Documente Academic

Documente Profesional

Documente Cultură

Stepper Motor With Cable - SparkFun Electronics

Încărcat de

Luis Alberto Barra0 evaluări0% au considerat acest document util (0 voturi)

201 vizualizări27 paginiSTEPPER MOTOR WITH CABLE

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSTEPPER MOTOR WITH CABLE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

201 vizualizări27 paginiStepper Motor With Cable - SparkFun Electronics

Încărcat de

Luis Alberto BarraSTEPPER MOTOR WITH CABLE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 27

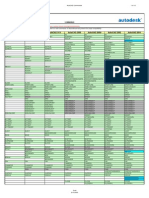

SparkFun Electronics

Home | Product Categories | Motors | ROB-09238

0 items in cart

$ USD

You are not logged in.

log in

images are CC BY-NC-SA 3.0

$14.95

quantity

In stock 1,718 in stock

$14.95 price

$13.46 10+ units

$11.96 100+ units

Stepper Motor with Cable

ROB-09238 In Fritzing Library

Description: This is a simple, but very powerful stepper motor with a 4-wire cable attached.

Features:

Step Angle (degrees) :1.8

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

1 of 27 07/08/12 11:35

2 Phase

Rated Voltage : 12V

Rated Current : 0.33A

Holding Torque : 2.3kg*cm

5mm Diameter Drive Shaft

Winding resistance: 32.6 !

Winding inductance: 48 mH

Max ux linkage: 1.8 Vs

Maximum Detent Torque: 0.016 N.M

Total inertia (kg.m.m): 3.5 Kg.m.m

Total friction (kg.m/s): 4 Kg.m/s

Documents:

Datasheet

! Comments 117 comments

Login or register to post comments.

GarageDeveloper | about 3 years ago 3

just for people who buy this ive made a post on my blog for creating a surveilance system using

the motor http://garagedeveloper.wordpress.com/2009/12/05/the-diy-surveillance-system-using-

a-webcam-part-1/ . all is open source with code so :) thanks spark fun

Member #171331 | about 2 years ago 2

Hi. Is this a Bipolar or a Unipolar Stepper Motor? Can I control this motor using ULN2003 IC?

Nakor | about 2 years ago 1

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

2 of 27 07/08/12 11:35

Bipolar.

Newbie | about 3 years ago 1

What kind of battery do I need for this?

Lyouss | about 3 years ago 1

Batteries wont last long with a motor like this. You better use a power supply.

I tried to make it work with a little higher current, and I could feel the magnets move inside.

Unfortunately, the head doesnt spin

Any clues about whats happening here?

EmbeddedMan | about 3 years ago 2

What stepper driver chip/circuit are you using? This motor works quite nice with the

EasyDriver (also sold by SparkFun). But you cant just put current into this motor since

its a stepper motor, you need a stepper driver circuit that will sequence the two phases

correctly.

Lyouss | about 3 years ago 1

Thank you for the answer.

Of course Im not just putting current into the motor.

I use a Unipolar Stepper controller from Phidgets (http://www.phidgets.com

/products.php?category=13&product_id=1062) because I use it with max/msp and

they objects for all their devices

Again, I hear the magnets activate, but the head doesnt spin! I must be doing

something right since I feel/hear the motor working. But something is wrong!

Also, I cant nd a power supply with the right current/voltage combination!

Any help would be appreciated thanks!

EmbeddedMan | about 3 years ago 2

This is a bi-polar stepper motor (all 4-wire stepper motors are bi-polar) and

so you will not be able to use a uni-polar driver with it.

The product description should be updated with this information.

Lyouss | about 3 years ago 1

Or could it be that this stepper is bi-polar and my controller unipolar?

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

3 of 27 07/08/12 11:35

mattgilbert | about 3 years ago 1

Is this NEMA 23? (Compatible with this tutorial:

http://reprap.org/bin/view/Main/McWire_Cartesian_Bot_1_2 )

BrainSlugs83 | last year 1

No, NEMA 23 would mean the face was 2.3" inches in width and 2.3" inches in height

(NEMA doesnt specify a depth.) This motor is closer to 1.7"x1.7" so I would call it a

NEMA 17.

champro | about 3 years ago 1

it looks like from yourtube videos Ive seen that this motor used to come with a much longer

shaft. Any word on whether this has changed with this batch of motors, or could the data sheet

be off.

bingnet | about 3 years ago 1

This is a 200 step motor? What is the % margin of error per step? For example, with 5% MoE I

can expect 1/8 step accuracy. With 10% MoE I can only use " steps reliably.

bingnet | about 3 years ago 1

Found in the datasheet: 1.8 degrees +/ 5%

cvilad | about 3 years ago 1

Great motor. Any source for similar motors but smaller?

Thanks

kalou | about 3 years ago 1

Seems to be a nema 17 (31mm)

Mis | about 3 years ago 1

If you go by measurements on the picture here, motor body face size is about 26 mm square, yet

datasheet with link above species 43 mm. Which motor exactly are you selling?

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

4 of 27 07/08/12 11:35

john | about 3 years ago 1

I have this motor and the EasyDriver V4.2. I have looked at many different posts and it would

appear that I have everything hooked up correctly. When I send pulses to the motor to drive it,

the motor just vibrates. It may be a similar issue to that posted by Lyouss on Oct. 8th 2009.

Another symptom is that when I do single steps, there are times when my power supply is

drawing the entire amount of current (aprox. 0.6 amps) and there are times when the current

drops to about 0.3 amps and the motor loses its holding torque. Any help would be much

appreciated.

EmbeddedMan | about 3 years ago 1

John, contact me at brian_schmalz (at) yahoo (dot) com and I can help you try and gure

out whats going on with your setup.

JoshFranz | about a year ago 1

I had a similar issue. Turns out I was trying to run the motor faster than it could. Try

slowing down.

gmrple | about 10 months ago

Also be mindful that youre not running it too slow. The FAQ on the EasyDriver

site recommends running it at 500Hz (a pulse ever7 .002 seconds).

semepe | about 3 years ago 1

Does anyone know how to use this with Ladyadas motorshield?

danpapuga | about a year ago 1

I have used it with Ladyadas motorshield, just follow the examples she uses on the

website.

psuguy | about 3 years ago 1

Does anyone know where I can nd a pull-out curve for this motor? I need to know the torque

vs. speed characteristics.

sabretooth91 | about 2 years ago 1

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

5 of 27 07/08/12 11:35

Do you sell any wheels that t this motor? I see you have wheels that t to the DC motors. It

looks like the shaft diameter is 5mm. Thanks for any help.

K6rov | about 2 years ago 1

When do you expect these motors to be in stock again.

plaskut | about 2 years ago 1

Mis: If you go by measurements on the picture here, motor body face size is about 26 mm

square, yet datasheet with link above species 43 mm. Which motor exactly are you selling?

id like info on this too. i hope to dear god its 43mmx43mm, otherwise im returning.

RobertC. | about 2 years ago 1

The datasheet is correct. We are in the process of posting a new picture showing correct

scale. But the datasheets dimensions are accurate.

plaskut | about 2 years ago 1

oh good. thats fairly thick shaft at 5mm. wonder if i can machine a notch into it. it

would be nice if it already had one.

RobertC. | about 2 years ago 1

For something this size, a set screw coupler would be ne, since it wont

have that much torque to begin with. Good luck machining it. Ive tried

something similar on my milling machine and ended up polishing the metal

and dulling a bit. It was fun though I guess.

c6burns | about 2 years ago 1

hahaha yes the hardened shafts are a no-go but quite correct, with

this little torque it wont matter you have no attened edge on the shaft

for the grub screw

Reggie | about 2 years ago 1

I assume this is a standard NEMA-17 mount stepper. If not, let me know. Also, Ive been

looking around the web for a wheel to t this 5mm shaft. Does anybody have any suggestions?

Ultimately, Id love to put an omniwheel on this thing but for now a regular wheel will do.

Thanks,

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

6 of 27 07/08/12 11:35

Reggie

BrainSlugs83 | last year 1

Ive found that rubber hosing from the automotive store works great for connecting two

shafts of different sizes together, rst a thinner width for the thinner shaft so the shafts are

about the same size and then another section of hose (maybe 3" length) to connect the

two, with metal clamps on either side.

mrmark | about 10 months ago 1

Try this: http://www.pololu.com/catalog/product/1203 also look around a little bit too,

they have some good stuff thats allot cheaper then sparkfun.

JohnBaloo | about 2 years ago 1

Can you please identify the A & B wires for this stepper motor, and how they would connect to

the easydriver ??

Thanks

John

RobertC. | about 2 years ago 1

Check out this site:

http://www.piclist.com/techref/io/stepper/wires.htm

Color coding isnt universal. Just get a meter and you can gure it out in a minute or so.

BitStream | about 2 years ago 1

What sort of speed should I be able to get out of this motor?

I cant seem to get more than about 60RPM out of it, seems a little slow?

BitStream | about 2 years ago 1

Im using an freshly ordered EasyStepper, tried half, quarter and eigth step modes, cant

seem to get anything useful out of it.

Im driving it with an Arduino running the RepRap GCode rmware, and Ive tried it

using a 2khz output from a DSO Nano scope, above 2khz it turns into a stutter.

N8B | about 2 years ago 1

Ive never seen these motors go faster than 60 RPM, fresh out of the box or old. If

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

7 of 27 07/08/12 11:35

someone knows otherwise please speak up. Here is some handy info on stepper

basicsin case you dont already know all the stuff in it:

http://www.solarbotics.net/library/pdib/pdf/motorbas.pdf

acx | about 2 years ago 1

I have one of these running at 300 RPM using an EasyDriver at 20V its certainly

not a speed demon, but its quite usable. The two tricks to getting it to go a little

faster were disabling microstepping and using a higher voltage. Microstepping is

useful if you need a very small, precise movement, but it only slows you down if

youre trying to do fast, large movements. I had no trouble running at 180 RPM at

12V once microstepping was disabled. The second trick is to use higher voltages;

the maximum voltage given for a stepper is usually the safe voltage to use without

a current limiter, but you can generally use higher voltages if you have a driver that

will limit the maximum current (like the A3967 on the EasyDriver).

c6burns | about 2 years ago 1

Yes, higher voltage to the motor should charge the coil faster and thus run the

driver cooler (faster charging means the gate sourcing the coils is open for

less time). V regulator will be hotter tho working harder to make the higher

input into 5V

KreAture | about a year ago 1

I found that by using a smooth accelleration curve I can run mine at 600 rpm

with 26v supply.

Its clear though that SparkFun should be selling a 2 or 2.5 amp version

Member #182165 | about 4 months ago 1

No, its not the amps, its the inductance that is killing the speed. The

larger nema 17 is a low inductance motor and thus looses torque at

speed at a much lower rate. You cannot beat physics, an inductor takes

time to reach current, the larger the inductor, the longer the time. So if

you cannot change current in the poles fast, obviously you cannot

make a rotor spin fast with much torque. These motors were wound for

12 volts such that a simple H-bridge could drive them with no current

limiting as the motors are self limiting by design. Modern drivers

current limit the coil and thus you use a higher voltage, but this is

really only effective on low inductance coils, otherwise it just ends up

as waste heat (the high resistance factor comes into play).

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

8 of 27 07/08/12 11:35

Ritch | about 2 years ago 1

This is for comparison to other motors (to show you how good this really is). Datasheet Torque

converted. This little baby is two times more powerful for its current than any Ive found.

0.230000 Newton Meters

23.0000 Newton Centimeters

2.30000e6 Dyne Centimeters

2.34535 Kilogram Centimeters

2345.35 Gram Centimeters

32.5708 Ounce Inches

2.03567 Pound Inches

0.169639 Pound Feet

KreAture | about a year ago 1

Which in turn make its torque-curve drop of faster making it slower.

antenna | about 2 years ago 1

Hi!!! Does anybody know where I con buy a pulley/gear for this motor? thx!

MikeGrusin | about 2 years ago 1

McMaster-Carr is our go-to source for all things mechanical. Search on the drive shaft

diameter and you should nd all sorts of options.

AKA | about 2 years ago 1

Has anyone actually found the appropriate couplers on mcmaster? I cant nd

anything thats metric and smaller than 10mm

Thanks, AKA

c6burns | about a year ago 1

I am going to live dangerously and use a 3/16 (0.1875 in / 4.7625mm) double

wide collar from Ruland (WCL-3-A). I saw grainger USA has 5mm inside

diameter collars, but minimum order to Canadian subsidiary is 250 units X_x

frasenci | about 2 years ago 1

Shaft Copuling, look here

http://www.servocity.com/html/rigid_shaft_couplers.html

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

9 of 27 07/08/12 11:35

Greetings

FAA

Jade | about 2 years ago 1

Warning. Just got 4 of these motors in the mail. 3 were ne, but the 4th wouldnt spin at all,

even when cranked by hand. There was some mechanical obstruction. I opened up the motor

and discovered that the insides were rusty with chipped paint on the magnetric drum.

Please check your storage conditions, Sparkfun guys. Also, before sending the things out, do a

hand crank test. If the gears are welded, it should be obvious that that the device has issues.

Check the following shipment for rust, label: Mercury Motor SM-42BYG011-25 23/2010.

RobertC. | about 2 years ago 1

Yep, we just realized this! We are removing the bad ones from stock right now. Email us

at techsupport@sparkfun.com and we can take care of you. For everyone else, we will be

removing any bad stock we have and hand-checking them all, so you can still order them,

we will make sure that you dont get a bad one, thanks!

holyjewsus | about 2 years ago 1

Hey, not sure if this is the place for this, but I just ordered 3 of these a few days ago that went

out today possible that they are bad?

RobertC. | about 2 years ago 1

No, this is not the right place for this. Contact customerservice@sparkfun.com for this

type of question. Also, you should be ne. We found only about a 10% problem rate.

Contact customer service if you run into any issues.

Currentamps | about 2 years ago 1

I love these little motors. They are easy and fast to setup with the Easy Driver board also

offered here on Sparkfun, and will work wonders in any project.

For those looking for simplied code for Arduino + Easy Driver + 2 button forward/reverse

control visit:

http://currentamps.com/projects/2-button-stepper-motor-control

N.Poole | about 2 years ago 1

Another interesting DJ-related post:

This motors torque drops it somewhere between a Technics 1200Mk2 Turntable and a Numark

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

10 of 27 07/08/12 11:35

TT500.

Also, stepper-motor vibration could be mechanically mitigated

Also 33.3rpm wouldnt be a problem for this motor

Do you see where Im going with this?

Someone please build a really smart turntable before I do. Do I have to do everything myself?

(Also build the chassis out of laser-cut parts from Ponoko and add fun lights and maybe

a little display of some kind)

Member #159534 | about 2 years ago 1

What is the sequence for this motor?

RobertC. | about 2 years ago 1

Im not sure what you mean. Maybe you can email techsupport@sparkfun.com and they

can help you out. Sorry!

Member #155115 | about 2 years ago 1

It says in the datasheet that the motor has a holding torque of .23 N.M. But not sure what the

NM means. I have this stepper motor, but it does not seem to be able to turn heavier objects like

a 1 pound 3 t cardboard disc. I assume I need a stepper with more holding torque. Would I be

correct?

Member #157383 | about 2 years ago 1

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

11 of 27 07/08/12 11:35

I bought 3 of these and got 3 matching easy drivers v4.3

I measured the wires and got 34.5 ohms on the following pairs of wires:(red, green) (blue,

yellow) any other combination yields 0 ohms.

I connected one pair to [A] and the other to [B] on easy driver. (Gnd, Stepper, Dir) on the easy

driver gnd and stepper are connected to digital pins on an Arduino Uno (gnd is not connected to

anything).

The power source a power supply that reads 9VDC @ 800ma (even though when i measure the

voltage it reads 13.2 Volts).

When I power everything up and send it pulses to step it does step and it changes direction. The

problem is that it jitters way too much and is very noisy and it doesnt stay in one position.

I connected MS1 and MS2 to the Ground and Positive pins of the power connector using a 10K

ohms resistor in an attempt to disable or enable Micro Stepping, and that had no effect. Playing

with the current regulating Potentiometer on the easy driver didnt help either.

What am I doing wrong?

Thanks for your help!

Member #157383 | about 2 years ago 1

I meant Dir and Step are connected to pins on the Arduino. Sorry for the typo!

The Thnikkaman | about a year ago 1

Try connecting it to ground, usually it helps when you have a complete circuit.

Member #151364 | about 2 years ago 1

Hey Sparkfun,

Could you please answer these questions?

1. Will this motor work with EasyDriver Stepper Motor Driver (sku: ROB-09402)?

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

12 of 27 07/08/12 11:35

2. Please tell me Wall Adapter for this motor.

Thank you very much.

D

c6burns | about a year ago 1

Yes, the specications of the easydriver clearly state current can be limited to the

rated current of the motor

1.

Read the specications of the easydriver and then read the output of the wall

adapter. If the wall adapter output falls within the specications then you can use it

:D

2.

williams | about 2 years ago 1

4 wires, no directions. What wires go where using the mini stepper sold here? tia

dustynrobots | about 2 years ago 1

I used these motors in a drawing machine installation we called SADbot: the Seasonally

Affected Drawing robot. Check out the Instructable here: http://www.instructables.com

/id/SADbot-the-Seasonally-Affected-Drawing-robot/

Did anyone else have problems with these burning out after a while? We had the installation on

daily for about 6 hours, and over the course of about a month and a half had to replace 2 or 3 of

them. A few students of mine used them as well and they burnt out after much less usage.

williams | about 2 years ago 1

It says 0.33A. Is that the max amps the motor should ever see from driver? Or the amount it

draws?

I have had it up around 210rpm. But hard to go any faster because of the ~1ms signal delay you

need between high/low signals sent to the board. It seems to me a better general step driver

would be a board that you raise one pin high to move and the driver handles the timing on the

board. Another pin would output step completion signals. That way you have a feedback loop

and can take Step pin low after N steps complete.

c6burns | about 2 years ago 1

0.33A is the amount of current that is completely safe to continuously run through the

windings. The motor will draw its rated current at its rated voltage generally you will

make an adjustment for the voltage(and consequently current) on the driver, read the

datasheet of your driver

If you want to receive a pulse as feedback instead of pulsing the driver yourself for each

step, its up to you to do some work (obviously) :D

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

13 of 27 07/08/12 11:35

Member #197954 | about 2 years ago 1

Can anyone tell me how many steps this motor can cycle through in one second? Is there a min

/ max to what you can set with the Easy Stepper?

jandirks | about 2 years ago 1

Will this item come back in stock soon?

Member #171038 | about 2 years ago 1

Im using this motor with the Easydriver. The Easydriver will limit the current up to 0.8A. This

motor needs 12V 0.3A. I only got a power supply 12V 1A.

Now Im wondering, will it be safe to feed the motor 0.8A with the Easydriver? Does this mean

I have to let it rotate slower because else the motor will burn? Im new to this (trying to build a

CNC) :) THNX

c6burns | about 2 years ago 1

It will get hot and wear out much faster. It will probably be too hot to touch after an hour

of machining this motor doesnt have the torque for a CNC unless you are milling only

styrofoam hahaha

The worst part is you wont get much additional torque at all from that extra 500mA

just lots of heat :)

For this motor think plotter, not milling machine

Member #171038 | about 2 years ago 1

I overlooked the 150mA 750mA function on the Easydriver. Just going to give it a try.

And no, its not going to be a big CNC, just a toy hobby one..

c6burns | about 2 years ago * 1

Well it can do it as long as the slides have nice low friction, tho Z might be an issue

The motor is the same mounting and shaft size as the smaller (or older) zenbot

machines, though you probably wouldnt be able to use it on one and actually mill

anything.

That being said, it is a stepper and you can learn the same mechanics of a very

large system by experimenting with these tiny motors for a very low cost. I adore

these motors myself if you nish that CNC, post some links about it :)

EDIT: I just tested the motor on my smallest table and it did better than I expected.

You will probably be able even to do light engraving with the right setup and most

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

14 of 27 07/08/12 11:35

of all you will have fun trying, good luck :D

Member #171038 | about 2 years ago 1

2.3kg*cm doesnt sound too bad. And ofcourse there are a lot of tricks to

help the motor a little bit. Fine threads will require more rotations but less

torque.

Anyway, thanks for the info! Hope my motor doesnt get too hot ;)

williams | about 2 years ago 1

4-M3 4.5mm for the screw holes.

How do you read that? Is that M3 x 4.5mm?

Member #98689 | about a year ago 1

I wish you add belts and pulleys for this motor as it is essentially parts of most automation and

control projects .

Member #209079 | about a year ago 1

I am using this with the easydriver and everything worked perfectly. However, I took off the

bottom of the motor in order to mark where I would place it (i thought I could use the screw

holes on the bottom to mount it). But now, when I connected everything back together, I power

up the board and the stepper motor just holds steady, it does not turn at all. I didnt know if this

sounded like a problem w/ the motor or the electronics.

freddyhfk | about a year ago 1

hello everyone. where you can nd a gear reduction with ratio of 10 or more, for this motor?

Member #219116 | about a year ago 1

Im trying to wire this motor up to the Adafruit motor shield but i cant seem to get the wiring

right. Can anyone help? What colours go where? Everything on the board has been tested and is

working ne.

Member #219116 | about a year ago 1

Will i be able to power this with this supply: http://www.sparkfun.com/products/9442 ??

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

15 of 27 07/08/12 11:35

turbclnt | about a year ago 1

Does anyone have the solution for the question that a lot of people askedMy stepper motor

just vibrates, and wont spin at all. Im using the adafruit motorshield as a driver. Ive already

tried ipping phases, changing voltages, etc. Im only trying to get the thing to spin at 10rpm. I

never knew using a motor could be so complicated!

HMav | about a year ago 1

In my (limited) experience with steppers 2 things would always cause them to vibrate but not

spin. Either trying to drive them too fast (speed must be ramped up gradually) and hooking up

the wires incorrectly. A google search will turn up loads of help, and a multimeter is a must for

guring these things out.

Ehsan | about a year ago 1

Hi, How hot are these steppers suppose to get? I am running them for 20 minutes, they are very

hot. I could not nd the data sheet anywhere.

mvonrose | about a year ago 1

Anyone know where you can buy gears/chain/mechanics to use with this motor?

Member #231172 | last year 1

This Stepper Motor really woks great with the Domo*pes lots of torque at high speeds.

http://cncsnap.com/node/149

http://cncsnap.com/wiki/domopes

Thanks for caring a great Product sparkfun.

MontyS | last year 1

I bought 4 of these in May for my Mendel 3D printer. One has failed on the Y-axis. What is

the warranty, if any?

Member #150666 | about 11 months ago 1

Can you drive this with less than 12V? I would like to use a 7.4V lipo battery for short time

frames.

RobertC. | about 11 months ago 1

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

16 of 27 07/08/12 11:35

yes, they can work on lower voltages. a 7.4v lipo should be good for them. keep in mind

if you have the motor hold, it will drain the battery quickly.

Member #242195 | about 11 months ago 1

On the easy driver I have to current turned down, but these motors still get too hot to touch after

30 min or so. Is this normal?

AtomicProf | about 11 months ago 1

Im running one using the easy driver, I have the current pot, turned all the way CCW, at

9 Volts. It is slightly warm to the touch.

LightMouse | about 10 months ago 1

It had this problem for me when I had it mis-wired. Im driving my Arduino at 12vdc,

500mA, and using the Vin on the Arduino to the M+, and it works ne.

AtomicProf | about 11 months ago 1

Any guidance on what the screw denition in the Spec sheet means? 4-m3, and 4 .5mm. It was

asked earlier with no reply. This seems like something people would like to know.

Jagrolet | about 11 months ago 1

I am using Qty(4) of M3x.5

I think the number 4 in the reference is the Quantity needed.

I agree thats a really goofy way to show the screw call out.

Thats a metric 3mm screw with a 0.5mm thread pitch and 4 needed.

Basically a standard off the shelf metric screw.

Oh yeah, The screw holes in the motor are about # in deep.

Hope that helps.

AtomicProf | about 11 months ago 1

Thank You, Jagrolet.

I picked up these screws at my local ACE hardware, Home Depot didnt carry

anything under 4mm.

swort | about 10 months ago 1

When will sparkfun publish an arduino library for the EasyDriver ?

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

17 of 27 07/08/12 11:35

EmbeddedMan | about 6 months ago 1

No need there are several libraries out there for stepper motors. The one I use a lot, and

really like (and supports Easy Driver and Big Easy Driver out of the box) is AccelStepper

(http://www.open.com.au/mikem/arduino/AccelStepper/). It now even works with PIC32

based chipKIT boards and the UBW32. See my video for an example:

http://www.youtube.com/watch?v=7Ga6RMYwuQI

*Brian

alex_irimiea | about 6 months ago 1

You might want to check this tutorial (in case you havent done so already):

http://bildr.org/2011/06/easydriver. It quite easy to follow and implement. Hope this

helps!

mrmark | about 10 months ago 1

I am going to build a reprap soon, and I was wondering if these steppers would be adequate for

the 2 Pursa z motors. and possibly if sparkfuns new 400 step/rev steppers would be good for

everything else

Thanks

wes03 | about 10 months ago 1

Is this stepper motor rated at .33A per phase for a total of .66A?

Member #227114 | about 9 months ago 1

What kind of plug would you put on the end of the wires and how would you put it on?

Member #227114 | about 9 months ago 1

What kind of plug would you put on the end of the wires and how would you put it on?

Member #227114 | about 9 months ago 1

How would you apply a plug like this http://www.sparkfun.com/products/10551 ?

Member #227114 | about 9 months ago 1

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

18 of 27 07/08/12 11:35

How would you apply a plug like this http://www.sparkfun.com/products/10551 ?

Member #221058 | about 9 months ago 1

Hi,

Im using a bunch of these Sparkfun steppers with Easydriver, and everything works ne,

except the steppers seem to have very little torque; for instance, I can easily make them stop

turning by simply applying a little pressure with two ngers; I dont need it to run a mill or

anything remotely that demanding, just raise a 40g weight by turning a screw Is there any

way I can (rst) measure the actual torque the stepper is building, and (then) improve it?

Thanks, G

aristides | about 8 months ago 1

would this be enough to close/open some roller blinds? thanks

steven6282 | about 8 months ago 1

Im confused by the holding torque on this stepper. The data sheet says .23N.M, but the

description says 2.3kgcm. Just using google to convert 2.3kgcm is ~207 oz.in, but .23N.M is

only ~32 oz.in Unless Im mistaken about how to do the conversions. Im guessing its the latter

(~32 oz.in) though because at only .33A per phase I doubt its capable of much more than that.

Member #277814 | about 7 months ago 1

according to http://www.numberfactory.com/nf_torque.html 2.3kgcm is ~32oz-in

do you think this can work in a hobby-cnc?

alex_irimiea | about 6 months ago 1

Does anyone know (or even tried) a worm drive suitable for this stepper motor? Besides the

Universal Mounting Hub compatible with this motor, I could not nd any other mechanical

parts available on sparkfun.com :( In my opinion, things like shaft couplings, worm drives, etc.

would be very useful for any robotics project. I know that Sparkfun is more electronics

oriented, but it would be nice to nd all these things in one place.. Thanks in advance!

MikeGrusin | about 6 months ago * 1

Were still a relatively small company, with limited inventory space, so we have to be

selective about what we do and dont carry. Most of what we offer is the stuff were good

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

19 of 27 07/08/12 11:35

at (red boards), and we try to have enough extra hardware to get most of your project

done. But for more esoteric hardware, were happy to point you towards cool companies

like McMaster-Carr which have vastly more mechanical stuff than well ever be able to

carry.

alex_irimiea | about 6 months ago 1

Thanks a lot for the info! They seem to have a bunch of mechanical stuff there! :)

Member #224245 | about 3 months ago * 1

The above question was about shaft couplers, but I am interested in a motor mount. Since this

looks like a NEMA 17 size, I looked for motor mounts of that size but, surprisingly, was not

able to nd any (including looking on McMaster-Carr).

Any suggestions for a motor mount for this motor? I also have a NEMA 14 size stepper that I

need to mount, so suggestions for that size would be appreciated as well.

Ahmed_Fararjeh | about 2 months ago 1

hi

Ludovic Vignals | about 2 months ago 1

Hi! I have a 12V and 1.5 amp power supply for two of those steppers. Since they are rated 0.33

amp, I was thinking having a 3 way current divider circuit to route manage the power supply,

routing .35 amp to each stepper motor and the remaining .8 amp to additional circuit to either

use and/or transduce into heat. Is there a clever way to manage the difference in power supply

and stepper amp rating? Assuming I cannot replace the power supply with a smaller one more

adapted to the 2 steppers. And second question, how does the amp consumption will evolve

with speed variation? 0.33A on 12V at what speed?

MikeGrusin | about 2 months ago * 1

Thanks to Ohms law, current (very helpfully) doesnt work that way. A power supply is

rated by its voltage output (which stays constant), and a maximum current capacity.

Without anything connected to the supply, its voltage output will be e.g. 12V, but its

current output will be 0A since theres nothing to draw any current.

Anything you connect to the supply that does draw current will basically use only what it

needs. So you can connect your power supply to all your motors and other circuitry in

parallel, and each one will only draw the power it requires at the speed/load youre

running it at. As long as everything you have connected isnt drawing more than 1.5A

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

20 of 27 07/08/12 11:35

total, your system will work ne. No extra current-dividing circuitry is necessary.

Im not sure of the answer to your second question. For motors, current consumption

generally goes up linearly with an increase in speed, but I dont know what speed the

rated current corresponds to, or if its just an indication of the resistance of the driving

coil. Anyone out there know the answer?

Ludovic Vignals | about 2 months ago 1

Thanks Mike for clarifying this for me. I tested the current consumption and here is

what I found, there is between 0.2A and 0.35A of current consumed when in

motion but the consumption interestingly jumps to 0.520A when at still. I did a

quick test to validate my theory and it seems that if I constrain the Amps directed

to the motor then the holding torque lowers and it becomes easier to rotate the shaft

by hand despite the applied current. Doesnt that mean this Stepper should be rated

0.52A rather than 0.33A if it draws 0.52A to maintain a still position at full torque

or does it mean that Amps should be electronically constrained to 0.33A to limit

heat and avoid shorten life? I got to say as part of my discovery of that I am pretty

pleased by the strength and accuracy of this little motor. The only down side is that

there are no details on wiring polarity and actual wires on the motor which forced

me to try quite a few congurations before it worked with the IC driver. A better

doc/datasheet could have saved me a couple hours during my last weekend.

! Related Products13 related

Stepper Motor - 29 oz.in (200 steps/rev, Threaded Shaft)

In stock ROB-10848

$29.95

Stepper Motor - 29 oz.in (200 steps/rev, Threaded Shaft)

Description: These steppers have a threaded shaft, which allows them to be used a

Read Full Description

In stock ROB-10848 $29.95

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

21 of 27 07/08/12 11:35

Robotic Claw Pan/Tilt Bracket

In stock ROB-10826

$29.95

Robotic Claw Pan/Tilt Bracket

Description: This is a pan/tilt bracket designed specically to work with the robotic

Read Full Description

In stock ROB-10826 $29.95

Stepper Motor - 125 oz.in (200 steps/rev)

In stock ROB-10847

$23.95

Stepper Motor - 125 oz.in (200 steps/rev)

Description: These steppers are a great way to get things moving, especially when

Read Full Description

In stock ROB-10847 $23.95

EasyDriver Stepper Motor Driver

In stock ROB-10267

$14.95

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

22 of 27 07/08/12 11:35

EasyDriver Stepper Motor Driver

Description: The EasyDriver is a simple to use stepper motor driver, compatible wi

Read Full Description

In stock ROB-10267 $14.95

L6470 Stepper Driver Breakout

In stock BOB-10859

$34.95

L6470 Stepper Driver Breakout

Description: STMicro's L6470 (a.k.a "dSPIN") is a 3A, 8-45V bipolar stepp

Read Full Description

In stock BOB-10859 $34.95

Big Easy Driver

In stock ROB-10735

$22.95

Big Easy Driver

Description: The Big Easy Driver, designed by Brian Schmalz, is a stepper motor driver

Read Full Description

In stock ROB-10735 $22.95

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

23 of 27 07/08/12 11:35

Small Stepper Motor

In stock ROB-10551

$6.95

Small Stepper Motor

Description: These small steppers are a great way to get things moving, especiall

Read Full Description

In stock ROB-10551 $6.95

Quadstepper Motor Driver Board

In stock ROB-10507

$64.95

Quadstepper Motor Driver Board

Description: The Quadstepper motor driver board allows you to control up to 4 bipolar s

Read Full Description

In stock ROB-10507 $64.95

Universal Mounting Hub - 5mm Aluminum

In stock ROB-10006

$7.49

Universal Mounting Hub - 5mm Aluminum

Description: The universal aluminum mounting hub allows you to mount custom wheels and

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

24 of 27 07/08/12 11:35

Read Full Description

In stock ROB-10006 $7.49

Rotary Encoder - 200 P/R (Quadrature)

In stock COM-10932

$39.95

Rotary Encoder - 200 P/R (Quadrature)

Description: This 200 pulse per rotation rotary encoder outputs gray code which you can

Read Full Description

In stock COM-10932 $39.95

Rotary Encoder - 1024 P/R (Quadrature)

In stock COM-11102

$39.95

Rotary Encoder - 1024 P/R (Quadrature)

Description: This 1024 pulse per rotation rotary encoder outputs gray code which

Read Full Description

In stock COM-11102 $39.95

Stepper Motor - 68 oz.in (400 steps/rev)

Out of stock ROB-10846

$16.95

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

25 of 27 07/08/12 11:35

SparkFun?

SparkFun is an online

retail store that sells the

bits and pieces to make

your electronics projects

possible. Whether it's a

robot that can cook your

breakfast or a GPS cat

tracking device, our

products and resources

are designed to make the

world of electronics

more accessible to the

Resources

Feeds

Forum

SparkFun IRC

Channel

BatchPCB

Open Circuits

Ponoko - Your

Personal Factory

Jobs @ SparkFun

Sell Your Widget

on SparkFun

Become a

Feedback

What's on your mind?

For which department?

General

Please include your

email address if you'd

like us to respond to a

specic question.

Stepper Motor - 68 oz.in (400 steps/rev)

Description: These steppers are a great way to get things moving, especially when

Read Full Description

Out of stock ROB-10846 $16.95

Rotary Encoder - 200 P/R

In stock COM-10790

$29.95

Rotary Encoder - 200 P/R

Description: This 200 pulse per rotation single-output encoder outputs electrical pulse

Read Full Description

In stock COM-10790 $29.95

SparkFun

Electronics |

Boulder,

Colorado |

Customer

Service

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

26 of 27 07/08/12 11:35

average person. In

addition to products,

SparkFun also offers

classes and a number of

online tutorials designed

to help educate

individuals in the

wonderful world of

embedded electronics.

SparkFun

Distributor

Request SparkFun

Sponsorship

Take the SparkFun

Quiz

Tell us about a

project

SparkFun

Kickstarter

Projects

Stepper Motor with Cable - SparkFun Electronics https://www.sparkfun.com/products/9238

27 of 27 07/08/12 11:35

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 90-Day Performance ReviewDocument2 pagini90-Day Performance ReviewKhan Mohammad Mahmud HasanÎncă nu există evaluări

- PT-1971B Recomendado Spare Partes E900Document18 paginiPT-1971B Recomendado Spare Partes E900Juan Carlos MuñozÎncă nu există evaluări

- Install OpenERP On UbuntuDocument9 paginiInstall OpenERP On UbuntuQuynh NguyenÎncă nu există evaluări

- QAV - 1.1. Report (Sup1)Document2 paginiQAV - 1.1. Report (Sup1)Rohit SoniÎncă nu există evaluări

- FKB Stories Who Takes The Train - en PDFDocument19 paginiFKB Stories Who Takes The Train - en PDFJaione IbarguengoitiaÎncă nu există evaluări

- Air Force Qualification TrainingDocument51 paginiAir Force Qualification TrainingJanJanLuÎncă nu există evaluări

- R1 6a Training r2Document95 paginiR1 6a Training r2dot16eÎncă nu există evaluări

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 paginiAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Încă nu există evaluări

- Expansion JointsDocument29 paginiExpansion Jointsvarma101100% (1)

- Stone MasonaryDocument23 paginiStone MasonarypurvaÎncă nu există evaluări

- Business Plan ScrunshineDocument2 paginiBusiness Plan ScrunshineEnjhelle MarinoÎncă nu există evaluări

- 9 3 21 Compair Atvt enDocument4 pagini9 3 21 Compair Atvt enAcika PeleÎncă nu există evaluări

- Minor ProjectDocument49 paginiMinor Projectapi-334907813Încă nu există evaluări

- Alufusion Eng TrocalDocument226 paginiAlufusion Eng TrocalSid SilviuÎncă nu există evaluări

- OZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)Document4 paginiOZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)ilpupÎncă nu există evaluări

- Introduction To Politics SyllabusDocument10 paginiIntroduction To Politics SyllabusJoey BeetzÎncă nu există evaluări

- Presented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainDocument57 paginiPresented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainAnis VohraÎncă nu există evaluări

- Models, Databases, and Simulation Tools Needed For The Realization of Integrated Computational Materials Engineeriing 2011 ASM International PDFDocument205 paginiModels, Databases, and Simulation Tools Needed For The Realization of Integrated Computational Materials Engineeriing 2011 ASM International PDFLuisGuzmanÎncă nu există evaluări

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument14 paginiWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraÎncă nu există evaluări

- ASTM 6365 - 99 - Spark TestDocument4 paginiASTM 6365 - 99 - Spark Testjudith_ayala_10Încă nu există evaluări

- Caledonian: BS 6346 PVC Insulated, Armored Power and Control CablesDocument28 paginiCaledonian: BS 6346 PVC Insulated, Armored Power and Control CablessurenediyaÎncă nu există evaluări

- Reservoir SimulationDocument75 paginiReservoir SimulationEslem Islam100% (9)

- Electronic Vehicle and Fueled Vehicle in Iloilo CityDocument7 paginiElectronic Vehicle and Fueled Vehicle in Iloilo CityGm MuyaÎncă nu există evaluări

- Kode Simbol Rate TVDocument10 paginiKode Simbol Rate TVAndri PÎncă nu există evaluări

- Sample Maths Exam PDFDocument11 paginiSample Maths Exam PDFAnonymous oJ0Dl7rWÎncă nu există evaluări

- 5 Arduino IDE GyroDocument12 pagini5 Arduino IDE Gyrowaleed_buttzÎncă nu există evaluări

- Essay On The Traffic Conditions in Big CitiesDocument3 paginiEssay On The Traffic Conditions in Big CitiesCeciliaÎncă nu există evaluări

- Ina201 Industrial Network ArchitectureDocument2 paginiIna201 Industrial Network ArchitectureFranÎncă nu există evaluări

- Synposis FPGA Synthesis User GuideDocument484 paginiSynposis FPGA Synthesis User GuideVijendraKumarÎncă nu există evaluări

- GSM BSS Integration For Field Maintenance: ExercisesDocument14 paginiGSM BSS Integration For Field Maintenance: Exercisesswr cluster100% (1)