Documente Academic

Documente Profesional

Documente Cultură

Power Electronics For Renewable Energy Systems

Încărcat de

shanmugam.s0 evaluări0% au considerat acest document util (0 voturi)

65 vizualizări8 paginiWind energy and the solar energy are most widely used among the renewable energy sources. Power Electronics is needed in almost all kinds of renewable energy system. It controls the renewable source and interfaces with the load effectively.

Descriere originală:

Titlu original

Power Electronics for Renewable Energy Systems

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWind energy and the solar energy are most widely used among the renewable energy sources. Power Electronics is needed in almost all kinds of renewable energy system. It controls the renewable source and interfaces with the load effectively.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

65 vizualizări8 paginiPower Electronics For Renewable Energy Systems

Încărcat de

shanmugam.sWind energy and the solar energy are most widely used among the renewable energy sources. Power Electronics is needed in almost all kinds of renewable energy system. It controls the renewable source and interfaces with the load effectively.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Power Electronics for Renewable Energy Systems:

Wind Turbine and Photovoltaic Systems

U. M. Choi, and K. B. Lee

Division of Electrical and Computer Engineering

Ajou University

Suwon, Korea

dolmeng7@naver.com, kyl@ajou.ac.kr

F. Blaabjerg

Department of Energy Technology

Aalborg University

Aalborg, Denmark

fbl@et.aau.dk

Abstract The use of renewable energy sources are increased

because of the depletion of natural resources and the increasing

pollution level from energy production. The wind energy and the

solar energy are most widely used among the renewable energy

sources. Power electronics is needed in almost all kinds of

renewable energy system. It controls the renewable source and

interfaces with the load effectively, which can be grid-connection

or working in stand-alone mode. In this paper, overview of wind

and photovoltaic energy systems are introduced. Next, the power

electronic circuits behind the most common wind and

photovoltaic configurations are discussed. Finally, their controls

and important requirements for grid connection are explained.

Keywords- power electronics, renewable energy system, wind

turbine, photovoltaic

I. INTRODUCTION

In the last decade, renewable energy systems have

experienced the largest growths in percentage with more than

30% per year, similar to the growth of coal and lignite energy

systems, because of the exhaustion of natural resources and the

increasing pollution levels caused by the use of fossil fuels and

nuclear energy [1]. The ever-increasing demand for energy can

lead to problems for power distributors, such as grid instability

and outages [2]. The importance of producing more energy and

the interest in clean technologies has provoked increased

development of renewable energy systems. One driving force

in Europe was initiated in March 2007, when EU Heads of

State adopted a binding target of 20 % of energy generated by

renewable sources by 2020. Similarly, a plan for 20 %

renewable energy sources by 2025 has been adopted in the US

[1].

Among renewable energy sources, wind energy and solar

energy have recently become the most interesting. There is a

widespread use of wind turbine systems in power distribution

networks as well as increasing numbers of wind power stations

connected to the transmission networks. Denmark, for

example, has a high wind energy power capacity penetration

over 30 % in major areas of the country, and today 28 % of all

electrical energy consumption in the country is covered by

wind energy. The aim is to achieve a 100 % non-fossil-based

power generation system by 2050 [3].

According to the GWEC (Global World Energy Council)

[4], the cumulative worldwide installed wind power by the end

of 2011 was 237.7GW. In 2011, the wind power grew by about

6% compared to 2010, and the 40.6 GW wind power brought

on line. The China (26.2 %), USA (19.7%), and Germany

(12.2%) comprise the large proportion of world cumulative

wind power capacity.

The world wide cumulative and annual installed

photovoltaic power in 2011, according to the EPIA, was 69.68

GW and 29.7 GW, respectively [4]. It can produce 85 TWh of

electricity every year and this energy volume is sufficient to

cover the annual power supply needs of over 20 million

households. In terms of cumulative installed capacity, Europe

still leads the way with more than 51 GW installed as of 2011.

Next are Japan (5 GW) and the USA (4.4 GW), and then China

(3.1 GW) is followed. Europe has increased its cumulative

capacity base by 50% compared to 2010 with almost 22 GW of

grid-connected PV installations until 2011. The Italy (9.3 GW)

and Germany (7.5 GW) comprise the large proportion about

60% of global market. The overall PV penetration is quite low

but the EPIA estimate it could be as high as 12 % in 2020.

Another important aspect is that the cost of PV panels dropped

during 2008 by around 40 % to levels under 1/W [1], [5].

The increasing use of renewable energy systems requires

new strategies for the operation and management of the

electricity grid in order to maintain or to improve power-supply

reliability and quality. Additionally, regulation of the grid leads

to new management structures in which trading of energy and

power is becoming increasingly important. Power electronics,

the technology to convert electric power efficiently from one

stage to another, is essential for distributed renewable energy

systems to achieve high efficiency and performance. The

power electronics field has grown during the last decades for

two main reasons. Firstly, the development of fast

semiconductor switches that are capable of switching quickly

and handling high power. Secondly, the production of micro-

controllers that can implement advanced and complex control

algorithms. These factors have led to the development of cost-

effective and grid-friendly power converters [6].

This paper discusses wind turbine and photovoltaic (PV)

systems representative of these renewable energy systems.

In section II, the overview of wind turbine system and grid

converter structure adopted in wind turbine system are

discussed. The structures are classified into reduced power, full

power, and multiple-cell full power.

Further, control strategy of wind turbine systems and the fault-

ride-through requirement are explained.

In section III, the overview of wind turbine system and

design of PV converters are discussed. Then control methods

of PV systems and several standards for anti-islanding are

expressed.

II. WIND TURBINE SYSTEMS

Wind turbine systems consist of two parts: a mechanical

part and an electrical part, as shown in Fig. 1. The mechanical

power system extracts the kinetic energy from the wind and

makes it available to a rotating shaft, while the electrical power

system transforms the electrical energy so that it is suitable for

the electrical grid. The mechanical energy is converted to

electrical energy by an electric generator connected between

the mechanical system and the electrical system [1]. There are

three stages used to optimize extraction of the wind energy.

The first stage is the mechanical stage, where the pitch of the

blade, yaw of the turbine shaft and speed of the motor shaft are

regulated. The second stage, electromechanical, can have

variable components such as pole pairs and rotor resistors, an

external excitation and/or a power converter that adapts the

speed or the torque of the motor shaft and waveforms of the

generator voltages/currents. The electrical stage is the third one,

where the waveforms of the grid currents are adapted. Power

electronic converters may be present in the second and/or third

stage [2].

A. Structures of wind power system

1) Reduced power converter structure [2], [7], [8]

Fig. 2 (a) shows a wind turbine system where the generator

is an induction generator with a wounded rotor. An extra

resistance controlled by power electronics is added in the rotor,

which gives a speed range of 2% to 4%. The power converter

for the rotor resistance control is for low voltage but high

currents. At the same time, an extra control freedom is obtained

at higher wind speeds in order to maintain a fixed output

power. This solution needs a soft-starter and a reactive power

compensator. The other reduced power structure is that of a

doubly-fed induction generator with a wounded rotor (DFIG),

as shown in Fig. 2 (b). In this case, slip rings are needed to

connect the converter with the rotor and control its currents. A

gear-box is still needed and speed regulation via the rotor is

used to optimize power extraction from the wind.

If the generator is running super-synchronously, electrical

power is delivered through both the rotor and stator. If the

generator is running sub-synchronously, electrical power is

only delivered into the rotor from the grid. A speed variation of

30 % around the synchronous speed may be obtained by the

use of a power converter rated 30% of nominal power.

Fig. 3. Full power converter structures: (a) induction generator with

gear-box (b) multipole synchronous generator.

Fig. 2. Reduced power converter structures for wind turbines (a) rotor-

resistance converter (b) doubly-fed induction generator.

Fig. 1. Basic power conversion principle in a wind power system.

2) Full power converter structure [2], [7], [8]

These wind turbines have a full power converter between

the generator and grid, which gives extra losses in the power

conversion but also added technical performance. Fig. 3 shows

the turbine structure with full power converters. The converter

may perform reactive power compensation and maintains a

smooth grid connection over the entire speed range.

Fig. 3(a) shows a full-scale power structure with gear-box.

The generator can be asynchronous, electrically excited

synchronous (WRSG), or a permanent magnet excited

(PMSG). If a multi-pole generator is used, such as a multiple

wound rotor synchronous generator or permanent-magnet

synchronous generator, the gear-box can be eliminated, as

shown in Fig. 3(b) [13]. The trend for large scale wind turbines

are full scale power conversion.

3) Multiple-cell full power structure [9]-[11]

To increase the overall power of the system, several power

converters are used in parallel or in cascade. Using multiple-

cell full power structure, the capacity of each switching device

can be reduced and these provide redundancy because if one of

power converter is failure, the system can still provide a part of

the power. Furthermore, the commutation of different

converters could be synchronized to reduce output harmonics

using interleaved modulation.

Fig. 4(a) shows the multiple-cell structure with full power

converter connected in parallel and interleaved on the grid side.

Fig. 4(b) shows the n-leg diode bridge producing a high DC

voltage shared among converters connected in parallel and

interleaved on the grid side.

B. Wind turbine system control [1], [2], [11]

The goal of Wind Turbine System (WTS) control is to

maximize the power production. The electrical and mechanical

systems are characterized by different control goals but interact

in view of the main aim that the control of power injected into

the grid. The mechanical system is controlled to limit the

power, capture the maximum energy, limit the speed and

reduce the acoustical noise. The electrical system control is

responsible for the interconnection with grid and

active/reactive power control, and the overload protection.

Fig. 5 shows the general scheme of wind turbine control.

The pitch control is used to limit the aerodynamic power

generated by the rotor above rated wind speeds. The generator

side converter is controlled to extract the maximum power

Identify applicable sponsor/s here. If no sponsors, delete this text box.

(sponsors)

Fig. 5. General scheme of wind turbine control.

Fig. 4. Multi-cell full power structure (a) connected in parallel and interleaved on the grid side. (b) n-leg diode bridge producing a high DC voltage shared

among converters connected in parallel and interleaved on the grid side.

from the wind. The control of grid-side converter is keeping the

DC-link voltage fixed. Both converters use the internal current

and voltage loops. The state variables of the LCL filter are

controlled for system stability. The grid fault ride through and

the support is needed for grid voltage restoration. The inertial

emulation is a control function aiming at emulates the relation

between active power and frequency. Power smoothing is

accomplished by supplying a compensation power from an

energy storage system. The energy storage can be connected to

the alternating current grid or to the DC-link of the variable-

speed WTS.

C. Fault ride-through requirement for wind turbine systems.

Wind energy plays an important role in the worlds energy

market. As the wind energy capacity connected to the grid

increase, their dynamic behaviors and performances are critical

to the stability and quality of grid. To enable a large-scaled

application of wind energy without compromising the power

system stability, the WTs should be connected continually and

contribute to the grid in case of grid fault. The WTs should

supply active/reactive power for grid frequency and voltage

recovery, immediately after the grid fault occurs. Therefore,

several grid-connection codes are introduced for WTs

especially in places such as Denmark, Spain, UK, US and

Germany. Among these requirement, fault ride-through (FRT)

is regarded as the main challenge to the WTs.

E. ON-Netz in Germany has the hardest FRT requirements.

Fig. 6(a) shows the FRT requirement of E. ON-Netz.

According to Fig. 6, the generator must be operated

continuously for 150 ms at zero grid voltage. In dotted area, if

the facility is facing stability issues, short time interruptions

with resynchronization are allowed for a maximum 2sec. In the

light grey area, later than 2 sec, short disconnection with

resynchronization can be allowed after agreement with the

transmission system operators. For faults longer than 1.5 sec,

stepwise interruptions are allowed. After the fault clearance,

active power in-feed must increase with a rate of 10% of the

rated power per second. For all generators that do not

disconnect from the grid during the fault, the active power

must be continued immediately after fault clearance and

increased to the original value with a gradient of at least 20%

of rated power per second. The generator should not produce

any active power and all of the output should be reactive power

when the grid voltage is less than the 50% of rated value as

shown in Fig 6(b). From less than 90% to less than the 50% of

rated grid voltage, increase the reactive current at a rate of 2%

per a percentage of grid voltage reduction as shown in Fig.

6(b). More than 90% of grid voltage is considered to the

normal condition [12], [13].

III. PHOTOVOLTAIC SYSTEMS

While the worlds energy demand is steadily increasing, PV

power supply to the utility grid is gaining more and more

visibility. With reductions in system costs, such as for PV

modules, inverters, cables, fittings and man power, the PV

technology has the potential to become one of the main

renewable energy sources for future electricity supply [7].

Fig. 7 shows the typical structure of a PV system. The

generated dc voltage is boosted by the dc-dc converter and the

current is converted to a suitable ac current by the dc-ac

inverter.

A. PV cell

The PV cell is an all-electrical device that produces

electrical power when connected to a suitable load and exposed

to sunlight. Fig. 8 shows a simplified PV cell model. Without

any moving parts inside the module, wear-and-tear is very low

and module lifetimes of more than 25 years can easily be

reached. However, aging may reduce their power generation

capability to 7580 % of the nominal value. A typical PV

module is made up of around 36 or 72 cells connected in series,

encapsulated in a structure made of, for example, aluminum

and Tedlar [7]. The curves of PV-cell current-voltage and

power-voltage characteristics are changed by cell temperature

and incident solar radiation.

Fig. 8. Simplified PV cell model.

Fig. 7. Typical structure of PV systems.

Fig. 6. Fault Ride Through requirement given by E. ON-Netz. (a) FRT

requirement (b) Requirements of reactive power provision.

Since the power produced by the cell influences other

parameters, Maximum Power Point Tracking (MPPT) is

required to maximize energy capture to the highest possible

efficiency over a wide range, due to morning-noon-evening

and winter-summer variations [14]. Fig. 9 shows the

characteristics of a PV cell.

B. Design of PV converter [15]-[17]

During the last decade, there have been significant

advances in PV inverter technologies. Inverter prices have

decreased around 50% and efficiency and reliability have

increased considerably. To decrease the cost and increase the

efficiency of PV system, many inverter designs have been

developed.

1) Centralized inverter

Fig. 10(a) shows a centralized inverter layout interfacing a

large number of PV modules with the grid Here, the PV

modules are divided into series connections called strings. The

strings are arranged in parallel and connected to one common

central inverter, in order to reach high power. This centralized

inverter has significant disadvantages, such as a need for high-

voltage DC cables between PV panels and inverter, power

losses due to common MPPT, power losses due to module

mismatch, losses in the string diodes, and the fact that the

reliability of the whole system depends on one inverter [17].

2) String inverter

The string inverter, shown in Fig. 10(b), is a reduced

version of the centralized inverter where single strings of PV

modules are connected to separate inverters that are paralleled

and connected to the grid. If the string voltage is high enough,

voltage boosting is not necessary and the efficiency can be

improved. Fewer PV panels can also be used, but a DC-DC

converter or a line frequency transformer is then needed to

boost the voltage. The advantages of the string inverter

compared with the centralized inverter are as follows: no losses

in the string diodes, separate MPPTs for each string, better

yield due to separate MPPTs, and lower price due to the ease of

mass production.

3) Module inverter

As shown in Fig. 10(c), the AC module is made up of a

single solar panel connected to the grid by its own inverter. The

advantage of this configuration is that mismatch losses are

significantly reduced and it is possible to maximize the power

production of each separate MPPT. This results in better

optimization of power extraction than in the case of the string

inverter. Furthermore, the modular structure simplifies the

modification of the whole system because of its plug-and-play

nature. However, it has a low efficiency due to the high-voltage

amplification, low power conversion and the price per watt is

still higher compared with the previous inverters [16].

4) Multi-string inverter

The multi-string inverter, illustrated in Fig. 10 (d), is a

further development on the string inverter. Here, several strings

are interfaced with their own dc-dc converter to dc-ac inverter

[8], [9]. It combines the advantages of both string and module

inverters by having many dc-dc converters with separate

MPPTs that feed energy to a common dc-ac inverter [18], [19].

The multi-string concept is a flexible solution, having a high

overall efficiency of power extraction because it is possible to

control each PV string individually.

Fig. 9. Characteristics of PV cells (a) V-I curve (b) V-P curve.

Fig. 10. Structure of different PV systems (a) centralized inverter (b) string inverter (c) module inverter (d) multi-string inverter.

C. Topologies of converters for Photovoltaic system

The transformerless PV (photovoltaic) converters are

widely used in grid-connected renewable energy systems

because of its advantages. They can reduce the costs, size, and

weight. First of all, they can increase the total efficiency of PV

system. Many topologies have been proposed during the last

few years. Among them, in this chapter, the H-bridge, H5-

bridge, HERIC, Neutral-Point clamped (NPC), and Conergy

NPC are introduced [1], [15], [18].

1) H-bridge converter

Fig. 11 (a) shows the H-bridge converter topology. Most

single-phase H-bridge converters use unipolar modulation. The

output voltage is positive when the switches S

1

and S

4

are

turned on. Adversely, output voltage is negative when the S

2

and S

3

are turned on. The zero output voltage states are

possible when the switches S

1

and S

3

are turned on or S

2

and S

3

are turned. The unipolar modulation has various advantages.

The ripple current is significantly reduced. Further, it yields

lower filtering requirements and lower core losses because the

output voltage has the three-levels. However, if this topology

and modulation are applied, common mode voltage V

PE

has

switching frequency components and it yields high leakage

current and EMI.

2) H5-bridge converter

The H5-bridge topology is derived from H-bridge by SMA.

It is made up of standard H-bridge topology with an additional

fifth switch S

5

in the positive bus of DC-link as shown in Fig.

11 (b). The switch S

5

is turned off when the zero voltage state.

Using this topology, the efficiency can be increased up to 98%

because the reactive power exchange between the filter L and

DC-link capacitor is prevented during the zero switching state.

Additionally, this topology isolates the PV module form the

grid during the zero switching state. Because of this, the

common mode voltage V

PE

has only grid frequency

components and no switching frequency components. It leads a

very low leakage current and EMI. However, the H5 requires

additional switch.

3) HERIC converter

Fig. 11 (c) shows the HERIC (highly efficiency and reliable

inverter concept) converter topology. It also derived from H-

bridge topology by adding a bypass leg in the AC side using

bidirectional switch or two IGBTs. The AC bypass provides

the same function as the fifth switch in case of the H5-bridge

topology. During the positive period of grid voltage, switch S

6

is turned on and it is used during the freewheeling period of S

1

and S

4

. Adversely, during the negative period of grid voltage,

switch S

5

is turned on and it is used during the freewheeling

period of S

2

and S

3

. Using this topology, the efficiency can be

increased up to 97% and leads a very low leakage current and

EMI. However, two switches are required.

4) NPC converter

The NPC converter topology consists of four IGBTs, two

clamped diodes and two capacitors as shown in Fig. 11 (d).

This topology has the three voltage states. The output voltage is

V

PV

/2 when the switch S

1

and S

2

are turned on, on the other

hands, when the switches S

3

and S

4

are turned on, the output

voltage state is V

PV

/2. If the output current is positive, the

output voltage is zero when the switch S

2

is turned on. If the

output current is negative, the output voltage is zero when the

switch S

3

is turned on. The NPC has very similar performance

in comparison with H5 and HERIC. Using this topology, the

efficiency can be increased up to 98%. The V

PE

is constant and

it is equal to V

PV

/2 without switching frequency components.

It leads a very low leakage current and EMI. Additionally, it is

possible to reduce the voltage capacity to V

PV

/2. However, this

topology requires additional two diodes and two IGBT. Further,

the neutral point voltage unbalancing can be occurred.

Fig. 10. Topologies of converters for Photovoltaic system (a) H-bridge (b) H5-bridge (c) HERIC (d) NPC (e) Conergy NPC.

5) Conergy NPC converter

Fig. 11(e) shows the Conergy NPC converter topology

where the bidirectional switch is connected between the

neutral-point and its output and a full-bridge is used instead of

a half-bridge. The main concept of the Conergy NPC inverter

is that zero voltage can be produced by the clamping the output

to neutral-point of the DC-link using switch S

2

or S

3

depending

on the current direction. The Conergy NPC converter topology

has slightly higher efficiency in comparison with NPC. The

conduction loss of Conergy NPC is lower than the NPC

because the current is conducted through a single switch. The

other performances are similar with NPC converter. However,

the voltage capacity of switch S

1

and S

4

are double as compared

with switches used in NPC converter.

D. Photovoltaic system control [1], [19], [20]

The PV inverter converts the DC power produced by the

solar modules to grid synchronized AC power. Fig. 12 shows

the generic control structure for PV inverter with a boost stage.

On the PV array side, a Maximum Power Point Tracker

(MPPT) control is implemented in order to collect the

maximum available power at every operating point because the

characteristic of the PV modules are influenced by the solar

radiation and the temperature as mentioned earlier. The MPPT

can be performed through DC voltage, AC current or AC

voltage control [7]. Through the current control, photovoltaic

systems harmonic rejection is achieved to satisfy the THD

requirement imposed by standards. Furthermore, the systems

can be stable in case of large grid impedance variations by the

current control. In order to synchronize the injected grid

current with the grid voltage to achieve unity power factor, the

Phase Locked Loop (PLL) control is performed. The Anti-

Islanding (AI) protection control is fulfilled to stop the power

production of the photovoltaic systems in the case of abnormal

conditions. Grid monitoring is also needed for synchronization

and fast voltage/frequency detection for passive AI.

E. Anti-Islanding requirement for PV systems

Islanding for grid-connected PV systems takes place when

the PV inverter is not disconnected for a very short time after

the grid is tripped. The grid disconnection can occur as a result

of a local equipment failure detected by ground fault protection

or an intentional disconnection of the line for servicing.

In the above situations, if the PV inverter is not disconnected to

the grid following problems can occur. For the first, it can

cause a safety-accident of line workers who misapprehended

the situation as blackout. Second, when the grid connection is

restored, it provokes the damage to the connected equipments

due to out-of-phase between grid and PV systems. In order to

avoid these serious problems, Anti-Islanding (AI) requirements

have been issued in standards.

1) Anti-Islanding defined by IEEE Std. 1547.1 [21], [22]

In IEEE 1547.1, the test setup for anti-islanding

requirements is described as shown in Fig. 13, where the EUT

represents the Equipment Under Test. The RLC load is

connected in parallel between the PV inverter and the grid. The

LC load should be adjusted to resonate at the rated grid

frequency f

grid

, and to have a quality factor Q

f

=1. The values of

RLC load can be calculated as

2 2

2

, ,

2 2

f

grid f grid

PQ

V V

R L C

P f PQ f V

= = =

(1)

The RLC load shown in Fig. 13 should be set so that the

grid current which flows through S

3

should be lower than 2%

of the rated value on the steady-state condition. In this

condition, the disconnection should be detected within 2 sec

after S

3

is opened.

2) Anti-Islanding defined by VDE 0126-1-1 [23]

There are two anti-islanding methods in the VDE 0126-1-1.

a) Impedance measurement

Fig. 14 shows the test circuit for anti-islanding

requirements in VDE 0126-1-1. The procedure is based on

local balancing of active and reactive power using variable

RLC load. The switch S is opened in order to increase the grid

Fig. 13. The test setup for anti-islanding requirements in IEEE 1547.1.

Fig.12. Generic control structure for PV inverter with boost stage.

impedance by 1 . The inverter should be disconnected within

5 sec. The test should be repeated for different values of R

2

and

L

2

in the range of 1 .

b) Disconnection detection with RLC resonant load

The test circuit is same with the Fig. 13. the RLC load

should be set that the quality factor Q

f

> 2 using (1). In

balanced power condition, the inverter should be disconnected

within 5 sec after S

3

is opened for the 25%, 50% and 100% of

rated power.

3) Anti-Islanding defined by IEC 62116 [24]

The test circuit is same as in the IEEE 1547.1 test shown in

Fig, 13 and the power should be balanced before the island

detection test. The test is tested at three levels of output power

but conditions to confirm the island detection is similar to

IEEE 1547.1 test. The test is performed divided into three cases

according to the power level: case A (100~105%), case B

(50~66%), and case C (25~33%). For case A, the inverter is

tested in step of 5% both real and reactive power in an interval

of 10 % from the inverters operating output power. The case

B and C are evaluated by reactive power deviation from -5 to

5% at a step of 1% of inverter output power. The maximum

trip time is 2 sec. it is same as in IEEE 1547.1 standards.

IV. CONCLUSION

This paper has discussed wind turbine and photovoltaic

(PV) systems which are representative of these renewable

energy systems. First, the overview of wind turbine systems

and grid converter structure adopted in wind turbine system are

discussed. The structures are classified into reduced power, full

power, and multiple-cell full power. Further, control strategy

of wind turbine systems and the fault-ride-through requirement

are explained. Next, the overview of wind turbine system and

design of PV converters are discussed. Then control methods

of PV systems and several standards for anti-islanding are

expressed which are important for safety.

REFERENCES

[1] R. Teodorescu, M. Liserre and P. Rodriquez, Grid Converters for

Photovoltaic and Wind Power System, West Sussex: John Wiley & Sons

Inc, 2011.

[2] F. Blaabjerg, R. Teodorescu, M. Liserre and A. Timbus, Overview of

Control and Grid Synchronization for Distributed Power Generation

System, IEEE Transactions on Industrial Electronics, vol. 53, no. 5,

pp. 1398-1409, Oct. 2006.

[3] F. Blaabjerg, M. Liserre, and K. Ma, Power Electronics Converter for

Wind Turbine Systems, IEEE Transactions on Industry Applications,

vol. 48, no. 2, pp. 708-719, Mar/Apr. 2012.

[4] GWEC, Global Wind Report 2011-Annual market update, 2011.

[Online].Available:

http://www.gwec.net/fileadmin/documents/NewsDocuments/Annual_rep

ort_2011_lowres.pdf.

[5] EPIA, Global Market Outlook for Photovoltaics until 2016, May

2012. [Online].Available:

http://files.epia.org/files/Global-Market-Outlook-2016.pdf.

[6] J. M. Carrasco, L. G. Franquelo, J. Bialasiewicz, E. Galvan, R. P.

Guisado, M. A. M. Prats, J. I. Leon, and N. M. Alfonso, Power-

Electronics systems for the Grid Integration of Renewable Energy

Source: A Survey, IEEE Transactions on Industrial Electronics, vol.

53, no. 4, pp. 1002-1016, Aug. 2006.

[7] F. Blaabjerg, Z. Chen, and S. B. Kjaer, Power Electronics as Efficient

Interface in Dispersed Power Generation Systems, IEEE Transactions

on Power Electronics, vol. 19, no. 5, pp. 1184-1193, Sep. 2004.

[8] S. Muller, M. Deicke, and R. W. De Doncker, Doubly fed induction

generator systems for wind turbines, IEEE Industry Applications

Magazine, vol. 8, no. 3, pp. 26-33, May/Jun. 2002.

[9] D. Schreiber, Power converter circuit arrangement for generators with

dynamically variable power output, US Patent App. 10/104, 474, 2002.

[10] B. Andresen, and J. Brik, A high power density converter system for

the Gamesa G10x 4.5 MW Wind turbine, in Proc. of EPE07 Conf., pp.

1-7, 2007.

[11] M. Liserre, R. Cardenas, M. Molinas and J. Rodriguez, Overview of

Multi-MW Wind Turbines and Wind Parks, IEEE Transactions on

Industrial Electronics, vol. 58, no. 4, pp. 1081-1095, Apr. 2011.

[12] H. G. Jeong, U. M. Choi, and K. B. Lee, Control Strategies for Wind

Power Systems to Meet Grid Code Requirements, in Proc. of

IECON11 Conf., pp. 1250-1255, Nov. 2011.

[13] E. ON Netz Gmbh, Grid Code High and extra high voltage, Apr.

2006. [Online].Available:

http://www.nerc.com/docs/pc/ivgtf/German_EON_Grid_Code.pdf.

[14] S. Kjaer, J. Pedersen and F. Blaabjerg, Power inverter topologies for

photovoltaic modules A review, in Proc. of IAS02 Conf., vol. 2, pp.

782-788, Oct. 2002.

[15] T. Kerekes, Analysis and Modeling of Transformerless Photovoltaic

Inverter Systems, Dessertation submitted to the Faculty of Engineering,

Science & Medicine at Aalborg University, Aug. 2009.

[16] S. B. Kjaer, J. Pedersen and F. Blaabjerg, A review of single-phase grid

connected inverters for photovoltaic modules, IEEE Transactions on

Industry Applications, vol. 41, no. 5, pp. 1292-1306, Sep. 2005.

[17] M. Meinhardt, G. Cramernd, B. Burger, and P. Zacharias, Multi-string-

converter with reduced specific costs and enhanced functionality, Solar

Energy, vol. 69, no. 1-6, pp. 217-227, July 2001.

[18] T. Kerekes, R. Teodorescu, P. Rodriguez, G. Vazquez, and E. Aldabas,

A New High-Efficiency Single-Phase Transformerless PV Inverter

Topology, IEEE Transactions on Power Electronics, vol. 58, no. 1,

pp. 184-191, Jan. 2011.

[19] R. A. Mastromauro, M. Liserre, and A. D. Aquila, Control Issues in

Single-Stage Photovoltaic Systems: MPPT, Current and Voltage

Control, IEEE Transactions on Industrial Infornatics, vol. 8, no. 2, pp.

241-254, May 2012.

[20] S. Balathandayuthapani, C. S. Edrington, S. D. Henry, and J. Cao,

Analysis and Control of a Photovoltaic System: Application to a High-

Penetration Case Study, IEEE Systems Journal, vol. 6, no. 2, pp. 213-

219, June 2012.

[21] UL Std 1741, Inverter, Converter, and Controllers for Use in

Independent Power Systems, Underwriters Laboratories Inc. US, 2001.

[22] IEEE Std 1547.1-2005, Standard Conformance Test Procedures for

Equipment Interconnecting Distributed Resources with Electric Power

Systems, IEEE, July 2005. ISBN 0-7381-4736-2 SH95346.

[23] VDE V 0126-1-1, Automatic Disconnection Device between a

Generator and the Public Low-Voltage Grid, Document 0126003, VDE

Verlag, 2006.

[24] IEC 62116 CDV Ed. 1, Test Procedure of Islanding Prevention

Measures fot Utility-Interconnected Photovoltaic Inverters, IEC

82/402/CD, 2005.

Fig. 14. The test circuit for anti-islanding requirements in VDE 0126-1-1 in

PV systems [1].

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- JMC (Te 03)Document1.130 paginiJMC (Te 03)shanmugam.s100% (1)

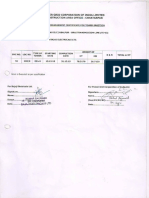

- Power Grid Corporation of India Limited: Pit MarkingDocument12 paginiPower Grid Corporation of India Limited: Pit Markingshanmugam.sÎncă nu există evaluări

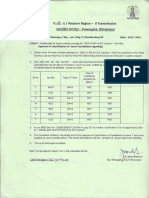

- Ammendment I JO TL (TE 03)Document26 paginiAmmendment I JO TL (TE 03)shanmugam.sÎncă nu există evaluări

- Power Grid Corporation of India Limited: Construction Area Office: ChhatarpurDocument40 paginiPower Grid Corporation of India Limited: Construction Area Office: Chhatarpurshanmugam.sÎncă nu există evaluări

- Bom Sl. No. SL - NO. Mark No. Part: Basic BodyDocument4 paginiBom Sl. No. SL - NO. Mark No. Part: Basic Bodyshanmugam.sÎncă nu există evaluări

- Erection JMC Jo (Te 03)Document6 paginiErection JMC Jo (Te 03)shanmugam.sÎncă nu există evaluări

- Stringing Drum ScheduleDocument124 paginiStringing Drum Scheduleshanmugam.s100% (4)

- Power Grid Corporation of India Limited: Pit MarkingDocument12 paginiPower Grid Corporation of India Limited: Pit Markingshanmugam.sÎncă nu există evaluări

- SFQP Coarse AggregateDocument1 paginăSFQP Coarse Aggregateshanmugam.sÎncă nu există evaluări

- Stringing Drum ScheduleDocument124 paginiStringing Drum Scheduleshanmugam.s100% (4)

- JMC ErectionDocument1 paginăJMC Erectionshanmugam.sÎncă nu există evaluări

- Classification 03Document2 paginiClassification 03shanmugam.sÎncă nu există evaluări

- POUR CARD and Foundation FormatsDocument16 paginiPOUR CARD and Foundation Formatsshanmugam.s100% (1)

- Stringing Drum ScheduleDocument124 paginiStringing Drum Scheduleshanmugam.s100% (4)

- Foundation Check ListDocument10 paginiFoundation Check Listshanmugam.sÎncă nu există evaluări

- SFQP Reinforcement SteelDocument1 paginăSFQP Reinforcement Steelshanmugam.sÎncă nu există evaluări

- Spacer DrawingDocument2 paginiSpacer Drawingshanmugam.sÎncă nu există evaluări

- SFQP Fine AggregateDocument1 paginăSFQP Fine Aggregateshanmugam.sÎncă nu există evaluări

- Approved Detail Survey Tower Schedule (AP 95-AP128)Document10 paginiApproved Detail Survey Tower Schedule (AP 95-AP128)shanmugam.sÎncă nu există evaluări

- Insert A Check Mark Symbol - WordDocument3 paginiInsert A Check Mark Symbol - Wordshanmugam.sÎncă nu există evaluări

- SFQP CubeDocument1 paginăSFQP Cubeshanmugam.sÎncă nu există evaluări

- SFQP Reinforcement SteelDocument1 paginăSFQP Reinforcement Steelshanmugam.sÎncă nu există evaluări

- SFQP Reinforcement SteelDocument1 paginăSFQP Reinforcement Steelshanmugam.sÎncă nu există evaluări

- PV-Grid Tie System Energizing Water Pump: Sameer Khader, Abdel-Karim DaudDocument10 paginiPV-Grid Tie System Energizing Water Pump: Sameer Khader, Abdel-Karim Daudshanmugam.sÎncă nu există evaluări

- Ec 353 MPDocument34 paginiEc 353 MPanvesh_tatikondaÎncă nu există evaluări

- Solar Powered Water Pumping Systems: Feature ArticleDocument5 paginiSolar Powered Water Pumping Systems: Feature ArticleSamir Fassi FassiÎncă nu există evaluări

- Design and Simulation of PV Water Pumping SystemDocument104 paginiDesign and Simulation of PV Water Pumping Systemshanmugam.s100% (7)

- Chapter - 5 Photovoltaic Powered Induction Motor DriveDocument29 paginiChapter - 5 Photovoltaic Powered Induction Motor Driveshanmugam.sÎncă nu există evaluări

- Anatomic Therapy English Part1Document92 paginiAnatomic Therapy English Part1shanmugam.sÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 02 DT - New IEC StandardDocument2 pagini02 DT - New IEC StandardkfaliÎncă nu există evaluări

- METKA EGN Company Profile PDFDocument11 paginiMETKA EGN Company Profile PDFParas NakraÎncă nu există evaluări

- Governor Characteristics ForDocument29 paginiGovernor Characteristics ForCristian MontoyaÎncă nu există evaluări

- Solar+Guide+Book - IfcDocument204 paginiSolar+Guide+Book - IfcRami ReddyÎncă nu există evaluări

- PX4012 - RetDocument8 paginiPX4012 - Retvivekananthan.mechÎncă nu există evaluări

- DC50CDocument2 paginiDC50CbarbastylÎncă nu există evaluări

- Alternative Elecctrical Energy Sources GeothermalDocument39 paginiAlternative Elecctrical Energy Sources GeothermalJose Corbacho100% (1)

- Solar Outlook: Middle East Solar Industry AssociationDocument32 paginiSolar Outlook: Middle East Solar Industry AssociationANSHUMANÎncă nu există evaluări

- Sanjay Govindjee-Engineering Mechanics of Deformable Solids - A Presentation With Exercises-Oxford University Press (2013)Document351 paginiSanjay Govindjee-Engineering Mechanics of Deformable Solids - A Presentation With Exercises-Oxford University Press (2013)ppcastillom100% (1)

- DCRP Active Product List July 2017Document47 paginiDCRP Active Product List July 2017WaleedBarwaniÎncă nu există evaluări

- Calibracion de Valvulas 3408Document96 paginiCalibracion de Valvulas 3408rigoberto otinianoÎncă nu există evaluări

- Relief Valve Version 1Document37 paginiRelief Valve Version 1ChakerZagrouba100% (2)

- 2059 s19 QP 2Document24 pagini2059 s19 QP 2UserÎncă nu există evaluări

- Energy Transition Initiative Islands, Energy Snapshot Antigua and Barbuda, May 2015Document4 paginiEnergy Transition Initiative Islands, Energy Snapshot Antigua and Barbuda, May 2015Detlef LoyÎncă nu există evaluări

- CLEXTRAL Preconditioner Plus EN PDFDocument2 paginiCLEXTRAL Preconditioner Plus EN PDFÁrpád OrbánÎncă nu există evaluări

- POWER Magazine - May 2023-1Document43 paginiPOWER Magazine - May 2023-1MarcialgonzalezpÎncă nu există evaluări

- 1 MW PV Solar Power Project - Brief AnalysisDocument5 pagini1 MW PV Solar Power Project - Brief AnalysisDalveer SinghÎncă nu există evaluări

- Axem Disc DC Servo Motor ManualDocument12 paginiAxem Disc DC Servo Motor ManualjohnysonycumÎncă nu există evaluări

- Daily Activity Report Actual - Instrument & Electrical Technician WEEK-20Document6 paginiDaily Activity Report Actual - Instrument & Electrical Technician WEEK-20Denan AprilioÎncă nu există evaluări

- P1 4 Generating Electricity QsDocument10 paginiP1 4 Generating Electricity QsTim LawrenceÎncă nu există evaluări

- GCB - Application GuideDocument80 paginiGCB - Application GuiderpshvjuÎncă nu există evaluări

- 5KW Hybrid Inverter 5.45KW Panels With Smart Storage 6.5KWHDocument1 pagină5KW Hybrid Inverter 5.45KW Panels With Smart Storage 6.5KWHM RaffiÎncă nu există evaluări

- SolarEnergy FundamentalEconomicEnergyAnalysis PDFDocument90 paginiSolarEnergy FundamentalEconomicEnergyAnalysis PDFAnuj Sharma100% (1)

- DaihatsuDocument10 paginiDaihatsuMANIU RADU-GEORGIANÎncă nu există evaluări

- HB 12-1105 Concerning Wind Energy Property RightsDocument3 paginiHB 12-1105 Concerning Wind Energy Property RightsSenator Mike JohnstonÎncă nu există evaluări

- Naphthenics Magazine Issue 3-2012Document16 paginiNaphthenics Magazine Issue 3-2012Atomer FormationÎncă nu există evaluări

- The History of Using Solar EnergyDocument8 paginiThe History of Using Solar Energyarnika33Încă nu există evaluări

- GHG Emission India - Cement Tool FinalDocument75 paginiGHG Emission India - Cement Tool FinaljagrutÎncă nu există evaluări

- Hydropower Project Summary by TeslaDocument31 paginiHydropower Project Summary by TeslaLuthfi NaufalÎncă nu există evaluări

- Lorentz Ps Manual enDocument48 paginiLorentz Ps Manual enOsama Wais100% (1)