Documente Academic

Documente Profesional

Documente Cultură

Datasheet SimSci DynsimCheckoutSoftware 08-10

Încărcat de

Mateo QuispeDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Datasheet SimSci DynsimCheckoutSoftware 08-10

Încărcat de

Mateo QuispeDrepturi de autor:

Formate disponibile

Software Datasheet

Summary

Put the power of

simulation into hands

of control application

engineers for control

system design

validation. Medium-

Fidelity simulation is

forgiving to use and is

suitable for Operator

Familiarization.

Business Value

Validating control

system design

before it is installed

in plant can recoup

your investment many

times over through

trouble-free startup.

Previously only the

purview of High-

Fidelity (expensive,

long-schedule) or Low-

Fidelity (very limited

testing ability), Medium-

Fidelity fits within

challenging project

schedules and can live

on to provide cost-

effective operations

training after delivery.

THE FIRST PROCESS SIMULATION PRODUCT DESIGNED

SPECIFICALLY FOR CONTROL SYSTEM VALIDATION

In new or upgraded plant control designs, often the control or safety system is

the critical path risk to completing the plant startup on schedule. High-Fidelity

simulation often cannot ft into the compressed timeline needed to support

startup. Low-Fidelity Tieback simulation is a good tool for basic testing, but

only effectively tests single loops at a time.

Enter DYNSIM Checkout

a highly forgiving unit operation modeling

environment designed with control validation in mind. While similar in

structure to DYNSIM High-Fidelity, Checkout forgoes the need for detailed

engineering data and complex thermodynamics. In exchange for some rigor,

DYNSIM Checkout offers a tool for validating multiply-interacting control loops

and complex control during the acceptance test cycle. In addition, DYNSIM

Checkout can be used for Operator Familiarization, learning how to start and

operate equipment, how to satisfy interlocks, how to manipulate the process,

and how to recognize the operating state of the process by interpreting the

various sensor readings.

KEY FEATURES

Robust models do not require rigorous thermodynamics

User-friendly data entry requires only information commonly found in a Piping

and Instrumentation Diagram (P&ID) or Process Flow Diagram (PFD)

Models run out-of-the-box, forgiving of bad or missing information

Transmitter with calibration to scale model values to desired engineering units

Models able to be generated automatically from Intergraph Smart P&ID

DYNSIM Checkout

Invensys, the Invensys logo, ArchestrA, Avantis, Eurotherm, Foxboro, IMServ, InFusion, SimSci-Esscor, Skelta, Triconex, and Wonderware are trademarks of Invensys plc, its subsidiaries or afliates.

All other brands and product names may be the trademarks or service marks of their representative owners.

2010 Invensys Systems, Inc. All rights reserved. No part of the material protected by this copyright may be reproduced or utilized in any form or by any means, electronic or mechanical, including

photocopying, recording, broadcasting, or by any information storage and retrieval system, without permission in writing from Invensys Systems, Inc.

Invensys Operations Management 5601 Granite Parkway III, #1000, Plano, TX 75024 Tel: (469) 365-6400 Fax: (469) 365-6401 iom.invensys.com

AUTO-MODEL GENERATION:

PLUGGING DIRECTLY INTO THE PLANT DESIGN

As plant designs become increasingly complex, developers of Plant Lifecycle Management software

are increasingly moving toward an object-oriented representation of a plant so that common data are

shared between applications such as Instrumentation, Piping and Instrumentation Diagrams, Process

Flow Diagrams, Electrical, Construction, etc. Taking advantage of the fact that the topology of a DYNSIM

process model is very similar to a P&ID, Invensys has developed a tool to transform the plant design in

the P&ID to DYNSIM models. Additionally, Instrumentation data can be used to link control system I/O

points to transmitter and actuator tags on the P&ID, thus simplifying and shortening the control system

to simulator model integration phase. The combined result of these features is a model that can be built

more quickly and integrated and made available for control system checkout.

INDUSTRIES SERVED

Water & Wastewater Pulp & Paper Consumer Packaged Goods

Metals & Mining Food & Beverage Chemical, Batch, Pharmaceutical

DYNSIM Checkout now has models dedicated to bulk solids handling and various solid-liquid-vapor

transport and separation processes.

UNIT OPERATIONS SIMULATED

Process Stream Relief Valve Heat Exchanger Combustor

Mechanical Stream Three-Way Valve Utility Exchanger Reactor

Source Pump Transmitter Tank

Sink Expander Conveyer Ejector

Valve Drum Mill Screen

Shaft Header Pulverizer

Pipe Compressor Bin

CONTROL SYSTEM CONNECTIVITY

DYNSIM Checkout integrates seamlessly with FSIM Plus (an Invensys Foxboro

I/A Series

virtual

control system) and TRISIM Plus (a Triconex

safety system simulation). In addition, DYNSIM Checkout

matches up to various third-party control system simulations and emulations, and supports various

interconnectivity protocols (such as OPC and Modbus).

DYNAMIC SIMULATION SUITE

Dynamic Simulation Suite (DSS) provides the full power of rigorous dynamic simulation for plant

engineers, operators, and managers to use in optimizing plant operations and design. DSS is comprised

of the DYNSIM, FSIM Plus, and TRISIM Plus programs offering a professional grade alternative to dated,

fragmented, and hard-to-use products, with which many plants currently struggle. All DSS products can

communicate among themselves, allowing a perfect combination to suit your exact plant requirements.

Rev. 08/10 PN SE-0130

S-ar putea să vă placă și

- 6m RTP Design ReportDocument25 pagini6m RTP Design Reportmanohargud100% (1)

- Retail Delmia v5r18 Digital Manufacturing PortfolioDocument20 paginiRetail Delmia v5r18 Digital Manufacturing PortfolioRilton Lima OliveiraÎncă nu există evaluări

- Frequency, Energy, Wavelength Activity C12!2!01Document7 paginiFrequency, Energy, Wavelength Activity C12!2!01Niko BrocesÎncă nu există evaluări

- Wind Loading of Industrial, Mining and Petrochemical StructuresDocument16 paginiWind Loading of Industrial, Mining and Petrochemical StructuresapirakqÎncă nu există evaluări

- K-Chief: All Control Requirements Fulfilled - in A Uniform SystemDocument16 paginiK-Chief: All Control Requirements Fulfilled - in A Uniform Systemdnse90900Încă nu există evaluări

- Catalogue PlantpAxDocument16 paginiCatalogue PlantpAxaharnishaÎncă nu există evaluări

- Controller System For Industrial Automation: Analogue Vs Digital ControllersDocument27 paginiController System For Industrial Automation: Analogue Vs Digital ControllerstrlucÎncă nu există evaluări

- HMIDocument447 paginiHMIsokol_polece100% (2)

- Surveying Lecture 1Document39 paginiSurveying Lecture 1Ruel Torres50% (4)

- Plantpax Process Automation Solution For Oil and GasDocument24 paginiPlantpax Process Automation Solution For Oil and GaszkaticÎncă nu există evaluări

- Inprocess Webinar SlidesDocument38 paginiInprocess Webinar Slidesreclatis14100% (2)

- PlantPAx Distributed Control System - The Modern DCSDocument20 paginiPlantPAx Distributed Control System - The Modern DCSVÕ QUỐC HIỆUÎncă nu există evaluări

- Introduction to N.C.M., a Non Contact Measurement ToolDe la EverandIntroduction to N.C.M., a Non Contact Measurement ToolÎncă nu există evaluări

- Networked Control System: Fundamentals and ApplicationsDe la EverandNetworked Control System: Fundamentals and ApplicationsÎncă nu există evaluări

- FL PlantCruise by Experion Launch in ChinaDocument7 paginiFL PlantCruise by Experion Launch in ChinaaharnishaÎncă nu există evaluări

- Sppa T3000Document6 paginiSppa T3000Dipti BhanjaÎncă nu există evaluări

- Shear Strengthening of T-Beam With FRPDocument3 paginiShear Strengthening of T-Beam With FRPRal GLÎncă nu există evaluări

- Siemens Plant Simulation PDFDocument87 paginiSiemens Plant Simulation PDFMarko Matić100% (1)

- IAB - Proj Dimas: Integrated Architecture BuilderDocument114 paginiIAB - Proj Dimas: Integrated Architecture BuilderDimas CaceresÎncă nu există evaluări

- Balancing Procedure Method - SKF ArticleDocument6 paginiBalancing Procedure Method - SKF ArticlebackvlackoÎncă nu există evaluări

- Siemens Teleperm Manuals and GuidesDocument17 paginiSiemens Teleperm Manuals and GuidesMuhammad SyaifulhaqÎncă nu există evaluări

- PCS7Document92 paginiPCS7stalindcunha1Încă nu există evaluări

- Process Control A First Course With MATLAB Cambridge - Series - in - Chemical - EngineeringDocument255 paginiProcess Control A First Course With MATLAB Cambridge - Series - in - Chemical - EngineeringMateo QuispeÎncă nu există evaluări

- SIMIT Getting Started GuideDocument69 paginiSIMIT Getting Started GuideMateo QuispeÎncă nu există evaluări

- SIRIUS Modular System - Brochure1Document6 paginiSIRIUS Modular System - Brochure1Tuhin SarkarÎncă nu există evaluări

- Ballast SystemDocument2 paginiBallast SystemArchie MarchieÎncă nu există evaluări

- Plant Simulation: Simulation and Optimization of Production Systems and ProcessesDocument2 paginiPlant Simulation: Simulation and Optimization of Production Systems and ProcessesMateo QuispeÎncă nu există evaluări

- 2018 Applications Industry4Document123 pagini2018 Applications Industry4Ridwan MerduÎncă nu există evaluări

- Simit enDocument6 paginiSimit enTheFenix OlÎncă nu există evaluări

- PLC SCADA Presentation: Automation Tools and Their UsesDocument23 paginiPLC SCADA Presentation: Automation Tools and Their UsesEsha PCE/17/EE/022Încă nu există evaluări

- iPRSM Brochure 0611Document6 paginiiPRSM Brochure 0611Hardy HendraÎncă nu există evaluări

- Dffa b10056 01 SB Tia Migration144dpi PDFDocument2 paginiDffa b10056 01 SB Tia Migration144dpi PDFMarco Antonio Dominguez OrtegaÎncă nu există evaluări

- Brochure Simatic Wincc v72 enDocument8 paginiBrochure Simatic Wincc v72 enjeanfmirandaÎncă nu există evaluări

- CSI PresentationDocument29 paginiCSI PresentationAdneya AudhiÎncă nu există evaluări

- Totally Integrated AutomationDocument8 paginiTotally Integrated AutomationShamim Ahsan ParvezÎncă nu există evaluări

- DFMC b10011 00sinamicsstartdrivedeenus 72Document10 paginiDFMC b10011 00sinamicsstartdrivedeenus 72Tun Myint OoÎncă nu există evaluări

- Essentials Of: The Modern DcsDocument7 paginiEssentials Of: The Modern DcsMohammad Yasser RamzanÎncă nu există evaluări

- Glass: Leading The Way in Glass Manufacturing SolutionsDocument12 paginiGlass: Leading The Way in Glass Manufacturing Solutionsshaileshgupta83Încă nu există evaluări

- Product Lifecycle ManagementDocument21 paginiProduct Lifecycle ManagementSwarnim SinghÎncă nu există evaluări

- Proficy IFIX - IntellutionDocument8 paginiProficy IFIX - IntellutionthlsatheeshÎncă nu există evaluări

- Supervisory Control and Data Acquisition (Scada)Document21 paginiSupervisory Control and Data Acquisition (Scada)Vikas ChoudharyÎncă nu există evaluări

- COMOS WalkinsideDocument2 paginiCOMOS WalkinsideridipisaÎncă nu există evaluări

- Stepping Up With SIPLUSDocument12 paginiStepping Up With SIPLUScc_bauÎncă nu există evaluări

- Oil & Gas Floating Production SolutionsDocument24 paginiOil & Gas Floating Production SolutionsMikel IglesiasÎncă nu există evaluări

- SIMOTICS MotorsDocument26 paginiSIMOTICS MotorsJeimy Rafael Zacarias RodriguezÎncă nu există evaluări

- DRV-SINUMERIK SIMODRIVE-Catalog NC60 PDFDocument536 paginiDRV-SINUMERIK SIMODRIVE-Catalog NC60 PDFBasalic GeorgeÎncă nu există evaluări

- Dresser-Rand Control Systems: Easy To Use, Understand and OperateDocument6 paginiDresser-Rand Control Systems: Easy To Use, Understand and OperateNistha ChakrabortyÎncă nu există evaluări

- Sitras RSC: FeaturesDocument4 paginiSitras RSC: FeaturesAnonymous m1cSnEavoÎncă nu există evaluări

- INCONTROL Simulation Solutions ED9 S ENGDocument2 paginiINCONTROL Simulation Solutions ED9 S ENGzeeshanahmad111Încă nu există evaluări

- Advancing Automation: Iiot and Industry 4.0Document28 paginiAdvancing Automation: Iiot and Industry 4.0Martina Chila RamirezÎncă nu există evaluări

- Meet The Future Edge Programmable Industrial ControllersDocument12 paginiMeet The Future Edge Programmable Industrial Controllersmrme44Încă nu există evaluări

- Dcs Bu33g01a13 01e YokogawaDocument21 paginiDcs Bu33g01a13 01e Yokogawawira ekaÎncă nu există evaluări

- Delmia Apriso Process Builder DatasheetDocument2 paginiDelmia Apriso Process Builder Datasheetshubham.v.d.06Încă nu există evaluări

- Unit 1Document21 paginiUnit 1John Aubrey MatiasÎncă nu există evaluări

- Unity ProDocument8 paginiUnity Prodongotchi09Încă nu există evaluări

- Totally Integrated Automation PortalDocument8 paginiTotally Integrated Automation PortalPedroÎncă nu există evaluări

- LMS Imagine (1) .Lab AMESim BrochureDocument12 paginiLMS Imagine (1) .Lab AMESim BrochureIoana H0% (1)

- Drive Solutions: We EngineerDocument8 paginiDrive Solutions: We EngineerDoDuyBacÎncă nu există evaluări

- 3-Totally Integrated Automation ChemicalDocument30 pagini3-Totally Integrated Automation ChemicalUmesh SÎncă nu există evaluări

- 5939 VM600 Integrated-BrochureDocument8 pagini5939 VM600 Integrated-BrochurescribdkhatnÎncă nu există evaluări

- Info PLC SiemensDocument22 paginiInfo PLC SiemensCristián Rodríguez UgarteÎncă nu există evaluări

- How To Setup Teamviewer VPNDocument2 paginiHow To Setup Teamviewer VPNশরীফ সিকদারÎncă nu există evaluări

- Agility Platform WebDocument2 paginiAgility Platform WebvishnuprakashÎncă nu există evaluări

- Descriere Aplicatie SCADADocument2 paginiDescriere Aplicatie SCADASilviu DochiaÎncă nu există evaluări

- NUMECA CorporateDocument19 paginiNUMECA CorporateAji PurwantoÎncă nu există evaluări

- Ftserver Gen 12 Data SheetDocument4 paginiFtserver Gen 12 Data SheetK.S HongÎncă nu există evaluări

- LT-1040 FX-350 Programming Manual PDFDocument48 paginiLT-1040 FX-350 Programming Manual PDF997147088Încă nu există evaluări

- 7 - Parviz D - Entekhabi-AutoCAD Workbook2D-Hartnell College EngineeringTechnologyDocument66 pagini7 - Parviz D - Entekhabi-AutoCAD Workbook2D-Hartnell College EngineeringTechnologyandresboy123Încă nu există evaluări

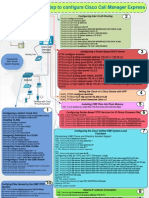

- Configure Cisco Voice Gateway and Call Manager ExpressDocument1 paginăConfigure Cisco Voice Gateway and Call Manager ExpressSudhir Vats100% (2)

- M190 OPL Dryer Powerful 190-lb Commercial DryerDocument2 paginiM190 OPL Dryer Powerful 190-lb Commercial DryerMateo QuispeÎncă nu există evaluări

- Application For Process Automation: Configuration of Redundant I/O ModulesDocument68 paginiApplication For Process Automation: Configuration of Redundant I/O ModulesMateo QuispeÎncă nu există evaluări

- Somachine DataloggingDocument62 paginiSomachine DataloggingMateo QuispeÎncă nu există evaluări

- CP342-5 DP Master Slave enDocument12 paginiCP342-5 DP Master Slave enmateoÎncă nu există evaluări

- Imaq Vision For Labview User ManualDocument141 paginiImaq Vision For Labview User ManualMateo QuispeÎncă nu există evaluări

- PDFDocument22 paginiPDFMateo QuispeÎncă nu există evaluări

- Si ReferenceDocument103 paginiSi ReferenceMateo QuispeÎncă nu există evaluări

- IA NT STD 2 4 Reference Guide PDFDocument75 paginiIA NT STD 2 4 Reference Guide PDFMateo QuispeÎncă nu există evaluări

- Operation Manual PCS7 LAB Collection 3p1 enDocument76 paginiOperation Manual PCS7 LAB Collection 3p1 enMateo QuispeÎncă nu există evaluări

- PDFDocument48 paginiPDFMateo Quispe100% (1)

- InfoPLC Net EIO0000001762.00 M221 Temperature ControlDocument30 paginiInfoPLC Net EIO0000001762.00 M221 Temperature ControlMateo QuispeÎncă nu există evaluări

- infoPLC - Net - 20140402 RA - Eplan - Webinar - PDFDocument26 paginiinfoPLC - Net - 20140402 RA - Eplan - Webinar - PDFJaime RamosÎncă nu există evaluări

- Modbus TCP Kopplung Doku v12 en - pdfuUUffffRLsEDocument80 paginiModbus TCP Kopplung Doku v12 en - pdfuUUffffRLsEMateo QuispeÎncă nu există evaluări

- Dynsim 5.0 Getting Started: An Installation and Tutorial GuideDocument93 paginiDynsim 5.0 Getting Started: An Installation and Tutorial GuideMateo QuispeÎncă nu există evaluări

- A Dual-Rate Model Predictive Controller For Fieldbus Based DistriDocument145 paginiA Dual-Rate Model Predictive Controller For Fieldbus Based DistriMateo QuispeÎncă nu există evaluări

- DSP LabviewDocument25 paginiDSP LabviewKalamchety Ravikumar SrinivasaÎncă nu există evaluări

- MÍN. SU2 DIN NO2 SU1 AL2 FR2 IT2 ES1 IT1 POR AR1 AR2 COL football betting oddsDocument8 paginiMÍN. SU2 DIN NO2 SU1 AL2 FR2 IT2 ES1 IT1 POR AR1 AR2 COL football betting oddsdiego_11404Încă nu există evaluări

- APC AddOns en 2Document48 paginiAPC AddOns en 2Mateo QuispeÎncă nu există evaluări

- Service & Support: Configuration of An S7-300 CPU As DP Slave To A CP 342-5 As DP MasterDocument14 paginiService & Support: Configuration of An S7-300 CPU As DP Slave To A CP 342-5 As DP MasterMateo QuispeÎncă nu există evaluări

- Lab 10 Mechanical MotionDocument11 paginiLab 10 Mechanical MotionMateo QuispeÎncă nu există evaluări

- PID Control With Gain Scheduling and PID TuningDocument42 paginiPID Control With Gain Scheduling and PID TuningIgor RokvicÎncă nu există evaluări

- S7 WCF Blocks Supplements eDocument28 paginiS7 WCF Blocks Supplements emrbundlezÎncă nu există evaluări

- PCS 7 Cascad ControlDocument27 paginiPCS 7 Cascad ControlIgor RokvicÎncă nu există evaluări

- 05 06 - 103 6Document4 pagini05 06 - 103 6Mateo QuispeÎncă nu există evaluări

- Refractory Degradation in Glass Tank Melters. A Survey of Testing MethodsDocument5 paginiRefractory Degradation in Glass Tank Melters. A Survey of Testing MethodsRizqi Ahmad FauzanÎncă nu există evaluări

- Anterior Segment OctDocument53 paginiAnterior Segment OctA.c. RaghuÎncă nu există evaluări

- HQD Series Meters and IntelliCAL Probes Data Sheet (Lit 2599)Document8 paginiHQD Series Meters and IntelliCAL Probes Data Sheet (Lit 2599)prannoyÎncă nu există evaluări

- Important Link For Class XII - 1Document3 paginiImportant Link For Class XII - 1Utsaw SagarÎncă nu există evaluări

- Fracture Mechanics Study Compact Tension SpecimenDocument7 paginiFracture Mechanics Study Compact Tension SpecimencsmanienÎncă nu există evaluări

- Role of Energy Loss On Discharge Characteristics of Sluice GatesDocument25 paginiRole of Energy Loss On Discharge Characteristics of Sluice GatesBabak mahmoudiÎncă nu există evaluări

- Masterbatches protect plastics from UV damageDocument1 paginăMasterbatches protect plastics from UV damageSidharth JainÎncă nu există evaluări

- The Effect of Vehicle Noise On Automatic Speech Recognition SystemsDocument4 paginiThe Effect of Vehicle Noise On Automatic Speech Recognition SystemsadityaÎncă nu există evaluări

- Chapter 3a - Angular MeasurementDocument25 paginiChapter 3a - Angular Measurementsmithson JoeÎncă nu există evaluări

- Dynamic IEEE Test Systems for Transient AnalysisDocument10 paginiDynamic IEEE Test Systems for Transient AnalysisSlobdanÎncă nu există evaluări

- Handbook of Magnetic PDFDocument572 paginiHandbook of Magnetic PDFQassem MohaidatÎncă nu există evaluări

- Soundness TestDocument4 paginiSoundness TestC-one Goncalves100% (2)

- CDI Spark 2530 Datasheet En-PDocument2 paginiCDI Spark 2530 Datasheet En-PKristianto Mathers IIIÎncă nu există evaluări

- Performance of HT & LT Catalyst: Amit Kumar Jha MT (Chemical) # 0247/7161Document25 paginiPerformance of HT & LT Catalyst: Amit Kumar Jha MT (Chemical) # 0247/7161sb1984_hithaldiaÎncă nu există evaluări

- Alat Ukur Ketebalan Besi - Jual Ultrasonick Thickness Gauge Mitech MT 180 0812 9595 8196Document2 paginiAlat Ukur Ketebalan Besi - Jual Ultrasonick Thickness Gauge Mitech MT 180 0812 9595 8196Regi EgiÎncă nu există evaluări

- Lap Reoprt 1Document9 paginiLap Reoprt 1api-350815927Încă nu există evaluări

- CBSE Class 9 Work and Energy PDFDocument5 paginiCBSE Class 9 Work and Energy PDFRitesh PandeyÎncă nu există evaluări

- Salem Product CatalogueDocument6 paginiSalem Product Cataloguedramilt0% (1)

- Expt 4-Ionic EquilibriaDocument42 paginiExpt 4-Ionic EquilibriatwinkledreampoppiesÎncă nu există evaluări

- G-Snack Evolution Rev05Document2 paginiG-Snack Evolution Rev05whaleÎncă nu există evaluări

- Boiler Performance Guarantee R0Document3 paginiBoiler Performance Guarantee R0Prafitri KurniawanÎncă nu există evaluări

- C 0024 - TLZ THLZ - 04 08Document46 paginiC 0024 - TLZ THLZ - 04 08Oscar Alvitez DominguezÎncă nu există evaluări

- Principles of Rotary Flight HelicopterDocument2 paginiPrinciples of Rotary Flight Helicopterrex-strikerÎncă nu există evaluări

- Production Drawings & Process ModelsDocument15 paginiProduction Drawings & Process ModelsnotonectalÎncă nu există evaluări