Documente Academic

Documente Profesional

Documente Cultură

A Design and Simulation of Optical Pressure Sensor Based On Photonic Crystal in Sub-Micron Range

Încărcat de

prjpublicationsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Design and Simulation of Optical Pressure Sensor Based On Photonic Crystal in Sub-Micron Range

Încărcat de

prjpublicationsDrepturi de autor:

Formate disponibile

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

20

A DESIGN AND SIMULATION OF OPTICAL PRESSURE SENSOR

BASED ON PHOTONIC CRYSTAL IN SUB-MICRON RANGE

[1]

Rajeshwari S,

[2]

Indira Bahaddur,

[3]

Dr. Preeta Sharan,

[4]

Dr. P C Srikanth

[1]

Department of ECE, Malnad College of Engineering, Hassan, India,

[2]

Department of ECE, Assistant Professor, Malnad College of Engineering, Hassan, India

[3]

Department of ECE, Professor, The Oxford College of Engineering, VTU, Bangalore, India

[4]

Department of ECE, Professor, Malnad College of Engineering, Hassan, India

ABSTRACT

MOEMS based micro-sized pressure sensor can be developed to detect even

sub-micron range dimension change using the photonic crystal. The applied pressure on the

object will change the dimension of the waveguide carved in the photonic crystal. As a result,

this change in spacing can alter the propagation feature of electromagnetic waves that pass

through them that is changing the transmission spectrum. So, this change can directly be

mapped to pressure on the observed object. In this paper, the pressure sensor using photonic

crystal has been modeled and analyzed.

Keywords: FDTD, MOEMS, Micro-optics, Photonic crystal, Photonic sensing technology,

Pressure Sensor

I. INTRODUCTION

Integrated photonics has opened a way to develop sensor systems which can replace the

conventional electronic pressure sensors. The miniaturization, extreme efficiency and high

sensitivity has made photonic sensor most viable solution to the conventional pressure sensor

with limitations like inefficiencies in harsh environment, high cost and low sensitivity.

Opto-mechanical micro sensor technology can be explored to develop pressure sensor. MEMS

merged with Micro-optics involves sensing or manipulating optical signals on a very small size

scale using integrated mechanical, optical, and electrical systems, giving rise to a new class of

MOEMS technology.

IJECERD

PRJ

PUBLICATION

International Journal of Electronics and Communication

Engineering Research and Development

(IJECERD)

ISSN 2248 9525 (Print)

ISSN 2248 9533 (Online)

Volume 4, Number 2, April- June (2014), pp. 20-27

PRJ Publication, http://www.prjpublication.com/IJECERD.asp

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

21

Photonic sensing technology is innovative approach to identify and measure physical

variables. Photonic crystal is array of periodic change in refractive index which can engineer

the flow of light passing through it. The slightest change in the arrangement of index of

refraction and corresponding dimension alters the transmission spectrum, which provides the

photonic crystal very sensitive detection capability. Stable alignment, thermal stability, low

cost, low energy requirement, faster response and compatibility with fiber-optic cable makes

photonic sensor for pressure sensing have applications in various field from structural health

monitoring, underwater applications, bio-medical applications to aerospace engineering.

In this paper, we propose a model for photonic crystal based pressure sensor. The model

consists of a waveguide carved in two dielectric slabs surrounded by photonic crystal. The

dielectric slabs are mobile. The photonic crystal is mounted on the object under observation. As

such its pressure can be coupled to the movement of the dielectric slabs in the photonic crystal

and pressure variation can be mapped to the separation of these slabs and thus measured. As a

consequence the optical properties of the photonic crystal like the transmission spectrum

change. The altered transmission spectrum act as a signature of the pressure applied. The

spectral analysis has been done to detect the change in the pressure.

II. THEORY

The photonic crystal is defined as periodic profile of refractive index which allows the

controlled flow of the light through it. The artificial photonic crystal structures can be

fabricated using immensely developed CMOS technology. It appears in one-dimension,

two-dimension and three dimensions. It exists in two configurations: rods in air configuration

and holes in slab configuration. The photonic crystal appears in different lattice structures

example square lattice and hexagonal lattice. In this paper, two works are carried out. One is

using two-dimensional square lattice photonic crystal with rods in air figuration and another is

using two-dimensional hexagonal lattice photonic crystal with holes in slab configuration.

The defect engineering is an important aspect of the photonic crystal which is

responsible for the controlled propagation of light through it. Defect engineering is the

controlled change in the index profile of the photonic crystal to modify course of the

electromagnetic waves passing through it. The line defect and point defect are the two types of

defect popularly used and are very useful for creating band gap structures for different

applications.

The photonic band gap property can be explored for the sensing applications. The band

gap is referred to as an optical insulator. The bandgap property is precisely dependent on the

refractive index arrangement of the photonic crystal. The smallest change in the refractive

index profile example change in radius of holes or change in the dimension of the waveguide,

there is a precise change in the band gap property. Thus the band gap structures are efficient and

highly sensitive sensor devices.

FDTD (Finite Difference Time Domain) Method: FDTD method provides a solution to

Maxwell's equation. In FDTD method a finite rectangular grid is divided into space and time.

These equations are solved using MEEP simulation tools. MEEP implements FDTD method to

compute transmission spectrum.

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

22

The model of photonic crystal consist waveguide carved with the help of two dielectric

slabs, with the upper plate mobile. As the pressure is applied on the photonic crystal, the

dielectric slab moves and change the dimension of the waveguide. As a result the index profile

of the photonic crystal is altered and thus changing the spectral property. This change in optical

property is directly proportional to the applied pressure.

III. DESIGNS

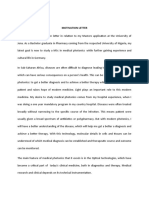

1. Pressure sensor using rods in air configuration photonic crystal:

The first design of Pressure sensor is a two dimensional, square lattice photonic crystal

with a line defect in rods in air configuration. The model consists of waveguide carved with the

help of two dielectric slabs. The upper dielectric slab is mobile with respect to the pressure

applied.

Following points explain the design parameters of the modeled pressure sensor:

a) Rods in air configuration.

b) Radius of rods 0.17m.

c) Square Lattice.

d) Lattice constant 'a'=1m.

e) Dielectric constant of dielectric slab is 11.56.

f) The length of each plate is 10m and width is 1m.

g) Dielectric constant of the waveguide is 1 (Air).

h) Height of slab is infinity

i) Light source: Unit Gaussian Pulse with center frequency at 0.4, width of the pulse is

0.3.

j) Minimum distance between dielectric slabs is zero m and the maximum distance

between dielectric slabs is 2m

The structure of the design-1 model is illustrated in the Figure 1 with maximum

separation and figure 2 with minimum separation between dielectric slabs.

Figure 1: Model of the pressure sensor (rods in air configuration)

Pressure applied

Light

Source

Spectrum

Analyzer

Mobile

dielectric

slab

Waveguide

Photonic

Crystal

Separation

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

23

Figure 2: Model of the pressure sensor with minimum separation

(rods in air configuration)

2. Pressure sensor using holes in slab configuration photonic crystal

The second design of Pressure sensor is a two dimensional, hexagonal lattice photonic

crystal with a line defect in holes in slab configuration. The model consists of waveguide

carved with the help of two dielectric slabs. The upper dielectric slab is mobile with respect to

the pressure applied.

Following points explain the design parameters of the modeled pressure sensor:

a) Holes in slab configuration.

b) Holes in slab 0.40m.

c) Hexagonal Lattice.

d) Lattice constant 'a'=1m.

e) Dielectric constant of dielectric slab is 11.56.

f) The length of each plate is 10m and width is 1m.

g) Dielectric constant of the waveguide is 1 (Air).

h) Height of slab is infinity

i) Light source: Unit Gaussian Pulse with center frequency at 0.4, width of the pulse is 0.3.

j) Minimum distance between dielectric slabs is zero m and the maximum distance

between dielectric slabs is 0.5m

The structure of the design-2 model is illustrated in the Figure 3 with maximum

separation and figure 4 with minimum separation between dielectric slabs.

Figure 3: Model of the pressure sensor (holes in slab configuration)

Photonic

Crystal

Pressure applied

Mobile

dielectric

slab

Spectrum

Analyzer

Light

Source

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

24

Figure 4: Model of the pressure sensor with minimum separation

(holes in slab configuration)

The modeling and simulation has been done with the help of MEEP simulation tool.

MEEP tool works in time domain and provides implementation of Finite Difference Time

Domain Method. MEEP is MIT Electromagnetic Equation Propagation. MEEP is

'dimensionless' tool where

0, 0

, c are unity. The output of MEEP is the transmitted power; the

transmission spectrum is obtained using output from MEEP.

Operation: The Gaussian light pulse is passed through one end of the photonic crystal while the

spectrum analyzer is placed in the other end. The applied pressure moves the mobile plate

reducing or increasing the distance between two dielectric slabs. The movement of the plate is

considered in 20 steps, each step of 0.1m for design1 and for design2 we have considered in 5

steps, each step of 0.1m. The changed dimension of the waveguide alters the light propagation

and thus changing the transmission spectrum. The transmission spectrum is observed at each

step of 0.1m increase or decrease in distance between the two dielectric slabs.

IV. RESULTS

The transmission spectrum is plotted as shown in figure 5 given below.

Figure 5: The transmission spectrum for zero separation between the dielectric slabs in

design-1

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

25

Figure 6: The transmission spectrum for 0.1, 0.2, 0.3, 0.4, 0.5 dimension(m) of the

waveguide in design-1

Figure 6: The transmission spectrum for 0.6, 0.7, 0.8, 0.9, 1 dimension (m) of the

waveguide in design-1

Figure 7: The transmission spectrum for 1.1, 1.2, 1.3, 1.4, 1.5 dimension (m) of the

waveguide in design-1

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

26

Figure 8: The transmission spectrum for 1.6, 1.7, 1.8, 1.9, 2 dimension (m) of the waveguide

in design-1

.

Figure 9: The transmission spectrum for 0.5, 0.4, 0.3, 0.2, 0.1, and 0 dimension (m) of the

waveguide in design-2

V. CONCLUSION

In this paper, we are successful in modeling and analyzing pressure sensor using photonic

crystal in sub-micron range. The varying spectrum of the waveguide can suitably and

efficiently represent and measure pressure applied on the object. Further, it can be designed and

fabricated to measure expansion or compression or both.

REFERENCES

[1] An article 'Recent advancement in sensor technology for underwater environment' by

Mohd Rizwal Arsad, Indian Journal Of Marine Sciences, Vol. 38(3), September 2009,

pp. 267-273

[2] 'Optical Fiber Sensor for Chemical Detection', US patent number 4834496, May

30,1989

[3] 'Sensor Device', by Mitsuro Sugita, US patent number US7391945, 2008

International Journal of Electronics and Communication Engineering Research and Development

(IJECERD), ISSN 2248-9525(Print), ISSN- 2248-9533 (Online) Volume 4, Number 2, April-June (2014)

27

[4] 'Two-Dimensional Photonic Crystal', by Susumu Noda et al. US patent number

US7853111B2, 2010.

[5] http://abinitio.mit.edu/wiki/index.php

/Meep_Introduction/Transmission.2Freflection_spectra

[6] 'Photonic Crystals: Modeling The Flow Of Light', by John D. Joannopoulos, Steven G.

Johnson, Robert D. Meade.

[7] 'A Novel Method for Switching and Tuning of PBG Structures', Jack Wu, S. N. Qiu, C.

X. Qiu,2 and I. Shih, Department of Electrical and Computer Engineering McGill

University, 2004.

[8] 'Photonic Crystals: Modeling The Flow Of Light', by John D. Joannopoulos ,Steven G.

Johnson, Robert D. Meade.

[9] http://en.wikipedia.org/wiki/Photonic_ crystal # Fabrication_challenges

[10] http://ab-initio.mit.edu/MEEP/Tutorial.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Answers Sample Exam Questions Set 2Document11 paginiAnswers Sample Exam Questions Set 2dwiaryantaÎncă nu există evaluări

- Mems Based Optical Sensor For Salinity MeasurementDocument4 paginiMems Based Optical Sensor For Salinity MeasurementprjpublicationsÎncă nu există evaluări

- An Approach To Design A Rectangular Microstrip Patch Antenna in S Band by TLM ModelDocument7 paginiAn Approach To Design A Rectangular Microstrip Patch Antenna in S Band by TLM ModelprjpublicationsÎncă nu există evaluări

- Precision Face Image Retrieval by Extracting The Face Features and Comparing The Features With Database ImagesDocument7 paginiPrecision Face Image Retrieval by Extracting The Face Features and Comparing The Features With Database ImagesprjpublicationsÎncă nu există evaluări

- A Novel Modified Distributed Arithmetic Scheme For Lms Low Power and Reduced Area Fir Adaptive Filter ImplementationDocument11 paginiA Novel Modified Distributed Arithmetic Scheme For Lms Low Power and Reduced Area Fir Adaptive Filter ImplementationprjpublicationsÎncă nu există evaluări

- Implementation and Analysis of Multiple Criteria Decision Routing Algorithm For Wireless Sensor NetworkDocument8 paginiImplementation and Analysis of Multiple Criteria Decision Routing Algorithm For Wireless Sensor NetworkprjpublicationsÎncă nu există evaluări

- Pattern Recognition Using Video Surveillance For Wildlife ApplicationsDocument8 paginiPattern Recognition Using Video Surveillance For Wildlife Applicationsprjpublications100% (1)

- Preparation Gade and Idol Model For Preventing Multiple Spoofing Attackers in Wireless NetworksDocument9 paginiPreparation Gade and Idol Model For Preventing Multiple Spoofing Attackers in Wireless NetworksprjpublicationsÎncă nu există evaluări

- Encryption Based Multi User Manner Secured Data Sharing and Storing in CloudDocument9 paginiEncryption Based Multi User Manner Secured Data Sharing and Storing in CloudprjpublicationsÎncă nu există evaluări

- Anempirical Study On The Performance of Self-Financing Engineering Colleges (Autonomous and Non-Autonomous) - Ateacher's PerspectiveDocument17 paginiAnempirical Study On The Performance of Self-Financing Engineering Colleges (Autonomous and Non-Autonomous) - Ateacher's PerspectiveprjpublicationsÎncă nu există evaluări

- Extended Information Technology Enabled Service Quality Model For Life Insurance Services and Its Managerial ImplicationsDocument17 paginiExtended Information Technology Enabled Service Quality Model For Life Insurance Services and Its Managerial ImplicationsprjpublicationsÎncă nu există evaluări

- A Secure Payment Scheme in Multihop Wireless Network by Trusted Node Identification MethodDocument7 paginiA Secure Payment Scheme in Multihop Wireless Network by Trusted Node Identification MethodprjpublicationsÎncă nu există evaluări

- Review of Three Categories of Fingerprint RecognitionDocument5 paginiReview of Three Categories of Fingerprint RecognitionprjpublicationsÎncă nu există evaluări

- Impact of Stress Management by Development of Emotional Intelligence in CMTS, BSNL, Tamilnadu Circle - A StudyDocument15 paginiImpact of Stress Management by Development of Emotional Intelligence in CMTS, BSNL, Tamilnadu Circle - A StudyprjpublicationsÎncă nu există evaluări

- Influences of Child Endorsers On The ConsumersDocument9 paginiInfluences of Child Endorsers On The ConsumersprjpublicationsÎncă nu există evaluări

- Mathematical Modeling Approach For Flood ManagementDocument10 paginiMathematical Modeling Approach For Flood ManagementprjpublicationsÎncă nu există evaluări

- Smes Role in Reduction of The Unemployment Problem in The Area Located in Saudis Northern BoardersDocument13 paginiSmes Role in Reduction of The Unemployment Problem in The Area Located in Saudis Northern BoardersprjpublicationsÎncă nu există evaluări

- The Role of Green Intellectual Capital Management in Acquiring Green Competitive Advantage For CompaniesDocument18 paginiThe Role of Green Intellectual Capital Management in Acquiring Green Competitive Advantage For Companiesprjpublications100% (1)

- Employee Spirituality and Job Engagement A Correlational Study Across Organizational HierarchyDocument19 paginiEmployee Spirituality and Job Engagement A Correlational Study Across Organizational HierarchyprjpublicationsÎncă nu există evaluări

- Comparison of Actual Release Schedule and OptimalDocument9 paginiComparison of Actual Release Schedule and OptimalprjpublicationsÎncă nu există evaluări

- Reduction of Executive Stress by Development of Emotional Intelligence - A Study With Reference To CMTS, BSNL, TN CircleDocument18 paginiReduction of Executive Stress by Development of Emotional Intelligence - A Study With Reference To CMTS, BSNL, TN CircleprjpublicationsÎncă nu există evaluări

- Faulty Node Recovery and Replacement Algorithm For Wireless Sensor NetworkDocument9 paginiFaulty Node Recovery and Replacement Algorithm For Wireless Sensor NetworkprjpublicationsÎncă nu există evaluări

- Mathematical Modeling Approach For Flood ManagementDocument10 paginiMathematical Modeling Approach For Flood ManagementprjpublicationsÎncă nu există evaluări

- Studies On Removal of Acid Orange 7 by Advanced Oxidation Process Using Uv and Hydrogen Peroxide (H2o2)Document8 paginiStudies On Removal of Acid Orange 7 by Advanced Oxidation Process Using Uv and Hydrogen Peroxide (H2o2)prjpublicationsÎncă nu există evaluări

- Study On Gis Simulated Water Quality ModelDocument11 paginiStudy On Gis Simulated Water Quality ModelprjpublicationsÎncă nu există evaluări

- Ijcerd: Effect of Controlled Temperature (27°C-42°C) On Strength of M20 Grade of ConcreteDocument11 paginiIjcerd: Effect of Controlled Temperature (27°C-42°C) On Strength of M20 Grade of ConcreteprjpublicationsÎncă nu există evaluări

- A Study of Bacteriological Contamination ofDocument8 paginiA Study of Bacteriological Contamination ofprjpublicationsÎncă nu există evaluări

- Ijcerd: Effect of Controlled Temperature (27°C-42°C) On Strength of M20 Grade of ConcreteDocument11 paginiIjcerd: Effect of Controlled Temperature (27°C-42°C) On Strength of M20 Grade of ConcreteprjpublicationsÎncă nu există evaluări

- 1effectofglassonstrengthofconcretesubjected 130701063605 Phpapp02Document12 pagini1effectofglassonstrengthofconcretesubjected 130701063605 Phpapp02Bajrang GuptaÎncă nu există evaluări

- 1 Manufactured Sand, A Solution and An AlternativeDocument7 pagini1 Manufactured Sand, A Solution and An AlternativeprjpublicationsÎncă nu există evaluări

- Lecture 7: Laser Oscillation: You Can Download and Read Reading Materials PDFDocument14 paginiLecture 7: Laser Oscillation: You Can Download and Read Reading Materials PDFAl-Ami SarkerÎncă nu există evaluări

- Introduction To Lasers Poster 2Document8 paginiIntroduction To Lasers Poster 2aarushraj0001Încă nu există evaluări

- Nanotechnology: S. Tom PicrauxDocument18 paginiNanotechnology: S. Tom PicrauxrinilkvÎncă nu există evaluări

- lfw201901 DL PDFDocument124 paginilfw201901 DL PDFNitika GuptaÎncă nu există evaluări

- Red Tact Ion Conclusion Future ScopeDocument13 paginiRed Tact Ion Conclusion Future ScopeSubash Narayana SwamyÎncă nu există evaluări

- What Every Electrical Engineering Student Must KnowDocument74 paginiWhat Every Electrical Engineering Student Must KnowShambukari JayanthÎncă nu există evaluări

- Medical PhotonicsDocument2 paginiMedical PhotonicsZikoraÎncă nu există evaluări

- Education Guide: Bachelor Program Bachelor ProgramDocument30 paginiEducation Guide: Bachelor Program Bachelor ProgramSam HugoÎncă nu există evaluări

- Montasir Qasymeh, PH.D., IEEE SMDocument9 paginiMontasir Qasymeh, PH.D., IEEE SMSheikh Nasiruddin100% (1)

- MicrophtonicsDocument18 paginiMicrophtonicsimdassÎncă nu există evaluări

- Some Applications On The Fields of Laser, PCF and PCF-Sensor by Comsol SoftwareDocument32 paginiSome Applications On The Fields of Laser, PCF and PCF-Sensor by Comsol SoftwareNadia F Mohammad Al-RoshdeeÎncă nu există evaluări

- 博士 Umenyi Amarachukwu ValentineDocument163 pagini博士 Umenyi Amarachukwu Valentinetustttt100% (1)

- Study Plan M.Sc. Mechatronics Specialization: Photonic EngineeringDocument2 paginiStudy Plan M.Sc. Mechatronics Specialization: Photonic EngineeringkevinÎncă nu există evaluări

- Kaertner - 2010 - Fundamentals - of - PhotonicsKaertner 2010 Fundamentals of PhotonicsDocument361 paginiKaertner - 2010 - Fundamentals - of - PhotonicsKaertner 2010 Fundamentals of Photonicsstlsgrg17Încă nu există evaluări

- FOCT NPTEL Week3 Assignment Questions&SolutionsDocument12 paginiFOCT NPTEL Week3 Assignment Questions&SolutionsRoopali Agarwal100% (1)

- LED ClassDocument10 paginiLED Classshubham saurabhÎncă nu există evaluări

- 15 Dangerously Mad Projects For The Evil GeniusDocument28 pagini15 Dangerously Mad Projects For The Evil GeniusRasheed Alcaraz0% (2)

- Physical Sciences Journal NamesDocument170 paginiPhysical Sciences Journal NamesDRSHÎncă nu există evaluări

- IV. Laser Diode (LD) or Semiconductor LaserDocument27 paginiIV. Laser Diode (LD) or Semiconductor LaserSagar BhardwajÎncă nu există evaluări

- What Determines The Color of An LED?: SemiconductingDocument1 paginăWhat Determines The Color of An LED?: SemiconductingSriramÎncă nu există evaluări

- A Review of Optical Neural NetworksDocument11 paginiA Review of Optical Neural NetworksBill PetrieÎncă nu există evaluări

- 02 em Fields TalkDocument21 pagini02 em Fields Talksuraj mani dasÎncă nu există evaluări

- Nanowires - Fundamental ResearchDocument564 paginiNanowires - Fundamental ResearchJosé Ramírez100% (1)

- About Engineering PhysicsDocument1 paginăAbout Engineering PhysicsPakhi ShrivastavaÎncă nu există evaluări

- All-Optical Diode Action in Asymmetric Nonlinear Photonic Multilayers With Perfect Transmission ResonancesDocument7 paginiAll-Optical Diode Action in Asymmetric Nonlinear Photonic Multilayers With Perfect Transmission ResonancesyassinebouazziÎncă nu există evaluări

- 2005 Hill Laser Diode PresentationDocument17 pagini2005 Hill Laser Diode PresentationSwapnil BhattacharyaÎncă nu există evaluări

- Photonics in LithuaniaDocument2 paginiPhotonics in LithuaniaDelphiÎncă nu există evaluări

- Photonic Integrated Circuits (PICs)Document12 paginiPhotonic Integrated Circuits (PICs)Nitin K. LoharÎncă nu există evaluări

- L Corner Introduction To Laser PhysicsDocument27 paginiL Corner Introduction To Laser PhysicsD4RK L1GHTÎncă nu există evaluări