaÎncă nu există evaluări

- RCC RESO 20 06 - (Central - Scheduling) PDFDocument57 paginiRCC RESO 20 06 - (Central - Scheduling) PDFSherwin SabandoÎncă nu există evaluări

- Compressor Anti SurgeDocument4 paginiCompressor Anti SurgeAboaliÎncă nu există evaluări

- The Jere Beasley Report, Jan. 2009Document52 paginiThe Jere Beasley Report, Jan. 2009Beasley AllenÎncă nu există evaluări

- Unit-44 Industrial Power,Electronics and storageDocument11 paginiUnit-44 Industrial Power,Electronics and storageChathura RanathungaÎncă nu există evaluări

- Instalacion Messenger 302-0417Document99 paginiInstalacion Messenger 302-0417emmanuelaÎncă nu există evaluări

- Proposed Medium-Rise Apartment Building Design AssessmentDocument17 paginiProposed Medium-Rise Apartment Building Design AssessmentRaynier LigayaÎncă nu există evaluări

- Tufftride - Qpq-Process: Technical InformationDocument19 paginiTufftride - Qpq-Process: Technical InformationmwasicÎncă nu există evaluări

- PVD Escravos - NigeriaDocument2 paginiPVD Escravos - NigeriaFioz AriyandiÎncă nu există evaluări

- Food and Beverage Industry in MENADocument64 paginiFood and Beverage Industry in MENADaria MotÎncă nu există evaluări

- Datasheet N2XH IEC 60502 1Document4 paginiDatasheet N2XH IEC 60502 1Marouan BouazizÎncă nu există evaluări

- Flying Injection ManualDocument40 paginiFlying Injection ManualSlainsha100% (1)

- PD Pilot DevicesDocument241 paginiPD Pilot DevicesaguilavmÎncă nu există evaluări

- WEG w22 Three Phase Electric MotorDocument44 paginiWEG w22 Three Phase Electric MotorMATIAS GODOYÎncă nu există evaluări

- Use and Maintenance Instructions - Ql0208-Rev.2-2017 - enDocument70 paginiUse and Maintenance Instructions - Ql0208-Rev.2-2017 - enmauriciojjÎncă nu există evaluări

- CB Materials Handling Brochure-May2010Document12 paginiCB Materials Handling Brochure-May2010Guglielmo CancelliÎncă nu există evaluări

- Airwide International-China (A) Key Account SellingDocument6 paginiAirwide International-China (A) Key Account SellingFahad ParvezÎncă nu există evaluări

- NX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor InstallationDocument67 paginiNX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor Installationsantifer26Încă nu există evaluări

- MD Class Test 1Document5 paginiMD Class Test 1Sambit Das0% (1)

- Basic ElexDocument160 paginiBasic ElexUmashankar VermaÎncă nu există evaluări

- Narayana GT 5 QPDocument17 paginiNarayana GT 5 QPGowri Shankar100% (1)

- Wet-Ic L&T Construction LTD., Water & Effluent Treatment IcDocument1 paginăWet-Ic L&T Construction LTD., Water & Effluent Treatment IcRahesh MÎncă nu există evaluări

- 7 markscheme-HL-paper1Document29 pagini7 markscheme-HL-paper1Onur YavuzcetinÎncă nu există evaluări

- D Regulators enDocument52 paginiD Regulators enmasakpÎncă nu există evaluări