Documente Academic

Documente Profesional

Documente Cultură

Rudder Calculation PDF

Încărcat de

eltioferdi0 evaluări0% au considerat acest document util (0 voturi)

488 vizualizări8 paginiRUDDER AREA a = TL / 100 [1+25 (B / L) 2] b - Ships Draught (m) a 8.02 m2 c Average of Above two areas are taken as a RUDDER AREA. Rudder deflection angle amax = 25 deg [?]max = 33 - 35 for sea-going with conventional rudder.

Descriere originală:

Titlu original

Rudder calculation.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentRUDDER AREA a = TL / 100 [1+25 (B / L) 2] b - Ships Draught (m) a 8.02 m2 c Average of Above two areas are taken as a RUDDER AREA. Rudder deflection angle amax = 25 deg [?]max = 33 - 35 for sea-going with conventional rudder.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

488 vizualizări8 paginiRudder Calculation PDF

Încărcat de

eltioferdiRUDDER AREA a = TL / 100 [1+25 (B / L) 2] b - Ships Draught (m) a 8.02 m2 c Average of Above two areas are taken as a RUDDER AREA. Rudder deflection angle amax = 25 deg [?]max = 33 - 35 for sea-going with conventional rudder.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

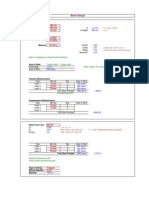

LOA (m) LBP (m) B(m) D(m) T(m) V (Knots)

69.63 61 15.4 6.04 5.07 13

No of Screw 1 Type Spade Rudder

Step 1 RUDDER AREA

a

Ar 5.26 m2

b

A = TL/100 [1+25 (B/L)

2

] For normal seagoing ships

Where

A - Rudder area (m

2

)

T - Ships Draught (m)

A 8.02 m2 LBP - Ships Length (m)

c Average of Above two areas are taken as a Rudder Area

Ar 7 m2

Step 2 RUDDER GEOMETRY

Area = b * c T = 1.4b+X X = 0.05D-.0055D

X 0.26878

b 3.43 m b - Span

C - Chord

c 1.94 m

Aspect Ratio = Span / Chord AR 1.77

Step 3 RUDDER MAXIMUM ANGLE

a max = (5/7)*max Where,

max - Angle of Attack

max - Rudder deflection Angle

max 25 deg max = 33 - 35 for sea-going with conventional rudder

b Rudder Deflection Rate

min = (24 * V)/L

min 5.11 deg/sec

RUDDER CALCULATION

For normal supply vessels the range of rudder area is 3-4 % of (L*T)

Taking the rudder area to be 3.5 % of (L*T)

Using DNV Rule

Step 4 RUDDER PROFILE

Taper Ratio is taken as 0.5 Taper Ratio = Ct/Cr

C = (Ct + Cr)/2 Cr 2.58 m

Ct 1.29 m

Sweep back angle is taken to be 7 deg (Apporx)

Step 5 LOCATION OF RUDDER TURNING AXIS

a For Tip 0.122173

BC = b/2 tan 7 BC 0.2105413 m

BD = ct/4 BD 0.3226511 m

AC = EF = C/4 AC = EF 0.4839767 m

AD = AB+BD AD 0.5960865 m

b For Root

IJ = b/2 tan7 IJ 0.2105413 m

JL = Cr/4 JL 0.6453023 m

HI = EF = C/4 HI = EF 0.4839767 m

HL = HI+IJ+JL HL 1.3398203 m

KL = HL-HK KL 0.7437338 m

c Let's take 25% of Area to be at forward part of the rudder Stock

Ar/4 1.6597705 m2

Step 6 RUDDER CONSTRUCTION

a Rudder Stock ds = 83.3 Kr (F

R

(V+3)

2

(A

R

2

X

PF

2

+N

2

)

1/2

)

1/3

Where,

Kr - Rudder coefficient 0.248

F

R

- Rudder profile coefficient

1

ds

158.885 mm Xpf = (0.12 * Ar)/6 0.133

Step 7 RUDDER BEARING

a Depth Z

B

= 1.25 ds Zb 198.61 mm

T= 0.2ds T 31.78 mm

b Clearance = 0.001*ds + 1 but not less than 1.5 mm

Clearance 1.2 mm

Step 8 RUDDER SCANTLING

a Plate Thickness

t= K(0.001Yw+0.61)[4-Yw /Xw](1.45+0.1(ds)

1/2

)

Where,

K 1

Yw = Vertical spacing between the horizontal web in mm.

Xw = horizontal spacing of the vertical web in mm

ds = the basic stock diameter, mm

Yw 600 mm Xw 900 mm

t 10.93 mm

step 8 Rudder Construction

1 Rudder Stock

s

where

Kr=Rudder coefficient = 0.248

F

R

= Rudder profile coefficient =1.0

V= Service speed =16 Kn

A

R

= Rudder area =10.5 m

2

X

PF

= 0.12 A

R

/ Y

R

Y

R

=Depth of rudder at the center line of stock

step2

Rudder Bearing

Depth Z

B

= 1.2 ds Zb= mm

Minimum thickness of the wall for the lower bearing is to be taken as the lesser of

0.2 or 100mm

T= 0.2ds T= mm

minimum7.0N/mm^2given bearing pressure on the projected area of the lowest

main bearing for metal

Basic stock diameter ds

ds = 83.3 Kr (F

R

(V+3)

2

(A

R

2

X

PF

2

+N

2

)

1/2

)

1/3

LOA (m) LBP (m) B(m) D(m) T(m) V (Knots)

322.26 305.4 50.9 25.45 18.97 13

No of Screw 2 Type Spade Rudder

Step 1 RUDDER AREA

a

Ar 98.49 m2

b

A = TL/100 [1+25 (B/L)

2

] For normal seagoing ships

Where

A - Rudder area (m

2

)

T - Ships Draught (m)

A 98.17 m2 LBP - Ships Length (m)

c Average of Above two areas are taken as a Rudder Area

Ar 98 m2

Step 2 RUDDER GEOMETRY

Area = b * c T = 1.4b+X X = 0.05D-.0055D

X 1.132525

b 12.74 m b - Span

C - Chord

c 7.72 m

Aspect Ratio = Span / Chord AR 1.65

Step 3 RUDDER MAXIMUM ANGLE

a max = (5/7)*max Where,

max - Angle of Attack

max - Rudder deflection Angle

max 25 deg max = 33 - 35 for sea-going with conventional rudder

b Rudder Deflection Rate

RUDDER CALCULATION

For normal supply vessels the range of rudder area is 3-4 % of (L*T)

Taking the rudder area to be 3.5 % of (L*T)

Using DNV Rule

min = (24 * V)/L

min 1.02 deg/sec

Step 4 RUDDER PROFILE

Taper Ratio is taken as 0.5 Taper Ratio = Ct/Cr

C = (Ct + Cr)/2 Cr 10.29 m

Ct 5.14 m

Sweep back angle is taken to be 7 deg (Apporx)

Step 5 LOCATION OF RUDDER TURNING AXIS

a For Tip 0.122173

BC = b/2 tan 7 BC 0.7822023 m

BD = ct/4 BD 1.2862295 m

AC = EF = C/4 AC = EF 1.9293443 m

AD = AB+BD AD 2.4333715 m

b For Root

IJ = b/2 tan7 IJ 0.7822023 m

JL = Cr/4 JL 2.5724591 m

HI = EF = C/4 HI = EF 1.9293443 m

HL = HI+IJ+JL HL 5.2840057 m

KL = HL-HK KL 2.8506342 m

c Let's take 25% of Area to be at forward part of the rudder Stock

Ar/4 24.581879 m2

Step 6 RUDDER CONSTRUCTION

a Rudder Stock ds = 83.3 Kr (F

R

(V+3)

2

(A

R

2

X

PF

2

+N

2

)

1/2

)

1/3

Where,

Kr - Rudder coefficient 0.248

F

R

- Rudder profile coefficient

1

ds

1414.525 mm Xpf = (0.12 * Ar)/6 0.360

Step 7 RUDDER BEARING

a Depth Z

B

= 1.25 ds Zb 1768.16 mm

T= 0.2ds T 282.90 mm

b Clearance = 0.001*ds + 1 but not less than 1.5 mm

Clearance 2.4 mm

Step 8 RUDDER SCANTLING

a Plate Thickness

t= K(0.001Yw+0.61)[4-Yw /Xw](1.45+0.1(ds)

1/2

)

Where,

K 1

Yw = Vertical spacing between the horizontal web in mm.

Xw = horizontal spacing of the vertical web in mm

ds = the basic stock diameter, mm

Yw 600 mm Xw 900 mm

t 21.02 mm

S-ar putea să vă placă și

- Rudder CalculationDocument8 paginiRudder CalculationGerard SargÎncă nu există evaluări

- Rudder CalculationDocument8 paginiRudder CalculationSantosh Kumar100% (3)

- Rudder DesignDocument11 paginiRudder Designnawan67% (3)

- Design of Ship RuddersDocument82 paginiDesign of Ship RuddersGerard Sarg100% (1)

- Lightweight Survey and Inclining ExperimentDocument24 paginiLightweight Survey and Inclining ExperimentFrankieÎncă nu există evaluări

- Free BoardDocument4 paginiFree BoardIan StefanusÎncă nu există evaluări

- Section Modulus CalculationDocument3 paginiSection Modulus Calculationtejaswi_rao_1Încă nu există evaluări

- Longitudinal Strength Calculation Report - R2 PDFDocument50 paginiLongitudinal Strength Calculation Report - R2 PDFAwwalin Bocah Ilang100% (1)

- Scantling 2Document33 paginiScantling 2Dominic VillamanteÎncă nu există evaluări

- Rudder and Steering CalculationDocument5 paginiRudder and Steering CalculationFrozen Naive100% (1)

- Scantling of ShipDocument84 paginiScantling of ShipVignesh Muthusamy0% (1)

- Coefficients of Form - Ship's Waterplane, Block, Midship and Prismatic CoefficientDocument5 paginiCoefficients of Form - Ship's Waterplane, Block, Midship and Prismatic CoefficientGiorgi KandelakiÎncă nu există evaluări

- Scantling Calculation PDFDocument6 paginiScantling Calculation PDFShyamshesha GiriÎncă nu există evaluări

- Bollards LectureDocument17 paginiBollards Lectureviahul100% (1)

- Scantling Calc 2007Document12 paginiScantling Calc 2007nourtia_nil0% (1)

- Na 3007 - Launching CalculationDocument5 paginiNa 3007 - Launching CalculationYe Win ThantÎncă nu există evaluări

- Initial Estimate of Ship Particulars FOR AFRAMAX CRUDE OIL TANKERDocument46 paginiInitial Estimate of Ship Particulars FOR AFRAMAX CRUDE OIL TANKERpramodkb_cusat100% (1)

- 08 Freeboard Calculation - SC4259 101 04Document5 pagini08 Freeboard Calculation - SC4259 101 04parthiv_mechmind1987Încă nu există evaluări

- Scantling CalculationsDocument70 paginiScantling Calculationsjrladdu100% (4)

- Ferry Open Freeboard CalculationDocument3 paginiFerry Open Freeboard CalculationgsoldatosÎncă nu există evaluări

- Inclining Experiment Report of Manzari - 1Document12 paginiInclining Experiment Report of Manzari - 1Hari RamÎncă nu există evaluări

- MV LaviniaDocument227 paginiMV LaviniaDominic VillamanteÎncă nu există evaluări

- Scantling Calculation PDFDocument22 paginiScantling Calculation PDFBarnil Samiu0% (1)

- Scantling 161001223025Document8 paginiScantling 161001223025Hoang Tien Dung100% (1)

- Naval Architecture Equation Summary SheetDocument11 paginiNaval Architecture Equation Summary SheetAnonymous JSHUTpÎncă nu există evaluări

- Freeboard and Loadline Calculation: Vessel Name M V KALA PANI (Passenger CUM Cargo Ship) Principal ParticularsDocument3 paginiFreeboard and Loadline Calculation: Vessel Name M V KALA PANI (Passenger CUM Cargo Ship) Principal Particularsmanish5lallÎncă nu există evaluări

- Scantling Calculation 1031Document9 paginiScantling Calculation 1031ShifatMahmudRumman100% (5)

- Report Project (Scantling)Document19 paginiReport Project (Scantling)FrankieÎncă nu există evaluări

- MO Aluminium Catamarans Rule Developments Supporting Document V1.0Document37 paginiMO Aluminium Catamarans Rule Developments Supporting Document V1.0tyu100% (2)

- Ship Form Coefficient PDFDocument10 paginiShip Form Coefficient PDFSurendra Kumar SinghÎncă nu există evaluări

- Linesplan & Hidrostatic Curve - MKDocument120 paginiLinesplan & Hidrostatic Curve - MKMuhammad Teguh PerdanaÎncă nu există evaluări

- Practical Design of Rudders - PARTB-1Document40 paginiPractical Design of Rudders - PARTB-1Shikha Bordia83% (6)

- Scantling CalculationDocument19 paginiScantling CalculationBarnil Samiu100% (1)

- Why Initial Met Height at 1 RadianDocument9 paginiWhy Initial Met Height at 1 RadianRanjeet SinghÎncă nu există evaluări

- Ship Hull DesignDocument66 paginiShip Hull DesignRiyan EsapermanaÎncă nu există evaluări

- Lines Plan Overview.Document13 paginiLines Plan Overview.aizadhafiz100% (1)

- On Basis Ship DesignDocument75 paginiOn Basis Ship DesignRENGANATHAN P100% (1)

- Calculation & Assignment of FreeboardDocument26 paginiCalculation & Assignment of Freeboardapi-26251207100% (7)

- Freeboard CalculationsDocument7 paginiFreeboard CalculationsTommyVercetti100% (1)

- Freeboard CalculationDocument4 paginiFreeboard CalculationLuca Luca100% (1)

- Hydrostatic BonjeanDocument84 paginiHydrostatic BonjeanAkmal AlparidziÎncă nu există evaluări

- Probabilistic Damage Stability RegulationsDocument54 paginiProbabilistic Damage Stability RegulationsReza BabriÎncă nu există evaluări

- Calculation-of-Displacement-LWT-and-DW BUDI OKEDocument28 paginiCalculation-of-Displacement-LWT-and-DW BUDI OKEBudi PrayitnoÎncă nu există evaluări

- Freeboard CalculationDocument45 paginiFreeboard CalculationgksahaÎncă nu există evaluări

- Ship Geometry - IDocument39 paginiShip Geometry - Isunnyasrahul raj100% (1)

- Hull Section ModulusDocument1 paginăHull Section ModulusluyogyiÎncă nu există evaluări

- Shipstrength SWBMDocument5 paginiShipstrength SWBMgamotontheosasÎncă nu există evaluări

- Stability and FormulasDocument68 paginiStability and FormulassubhenduhatiÎncă nu există evaluări

- Hull StructureDocument94 paginiHull StructureAktarojjaman MiltonÎncă nu există evaluări

- BTF141101 Freeboard Basel S5Document16 paginiBTF141101 Freeboard Basel S5tahtoh25100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDe la EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsÎncă nu există evaluări

- Headworks DesignDocument6 paginiHeadworks Designrajeshsapkota123100% (2)

- Isolated Footing (Aci)Document4 paginiIsolated Footing (Aci)Satya kaliprasad vangaraÎncă nu există evaluări

- RCC Design SheetsDocument40 paginiRCC Design SheetsIbrahim El SharÎncă nu există evaluări

- Structural Computation AnalysisDocument16 paginiStructural Computation Analysisjeromefamadico90% (20)

- RCC Design SheetsDocument40 paginiRCC Design SheetsAnonymous 9iK0i8h0dPÎncă nu există evaluări

- RCC Design SheetsDocument40 paginiRCC Design SheetsAnonymous nwByj9L100% (2)

- Staircase DesignDocument45 paginiStaircase DesignHenRy Ngu 旭67% (3)

- Edificios SMRF ACIDocument5 paginiEdificios SMRF ACIJorge AlbertoÎncă nu există evaluări

- Diving Systems Code of Safety For Diving Systems 1995Document29 paginiDiving Systems Code of Safety For Diving Systems 1995eltioferdiÎncă nu există evaluări

- Principles of Minimum Safe ManningDocument14 paginiPrinciples of Minimum Safe ManningeltioferdiÎncă nu există evaluări

- Manual de Instalacion de Motores Marinos CatDocument226 paginiManual de Instalacion de Motores Marinos CatGiancarlo Terrazas Rojas100% (5)

- IMO Safety SignsDocument40 paginiIMO Safety SignseltioferdiÎncă nu există evaluări

- Design, Construction and Equipment of Small Fishing Vessels of Less Than 15 Metres in Length Overall - Code of PracticeDocument75 paginiDesign, Construction and Equipment of Small Fishing Vessels of Less Than 15 Metres in Length Overall - Code of PracticeeltioferdiÎncă nu există evaluări

- TP15180EDocument40 paginiTP15180EDeanna BarrettÎncă nu există evaluări

- Guidelines For The Construction, Inspection, Certification, and Operation of Tugs Less Than 24 M in LengthDocument39 paginiGuidelines For The Construction, Inspection, Certification, and Operation of Tugs Less Than 24 M in LengtheltioferdiÎncă nu există evaluări

- Ships Windows and Side ScuttlesDocument4 paginiShips Windows and Side ScuttleseltioferdiÎncă nu există evaluări

- EN15085 European Quality RequirementsDocument4 paginiEN15085 European Quality Requirementseltioferdi100% (1)

- Liferafts VikingDocument16 paginiLiferafts Vikingeltioferdi100% (1)

- Confort Class and Passenger ShipsDocument4 paginiConfort Class and Passenger ShipseltioferdiÎncă nu există evaluări

- Helicopter Deck On Offshore InstalationsDocument16 paginiHelicopter Deck On Offshore InstalationseltioferdiÎncă nu există evaluări

- Manufacturing Program Programme de Fabrication: Programa de FabricaciónDocument11 paginiManufacturing Program Programme de Fabrication: Programa de Fabricacióneltioferdi100% (1)

- UK Search & Rescue Helicopter ServiceDocument381 paginiUK Search & Rescue Helicopter Serviceeltioferdi100% (1)

- Catalogo Marsili 2008 UKDocument34 paginiCatalogo Marsili 2008 UKeltioferdiÎncă nu există evaluări

- Electric Power Load Analysis (Epla) For Surface ShipsDocument46 paginiElectric Power Load Analysis (Epla) For Surface ShipseltioferdiÎncă nu există evaluări

- Large SubDocument18 paginiLarge Subrubbish007Încă nu există evaluări

- Vessel Registration GuideDocument30 paginiVessel Registration GuideeltioferdiÎncă nu există evaluări

- K5L2050 FinalDocument80 paginiK5L2050 Finaljasonelectronicsphil100% (2)

- TL 3.17 List of Approved Prototype Mods PDFDocument143 paginiTL 3.17 List of Approved Prototype Mods PDFomid omidiÎncă nu există evaluări

- Auto PilotDocument3 paginiAuto PilotsbdmanÎncă nu există evaluări

- CP 1 - PPT 2 - Manoeuvring CharacteristicsDocument28 paginiCP 1 - PPT 2 - Manoeuvring CharacteristicsAjay KumarÎncă nu există evaluări

- Maintenance Task List of AircraftDocument42 paginiMaintenance Task List of AircraftIshir SharmaÎncă nu există evaluări

- Arma3 Keyboard LayoutDocument2 paginiArma3 Keyboard LayoutMond NichromeÎncă nu există evaluări

- TCDocument34 paginiTCmaria jose carrion ramosÎncă nu există evaluări

- Making Vintage Aircraft in Wood (gnv64) PDFDocument68 paginiMaking Vintage Aircraft in Wood (gnv64) PDFLuis B Salgado Benítez100% (1)

- THC 1 Macro Perspective of Tourism and Hospitality 1 85 1 1Document85 paginiTHC 1 Macro Perspective of Tourism and Hospitality 1 85 1 1Family Sonza100% (1)

- AM902.0 KODIAK 100 Airplane Maintenance Manual - R-26 PDFDocument1.814 paginiAM902.0 KODIAK 100 Airplane Maintenance Manual - R-26 PDFOscar Bastidas83% (6)

- C208 Full Technical ExamDocument10 paginiC208 Full Technical ExamNaguibÎncă nu există evaluări

- P51 SpecificationsDocument32 paginiP51 SpecificationsPelayo Menendez RodriguezÎncă nu există evaluări

- 6.3-Aircraft Landing Gear System PDFDocument57 pagini6.3-Aircraft Landing Gear System PDFJack meÎncă nu există evaluări

- K Pos Autopilot - OM 7.1 PDFDocument34 paginiK Pos Autopilot - OM 7.1 PDFRafael AlvaresÎncă nu există evaluări

- Rudders: Semi Balanced RudderDocument10 paginiRudders: Semi Balanced RudderAurvin SinghÎncă nu există evaluări

- Inter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena City Course Module (Paper-Based) Student'SDocument8 paginiInter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena City Course Module (Paper-Based) Student'Schristian valdoriaÎncă nu există evaluări

- Manual Ingles Tecnico AeronauticoDocument17 paginiManual Ingles Tecnico AeronauticoBIGTONINOÎncă nu există evaluări

- MA3017 - 5 Dry Docking Preparation PDFDocument129 paginiMA3017 - 5 Dry Docking Preparation PDFARIF100% (1)

- 2019-Customer-Version-CT Super Series - 472.5kg-Specification-Prices - 02Document11 pagini2019-Customer-Version-CT Super Series - 472.5kg-Specification-Prices - 02Brooks OrtizÎncă nu există evaluări

- Data RefsDocument144 paginiData Refsigor pratesÎncă nu există evaluări

- Aerodynamic Analysis of Sailing ShipDocument12 paginiAerodynamic Analysis of Sailing ShipGohar KhokharÎncă nu există evaluări

- Trading Ships of The South China Sea - ShipbuildingDocument29 paginiTrading Ships of The South China Sea - ShipbuildingmrohaizatÎncă nu există evaluări

- 1.3.a-Science and Technology in The Middle AgesDocument17 pagini1.3.a-Science and Technology in The Middle Agestwinkledreampoppies100% (1)

- Cessna 206 Familiarisation CourseDocument4 paginiCessna 206 Familiarisation CourseAmmar A. AlliÎncă nu există evaluări

- Easa TCDSDocument53 paginiEasa TCDSAnonymous ucJM9AGdaÎncă nu există evaluări

- Salinan Dari KA B200 - B200GT - 250 PL21 Pilot Training ManualDocument453 paginiSalinan Dari KA B200 - B200GT - 250 PL21 Pilot Training ManualAhmad Ubaidillah100% (4)

- Docking ManeuveringDocument24 paginiDocking ManeuveringAlex OlteanuÎncă nu există evaluări

- Part 3. ST60 Instruments - TransducersDocument20 paginiPart 3. ST60 Instruments - TransducerspiopuliÎncă nu există evaluări

- Choosing HullDocument16 paginiChoosing Hullnyaungzin100% (1)

- 04 TRI Type Specific DocumentationDocument136 pagini04 TRI Type Specific DocumentationmkashiotÎncă nu există evaluări