Documente Academic

Documente Profesional

Documente Cultură

DW Brochure LR

Încărcat de

Vulpe Alina ElenaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DW Brochure LR

Încărcat de

Vulpe Alina ElenaDrepturi de autor:

Formate disponibile

About Dental Wings

Dental Wings is a leading provider of dental CAD / CAM solutions. The company is specialized in the development of 3D scanners

and CAD software dedicated to different dental market segments. DWOS, Dental Wings proprietary Digital Dentistry Platform, improves

the design and manufacture of dental prostheses. Dental laboratories enjoy the fexibility of performing designs on models scanned

in-house or on intra-oral or impression scans received directly from dentists. Similarly, restorations can be manufactured in-house

or outsourced to an increasing number of production centers.

Dental Wings is a Canadian based company whose headquarters and main development and manufacturing activities are located

in Montreal Quebec. For more information regarding Dental Wings please visit us at www.dwos.com

DWOS

Dental Wings Digital Dentistry Platform

DWOS represents the cornerstone of Dental Wings strategy to offer the dental market

the most advanced Product Life-Cycle Management (PLM) System. DWOS is built on a robust

proprietary platform, which has been specifcally designed for managing products and

their related work fows on a distributed architecture.

DWOS is the most fexible and versatile dental CAD / CAM solution on the market. Its

deployment is easy and can be adapted to respond to business objectives and operating needs

of small, medium and large laboratories. Laboratories which have integrated DWOS in their

daily operations have gained in productivity, improved the quality of their products and

increased the reliability of their processes.

The DWOS platform has established new standards for the dental market in terms of technology

integration. Thanks to its open and robust architecture, DWOS is todays most comprehensive

open CAD / CAM solution on the market. Better yet, DWOS is continuously evolving through

development partnerships with leading manufacturers.

DWOS is based on an open architecture and integrates the best available i) 3D Scanners,

ii) Design software and iii) Manufacturing solutions into one common platform.

DWOS

3D Scanners

The following 3D scanning technologies have been integrated or made compatible

with DWOS:

Intra-oral scanners: iTero (Cadent), FastScan Digital Impression

System (IOS technologies)

Impression scanner: iSeries (Dental Wings)

Model scanners: 3Series and 5Series (Dental Wings) as well

as any other 3D open scanner with an STL output.

DWOS Software Modules

DWOS provides the following proprietary software modules:

- Crown & Bridge (DWOS - CNB)

- Implants (DWOS - IMP)

- Rapid prototyping & manufacturing (DWOS RPM)

- CAM (DWOS CAM)

- Virtual model design (DWOS VMD)

Manufacturing Solutions

The following manufacturing processes have been integrated or made compatible

with DWOS:

Milling: ZenoTec T1, 2100, 4030 M1 (Wieland), Katana

(Noritake), Prismatic CZ (Glidewell), Yenadent

Rapid Protyotyping: Perfactory Series (Envisiontec), T612, D76

(SolidScape), ProJet DP 3000 (3D Systems)

Rapid Manufacturing: PM 100 T Dental (Phenix Systems), EOSINT M 270

(EOS), Imagen (Ex-One Company)

DHS Managing the outsourcing seamlessly

The DHS is the communication backbone

of DWOS. In a seamless manner, it

connects the clinical to the manufacturing

environment. The DHS communicates and

transfers data from any process step to

another in a fexible and secure manner.

In each process step of the prosthesis life-

cycle, dentists and dental technicians have

the choice to perform the job internally or

to outsource it using the DHS.

Scanning data originating from intra-oral,

impressions, or models scanners can

be transferred to the DWOS design center

in order to perform design work remotely.

Similarly the design data originating from

DWOS design modules can be transferred

to DWOS registered production centers

in order to outsource the manufacturing

of i) models, ii) design frameworks,

iii) full contours, iv) implant custom

abutments, etc.

DWOS delivers to its laboratory partners:

- An open solution, accessible to all and without any restrictions and limitations.

- Secure integration to a wide range of qualifed scanning, designing

and manufacturing solutions.

- An easy worldwide access to design and manufacturing centers.

- A digital platform in full compliance with ISO quality standards.

- A CAD / CAM solution in constant evolution, making DWOS users

immune from obsolescence.

When productivity, quality

and versatility matters

dwos.com

DENTAL

CLINIC / LAB

DESIGN /PRODUCTION

CENTERS

DHS

DENTAL HUB

SYSTEM

Description

The 5Series is a non-contact optical 3D scanning device. The system, with its

proven laser triangulation combined to fve axis of freedom is very versatile and

provides accurate measurements on a very large scanning volume (140 mm x

140 mm x 100 mm).

The 5Series is intuitive and is easy to use. The standard output format is STL.

However other fle formats are available upon request.

The 5Series is recommended for medium to large sized laboratories, where

productivity and versatility are a must. The 5Series is our scanner fagship.

Our development team continues to add new applications and features.

Applications

- Model scanning from single unit to full arch.

- Full arch scanning with palate for partial frameworks

- Multi-die scanning & designing capabilities (16 copings scanned

& designed simultaneously in 20 min).

- Scanning occlusion using check-bites or on positive models

using our patented axis-nder technique

- Impression scanning up to full arch

- Replication of wax-ups

- Scanning implants for custom abutments

dwos.com 3D Scanners

Benefts

Accuracy and Productivity

The operating principles of the 5Series are based on the parallelizing of various tasks

required to generate an accurate scan. The computation and post-processing are

executed in the background in hidden time. The user can continue his design work while

the scanner is performing other tasks. Using the 5Series with our Crown & Bridge

software design module, laboratories can achieve the following scan and design times:

- Scanning and designing simple copings using the multi-die batch mode in

about 1 min 15 sec

- Scanning and designing full contour crown, using the axis nder in less

than 7 min

- Scanning and designing 3 units bridge framework in less than 10 min

Versatility

The 5Series is a general purpose laboratory 3D scanner and is able to perform most

applications and clinical cases encountered in the daily operation of a dental laboratory.

The scanning volume is very large and allows the users to scan articulated models.

The fve axis of freedom provides better accessibility which allows accurate

measurements on impressions and wax-ups.

Fully integrated to DWOS / DHS

The 5Series STL output is fully and seamlessly integrated to DWOS design software

modules. Also, both scans and designs can be dispatched to design / production

centers using DHS.

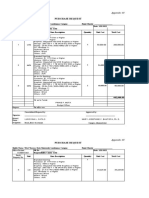

Specifcations

The 5Series is delivered in its standard version with the following components:

dwos.com 5Series

6

an impression

holder to scan silicone

and alginate-based

check bites and

replicates wax-ups

7

an axis nder

holder to scan

occlusions on

positive models

1

a fve axis scanner

2

a calibration tool kit

3

a kernel server

application to access

different DWOS

modules

5

a multi-die plate

holder for scanning

& designing up to

16 dies in one session

4

a model holder

for scanning plaster

preparations and

implants

Scanning specifcations

- Plaster, silicone or alginates

- Scanning volume: 140mm x 140mm x 95mm

- Accuracy: < 20 microns

- Scan points: single dies > 100,000 points

full arch > 1,000,000 points

- Simultaneous scan and design

Mechanical / Electrical

- Foot print (W x D x H): 47 cm x 47 cm x 40 cm

- Weight of the scanner: 33 kg

- Voltage: 110 / 220 volts

Fig.1 Full arch scan

Fig.3 Full arch scan in occlusion

Fig.5 Insertion axis validation

Fig.2 Full arch scan with antagonist on positive model

Fig.4 Margin edition

Fig.6 16 Dies on multi-die plate

Description

The 3Series is a non-contact optical 3D scanning device. The system combines

proven laser triangulation to three axis of freedom. The system is very versatile and

provides accurate measurements on a scanning volume of 90 mm x 90 mm x 90 mm.

The 3Series is intuitive and is very easy to use. The standard output format is STL.

However, other fle formats are available upon request.

The 3Series is our entry level scanner and is recommended for small and medium

sized laboratories. This scanner is particularly interesting for laboratories wich

desire a phased entry into CAD / CAM.

Applications

- Model scanning from single unit to full arch.

- Full arch scanning with palate for partial frameworks.

- Multi-die scanning & designing capabilities (6 copings scanned

& designed simultaneously in 10 min).

- Scanning occlusion using check-bites or on positive models

using our patented axis-nder technique.

- Scanning implants for custom abutments.

dwos.com 3D Scanners

Benefts

Simplicity and ease of use

With its powerful embedded computer, the 3Series has been engineered for a plug and play deployment. Combined with DWOS design software modules, the 3Series

represents a unique opportunity for laboratories, in terms of cost and capabilities, to control their designs and outsource their production using DHS services.

Specifcations

The 3Series is delivered in its standard version with the following components:

6

a multi-die plate

holder for scanning

& designing up to

6 dies in one session

(optional)

7

axis nder

holder to scan

occlusions on

positive models

(optional)

1

a three axis scanner

2

a calibration tool kit

3

a simple kernel

server application

5

a model holder

for scanning plaster

preparation and

implants (optional)

4

an embedded PC

(quad core Q8200, 2.33 gHz

frequency, 4Gb RAM, 500 Gb,

7200 rpm hard disk)

Scanning specifcations

- Plaster material

- Scanning volume:90 mm x 90 mm x 90 mm

- Accuracy: < 20 microns

- Scan points: single dies > 100,000 points

full arch > 1,000,000 points

- Simultaneous scan and design

Mechanical / Electrical

- Foot print (W x D x H): 33 cm x 39 cm x 41 cm

- Weight of the scanner: 20 kg

- Voltage: 110 / 220 volts

dwos.com 3Series

Fig.1 3 Units bridge using axis fnder

Fig.3 Full arch scan

Fig.2 Model scan ready for partial design

Fig.4 Lower jaw scan with wax-up

Description

The iSeries scanner is a non-contact optical scanner specifcally designed to scan

and digitize silicone or alginate-based impressions for the prosthetic and the

orthodontic markets. The operating principles of the iSeries were optimized to

take into account the various constraints which are generally encountered in

scanning impressions:

Negative shape constraints

Accurate measurements with wide access to most clinical cases including deep

and narrow shape impressions (e.g lower anteriors) are achieved with the iSeries by

placing two cameras at different angles. The frst camera having a wider inclination to

the laser measures, the global clinical case and the shallow region of the impression.

The second camera with a smaller inclination measures the deepest and narrowest

part of the impression. The global 3D scan is generated by combining the scan data

from each camera. In addition, the iSeries includes 5 axis of freedom which optimize

the orientation of the impressions with respect to the optical axis.

Impression materials constraints

The application of a very thin optical coating may be required, in order to have an

uniform optical response from the wide variety of impression materials currently

used in dental clinics.

Applications

The iSeries scanner functionalities were optimized to operate within a dental clinic.

The preferred confguration is to interface and drive the scanner from the practice

management system of the dental offce. The system operates with minimum

intervention and the acquired scans can be programmed to be transferred

seamlessly to the dental lab of choice.

dwos.com 3D Scanners

The iSeries scanner applications are as follows:

- Scanning impressions from single preparation to full arch

- Replication of wax-ups

Benefts

The iSeries scanner will generate accurate digital scans ready for electronical

transfer to laboratories. The benefts are:

More accurate clinical information

Scanning the impressions in the dental offce minimizes the alteration of the

impression materials during shipping. The accuracy of the process is also improved

by eliminating the traditional labor intensive plaster model production.

Reduced turn-around time

The turn-around time is reduced by at least 24 hours by eliminating the shipping

of impressions. Furthermore, laboratories can start their design process in

parallel, while the model is being manufactured.

Elimination of shipping costs

No need to pay for collecting and delivering impressions to the laboratories.

Eliminate ultimately the manufacturing of the physical model

Eventually, the manufacture of physical models mainly for single crowns

becomes unnecessary.

Specifcations

The iSeries is delivered in its standard version

with the following components:

1

a fve axis scanner

2

a calibration tool kit

3

a simple kernel

server application

4

an embedded PC

(quad core Q8200, 2.33 gHz

frequency, 4Gb RAM, 500 Gb,

7200 rpm hard disk)

Mechanical / Electrical

- Foot print (W x D x H): 33 cm x 39 cm x 41 cm

- Weight of the scanner: 20 kg

- Voltage: 110 / 220 volts

Scanning specifcations

- Silicone or alginates

- Scanning volume: 90 mm x 90 mm x 90 mm

- Accuracy: < 20 microns

- Scan points: > 1,000,000 points

dwos.com iSeries

Fig.1 Negative scan

Fig.3 Negative lower jaw on alginate

Fig.5 Single molar with occlusion using

axis fnder

Fig.2 Cleaned & reconstructed positive model

Fig.4 Positive model on lower jaw

Fig.6 Single molar with adjacents

Thanks to the deep roots of our development team in dental CAD / CAM, DWOS design

modules are the most comprehensive and intuitive software solutions for designing dental

restorations. Dental technicians grasp the DWOS design concept quickly and are in full

control of their design work.

DWOS design modules are fully integrated to our 3 and 5 axis Series scanners. Such

powerful combinations deliver higher productivity than any other existing solutions on

the market. By parallelizing the scan and design processes, we can defne the margin

lines on initial scans, while the 3D scanner is continuing its job.

Built on a completely open platform, users are always free to import from other scanning

technologies into DWOS, to perform their designs. Our laboratories equipped with DWOS

design software modules were among the frst to perform their restoration designs from

chair-side intra-oral scans generated by iTero (Cadent).

DWOS has adopted an outside to inside design strategy. This approach enables the

laboratories to design full contour by taking into account the full clinical situation

in one design step. The design module computes and delivers full anatomies.

The frameworks designs are dynamically adjusted to the full prostheses morphology

to allow for optimum porcelain support. DWOS design software includes: i) the crown

& bridge, and ii) the implants modules.

DWOS

SOFTWARE

Prostheses Design

dwos.com

DWOS - CNB - Crown & Bridge Module Features

Fig.1 Order management - Database overview

Fig.5 13 Units bridge with full restorations

Fig.9 Anatomy & framework simultaneous editing

Fig.2 Editing coping parameters

Fig.6 Cross section on anterior with space measuring

Fig.10 Dental band creation

Fig.3 Customizable anatomy library

Fig.7 Posterior bridge & anterior with opposing

Fig.11 Bridge with partial crown build-up

Fig.4 Insertion axis modifcation in CAD

Fig.8 Telescopic units

Fig.12 Overpressed on coping

DWOS - IMP - Implant Module Features

Fig.1 Implant kit creation Fig.2 Single custom abutment Fig.3 Gingival area edition Fig.4 Abutment & coping & press-over

DWOS

SOFTWARE

Manufacturing

The manufacturing software modules of DWOS represent the main interface between the design and production environments. They greatly facilitate the automation of several

tasks that are usually performed manually. The DWOS Manufacturing software includes three separate modules: i) DWOS RPM, ii) DWOS CAM and iii) DWOS VMD.

DWOS - RPM (Rapid Prototyping and Manufacturing)

The RPM module provides the fastest path to rapid-prototype frameworks,

full contours and models. It provides automatic generation of supports and

identifcation tags. The fles are positioned with an optimum orientation in

the allocated nesting space to maximize the number of cases and minimize

the printing time. The nested plate manufacturing batch fle is automatically

sent to the RP machine to start the fabrication process.

dwos.com

DWOS - CAM Module

The CAM module is fully integrated to DWOS platform and performs the following tasks:

Creation of the nesting blanks:

The users can create their own blanks

from cylindrical or cuboid shapes.

A confguration table enables the users

to set-up several key parameters:

i) geometrical dimensions of the nesting

blanks, ii) security distance of the milling

tools to the blank outer dimensions,

iii) automatic generation of milling links

and / or sintering stumps:

Nesting design fles

The design fles which are routed by DWOS to the CAM module are automatically

screened with respect to their dimensions. The designed fles are dragged to the nesting

blank with the milling links and /or sintering stumps generated automatically. A manual

editor allows the users to remove or change the orientation of the links and stumps.

Calculation of tool path trajectories:

DWOS - CAM module has integrated a tool-path calculation engine which generates

milling trajectories from 3 to 5 axis milling machines. DWOS development team

is currently working with material providers and milling machines manufacturers

to provide optimal milling strategies for different materials (ZrO2, Titanium, CrCo)

and indications (copings, full contour, long span bridge, custom abutments, etc.)

dwos.com

DWOS - VMD (Virtual Model Design)

The VMD module was developed by DWOS software team in response to the

increasing level of interest and activities related to the development of intra-oral and

impression scanners. The VMD module offers a unique opportunity for laboratories

for replacing their current tedious and labor intensive model making process by an

automated digital manufacturing process. The end results being the generation of

readily articulated models.

Fig.1 Preparing & Cleaning model

Fig.3 Model & Ditched Dies

Fig.5 Model & Opposing in occlusion

Fig.2 Die ditching parameters

Fig.4 Model & Ditched Dies - transparent

Fig.6 Model and ditched die

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Honeywell 7580g User Manual PDFDocument202 paginiHoneywell 7580g User Manual PDFIgor 7 Juli PrometÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- EZCAD 2.7.6 Software ManualDocument154 paginiEZCAD 2.7.6 Software Manualnammaris100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Samsung Clx-3170 N FN FW Clx-3175 Clx-3175n Xaz SMDocument216 paginiSamsung Clx-3170 N FN FW Clx-3175 Clx-3175n Xaz SMchamir100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Foxit PhantomPDF - Quick GuideDocument36 paginiFoxit PhantomPDF - Quick GuidearthuropÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- RevolutionDocument32 paginiRevolutiondoggy2178100% (4)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Guidelines For Digitization of ManuscriptsDocument12 paginiGuidelines For Digitization of ManuscriptsvskanchiÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- A Search Engine Backed by Internet-Wide ScanningDocument12 paginiA Search Engine Backed by Internet-Wide ScanningCleilson PereiraÎncă nu există evaluări

- KM-C2630 Service ManualDocument460 paginiKM-C2630 Service ManualAnonymous egTruyVdxvÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Bioimaging User GuideDocument2 paginiBioimaging User GuideShailesh KuknaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 022516-357F - Trimble MX9 - DS - USL - 0319 - LRDocument2 pagini022516-357F - Trimble MX9 - DS - USL - 0319 - LRYusuf WardhaniÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Epson NX230 NX330 NX430 SX230 SX235W SX430W SX435W SX440W SX445W TX230W TX235 TX235W TX430W TX435W ME OFFICE 535 570W PDFDocument63 paginiEpson NX230 NX330 NX430 SX230 SX235W SX430W SX435W SX440W SX445W TX230W TX235 TX235W TX430W TX435W ME OFFICE 535 570W PDFIon IonutÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Aficio 3035 3045 Parts ManualDocument162 paginiAficio 3035 3045 Parts Manualbill3759Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- PaperCut MF - Ricoh Embedded ManualDocument53 paginiPaperCut MF - Ricoh Embedded ManualDerick Ho Chin FaiÎncă nu există evaluări

- Laser ExtensometroDocument26 paginiLaser Extensometroalfgraga6043Încă nu există evaluări

- PT630 Operation ManualDocument42 paginiPT630 Operation ManualJose HurtadoÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Ibm Infoprint 1570 DatasheetDocument3 paginiIbm Infoprint 1570 DatasheetxyzÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Books Can SolutionDocument4 paginiBooks Can SolutionSunil PrabhakarÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- GeoTECH Free User ManuelDocument60 paginiGeoTECH Free User Manuelayaz5555Încă nu există evaluări

- 1 DScannerDocument74 pagini1 DScannerJOSE ALBERTO VELASQUEZ VILLEGASÎncă nu există evaluări

- TOFD - by Nicholas Bublitz - USA PDFDocument135 paginiTOFD - by Nicholas Bublitz - USA PDFhocimtm100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Brother 3550-4550-6550-7550-9000-9500 Service ManualDocument171 paginiBrother 3550-4550-6550-7550-9000-9500 Service ManualRandy_Engesett_2494Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- ICT EquipmentDocument33 paginiICT EquipmentWillmor Barrio BericoÎncă nu există evaluări

- Canon SmartBase MPC400, MPC600F Service ManualDocument179 paginiCanon SmartBase MPC400, MPC600F Service ManualEugenio BallesteroÎncă nu există evaluări

- Philips Ped ProtocolsDocument13 paginiPhilips Ped ProtocolsF CÎncă nu există evaluări

- 8620 Wearable Ring Scanner Data Sheet en PDFDocument2 pagini8620 Wearable Ring Scanner Data Sheet en PDFDinesh Kumar DhundeÎncă nu există evaluări

- e-STUDIO230-280-232-282-233-283 Service Manual V.10Document352 paginie-STUDIO230-280-232-282-233-283 Service Manual V.10kostas_san84% (19)

- S2000 Series Scanner Firmware Release NotesDocument13 paginiS2000 Series Scanner Firmware Release NotesHAITHM MURSHEDÎncă nu există evaluări

- Recruitment of Specialist Cadre Officers in Sbi On Contract BasisDocument2 paginiRecruitment of Specialist Cadre Officers in Sbi On Contract BasisDebashis MahantaÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Carestream Image Suite PACSDocument27 paginiCarestream Image Suite PACSRaghu Venkata50% (2)

- Chapter 3Document81 paginiChapter 3Chala AmenuÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)