Documente Academic

Documente Profesional

Documente Cultură

Fluent-Intro 15.0 WS03 Multi Species Postpro

Încărcat de

Tiago CandeiasDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fluent-Intro 15.0 WS03 Multi Species Postpro

Încărcat de

Tiago CandeiasDrepturi de autor:

Formate disponibile

2014 ANSYS, Inc. February 28, 2014 1 Release 15.

0

15.0 Release

Introduction to ANSYS

Fluent

Workshop 03

Multi-Species Flow and Post-

Processing

2014 ANSYS, Inc. February 28, 2014 2 Release 15.0

In this workshop you will analyze the release of heat and combustion gases from a single

car with an engine fire in a ventilated parking garage

The simulation will be run steady state assuming the fire has reached a stable developed

stage

Simulation Physics & Boundary Conditions

Mixture of N

2

, O

2

, CO

2

and H

2

0

6 m/s exhaust, 0.1 kg/s combustion gases (H

2

O and CO

2

) at 1200 K

80 N/m

3

momentum source in jets

Introduction

Fresh Air Inlet

velocity_inlet_fresh_air

Jet Fan

fluid_jet_fan

Heat and gas release from fire

mass_flow_inlet_car_fire_source

Air Outlet

pressure_outlet_all_air

Symmetry Plane

symmetry

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 3 Release 15.0

Important Note

NOTE:

This workshop has been designed to be completed in one of two ways

Please check with your trainer on whether you are to take the short or long option

[Short Option] This workshop can be used just to demonstrate post-processing in CFD-

Post

Pre-prepared results files are supplied, so please jump straight to page 35 for post-

processing

[Long Option] Follow all the instructions, which will demonstrate how to set up a multi-

species simulation of a car fire

Once the model is set up, you can choose to wait for it to converge, or then replace

your results with the supplied pre-prepared set

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 4 Release 15.0

If doing the short version (post-processing only)

please jump to page 35 now

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 5 Release 15.0

Learning Aims:

The first part of this workshop will show how to set up a multi-species problem.

The domain will contain a blend of several different gases (nitrogen, oxygen,

carbon dioxide, water vapor).

Other topics that will be introduced are:

Including gravitational (buoyancy) effects

Setting a momentum source term to account for a jet fan

Learning Objectives:

To understand how Fluent can be used to simulate mixtures of fluids, and

account for buoyancy effects. Note that a multi-species problem like this

assumes that the components are mixed at a molecular level (as normally

happens with gases). The alternative is a multi-phase problem where there is an

identifiable boundary between the components (either droplets / particles /

bubbles, or a free-surface). Multi-phase workshops include Workshop 2 (DPM)

and Workshop 8 (Tank Flush).

I Objectives (Flow Simulation Part)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 6 Release 15.0

Starting Workbench

Open Workbench

Start > Programs > ANSYS 15.0 > Workbench 15.0

Drag a Fluent Component System into the project schematic

Rename the system to Garage (RMB on cell A1 to rename the system)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 7 Release 15.0

Starting Fluent in Workbench

Start Fluent

Double click on the Setup cell to open Fluent

Choose 3D and Double Precision under Options and retain the other default

settings (if your computer has 2 or more nodes and parallel licenses are

available, you also could start Fluent parallel)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 8 Release 15.0

Import the existing mesh file

Under the Fluent File menu select Import >

Mesh

Select the file car_and_garage.msh and click OK

to import the mesh

To check for any problems in the mesh click

Check. There should be no problems reported in

the TUI window

Reorder the mesh using Mesh > Reorder >

Domain (from the menu)

Reordering the domain can improve the computational

performance of the solver by rearranging the nodes,

faces and cells in memory.

Retain defaults for the solver

Enable gravity and set z = -9.81 m/s

2

Import Mesh and General Setup

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 9 Release 15.0

Setting Physics (Turbulence)

Specify turbulence model

Select Models in the navigation pane

Double click Viscous in the model

selection pane. The Viscous Model panel

will open

Select k-epsilon (2 eqn) under Model,

Realizable under k-epsilon Model and

Enhanced Wall Treatment under Near-

Wall Treatment

Turbulence modeling, as with all physics

modeling, is a complex area. There are many

application specific options. The k-epsilon

model is a simple but robust model. The

documentation provides further guidance on

which models to use for specific applications.

Click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 10 Release 15.0

Setting Physics (Species / Mixture)

Specify species model

Double click Species in the model

selection pane to open the Species Model

panel

In this workshop the products of combustion

(heat & gases) will be modeled rather than the

reaction itself. You can see in the panel that if

it was desired to model fire by including the

reactions, there are several combustion models

available.

Select Species Transport and click OK

Switching on the species model will introduce

new material properties

An information box will appear. Click OK to

accept this

This setup will enable the tracking of non-

reacting chemical species

The species model requires the

definition of a mixture representing

the chemical species of interest. The

default mixture contains nitrogen,

oxygen and water vapour.

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 11 Release 15.0

Specify mixture

Select Materials in the navigation pane.

Note that under Mixture in the Materials pane the

default mixture is listed as containing nitrogen,

oxygen and water-vapor.=

Double click mixture-template, this will open the

Create/Edit Materials panel with the mixture

preselected

Defining Materials (1)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 12 Release 15.0

Defining Materials (2)

Add a mixture species

In the Create/Edit Materials panel click on

Fluent Database

The Fluent Database Materials panel will

appear

Select fluid as Material Type

All predefined fluids materials will be

listed under Fluent Fluid Materials

Select carbon-dioxide (co2)

Click Copy

Close the Fluent Database Materials panel

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 13 Release 15.0

Defining Materials (3)

Copying carbon-dioxide(co2) from the fluid database has made the species available to

the simulation, now add it to the mixture

In the Materials panel ensure Material Type is set to Mixture

Alongside Mixture Species, click Edit

In the Species panel select co2 from the Available Materials list and select Add

The Selected Species defines the component species of the mixture

The order of the species listed under Selected Species is important. The most

abundant species should be listed last

Use the Remove button to Remove n2, followed by the Add button to replace n2 as

the last species. Click OK (but dont close the mixture panel yet)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 14 Release 15.0

Defining Materials (4)

Specify mixture

Modify the existing settings for Thermal Conductivity and Viscosity to be mass-

weighted-mixing-law

Click Change/Create to apply the changes

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 15 Release 15.0

Defining Materials (5)

Specify solid material

Select Solid under Material Type. The default solid material is aluminum (al)

Modify aluminum (Name, Chemical Formula & Properties) as shown below

Click Change/Create and choose No for overwriting

Selecting No preserves the original material (aluminum) and adds the new material

Close the Create/Edit Materials panel

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 16 Release 15.0

Cell Zone Conditions

Set Cell Zone Conditions

Select Cell Zone Conditions from the

Navigation Pane

Select fluid_jet_fan, then edit

Activate Source Terms

Select the Source Terms tab and click on

Edit for Y Momentum

Add 1 source, select Constant and enter a

value of -80 (N/m

3

)

Click OK in both panels

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

We need to account for the air movement produced by the ceiling

jet fan. Here we have done this by adding momentum to the cell

zone local to the jet. The advantage of this technique (over using a

pair of velocity boundary conditions) is that we preserve the

species (smoke) concentration through the fan. If we had used

velocity boundary conditions, we would have needed a UDF to find

the concentration at the intake to the jet fan and apply that to the

jet fan discharge.

2014 ANSYS, Inc. February 28, 2014 17 Release 15.0

Set Boundary Conditions

Select Boundary Conditions from the Navigation Pane

Open velocity_inlet_fresh_air from the Zone list

Apply Momentum and Thermal settings as shown

Continued on next slide.....

Boundary Conditions (air inlet)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 18 Release 15.0

Boundary Conditions (air inlet)

Set Boundary Conditions.... cont

Apply Species settings as shown

Click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

The mixture species contains 4

components (h2o, o2, co2, and n2).

The most abundant species (n2) was

entered last when the mixture was

defined.

You do not need to enter a mass fraction

for n2. It will automatically account for the

remaining fraction not used by the first

three (in this case 0.77).

2014 ANSYS, Inc. February 28, 2014 19 Release 15.0

Boundary Conditions (air outlet)

Set Boundary Conditions

Open pressure_outlet_all_air from the Zone list

For Momentum, in Turbulence set intensity to 5% and viscosity ratio to 5

For Thermal, set the temperature to 293.15 K (as for previous BC)

For Species, set the o2 concentration to 0.23

Click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

So long as there is only flow out of the

domain here, these values for turbulence,

temperature and species will not be

needed.

However during the solution process there

may be some inflow though this boundary,

and therefore Fluent needs to know what

values to apply.

2014 ANSYS, Inc. February 28, 2014 20 Release 15.0

Set Boundary Conditions

Open mass_flow_inlet_car_fire_source from the Zone list.

Momentum: Mass Flow Rate to 0.1 kg/s, Normal to Boundary

Turbulence: 5% Turbulent Intensity, Turbulent Viscosity Ratio = 5

Thermal: 1200K

Species: set specify in mole fractions with 0.65 h2o and 0.35 co2

Boundary Conditions (fire source)

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 21 Release 15.0

Boundary Conditions (walls 1)

Set Boundary Conditions

Open walls_outer from the Zone list

Set the temperature to 300 K and click Shell Conduction

Enter the Shell Conduction Model Settings as shown

Click OK in both panels

The Shell Conduction option

enables thin walls to solve for heat

transfer in both the normal and

planar directions without the need to

volume mesh them.

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

After Shell Conduction is selected, certain fields in the Wall

panel are greyed out and their entries are superseded by the

entries in the Shell Conduction Model Settings Panel.

2014 ANSYS, Inc. February 28, 2014 22 Release 15.0

Boundary Conditions (walls 2)

Set Boundary Conditions

Select Copy from the Boundary Conditions Pane

Select walls_outer in the From Boundary Zone list and wall_ceiling and wall_floor

in the To Boundary Zones list

Click Copy, click OK in the question dialog box then Close

This will copy all boundary settings from the boundary zone walls_outer to both

wall_ceiling and wall_floor

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 23 Release 15.0

Operating Conditions

Set operating conditions

Select Operating Conditions

Apply Specified Operating Density settings as shown

Click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 24 Release 15.0

Operating Conditions

Notes

ANSYS Fluent avoids the problem of round-off error by subtracting the operating

pressure (generally a large pressure roughly equal to the average absolute pressure in

the flow) from the absolute pressure, and using the result (termed the gauge

pressure). The absolute pressure is simply the sum of the operating pressure and the

gauge pressure.

Operating temperature is only used when using the Boussinesq density model, so in

this case, it has no meaning.

Operating density is also a value for avoiding round-off errors. For simulations where

pressure boundary conditions are present it is important to set the value correctly

otherwise the pressure at the boundary will be incorrect and may lead to unphysical

flow conditions. Here you have to set it to the density for the conditions at the

pressure-inlet - a gas at 293.15 K with 23% O

2

and 77% N

2

. You can initialize your flow

field with these conditions to get the value for the operating density from the post-

processor (e. g. Reports -> Volume Integral). See the Users Guide Natural Convection

and Buoyancy-Driven Flows for more details.

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 25 Release 15.0

Solution Methods

Set solution methods

Select Solution Methods from the Navigation Pane

For Pressure-Velocity Scheme, set to Coupled

Under Spatial Discretization set Pressure to Body Force Weighted

The Body Force Weighted scheme is recommended for problems involving large

body forces

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 26 Release 15.0

Solution Controls

Set solution controls

Select Solution Controls from the Navigation Pane

Set the values shown below

Flow Courant Number = 50

Explicit Relaxation Factors 0.5 (Momentum & Pressure)

Density = 1

Body Forces = 1

Turbulent Kinetic Energy = 0.5

Turbulent Dissipation Rate = 0.5

Turbulent Viscosity = 0.7

h2o = 1

o2 = 1

co2 = 1

Energy = 1

Lower Under-Relaxation Factors will reduce the solution

change between iterations, leading to more stable

convergence though requiring more iterations to reach

convergence.

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 27 Release 15.0

Monitors (1)

Set solution monitors

Select Monitors from the Navigation Pane

Click Edit and set the Residual Monitors as shown below

By default ANSYS Fluent will plot residuals to the window and print to the console. The

default setting for the convergence criterion is Absolute which means that the solver will

continue until all residuals fall below the Absolute Criteria values specified in the Equations

box. Switching the Convergence Criterion to none will cause the solver to continue until a

maximum number of iterations is reached.

Click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 28 Release 15.0

Monitors (2)

Set surface monitors

Under Surface Monitors, click Create

It is important to ensure that solution variables have converged to sensible stable values.

Creating Surface Monitors enables solution values of interest to be monitored on specific

surfaces within the domain.

Set the Surface Monitor as shown below and click OK

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 29 Release 15.0

Monitors (3)

Set surface monitors

There are many different types of calculations that can be performed over surfaces listed

under Report Type.

Create a second monitor for the integral of the Total Surface Heat Flux on the surface

wall_ceiling plotting to window 3 and printing to the console, as shown below

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 30 Release 15.0

Monitors (3)

Notes on monitors

Buoyancy driven flows often show transient behavior. For this reason, the residuals

will often oscillate. Because of this, convergence should always be judged by solution

variable monitors and flux reports. The residuals will however give an indication of

overall convergence behavior and stability.

In cases of an oscillating steady state solution, a common approach is to continue

the simulation in transient mode. In many cases the oscillations will reduce

significantly after a few time steps.

The use of surface/volume monitors combined with residuals will provide the best

overall judge of solution convergence.

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 31 Release 15.0

Set initialization values

Select Solution Initialization and Hybrid Initialization

Hybrid Initialization performs a basic flow simulation (Laplace equation) to set up the

initial flow field. Simplified momentum and pressure equations are solved, and so the

general flow field can be quickly determined (unlike standard initialization which puts a

constant value in each grid cell). By having a more realistic starting point, less work will be

needed by the solver to converge the model.

Select More Settings, and for species settings, define the initial o2 concentration to

be 0.23, then OK

Only flow and pressure equations are being solved with the Hybrid method, so we need to

set a realistic, although constant, value for species

Select Initialize, and watch the TUI window for progress

Solution Initialization

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 32 Release 15.0

Running the Simulation

This simulation will take a long time to compute a converged solution this is not unusual

for such ventilation / natural convection cases. There are natural unsteady features in the

flow and the equation set is somewhat stiff to converge.

If you want to run the simulation yourself, set the case to run for 1000 iterations in Run

Calculation, and keep an eye on the solution progress

Alternatively, just load the results (data) file supplied with this workshop

File > Import > Data > car_and_garage_1000its.dat.gz

You can reproduce the residual graph (but not the surface monitors) shown below

by Monitors > Residuals > Select Residuals then Edit, then press the Plot button

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 33 Release 15.0

Check Convergence

Select Reports from the Navigation Pane and select Fluxes under Reports

Click Set Up

In the Flux Reports panel select Mass Flow Rate and select the inlet/outlet boundaries

(shown below) then click compute

Note that the Net Results indicate a good mass balance, but the monitors show the solution is not

completely converged. It is likely that there are some unsteady effects present that may necessitate

going to a transient (time dependent) simulation. This will be discussed in a later lecture.

Note that the energy balance can be checked in a similar way by selecting Total Heat Transfer Rate

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 34 Release 15.0

Exit

Close Fluent

Close ANSYS Fluent by selecting File>Close Fluent

ANSYS Fluent contains basic built in post-processing capabilities which can be used to

quickly assess results graphically and numerically during and after the solution

The remainder of this workshop will introduce some features of CFD-Post, which is a

powerful, separate post-processing application containing many more advanced

features than Fluent

Introduction Part 1: Long Version Setup Solving Proceed to Part 2.

2014 ANSYS, Inc. February 28, 2014 35 Release 15.0

Post-Processing in CFD-Post

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 36 Release 15.0

Learning Aims:

This workshop is designed to teach a range of skills in post-processing Fluent

results files using CFD-Post. Topics to be covered include:

Creating surface groups - Creating line graphs

Creating isosurfaces - Creating expressions (CEL)

Creating portable (.cvf) images - Performing integrals

Creating automatic reports - Volume rendering

Learning Objectives:

To understand the ways in which CFD-Post can be used both for high quality

images, as well as producing quantitative data from volume/surface integrals,

and writing custom functions.

I Objectives (Post-Processing)

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 37 Release 15.0

Starting CFD-Post

If you are doing the long version of this workshop:

Go to the ANSYS Workbench project page

Under Component Systems, pick Results and drag onto the desktop

Left click in the Solution cell (A3) and without releasing the mouse button, drag the

pointer on to the Solution Cell of the Results system (B2) (see image)

Start CFD-Post by clicking on the Results cell

If you are doing the short (post-processing only) version of this workshop:

Start CFD-Post from the Start menu:

Start Menu > ANSYS 15.0 > Fluid Dynamics > CFD-Post 15.0

Within CFD-Post, select File > Load Results and pick the supplied file:

car_and_garage_1000its.dat.gz

OK to the pop-up window

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 38 Release 15.0

Post-Processing Wall Temperature (1)

Add a Location representing a group of surfaces

This lets you group a selection of entities (in this case walls) and apply the same post-

processing treatment to all items in the group

Select Location > Surface Group, and enter the name Walls

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 39 Release 15.0

Post-Processing Wall Temperature (2)

Define Location details

The details of the new location will be

displayed in the bottom left pane

Select Locations, click on and

select all walls EXCEPT wall_car (CTRL

click to multiple select)

Click OK in the Location Selector

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 40 Release 15.0

Apply contour plot to Location

Select the Color tab, click on Mode and select:

Variable: Temperature

Range: Local

Apply

Modify the Legend

Select Default Legend

Right click, Edit

Under Appearance:

Precision 1

Change Scientific

to Fixed

Apply

Post-Processing Wall Temperature (3)

This option has allowed us to

produce a temperature contour

plot of identical colour range on

a group of surfaces.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 41 Release 15.0

Generate a figure for use later in a report

- Click the Figure icon

- Enter name Figure 1 Wall Temperature

- OK to the Insert Figure panel

Post-Processing Generating a Figure

Remember where this option is

(you will be asked to use it

several times on subsequent

slides).

We will be creating several

figures as we progress through

this workshop.

Later on we will demonstrate

how to use these figures to

automate report-writing.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 42 Release 15.0

Post-Processing Section Plane (1)

Add a Location representing a section plane

Select Location > Isosurface

In the pop-up window Enter name xzplane and click OK.

Under Geometry tab set Definition Variable to Y

Value to 9 [m]

Click Apply

In the model outline tree,

de-select the Walls option

so only the new slice plane

is visible

Continued on next slide..

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 43 Release 15.0

Post-Processing Section Plane (2)

Under Color set the Variable to Temperature

Under Render disable Lighting, then Apply to display

Generate a new Figure, and name it Figure 2 Temperature Slice

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 44 Release 15.0

Post-Processing Quick Animation

The slice through the model gives us a useful indication of what is happening in the

middle of the domain. A quick animation will transverse this slice through the model

so we can see what is happening elsewhere.

Click the Animation button in the top toolbar

Select Quick Animation

Highlight the xzplane object.

Press the Play button , and watch the display

When finished, use the stop button then Close

If required, this animation could be saved to disk in MPEG / AVI

formats.

The alternative to Quick Animation is Keyframe Animation. To use

this you set a series of key animation frames. These might have

different objects visible, different points in a transient simulation, or

might have the model rotated at a different viewing angle. The

animation will progress smoothly between these states.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 45 Release 15.0

Post-Processing 3d Isosurface [1]

First, change the look of the display:

Hide the plane xzplane previously created by un-ticking in the model tree

Expand the top of the model tree, expanding fluid_main_garage

Double-click on wall_car

Make sure the details box shows (wall_car), if not you will be modifying the wrong object!

For Color select constant, and pick yellow

Apply

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 46 Release 15.0

Post-Processing 3d Isosurface [2]

Add a 3D Isosurface representing gases

Select Location > Isosurfaces

Keep the default name Isosurface 1

Set the Variable to Co2.Mass Fraction and the value to 0.001

Set Color to be constant (in the Color tab) (keep default grey colour), then Apply

Generate a new Figure: Figure 3 CO2 Isosurface

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 47 Release 15.0

Add 3D streamlines to visualize flow

Hide the isosurface created in the previous step (un-tick in model tree)

Click the Streamline button and keep default name (Streamline 1)

Start From: velocity_inlect_fresh_air

# Points: 100

Under the Color tab set

Mode: Use Plot Variable

Range: Local

Apply

Generate a new Figure of this image

Figure 4 Streamlines

Post-Processing Streamlines

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 48 Release 15.0

Post-Processing Portable CVF Files [1]

Not only can CFD-Post export regular image formats (jpg /png), but in addition 3D images

can be saved. These images have the file extension .cvf

They can be viewed using a free CFD viewer that can be downloaded from the ANSYS

website. (Go to www.ansys.com, and search for CFD Post Viewer)

No license is required to use the viewer, so you can install this on any computer (e.g. laptop

used for presentations, or ask your client/customer to also download and install a copy).

The 3D image can be viewed using rotate / pan / zoom functionality just as in CFD-Post, and

can also be embedded in MS-Powerpoint. However the user cannot modify the image, they

cannot add/remove objects from the image, or alter color ranges.

This is a really powerful tool for when you come to present your project work. In many

cases a 2D jpeg image cannot explain 3D flow features. However rotating the model live in

front of your audience will help convey your findings.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 49 Release 15.0

Post-Processing Portable CVF Files [2]

In CFD-Post, click the camera icon:

For Format, select CFD-Viewer State(3D)

Click the folder icon to the right of the filename

Pick the directory you are working in (remember this!)

Save as filename car-streamlines.cvf

Click Save in both windows

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 50 Release 15.0

Post-Processing Portable CVF Files [3]

Minimise CFD-Post, and use Windows Explorer to browse to the folder used on the last slide

Note how this file (car-streamlines.cvf) is quite small (in this case about 170kB, and

therefore easy to email to your client or manager)

Double-click to open this file (it will take a few moments to launch the viewer application)

If you have ANSYS R15.0 installed on your machine, your computer will already have the

viewer, and will recognise this file extension. You only need to do a separate installation of

CFD-Post Viewer (from the ANSYS website) on machines that do not have Workbench

installed.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 51 Release 15.0

Post-Processing Portable CVF Files [4]

CFD-Post Viewer will look just like the graphical window of CFD-Post

Use left mouse button to rotate

Middle mouse button (or wheel) to zoom

Right mouse button to translate

Type question mark ? for a list of hotkeys

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 52 Release 15.0

Post-Processing Volume Rendering

Close the standalone viewer and return to CFD-Post

Hide the streamlines plot by un-ticking in model view

Select Volume Rendering, and use name Gas Cloud

Under Geometry, set Co2.Mass Fraction

Keep range as Global, then Apply

To make it easier to see the image, change the screen background colour to white:

Edit > Options > CFD-Post > Viewer

Set Color Type to Solid

Pick White from the color options

OK

This option applies a variable colour and

transparency to each grid cell depending on the

plot variable. For applications like this involving

smoke movement it makes it easy for the eye to

assess where the cloud is concentrated.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 53 Release 15.0

Post-Processing Quantitative

Until now we have used CFD-Post to create colour images to help interpret the CFD results.

Next we will look at some quantitative techniques for extracting numerical data (volume

integrals), and producing line graphs.

It is also possible to write your own arithmetic expressions for custom post-processing.

Create a line through the model:

Hide the Gas Cloud volume rendering

Location > Line and keep default name Line 1

Set Method Two Points

From: X=18 Y=3 Z=2

To: X=18 Y=18 Z=2

Set 40 samples along this line

Apply

This has created a horizontal line through the model,

passing above the front of the car.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 54 Release 15.0

Post-Processing Line Graph [1]

Select the Chart Icon from the top Toolbar

Keep the Default name Chart 1 then OK

Under General, set the Title to Temperature Profile

Under Data Series Set location to Line 1

Under X Axis, set variable to Y

Under Y Axis set variable to Temperature

Apply

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 55 Release 15.0

Post-Processing Line Graph [2]

The resulting graph looks like this:

The computation domain exists from

3m < y < 18m

The car (and fire source) is located at

8m < y < 10m

The jet fan is located at

13m < y < 15m

Notice that the peak temperature is

located not above the middle of the car

(y=9m) but moved some distance to the

left (circa y= 6.5 - 8m). This is a direct

effect of the air movement from the jet

fan.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 56 Release 15.0

Post-Processing Volume Integrals

The only source of carbon dioxide (co2) in the model is from

the car fire source (the inlet just comprises oxygen and

nitrogen). We will perform a volume integral to find out how

much co2 is present in the model.

Select Calculators tab

Select Function Calculator and double click

Function: volumeInt (for Volume Integral)

Location: fluid_main_garage

Variable: Co2.Mass.Fraction

Press Calculate

The result is about 0.57m

3

of CO

2

.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 57 Release 15.0

Post-Processing Expressions [1a]

It is possible to write your own arithmetic functions for post-processing, making use of

the data exported by the solver. The resulting expression may either return a single

value (first example, below), or produce a quantity that varies spatially for use in a

contour plot / line graph (second example, to follow).

Select Expressions tab

Right click in the window and select New

Enter name PressureDrop then OK

Enter the expression exactly as shown below, then Apply

The answer is approximately 35Pa

If you get any errors look at the next slide now, which

will help you understand why

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 58 Release 15.0

Post-Processing Expressions [1b]

Note how Pressure turns to

italics as soon as you type it

It is important to make the

first letter a capital P

For a full list of available

variables, right click in this

window and select Variables

This is the name of the boundary that you

are performing the average function on

For a full list of locations, right-click and

select Locations

Note that to compute the pressure drop,

we did not need to add the outlet boundary

...- ave(Pressure)@pressure_outlet_all_air

The outlet boundary was set to be a pressure

outlet in Fluent with a pressure of 0 Pa. This

term would return a zero value try it if you

like!

ave returns the average at

the location specified by

the @

For a list of functions

available, right-click in the

window and select

Functions > CFD-Post

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 59 Release 15.0

Post-Processing Expressions [2a]

The procedure to create an expression that can be plotted spatially is very similar,

there is just one additional step to assign it to a variable

As a simple example, lets convert temperature from K to C and plot this on the graph

Expressions > (Right click) New > name TemperatureConversion

Enter the expression Temperature/1[K] 273.15 then Apply

Note:

Initial capitals for Temperature

It will turn to italics if correct

Expressions must balance dimensionally

We cannot just enter Temperature 273.15 since Temperature has a unit [K]

By dividing by 1 [K] we remove the temperature unit

We could instead enter Temperature 273.15[K]

This expression is valid, but would return a value with units [K] which would be

misleading

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 60 Release 15.0

Post-Processing Expressions [2b]

Expressions cannot be plotted directly, they need to

be assigned to a Variable

Variables Tab > (Right click) New Enter name

TemperatureC

From the pull down list, select the expression

TemperatureConversion created on the last slide

Select Apply

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 61 Release 15.0

Post-Processing Expressions [2c]

Use this new temperature on the

Chart created earlier

(Top-Left) select Outline then

double-click on Chart 1

Under Y Axis change the variable

by clicking on the ... icon

Select this expression

TemperatureC

OK then Apply

At the bottom of the screen

change from 3D Viewer to Chart

Viewer

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 62 Release 15.0

Post-Processing Expressions [2d]

The graph now shows the result of our expression:

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 63 Release 15.0

Post-Processing Reports

In the options below the graphic

window, select Report Viewer

Select Refresh

Review what is shown in the report

window. You can see:

Names of the results file

Mesh summary

List of boundary conditions

All the Figures and Charts produced

during this workshop

If you select Publish this will be written

out in html format, along with copies of

all the results images

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 64 Release 15.0

State Files and Optional Extra Work

Use File > Save state as... and save to your working directory

The state file stores all the post-processing settings you have created. If CFD-Post is used

from WB, this is done automatically when closing CFD-Post.

If you have done the long version of this workshop, you will recall that we ran for a fixed

number of iterations, and wanted to examine the results to help us determine if the model

had converged or not. (The residuals were stuck and further iterations would not lower

the residuals). It might be be necessary to revisit the model setup, by moving to a

transient scheme, or modifying the modeling settings. A useful assessment of

convergence is to see if the results of interest remain unchanged as the solver settings are

enhanced.

The big advantage of having the state file is that if you choose to modify the solver

settings and re-run the model, you can quickly reproduce the equivalent post-processing

images. Simply load the new results file, then load the state file.

Likewise, it is common in project work to have run a series of models to test different

operating conditions. This technique will let you generate equivalent images so as to

produce a good like-for-like comparison in your presentation / report.

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 65 Release 15.0

State Files and Optional Extra Work

The Reports feature just demonstrated will let you customise the format of your

report

If you have finished this exercise ahead of the rest of the class, try experimenting with

the Report options in the left-hand toolbar

You can choose which objects are visible, add your own company logo, or add lines of

text to explain the content of the report

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

2014 ANSYS, Inc. February 28, 2014 66 Release 15.0

Wrap Up

CFD-Post is a very powerful post-processing tool, and capable of producing high quality

images quickly and easily

In this workshop we have shown how to produce contour plots, streamlines, and

isosurfaces (as seen in some other workshops for this course)

In addition you have used CFD-Post to perform volume integrals, create line graphs,

and to create your own arithmetic expressions for post-processing

3D images can be saved to disk, and viewed in a freeware viewer. This adds much

impact to presentations, and can be run on any computer (no license needed)

CFD-Post can also automate the report generation process

Post-processing is best learned by practice. If you have time now, try exploring the

other buttons in the interface

Part 2: Post-Processing Colour Images Line Graphs Expressions and Integrals Reports Summary

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- 6 Shearing Stresses PDFDocument18 pagini6 Shearing Stresses PDFTiago CandeiasÎncă nu există evaluări

- ANSYS Stress LinearizationDocument15 paginiANSYS Stress LinearizationTiago CandeiasÎncă nu există evaluări

- Introduction StressDocument25 paginiIntroduction StressAshraf QayyumÎncă nu există evaluări

- Introduction StressDocument25 paginiIntroduction StressAshraf QayyumÎncă nu există evaluări

- NASA - Obtain Coordinates of NACADocument27 paginiNASA - Obtain Coordinates of NACATiago CandeiasÎncă nu există evaluări

- ParasiteDocument44 paginiParasiteTiago CandeiasÎncă nu există evaluări

- French Oil Protectionism - Julien BraultDocument36 paginiFrench Oil Protectionism - Julien BraultTiago CandeiasÎncă nu există evaluări

- French Oil Protectionism: Macroeconomic Efficiency but Political InstabilityDocument41 paginiFrench Oil Protectionism: Macroeconomic Efficiency but Political InstabilityTiago CandeiasÎncă nu există evaluări

- French Oil Protectionism - Julien BraultDocument36 paginiFrench Oil Protectionism - Julien BraultTiago CandeiasÎncă nu există evaluări

- Fatigue Calculation by ANSYS PDFDocument8 paginiFatigue Calculation by ANSYS PDFgufeng0731Încă nu există evaluări

- The Re Use of Threaded FastenersDocument2 paginiThe Re Use of Threaded FastenersTiago CandeiasÎncă nu există evaluări

- Towards Veri Cation of Unstructured-Grid SolversDocument13 paginiTowards Veri Cation of Unstructured-Grid SolversTiago CandeiasÎncă nu există evaluări

- NASA - A Computer Program To Generate Two-Dimensional Grids About AirfoilsDocument63 paginiNASA - A Computer Program To Generate Two-Dimensional Grids About AirfoilsTiago CandeiasÎncă nu există evaluări

- A Parametric Blade Design System - AndersDocument50 paginiA Parametric Blade Design System - Andersaxeem1Încă nu există evaluări

- MorganDocument35 paginiMorganTiago CandeiasÎncă nu există evaluări

- Roe EulerDocument43 paginiRoe EulerTiago CandeiasÎncă nu există evaluări

- Fluent Moving FramesDocument86 paginiFluent Moving FramesTiago CandeiasÎncă nu există evaluări

- 11 - cisbEVALUATION OF WIND-DRIVEN VENTILATION IN BUILDING ENERGY SIMULATION: SENSITIVITY TO PRESSURE COEFFICIENTS at - Ramponi PDFDocument6 pagini11 - cisbEVALUATION OF WIND-DRIVEN VENTILATION IN BUILDING ENERGY SIMULATION: SENSITIVITY TO PRESSURE COEFFICIENTS at - Ramponi PDFTiago CandeiasÎncă nu există evaluări

- Continuous-Time Signals and Systems TablesDocument5 paginiContinuous-Time Signals and Systems TablesTiago CandeiasÎncă nu există evaluări

- Power Point Pablo Inore 2011Document5 paginiPower Point Pablo Inore 2011Tiago CandeiasÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- More Ways To Play DESPERADOS III! Fan Created Missions - Now You Can Download and Play Additional Missions, Created by TheDocument6 paginiMore Ways To Play DESPERADOS III! Fan Created Missions - Now You Can Download and Play Additional Missions, Created by TheKanÎncă nu există evaluări

- Ultra Trend DMS 4.1 ManualDocument22 paginiUltra Trend DMS 4.1 ManualejaqÎncă nu există evaluări

- Avsim CTD GuideDocument16 paginiAvsim CTD GuideUlrid YamnarmÎncă nu există evaluări

- Getting Started With PicasaDocument8 paginiGetting Started With PicasaBilal MaqsoodÎncă nu există evaluări

- ACNDocument22 paginiACNAmiable DollÎncă nu există evaluări

- CAN-EYE User Manual PDFDocument48 paginiCAN-EYE User Manual PDFkyuÎncă nu există evaluări

- Solid Works IntroDocument166 paginiSolid Works IntroPankaj DhankerÎncă nu există evaluări

- Techno TricksDocument14 paginiTechno TricksShiva KumaarÎncă nu există evaluări

- Be Sharp With C# (Chapter 1, Controls and Code)Document21 paginiBe Sharp With C# (Chapter 1, Controls and Code)Pieter Blignaut0% (1)

- A Manual For A Laboratory Information Management System (Lims) For Light Stable IsotopesDocument131 paginiA Manual For A Laboratory Information Management System (Lims) For Light Stable IsotopesAlvaro Felipe Rebolledo ToroÎncă nu există evaluări

- Font Expert 2010Document67 paginiFont Expert 2010Sergey KuzmichÎncă nu există evaluări

- Zloggmanager User Guide: ZloggDocument65 paginiZloggmanager User Guide: ZloggHong Anh LeÎncă nu există evaluări

- Known and Unknown #Windows ShortcutsDocument4 paginiKnown and Unknown #Windows ShortcutsLulzim BruçajÎncă nu există evaluări

- TILOS 8 Getting StartedDocument88 paginiTILOS 8 Getting StartedenfrspitÎncă nu există evaluări

- Blitzkrieg 2 - Editor Manual PDFDocument137 paginiBlitzkrieg 2 - Editor Manual PDFJuanAndresNavarroSotoÎncă nu există evaluări

- Keyboard Shortcuts: Connect To Online HelpDocument13 paginiKeyboard Shortcuts: Connect To Online HelpGilbertTrincheraÎncă nu există evaluări

- 6 Auj 19 UcDocument6 pagini6 Auj 19 UcleminhksvlÎncă nu există evaluări

- 100 Keyboard ShortcutsDocument4 pagini100 Keyboard ShortcutsrahmanagasÎncă nu există evaluări

- 6425CD ENU LabManualDocument414 pagini6425CD ENU LabManualaniyisethÎncă nu există evaluări

- X Steel Book SystemDocument291 paginiX Steel Book SystemFadi HamandiÎncă nu există evaluări

- Manual Autodesk P&IDDocument162 paginiManual Autodesk P&IDDavic Pérez Casado100% (2)

- Manual de Usuario MP3 Philips GoGearDocument34 paginiManual de Usuario MP3 Philips GoGearTeri MartinÎncă nu există evaluări

- Lab 1Document24 paginiLab 1Raffi SkÎncă nu există evaluări

- Technician's Facility For Westlock: User ManualDocument224 paginiTechnician's Facility For Westlock: User Manualm rioÎncă nu există evaluări

- Practical 1: Introduction to Microsoft WindowsDocument143 paginiPractical 1: Introduction to Microsoft Windowsroneil_nÎncă nu există evaluări

- Dokumen - Tips - Win Plot Users GuideDocument41 paginiDokumen - Tips - Win Plot Users GuideMantenimientoÎncă nu există evaluări

- 2017 - How To Complete A Clean Install and Uninstall of Revit Products - Revit Products - Autodesk Knowledge NetworkDocument6 pagini2017 - How To Complete A Clean Install and Uninstall of Revit Products - Revit Products - Autodesk Knowledge NetworkIhab El AghouryÎncă nu există evaluări

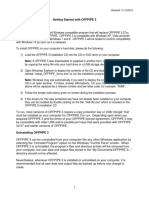

- Getting Started With OFFPIPE 3Document7 paginiGetting Started With OFFPIPE 3Bagus Bagaskara PutraÎncă nu există evaluări

- DCS Software Backup ProcedureDocument19 paginiDCS Software Backup ProcedureNazreen Mohammed100% (2)