Documente Academic

Documente Profesional

Documente Cultură

Use of Additive Materials in Sub Grade For Road Construction

Încărcat de

seventhsensegroup100%(1)100% au considerat acest document util (1 vot)

196 vizualizări6 paginiit is essential to constantly improve quality, strength

and durability of road. Conventionally bituminous roads have

worked well for long time. The main factor which generally

affect the bituminous roads are temperature, rainfall, traffic

load, land base, etc. & it cause cracks, potholes, rutting in road

surface. Sometimes failure of road also occurs. These failures can

be eliminated by using additive materials like Recron-3S, Fly

ash, Lime. These additives can be mixed with soil in various

proportions. It is also possible to increase strength of soil with the

use of additive materials. And the mixture of these additive

materials and soil can be used in sub-base and sub grade. With

different proportions of soil with additive materials California

Bearing Ratio value will be more compare to conventional

materials. And from that thickness of pavement can be

minimized to the certain extent.

Titlu original

Use of Additive Materials in Sub Grade for Road

Construction

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentit is essential to constantly improve quality, strength

and durability of road. Conventionally bituminous roads have

worked well for long time. The main factor which generally

affect the bituminous roads are temperature, rainfall, traffic

load, land base, etc. & it cause cracks, potholes, rutting in road

surface. Sometimes failure of road also occurs. These failures can

be eliminated by using additive materials like Recron-3S, Fly

ash, Lime. These additives can be mixed with soil in various

proportions. It is also possible to increase strength of soil with the

use of additive materials. And the mixture of these additive

materials and soil can be used in sub-base and sub grade. With

different proportions of soil with additive materials California

Bearing Ratio value will be more compare to conventional

materials. And from that thickness of pavement can be

minimized to the certain extent.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

196 vizualizări6 paginiUse of Additive Materials in Sub Grade For Road Construction

Încărcat de

seventhsensegroupit is essential to constantly improve quality, strength

and durability of road. Conventionally bituminous roads have

worked well for long time. The main factor which generally

affect the bituminous roads are temperature, rainfall, traffic

load, land base, etc. & it cause cracks, potholes, rutting in road

surface. Sometimes failure of road also occurs. These failures can

be eliminated by using additive materials like Recron-3S, Fly

ash, Lime. These additives can be mixed with soil in various

proportions. It is also possible to increase strength of soil with the

use of additive materials. And the mixture of these additive

materials and soil can be used in sub-base and sub grade. With

different proportions of soil with additive materials California

Bearing Ratio value will be more compare to conventional

materials. And from that thickness of pavement can be

minimized to the certain extent.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 6

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3790

Use of Additive Materials in Sub Grade for Road

Construction

Kishan khunt

#

#

Student of final year M. Tech Transportation System Engineering, BVM Engineering College, Vallabh vidyanagar, Anand,

Gujarat, India.

Abstract it is essential to constantly improve quality, strength

and durability of road. Conventionally bituminous roads have

worked well for long time. The main factor which generally

affect the bituminous roads are temperature, rainfall, traffic

load, land base, etc. & it cause cracks, potholes, rutting in road

surface. Sometimes failure of road also occurs. These failures can

be eliminated by using additive materials like Recron-3S, Fly

ash, Lime. These additives can be mixed with soil in various

proportions. It is also possible to increase strength of soil with the

use of additive materials. And the mixture of these additive

materials and soil can be used in sub-base and sub grade. With

different proportions of soil with additive materials California

Bearing Ratio value will be more compare to conventional

materials. And from that thickness of pavement can be

minimized to the certain extent.

Keywords Recron-3S, Lime, Fly ash, CBR, Black Cotton Soil

I. INTRODUCTION

Road is the basic & necessary requirement of transportation.

Generally there are two types of pavements used in the

construction of road named Flexible pavement & Rigid

pavement. In flexible pavements, wheel loads are transferred

by grain to grain contact of the aggregate through the granular

structure. The flexible pavement, having less flexural strength

of the pavement and the pavement act like rigid plate.

Additive materials are added in the sub grade and sub base

layer. Recron when mixed with soil and fly ash mixture gives

a wonderful result. Fibre absorbs everything and keeps the

road surface intact and many problems can be solved like

potholes, cracking & failure of pavement.

II. PROBLEMS IN FLEXIBLE PAVEMENT

Pavement failure is defined in terms of decreasing

serviceability caused by the development of cracks and ruts.

Failures of bituminous pavements are caused due to many

reasons or combination of reasons. Following are the various

reasons behind the failure of bituminous pavement.

Sudden increase in traffic loading especially on new

roads where the design is based on lesser traffic is a

major cause of cracking

Bleeding and Cracking in pavement due to rise in

temperature.

Provision of poor clayey sub grade results in

corrugation at the surface and increase in unevenness

Poor drainage conditions especially during rainy

season.

These are the reasons behind the failure pavement. These

problems can be eliminated to certain extent by using additive

materials with soil in sub grade and sub base layer.

III. ADDITIVE MATERIALS

Following are the additive materials which are used for the

improving strength of black cotton soil.

A. Black Cotton Soil

B. Fly Ash

C. Lime

D. Recron-3S

PROPERTIES OF BLACK COTTON SOIL:

CBR value: 2%

Specific Gravity: 2.14

Liquid Limit: 40%

Free Swell Index:>50%

Plastic Limit: 35 40%

Source: South Gujarat (Surat)

PHYSICAL PROPERTIES OF FLY ASH:

Density: 2.17 gm/cm

3

Bulk Density: 1.26gm/cm

3

Moisture Content: 2%

Particle Shape: Spherical, Irregular

Colour: Grey

Source: Ukai Thermal Power Station

CHEMICAL PROPERTIES OF FLY ASH

Sio

2

:30 - 60%

Al

2

O

3

: 11 - 19%

Fe

2

O

3

: 4 - 11%

MgO: 5 6%

CaO: 2 4%

Trace elements: Sodium, Potassium, Baron, etc.

PROPERTIES OF RECRON-3S:

Cut Length: 6mm or 12mm

Tensile Strength: 4000 6000kg/cm

2

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3791

Melting Point: >250C

Colour: White

Source: Reliance Industries

IV. PROPORTIONS OF ADDITIVE MATERIALS WITH

BLACK COTTON SOIL

Firstly Standard Proctor Test is performed as per IS: 2720-7,

& IS: 2720-8 on different proportions of additive materials,

Fly ash, Lime, Recron-3S with Black cotton soil to get desire

and best result. Following are the various proportions by total

weight of mixture.

1. Soil (100%)

2. Soil (88%) + Fly ash (10%) + Lime (2%)

3. Soil (83%) + Fly ash (15%) + Lime (2%)

4. Soil (78%) + Fly ash (20%) + Lime (2%)

5. Soil (81%) + Fly ash (15%) + Lime (4%)

6. Soil (85%) + Fly ash (12%) + Lime (3%)

7. Soil (84%) + Fly ash (12%) + Lime (3%) + Recron-3S

(1%)

8. Soil (83%) + Fly ash (12%) + Lime (3%) + Recron-3S

(2%)

From above proportions MDD (Maximum Dry Density) &

OMC (Optimum Moisture Content) is calculated.

Following are the results of above proportions for standard

proctor test.

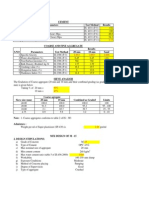

TABLE I

RESULT OF STANDARD PROCTOR TEST

Sr.

No.

Proportions MDD

(gm/cc)

OMC

(%)

1. Soil (100%) 1.07 23.85

2. Soil (100%) + Fly ash (10%) +

Lime (2%)

1.63 16.61

3. Soil (83%) + Fly ash (15%) +

Lime (2%)

1.61 14.51

4. Soil (78%) + Fly ash (20%) +

Lime (2%)

1.65 16.31

5. Soil (81%) + Fly ash (15%) +

Lime (4%)

1.67 16.12

6. Soil (85%) + Fly ash (12%) +

Lime (3%)

1.58 23.00

7. Soil (84%) + Fly ash (12%) +

Lime (3%) + Recron-3S (1%)

1.55 19.95

8. Soil (83%) + Fly ash (12%) +

Lime (3%) + Recron-3S (2%)

1.87 14.50

Result of standard proctor test is shown in TABLE-I, after

checking these results according to MDD & OMC. Best suited

proportions are selected which are listed below.

1. Soil (100%)

2. Soil (84%) + Fly ash (12%) + Lime (3%) + Recron-3S

(1%)

3. Soil (83%) + Fly ash (12%) + Lime (3%) + Recron-3S

(2%)

From the results of standard proctor test best proportions

are selected from their MDD & OMC. Now after

performing standard proctor test, California Bearing Ratio

test as per IS: 2720 part-16 is to be performed.

1. Soil (100%)

Result of standard proctor test is listed in table II and from

that data, graph is drawn which is shown in fig. 1

TABLE I

PROCTOR TEST RESULT FOR 100% SOIL

DATA SHEET FOR SOIL TEST

Soil (100%)

(Ref. std: IS 2720-7, IS: 2720-8) Volume of Mould: 1000cc

Water

in ml.

Water

of

Sampl

e in

(gms)

Moist

ure

Can

No.

M C +

Wet

Weigh

t

M C

+

Dry

Weig

ht

Moist

ure

Conte

nt (%)

Dry

Density

in gms/cc

150 1566 4 74.75 71.25 8.13 1.448

80 1668 611 62.37 58.76 11.30 1.489

80 1752 97 55.48 51.75 13.95 1.537

80 1832 69 58.87 53.89 17.32 1.562

80 1912 23 67.78 60.61 20.67 1.585

80 1996 2 80.28 70.37 24.20 1.607

80 1944 169 85.40 73.34 28.98 1.507

From Graph MDD: 1.608 gms/cc & OMC: 23.85%

Fig. 1 MDD Vs OMC Graph for 100% Soil Sample

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3792

TABLE III

CBR TEST RESULT FOR 100% SOIL

DATA SHEET FOR CBR TEST

Ref. Std. IS:2720 part-16

Sample: Soil (100%)

Sample Condition: Remoulded at OMC & ODD

Type of Compaction: Light Compaction

Test Condition: Soaked. Soaking for 96 Hours

Penetration Rate: 1.25 mm/min Surcharge Weight: 5.0 kg

Penetration

(mm)

Time

(min)

Penetration

Resistance

Reading

0.0 0.00 0.00

0.5 0.24 0.06

1.0 0.48 0.13

1.5 1.12 0.16

2.0 1.36 0.18

2.5 2.00 0.19

4.0 3.12 0.32

5.0 4.00 0.41

7.5 6.00 0.52

10.0 8.00 0.57

12.5 10.0 0.63

From the Graph

Corrections if any -

CBR at 2.5 mm 1.4

CBR at 5.0 mm 2.0

Fig. 2 CBR Test for 100% soil Sample

2. Soil (84%) + Fly ash (12%) + Lime (3%) + Recron-

3S (1%)

Result of standard proctor test is listed in Table IV and

from that data, graph is drawn which is shown in fig. 3

TABLE IV

PROCTOR TEST RESULT FOR Soil (84%) + Fly ash

(12%) + Lime (3%) + Recron-3S (1%)

DATA SHEET FOR SOIL TEST

Soil (85%) + Fly Ash (12%) + lime (3%)

(Ref. std: IS 2720-7, IS: 2720-8) Volume of Mould: 1000cc

Water

in ml.

Water

of

Sampl

e in

(gms)

Moist

ure

Can

No.

M C +

Wet

Weigh

t

M C

+

Dry

Weig

ht

Moist

ure

Conte

nt (%)

Dry

Density

in gms/cc

140 1632 10 57.43 55.20 8.38 1.506

50 1666 2 78.14 73.75 9.90 1.516

50 1716 20 55.65 52.69 12.20 1.524

50 1748 278 53.73 50.48 17.13 1.532

50 1794 117 47.66 43.62 14.42 1.528

50 1820 688 60.76 55.44 18.74 1.533

50 1856 87 78.14 73.75 19.75 1.550

50 1839 611 60.32 54.40 41.45 1.529

From Graph MDD: 1.55 gms/cc & OMC: 19.94%

Fig. 3 MDD Vs OMC Graph for 84% Soil + 12% Fly ash + 3% Lime + !%

Recro-3S Sample

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3793

TABLE V

CBR RESULT FOR Soil (84%) + Fly ash (12%) + Lime

(3%) + Recron-3S (1%)

DATA SHEET FOR CBR TEST

Ref. Std. IS:2720 part-16

Sample: Soil (84%) + FA(12%) + Lime(3%) + Recron-3S(1%)

Sample Condition: Remoulded at OMC & ODD

Type of Compaction: Light Compaction

Test Condition: Soaked. Soaking for 96 Hours

Penetration Rate: 1.25 mm/min Surcharge Weight: 5.0 kg

Penetration

(mm)

Time

(min)

Penetration

Resistance Reading

0.0 0.00 0.00

0.5 0.24 0.10

1.0 0.48 0.23

1.5 1.12 0.37

2.0 1.36 0.55

2.5 2.00 0.78

4.0 3.12 1.67

5.0 4.00 2.37

7.5 6.00 4.26

10.0 8.00 6.21

12.5 10.0 7.95

From the Graph

Corrections if any 1.74

CBR at 2.5 mm 13.7

CBR at 5.0 mm 18.3

Fig.4 CBR Test for 84% soil + 12% Fly ash + 3% Lime + 1% Recron-3S

Sample

3. Soil (83%) + Fly ash (12%) + Lime (3%) + Recron-

3S (2%)

Result of Standard Proctor Test is listed in Table VI

and from that data, graph is drawn which is shown in

fig. 5

TABLE VI

PROCTOR TEST RESULT FOR Soil (83%) + Fly

ash (12%) + Lime (3%) + Recron-3S (2%)

DATA SHEET FOR SOIL TEST

Soil (85%) + Fly Ash (12%) + lime (3%)

(Ref. std: IS 2720-7, IS: 2720-8) Volume of Mould:

1000cc

Wa

ter

in

ml.

Water

of

Sampl

e in

(gms)

Moist

ure

Can

No.

M C +

Wet

Weigh

t

M C

+

Dry

Weig

ht

Moist

ure

Conte

nt (%)

Dry

Density

in gms/cc

140 1508 1 44.81 43.84 6.50 1.416

50 1544 97 47.63 45.88 8.39 1.424

50 1578 669 46.13 43.57 10.21 1.432

50 1648 244 47.75 45.00 13.13 1.457

50 1698 246 47.23 44.45 14.26 1.486

50 1674 49 58.53 53.35 16.61 1.435

50 1742 686 63.72 57.22 19.88 1.453

50 1744 94 69.81 62.87 22.04 1.429

From Graph MDD: 1.487 gms/cc & OMC: 14.85%

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3794

Fig. 5 MDD Vs OMC Fraph for 83% Soil + 12% Fly ash + 3% Lime

+ 2% Recron-3S

TABLE VII

CBR TEST RESULTFOR Soil (83%) + Fly ash (12%) +

Lime (3%) + Recron-3S (2%)

DATA SHEET FOR CBR TEST

Ref. Std. IS:2720 part-16

Sample: Soil (83%) + FA(12%) + Lime(3%) + Recron-3S(2%)

Sample Condition: Remoulded at OMC & ODD

Type of Compaction: Light Compaction

Test Condition: Soaked. Soaking for 96 Hours

Penetration Rate: 1.25 mm/min Surcharge Weight: 5.0 kg

Penetration

(mm)

Time

(min)

Penetration

Resistance Reading

0.0 0.00 0.00

0.5 0.24 0.09

1.0 0.48 0.18

1.5 1.12 0.29

2.0 1.36 0.42

2.5 2.00 0.57

4.0 3.12 1.11

5.0 4.00 1.55

7.5 6.00 2.77

10.0 8.00 4.00

12.5 10.0 5.21

From the Graph

Corrections if any 1.84

CBR at 2.5 mm 9.30

CBR at 5.0 mm 12.2

Fig. 6 CBR Test for 83% Soil + 12% Fly ash + 3% Lime + 2% Recron-3S

Sample

V. RESULTS

The calculation for the various proportions is listed in

above tables. The results of CBR value for the different

proportions are as follows

TABLE VIII

RESULTS

Sr.

No

Proportions

MDD

(gm/cc)

OMC

(%)

CBR (%)

2.5

mm

5

mm

1. Soil (100%) 1.07 23.85 1.40 2.0

2.

Soil (84%) + Fly Ash (12%) +

Lime (3%) + Recron-3S (1%)

1.55

19.95

13.7

18.3

3.

Soil (83%) + Fly Ash (12%) +

Lime (3%) + Recron-3S (2%)

1.87

14.50

9.30

12.2

From the table VIII, it can be conclude that best proportion is

when soil is 84%, fly ash is 12%, lime is 3% and recron-3S is

1% by total weight. By mixing this proportion of additive

materials CBR value is more compare to other proportion of

additive materials. If the design parameters of pavements are

known, then design can be carried by using IRC: 37-2001.

And from that design thickness of layer can be computed.

VI. CONCLUSION

Strength of soil can be increased to the certain extent by

using additive material in soil. Especially Recron-3S, when

mixed with soil and fly ash mixtures gives a wonderful result.

Fibre absorbs everything and keeps the road surface intact and

many problems can be solved like potholes, cracking & failure

of pavement. Strength of soil is determined by performing

California bearing ratio test. Materials can be easily available

from the market so it is economical. Problems can be

eliminated by using additive materials in the sub grade layer

of pavement. It can be also used in sub base layer. Fibre plays

an important role with soil. Recron helps to bind the soil under

the road.

ACKNOLEDGEMENT

The author owes a many thanks to all persons who helped

and guided throughout the project. Special thanks to Dr.

Rakesh kumar SVNIT, Surat., who supported and guided very

well till the end. Sense of gratitude to Mr. Hitesh Desai, who

allowed me to use his infrastructure in his UNIQUE

Engineering Testing & Advisory Services, Surat. Thanks and

appreciations to my friends Bhavin Parmar, Dhvani sonani

and Akash Tandel for their help and support.

I nternational J ournal of Engineering Trends and Technology (I J ETT) Volume 4 I ssue 8- Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3795

REFRENCES

[1] IRC, Use of Lime- Fly ash Concrete as pavement Base or Sub base

IRC: 60-1976, Indian Road Congress.

[2] IRC, Guidelines for the design of flexible pavements, IRC: 37-2001,

Indian Road Congress

[3] IS: 2720 part-16, Laboratory Determination of California Bearing

Ratio Standard

[4] IS: 2720 part-7, Light/Standard Compaction Test for Soil

[5] IS:2720 part-8, Light/Standard Compaction Test for soil

[6] Dr. Pravin Kumar & Shelendra Pratap Singh, Reinforced Fly ash Sub

base in rural Roads

[7] Kalpna VInesh Maheshwari, Ex Student, SVNIT, Surat.

[8] R. D. Gupta, Javed Alam, Mohd. Farooqi Effects on CBR values and

other Geotechnical Properties of Fly ash mixed with lime and non

woven geo fabrics

AUTHORSS BIOGRAPHY

Kishan Khunt received his Bachelor of engineering

degree in Civil Engineering from the Government

Engineering College, Surat, Gujarat Technological

University in 2012. At present he is final year student of

M. Tech Transportations System Engineering From Birla

Vishvkarma Mahavidyalaya, Gujarat Technological

University.

S-ar putea să vă placă și

- Effect of Raw Meal Fineness On Quality of ClinkerDocument6 paginiEffect of Raw Meal Fineness On Quality of ClinkerPrasann R Namannavar100% (1)

- Vizcarra 2020 IOP Conf. Ser. Mater. Sci. Eng. 758 012090Document7 paginiVizcarra 2020 IOP Conf. Ser. Mater. Sci. Eng. 758 012090Michell Salinas VilcaÎncă nu există evaluări

- Exercise HighwayDocument7 paginiExercise HighwayOmar AbdelnabyÎncă nu există evaluări

- Final Year PresentationDocument44 paginiFinal Year PresentationHussain SajidÎncă nu există evaluări

- Irjmets ArticleDocument7 paginiIrjmets ArticleSuraj PandeyÎncă nu există evaluări

- Civ T Qac 00134 ProctorDocument6 paginiCiv T Qac 00134 ProctorIsaiahogedaÎncă nu există evaluări

- Effect of Engineering Properties of Soil On Pavement Failures in Ogbagi - Akoko Area, Southwestern, NigeriaDocument5 paginiEffect of Engineering Properties of Soil On Pavement Failures in Ogbagi - Akoko Area, Southwestern, NigeriaYidenek MekonnenÎncă nu există evaluări

- An Overview of Waste Materials Recycling in The Sultanate of Oman - 2004 - Resources Conservation and Recycling PDFDocument14 paginiAn Overview of Waste Materials Recycling in The Sultanate of Oman - 2004 - Resources Conservation and Recycling PDFrahminÎncă nu există evaluări

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 paginiPartial Replacement of Fine Aggregates by Using Waste GlassSruthiÎncă nu există evaluări

- Effect of Boundary Conditions On The Hydraulic Behavior of Geotextile Filtration SystemDocument19 paginiEffect of Boundary Conditions On The Hydraulic Behavior of Geotextile Filtration Systemjavad khosraviÎncă nu există evaluări

- M 15 Mix Designs As Per IS-10262-2009Document25 paginiM 15 Mix Designs As Per IS-10262-2009Prasad MsrkÎncă nu există evaluări

- The Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceDocument10 paginiThe Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceJessica ClarkÎncă nu există evaluări

- Suitability of RHA Treated BCS For Containment ApplicationDocument14 paginiSuitability of RHA Treated BCS For Containment Applicationhamisu dahiruÎncă nu există evaluări

- Efficacy of Class C Fly Ash As A Stabilizer For Marginal Residual SoilDocument8 paginiEfficacy of Class C Fly Ash As A Stabilizer For Marginal Residual SoilmakiÎncă nu există evaluări

- Characteristics of Permanent Deformation Rate of Warm Mix Asphalt With Additives Variation (BNA-R and Zeolite)Document8 paginiCharacteristics of Permanent Deformation Rate of Warm Mix Asphalt With Additives Variation (BNA-R and Zeolite)AhmedMahirÎncă nu există evaluări

- Ijciet: ©iaemeDocument6 paginiIjciet: ©iaemefndsfsbskbÎncă nu există evaluări

- Full FM 5-428 Concrete MasonryDocument337 paginiFull FM 5-428 Concrete MasonrycitizenkanegÎncă nu există evaluări

- Soil Analysis Lab ReportDocument12 paginiSoil Analysis Lab ReportDanielle Del ConteÎncă nu există evaluări

- Layers of Flexible PavementDocument52 paginiLayers of Flexible Pavementsavan chavanÎncă nu există evaluări

- Assignment1 Aggregate CVLE321 Fall 2013-2014Document1 paginăAssignment1 Aggregate CVLE321 Fall 2013-2014ayaÎncă nu există evaluări

- Ceramic WasteDocument6 paginiCeramic WasteShahab SadqpurÎncă nu există evaluări

- Dgar 1Document22 paginiDgar 1Moses KaswaÎncă nu există evaluări

- Comparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionDocument5 paginiComparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionIAEME PublicationÎncă nu există evaluări

- 1005-JBMS-Original Article-2260-1-10-20210322Document13 pagini1005-JBMS-Original Article-2260-1-10-20210322زھرة ٱلبيلسآنÎncă nu există evaluări

- ASIF 04 MS Thesis Presentation (Update)Document27 paginiASIF 04 MS Thesis Presentation (Update)tanvir_austÎncă nu există evaluări

- Concrete Mix Design: by K.ShahDocument48 paginiConcrete Mix Design: by K.ShahBùi Quang MinhÎncă nu există evaluări

- Georgees RomelDocument13 paginiGeorgees RomelJean PajueloÎncă nu există evaluări

- Ijciet: ©iaemeDocument6 paginiIjciet: ©iaemeIAEME PublicationÎncă nu există evaluări

- Experimental Characteristic of PET Plastic BottleDocument8 paginiExperimental Characteristic of PET Plastic BottleDimitrija AngelkovÎncă nu există evaluări

- Sand Test 1Document7 paginiSand Test 1Tapas Kumar DeÎncă nu există evaluări

- Comparison Study Between Lime Application Methods On Hma Asphalt Concrete in IraqDocument17 paginiComparison Study Between Lime Application Methods On Hma Asphalt Concrete in IraqAhmedMahirÎncă nu există evaluări

- 1 PBDocument9 pagini1 PBhysh89000Încă nu există evaluări

- Constructio and QC in Rigid Pavements As Per IRC 15 and 58 201Document192 paginiConstructio and QC in Rigid Pavements As Per IRC 15 and 58 201Vizag Roads100% (39)

- Stabilization of Black Cotton Soil Using Alkali Activated Fly AshDocument6 paginiStabilization of Black Cotton Soil Using Alkali Activated Fly AshIJIRSTÎncă nu există evaluări

- Characteristics of Permanent DeformationDocument9 paginiCharacteristics of Permanent Deformationali.engi1992Încă nu există evaluări

- Lab 13 Marshall Mix DesignDocument32 paginiLab 13 Marshall Mix DesignOtomen Yan Yan100% (9)

- Plagiarism Checker X Originality Report: Similarity Found: 2%Document7 paginiPlagiarism Checker X Originality Report: Similarity Found: 2%عبداللە عمر ابراهیمÎncă nu există evaluări

- 11.7 Crushing and Grinding: Emission CalculationsDocument4 pagini11.7 Crushing and Grinding: Emission Calculationskiranpatil1014532Încă nu există evaluări

- Construction and Building Materials: Telma Ramos, Ana Mafalda Matos, Bruno Schmidt, João Rio, Joana Sousa-CoutinhoDocument9 paginiConstruction and Building Materials: Telma Ramos, Ana Mafalda Matos, Bruno Schmidt, João Rio, Joana Sousa-CoutinhoTarek ChikerÎncă nu există evaluări

- Strength of ConcreteDocument3 paginiStrength of ConcretelombangrurusÎncă nu există evaluări

- Soil Stablization Using Shredded Rubber TyreDocument4 paginiSoil Stablization Using Shredded Rubber TyremahakÎncă nu există evaluări

- Effect of RHA On VSS of BCSDocument19 paginiEffect of RHA On VSS of BCShamisu dahiruÎncă nu există evaluări

- Concrete Making MaterialsDocument55 paginiConcrete Making Materialsjaffna100% (1)

- Analysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface MethodologyDocument11 paginiAnalysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface Methodologymehrdad_so1981Încă nu există evaluări

- Properties of Papercrete Concrete Containing Crushed Concrete WasteDocument11 paginiProperties of Papercrete Concrete Containing Crushed Concrete WasteRana AlshahwanyÎncă nu există evaluări

- 4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision ADocument236 pagini4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision AVallabhareddy Nageswara Rao60% (5)

- Soil Reinforcement and FoundationsDocument56 paginiSoil Reinforcement and FoundationsManoj Janardan Jayashree TerekarÎncă nu există evaluări

- Construction and QC in Flexible Pavements 18 08 2013Document134 paginiConstruction and QC in Flexible Pavements 18 08 2013apncrmptpqa100% (3)

- A 5 EE 437 Evaluation of Hydrated Lime EDocument8 paginiA 5 EE 437 Evaluation of Hydrated Lime Emohanadakkila1991Încă nu există evaluări

- Investigation To Improve The Sand Molding Formula of The Erg by Incorporating Local MaterialsDocument14 paginiInvestigation To Improve The Sand Molding Formula of The Erg by Incorporating Local MaterialsTJPRC PublicationsÎncă nu există evaluări

- Minerals 09 00022 PDFDocument19 paginiMinerals 09 00022 PDFRodrigo Alarcón VásquezÎncă nu există evaluări

- Proportioning Concrete MixturesDocument54 paginiProportioning Concrete Mixtureshola_kbÎncă nu există evaluări

- Microtrac Applications Notes Particle Size Measurement of Cement by Laser Diffraction Using S3500Document5 paginiMicrotrac Applications Notes Particle Size Measurement of Cement by Laser Diffraction Using S3500pas85Încă nu există evaluări

- Feasibility of Rice Husk Ash As Optional Mineral Filler in Microsurfacing Incorporating Type III AggregateDocument5 paginiFeasibility of Rice Husk Ash As Optional Mineral Filler in Microsurfacing Incorporating Type III AggregatePriyaraj23Încă nu există evaluări

- Behaviour of Clayey Soil Mixed With Randomly Distributed Rubber Tyre WasteDocument3 paginiBehaviour of Clayey Soil Mixed With Randomly Distributed Rubber Tyre Wasteanil kasotÎncă nu există evaluări

- Effect of Terrasil On The Hydraulic Conductivity and Strength Properties of SoilDocument8 paginiEffect of Terrasil On The Hydraulic Conductivity and Strength Properties of SoilAkolade adebolaÎncă nu există evaluări

- A.L BH#1 D3Document22 paginiA.L BH#1 D3ISHTIAQ NOORÎncă nu există evaluări

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceDe la EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceÎncă nu există evaluări

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesDe la EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerÎncă nu există evaluări

- Fabrication of High Speed Indication and Automatic Pneumatic Braking SystemDocument7 paginiFabrication of High Speed Indication and Automatic Pneumatic Braking Systemseventhsensegroup0% (1)

- Experimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilDocument7 paginiExperimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilseventhsensegroupÎncă nu există evaluări

- Comparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterDocument8 paginiComparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterseventhsensegroupÎncă nu există evaluări

- Optimal Search Results Over Cloud With A Novel Ranking ApproachDocument5 paginiOptimal Search Results Over Cloud With A Novel Ranking ApproachseventhsensegroupÎncă nu există evaluări

- An Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsDocument4 paginiAn Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsseventhsensegroupÎncă nu există evaluări

- Comparison of The Regression Equations in Different Places Using Total StationDocument4 paginiComparison of The Regression Equations in Different Places Using Total StationseventhsensegroupÎncă nu există evaluări

- Extended Kalman Filter Based State Estimation of Wind TurbineDocument5 paginiExtended Kalman Filter Based State Estimation of Wind TurbineseventhsensegroupÎncă nu există evaluări

- The Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyDocument3 paginiThe Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyseventhsensegroupÎncă nu există evaluări

- Design and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalDocument5 paginiDesign and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalseventhsensegroupÎncă nu există evaluări

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 paginiDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupÎncă nu există evaluări

- A Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseDocument8 paginiA Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseseventhsensegroupÎncă nu există evaluări

- Application of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementDocument8 paginiApplication of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementseventhsensegroupÎncă nu există evaluări

- Color Constancy For Light SourcesDocument6 paginiColor Constancy For Light SourcesseventhsensegroupÎncă nu există evaluări

- Ijett V5N1P103Document4 paginiIjett V5N1P103Yosy NanaÎncă nu există evaluări

- Implementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationDocument6 paginiImplementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationseventhsensegroupÎncă nu există evaluări

- High Speed Architecture Design of Viterbi Decoder Using Verilog HDLDocument7 paginiHigh Speed Architecture Design of Viterbi Decoder Using Verilog HDLseventhsensegroupÎncă nu există evaluări

- FPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorDocument4 paginiFPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorseventhsensegroupÎncă nu există evaluări

- An Efficient Expert System For Diabetes by Naïve Bayesian ClassifierDocument6 paginiAn Efficient Expert System For Diabetes by Naïve Bayesian ClassifierseventhsensegroupÎncă nu există evaluări

- An Efficient and Empirical Model of Distributed ClusteringDocument5 paginiAn Efficient and Empirical Model of Distributed ClusteringseventhsensegroupÎncă nu există evaluări

- Study On Fly Ash Based Geo-Polymer Concrete Using AdmixturesDocument4 paginiStudy On Fly Ash Based Geo-Polymer Concrete Using AdmixturesseventhsensegroupÎncă nu există evaluări

- Non-Linear Static Analysis of Multi-Storied BuildingDocument5 paginiNon-Linear Static Analysis of Multi-Storied Buildingseventhsensegroup100% (1)

- An Efficient Encrypted Data Searching Over Out Sourced DataDocument5 paginiAn Efficient Encrypted Data Searching Over Out Sourced DataseventhsensegroupÎncă nu există evaluări

- Separation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusDocument6 paginiSeparation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusseventhsensegroupÎncă nu există evaluări

- A Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersDocument6 paginiA Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersseventhsensegroupÎncă nu există evaluări

- A Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksDocument5 paginiA Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksseventhsensegroupÎncă nu există evaluări

- Key Drivers For Building Quality in Design PhaseDocument6 paginiKey Drivers For Building Quality in Design PhaseseventhsensegroupÎncă nu există evaluări

- Review On Different Types of Router Architecture and Flow ControlDocument4 paginiReview On Different Types of Router Architecture and Flow ControlseventhsensegroupÎncă nu există evaluări

- Ijett V4i10p158Document6 paginiIjett V4i10p158pradeepjoshi007Încă nu există evaluări

- Free Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodDocument8 paginiFree Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodseventhsensegroupÎncă nu există evaluări

- Performance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran OilDocument5 paginiPerformance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran OilseventhsensegroupÎncă nu există evaluări

- Hilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Document17 paginiHilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Farly VergelÎncă nu există evaluări

- Exxonmobil High Density Polyethylene Product Guide: Europe Asia Pacific Middle East AfricaDocument6 paginiExxonmobil High Density Polyethylene Product Guide: Europe Asia Pacific Middle East Africasébastien cardinale0% (1)

- Section-14 Durability r1Document8 paginiSection-14 Durability r1EEÎncă nu există evaluări

- Important Question ICSE 2010 Class 10th Hydrogen ChlorideDocument5 paginiImportant Question ICSE 2010 Class 10th Hydrogen ChlorideYash KapoorÎncă nu există evaluări

- TECH SPECS. Two Storey Residential House With Roof Deck VIRAY 042617Document27 paginiTECH SPECS. Two Storey Residential House With Roof Deck VIRAY 042617April Rose SantosÎncă nu există evaluări

- Balcony Glass Partition Calculation - JBRSDocument63 paginiBalcony Glass Partition Calculation - JBRSahsan khan100% (1)

- Price List For WIKA PDFDocument110 paginiPrice List For WIKA PDFMohammed AbdelsalamÎncă nu există evaluări

- Din 2393-2 PDFDocument5 paginiDin 2393-2 PDFKarthikeyan NÎncă nu există evaluări

- CHE 631: Chemical Reaction CHE 631: Chemical Reaction EngineeringDocument9 paginiCHE 631: Chemical Reaction CHE 631: Chemical Reaction EngineeringRavi kumarÎncă nu există evaluări

- NameDocument2 paginiNameJaedo CabantogÎncă nu există evaluări

- LUBCON Lubricants Textile Complete ENDocument5 paginiLUBCON Lubricants Textile Complete ENMajed DawaÎncă nu există evaluări

- California Green Building Standards Code - Residential Mandatory Measures (PDF) - 201502030949166410Document2 paginiCalifornia Green Building Standards Code - Residential Mandatory Measures (PDF) - 201502030949166410Darren StrongÎncă nu există evaluări

- Application & Construction: Simple Free Standing Walls in Clay BrickworkDocument3 paginiApplication & Construction: Simple Free Standing Walls in Clay BrickworkummerdÎncă nu există evaluări

- Hydrochloric Acid (HCL) CorrosionDocument3 paginiHydrochloric Acid (HCL) CorrosionAjmi HmidaÎncă nu există evaluări

- DLP PatentingDocument7 paginiDLP PatentingAon HemmatadÎncă nu există evaluări

- Materiales CompuestosDocument167 paginiMateriales CompuestosTatiana MerchanÎncă nu există evaluări

- 1 - Prelim - DDS Laboratory ExamDocument3 pagini1 - Prelim - DDS Laboratory ExamROLAND AMIEL PENALOZAÎncă nu există evaluări

- E TextilesDocument20 paginiE TextilesKhadeeja Ashna0% (1)

- Brochure 1 Chromatech Ultra F ROLLTECHDocument2 paginiBrochure 1 Chromatech Ultra F ROLLTECHmoczynskimarcinÎncă nu există evaluări

- Precast ConcreteDocument69 paginiPrecast Concretecapriciouskash70% (10)

- Lift VentDocument4 paginiLift Ventismi iqhwan ihsanÎncă nu există evaluări

- Catalog AmbienteDocument27 paginiCatalog AmbienteAdi ATMÎncă nu există evaluări

- High Energy Ball Mill SpecsDocument10 paginiHigh Energy Ball Mill SpecsRanveer ShekhawatÎncă nu există evaluări

- 2002 Tech VarahaluDocument11 pagini2002 Tech VarahaluMuhammad NaeemÎncă nu există evaluări

- Samir Bhojwani SahebDocument2 paginiSamir Bhojwani SahebstardennisÎncă nu există evaluări

- Tiled Steam Room and Steam Shower Technical Design ManualDocument96 paginiTiled Steam Room and Steam Shower Technical Design ManualLATICRETE® International100% (3)

- BUBBLE DECK SLAB FinalDocument25 paginiBUBBLE DECK SLAB FinalAkhila Das67% (3)

- Plastering-Method Statement (R)Document4 paginiPlastering-Method Statement (R)TATATAHERÎncă nu există evaluări

- Formwork ExampleDocument4 paginiFormwork ExampleDarwish Wahab100% (1)

- Batch Manufacturing RecordDocument7 paginiBatch Manufacturing RecordAnu JoshiÎncă nu există evaluări