Documente Academic

Documente Profesional

Documente Cultură

21 PDF

Încărcat de

Sella RfDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

21 PDF

Încărcat de

Sella RfDrepturi de autor:

Formate disponibile

6

Flax Oil and

High Linolenic Oils

Roman Przybylski

University of Manitoba

Winnipeg, Manitoba, Canada

1. INTRODUCTION

Many species in the Europhorbiaceae and Labiatae families produce seeds with a

high content of oil and contribution of linolenic acid of up to 76% (1). Flaxseed has

been used for years in the production of paints, varnishes, inks, and linoleum. In

food applications, axseed is more often used than oil because of its better stability

and because of the presence of ber, lignans, and a-linolenic acid (ALA), which

have health benets. Cold pressed axseed oil is not considered suitable for

deep-frying, although Chinese use it in stir-frying (2). In this chapter, oilseeds of

ax, perilla, camelina, and chia are discussed as sources of oils with elevated con-

tent of ALA. These oilseeds are produced in industrial quantities and can be con-

sidered as potential sources of new oils with specic nutritional and functional

properties.

Baileys Industrial Oil and Fat Products, Sixth Edition, Six Volume Set.

Edited by Fereidoon Shahidi. Copyright # 2005 John Wiley & Sons, Inc.

281

2. FLAX

2.1 Origin

Flax, widely adapted to warm and cool climates, has been cultivated for centuries in

various parts of the world for its stem ber, linen cloth, and seed. Linseed is an

alternative name used for ax. Crops grown for seed are termed linseed in India

and in the United Kingdom and axseed in Canada and the United States, and

ax oil or ax seed is used in many European countries.

Flaxseed/linseed is the annual cultivar of Linum usitatissimum L. Flax is a mem-

ber of the Linaceae family that includes ten genera and more than 150 species (3).

Approximately 200 species of Linum are known (3).

The crops grown for both seed and ber are generally called dual-purpose ax.

Initially, the same variety was used for both oil and ber production. Today, oil and

ber varieties are different and specically designed to serve the actual end use.

Fiber varieties usually have longer stem, 80120 cm tall, with fewer branches,

fewer seed capsules, and smaller seeds. Although oil type has shorter and heavily

branched stems, 6080 cm tall, with a higher number of seed capsules and larger

seeds.

All registered ax varieties in Canada have a dark brown seed coat. There are

available yellow seed-coated varieties grown in other countries such as the Omega

variety in the United States. Transition to different color is mainly esthetic, lighter

colored axseed our is produced from these seeds, and appearance of the product

is less affected when it is applied as an ingredient.

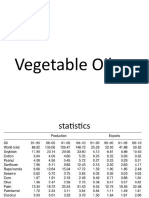

2.2 Production

More than 60 years ago, the average world production of axseed was about

3.4 million metric tons (MMT), which was more than sunower, 2.5 MMT, and

slightly lower than rapeseed, 3.8 MMT. In the same period, soybean was produced at

a level of 12.6 MMT (4). In those years, axseed was the third-most produced oil-

seed in the world by volume. Since then, world production of axseed has remained

between 2 and 3 MMT, and the production of other oilseeds has increased consid-

erably (4). In 20002001, world production of axseed was 2.34 MMT, with Canada

being the largest producer and exporter of this oilseed (See graph in Canola

chapter).

The total average yearly world production of axseed for the past ten years was

2.52 MMT (5). The principal growing areas for axseed are Canada, China, India,

Argentina, the United States, the United Kingdom, former USSR, and some

European countries (5). The average contribution of mentioned countries in the

world production of axseed is presented in Figure 1. Among mentioned producers,

Canada, China, and India contributed 34.9%, 18.7%, and 11.9%, respectively, to the

world production. The eight main axseed producers listed contributed up to 82%

of the total yearly axseed production.

282 FLAX OIL AND HIGH LINOLENIC OILS

Canada is one of the major axseed producers and exporters, where a minimal

amount of seeds is crushed to produce ax oil. Flax oil is mainly considered as a

health food product but not a commodity oil. Figure 2 shows yearly production of

axseeds in Canada for the past ten years. On average, Canada is producing above

800,000 MT (metric tons) of axseed per year (5). Part of this production is low

linolenic acid varieties, which contribute from 10% to 15% to the total production.

Recently, the food industry in North America and Europe has shown an

increased interest in utilization of axseed in food product formulations. This is

Figure 1. Major world producers of axseed (Ten-year average from 1990 to 2000). Production

averaged 2.52 million metric tons/year.

a

Former U.S.S.R. Source: Canadian Grains Council,

Statistical Handbook 2001 (5).

19911992 1993199419951996199719981999 2000 2001

M

e

t

r

i

c

T

o

n

s

(

x

1

0

0

0

)

200

300

400

500

600

700

800

900

1000

1100

1200

Figure 2. Flaxseed production in Canada. Data include low linolenic axseed. Source: Canada

Grains Council Statistical Handbook 2001 (5).

FLAX 283

mainly because of the presence of ALA, dietetic ber, and plant lignans, which

according to scientic evidence provide important health benets.

2.3. Physicochemical Properties of Flax Oil

Some physicochemical properties of conventional axseed oil and low linolenic

varieties are presented in Table 1. The higher specic gravity of 0.935 observed

for axseed oil than other vegetable oils can be directly attributed to the high con-

tribution of linolenic acid. It is in line with the specic density of fatty acids that

increases from 0.895 to 0.9038 and to 0.914 for oleic, linoleic, and linolenic acids,

respectively (7).

The amount of polyunsaturated fatty acids (PUFA) affects both melting and

ashpoints of vegetable oils. Melting temperature of oil is directly related to the

melting point of fatty acids, which decreases with unsaturation (7). The ash point

of axseed oil is relatively low compared with other vegetable oils; this can be

attributed to a high contribution of PUFA.

Unsaponiable matter content, saponication value, and iodine value are char-

acteristic for a high contribution of PUFA in the ax oil. The content of unsaponi-

able matter in ax oil is similar to other vegetable oils.

2.4. Chemical Composition of Flax Oil

Main components of vegetable oils, including ax oil, are triglycerols and usually

contribute more than 90% of all components (Table 1). Minor components in ax

oils were found to be at the similar level as in canola and soybean oils (10). The

presence of chlorophyll in ax oil usually indicates immaturity of axseed.

TABLE 1. Properties of Flaxseed Oils (69).

Linola

TM

Parameter Flaxseed Oil Crude RBD

Relative density (20

C/water at 4

C) 0.9250.935 0.921 0.920

Refractive Index (n

D

20

C) 1.4751.475 1.4657 1.4665

Melting Point (

C) 20 to 24

Flash Point, min. (

C, open cup) 120135

Viscosity (cp) 46.8 46.4

Iodine Value 182203 142 144

Unsaponiable Matter (%) 0.11.7 1.2 0.6

Saponication Value (mgKOH/g) 187195 185 185

Phosphorus (ppm) 1.030 300 1.0

Chlorophyll (ppm) 0.01.5 0.4 0.1

Free Fatty Acids (% of oleic) 0.12.0 0.3 <0.02

Triglyceride (%) 9498 9398 9698

RBDRened, bleached, and deodorized.

284 FLAX OIL AND HIGH LINOLENIC OILS

Fatty acid composition of regular ax oil is different from other commercial oils

because of the very high contribution of ALA, usually above 50% (Table 2).

Because of the high content of this unique fatty acid, axseed and ax oil are often

used as food supplements, where enrichment with omega-3 fatty acids is needed.

This fatty acid is susceptible to oxidation; it oxidizes 2040 times faster than oleic

acid and 24 times faster than linoleic acid (8). This property makes the oil a good

material for paint and plastic production where fast oxidation is required. Flax oil

contains low amounts of saturated fatty acids (SFA) compared with low linolenic

ax oil (Linola), soybean, and sunower oils; however, it is higher than canola

oil (Table 2). Canola oil contains the lowest amount of SFA among all commercial

oils.

The contribution of linolenic acid in axseed oil showed a wide range and was

affected by the growing conditions. Flax varieties grown in Western Canada, aver-

age from 495 samples analyzed, contained 5% palmitic acid (16:0), 3% stearic acid

(18:0), 17% oleic acid (18:1), 15% linoleic acid (18:2), and 59% linolenic acid

(18:3) (11). Although similar varieties were grown in North Dakota, the 11 cultivars

assessed showed the following fatty acid composition: 56% of 16:0, 36% of 18:0,

1929% of 18:1, 1418% of 18:2, and 4552% of 18:3 (12).

TABLE 2. Composition of Flaxseed and Major Oils (6, 10, Przybylski Unpublished Data).

Component Flax Linola

TM

Canola Soybean Sunower

Fatty Acids (%)

C16:0 5.3 6.1 3.8 11.2 6.0

C18:0 3.3 3.8 1.7 4.1 4.0

C18:1 17.9 15.5 58.2 24.3 16.5

C18:2 14.7 71.3 20.1 54.6 72.4

C18:3 58.7 2.0 9.6 8.3 0.5

SFA 9.0 10.0 6.2 15.6 11.2

MUFA 18.1 17.1 64.2 23.4 16.7

PUFA 72.9 72.9 29.6 61.0 72.1

Tocopherols (ppm)

Alpha 20 15 272 116 613

Gamma 200 200 423 737 19

Delta 7 5 275

Plastochromanol-8 120 110 75

Total 347 330 770 1128 632

Phytosterols (%)

Brassicasterol 1 1 14

Campesterol 27 23 28 18 7

Stigmasterol 8 4 1 15 7

b-Sitosterol 50 54 52 54 58

5

-Avenasterol 10 18 5 2 4

Total sterols (g/kg) 2.3 2.2 6.9 2.6 3.1

Abbreviations: Fatty Acids: SFAsaturated; MUFAmonounsaturated; PUFApolyunsaturated; Plasto-

chromanol-8derivative of gamma tocotrienol with longer side chain.

FLAX 285

Cool temperatures during the 1025 days after owering are the main cause for

higher amounts of linolenic acid in ax oils (14). For the same reason, axseed

grown in the Canadian prairies, northern latitude, produce oils with higher levels

of polyunsaturated fatty acids and lower contributions of oleic acid and saturated

fatty acids. This phenomenon was also observed for other oilseeds such as sun-

ower, canola, and soybean (7, 13, 14). Similarly, a wide variation in fatty acid

composition in Australian axseed samples was observed: 1325% of 18:1 and

4664% of 18:3 (6).

Analysis performed on varieties of axseeds collected from different ax grow-

ing regions of the world and later grown in Morden, Manitoba, Canada, showed

even wider distributions of oleic acid 1460%, linoleic acid 321%, and ALA

3172% (13). All of these data indicate that within ax, there is a wide distribution

of fatty acids, and this variability can be used for developing specialty oils based on

traditional breeding and to avoid GMO oils.

Flaxseed oils contain much lower amounts of tocopherols, half of the amount

present in sunower and canola oils and one-third of that present in soybean oil

(Table 2). A lower content of these antioxidants makes these oils even more suscep-

tible to oxidation. Gamma-tocopherol was found as the main tocopherol in ax oils,

with a contribution of about 80% to the total amount. This makes ax oil compar-

able with soybean oil. Among unique antioxidants detected in ax oils was plasto-

chromanol-8. This compound is a derivative of gamma tocotrienol with twice as

long unsaturated side chain. Plastochromanol-8 was found to be a more efcient

antioxidant than any tocopherols isomer (15). A low content of tocopherols in ax-

seed did not make them more susceptible to oxidation; experiments showed that

milled axseed could be stored for 28 months at ambient temperatures without

measurable changes in oxidation products. This can be attributed to the presence

of antioxidants other than tocopherols in the seeds (16).

Sterols or phytosterols are present in ax oils at a level lower than those in many

vegetable oils, 2.3 mg/g in axseed oil versus 4.1 to 6.9 mg/g in other oils (Table 2).

The composition of sterols was similar to other oils, where b-sitosterol was the

main component followed by campesterol and

5

-avenasterol. Brassicasterol was

found in trace amounts in ax oil. This phytosterol is characteristic to plants from

the Brassica family and often is used as a marker for oil adulteration (Table 2).

As discussed above, triacyglycerols are the main components of vegetable oils

and the composition of ax acylglycerols is presented in Table 3.

As expected from fatty acid composition, the main triacylglycerols contain lino-

lenic acid in their molecules and 84% of all triacylglycerols have this acid in their

structure (Table 3). Among them, 21% of total acylglycerols contained three ALA

in molecule, second by contribution were acylglycerols with two ALA, and linoleic

acid had the second-most abundant fatty acid present in the ax oil (17).

Flaxseed is the richest source of plant lignans containing 75800 times more

than that in other oilseeds, cereals, legumes, fruits, and vegetables (18). These plant

origin components act in mammalians as hormone-like phytoestrogens. Lignans are

compounds with a dibenzylbutane skeleton, which have been found in many higher

plants (1820). Plant lignans, namely, secoisolariciresinol diglycoside (SDG) and

286 FLAX OIL AND HIGH LINOLENIC OILS

matairesinol (MAT), are the main compounds among axseed lignans. Both are

structurally different from animal and human lignans, enterodiol (ED) and entero-

lactone (EL). Mammalian lignans are formed by intestinal microorganisms from

plant precursors (Figure 3). The concentration of mammalian lignan precursors is

measured by adding a particular food ingredient to the model of the intestinal

microorganism and assessing the amounts of released ED and EL (18). Similarly,

excretion of animal lignans in urine may be measured (18, 19). Figure 4 shows urin-

ary excretion of ED and EL when different plant components were included in the

diet. Flax oil is the second dominant source of mammalian lignans excreted after

axseed, in far higher amounts than other oils, oilseeds, and cereals.

Lignans from axseed have been shown to reduce mammary tumor size by more

than 50% and tumor number by 37% in carcinogen-treated rats (19, 20). Further-

more, it has been suggested that lignans have antimiotic, antiestrogenic, antiviral,

antibacterial, antifungal, and antioxidant properties (2033).

The presence of plant lignans in ax oil makes it nutritionally more valuable

than any other oil. When high levels of ALA and linoleic acid are considered in

the whole equation, axseed oil serves as the best oil in terms of its nutritional

and health value.

The Food and Drug Administration (FDA) regulations allow inclusion of ax-

seed in food products, but the amount allowed is limited to 12% (34).

TABLE 3. Composition of Triacyglycerols

in Flaxseed Oil (17).

Triacyglycerols

1

Contribution (%)

PLnLn 7.6

PLLn 6.7

PLL 1.5

POL 1.6

LnLnLn 20.9

LLnLn 13.8

LLLn 3.7

OLnLn 8.4

LLL 0.9

OLLn 5.3

OLL 0.9

SLLn 1.1

OOL 3.4

OOLn 7.3

POLn 4.0

SLnLn 3.2

POL 1.6

PLL 1.5

OOO 3.3

1

Abbreviations of fatty acid: Ppalmitic; Lnlinolenic;

Llinoleic; Ooleic; Sstearic.

FLAX 287

OR

OR

OH

OCH

3

H

3

CO

HO

OH

OH

OH

HO

OH

OCH

3

H

3

CO

HO

O

O

OH

HO

O

O

Bacterial

Fermentation

Bacterial

Fermentation

Bacterial

Fermentation

Secoisolariciresinol

Diglycoside (SDG)

Matairesinol

Enterodiol (ED) Enterolactone (EL)

Plant Lignans

Mammalian Lignans

Figure 3. Mammalian lignan formation in digestive tract and their plant precursors (19).

Figure 4. Total excretion of human lignans in the urine of rats after diet was supplemented with

various foods (18).

288 FLAX OIL AND HIGH LINOLENIC OILS

2.5. Low Linolenic Flaxseed Oil

Low linolenic acid varieties with yellow-seed coat ax trademarked Linola were

developed by the Commonwealth Scientic and Industrial Research Organization

(CSIRO) in Australia and distributed elsewhere under this name by United Grain

Growers, Canada (4). The Linola seed color has been changed to yellow to make

it distinguishable from the traditional axseed dark brown color. The generic com-

mon name Solin has been assigned by Flax Council of Canada for all low linolenic

ax varieties produced in Canada. Developmental work on Solin (Linola is a brand

name within Solin family) is continuing mainly to reduce saturated fatty acid and to

increase linoleic acid content above the 70% level and to increase the content of

antioxidants as well as to enhance nutritional properties of the meal.

The new oilseed crop is grown wherever ax and linseed varieties are currently

cultivated (35, 36). The climate in northern Europe is highly suitable for production

of Linola, where sunower and corn/maize cannot be produced. Linola seed can be

processed by existing crushing plants using similar processing parameters. Linola

meal is used for ruminant feed in the same way as linseed meal.

The fatty acid composition of the new crop has been modied, and the level of

linolenic acid has been reduced from over 50% to 2% (6). This greatly improves

oxidative stability of the oil, which by fatty acid composition is very close to sun-

ower and soybean oils (Table 2). Linola has been found to be more resistant to

oxidation than regular ax oil, and its stability is comparable with soybean, canola,

and sunower oils (Przybylski, unpublished data).

Rening of crude Linola oil by conventional steps, namely, degumming, alkali

rening, bleaching, and deodorization, produces colorless and odorless oil, which

has good oxidative stability (9). In addition, properties of crude and rened,

bleached, and deodorized (RBD) Linola oil are comparable with other commodity

oils (Table 1).

The FDA granted Generally Recognized as Safe (GRAS) status for Solin/Linola

oil in 1998 (38). This oil can be used as an ingredient in food product formulations

such as salad oil, cooking, and frying oil, and in fat phase to formulate margarine,

spreads, and shortenings (19, 37).

Because of several benecial nutritional properties, mainly related to the high

level of linoleic acid and lignans, there is a growing interest to use Linola seeds

and oil in bakery and confectionery applications. The golden-yellow-colored Linola

seeds can serve as an attractive and appealing topping for baking goods. It seems

evident that Linola/Solin seed and oil can have promising future applications in

food products (35).

2.6. Processing of Flaxseed and Oil

Flaxseed is covered with brous hull accounting for 25 to 45% of the seed weight

and contains 27% by weight of water-soluble carbohydrates. These components

called mucilage can interfere during processing (38). Flaxseed contains approxi-

mately 25% protein, 10% moisture, and 3545% of oil (6, 38, 11). In immature

FLAX 289

seeds, cyanogenic glucosides such as linamarin, linustatin, and neolinustatin can be

present at the level of 200650 mg/100 g of seeds (9). Enzyme linase is always pre-

sent in axseed, and it decomposes glucosides to many products, including

hydrocyanic acid, one of the most toxic substances. Newly developed varieties of

ax have lower amounts of glucosides in the seed. During processing, small

amounts of glucoside can be transferred into oil, whereas these compounds are

water-soluble.

Flaxseed contains a high amount of oil, but expressing oil from it is difcult and

often double pressing is required to efciently remove oil from the seeds. Proces-

sing steps for ax oil production are presented in Figure 5. Before crushing, cleaned

seeds are tempered to achieve a moisture level of 9.5% to 10%, this will minimize

the formation of ne particles when seeds are cracked or aked and will maximize

removal of oil from them. Moisturized seeds are passed through sets of corrugated

and smooth rolls to be cracked and aked, respectively. From the next processing

step, production of ax oil is differentiated from that for Solin/Linola oil (7). The

ax oil for human consumption is cold-pressed, and further purication of oil is

not applied. According to industry standards, cold pressing is achieved when the

temperature of oil coming from the extruder does not exceed 35

C and pressing

is performed under protection from oxygen, usually under a blanket of nitrogen.

Good practice requires utilization of expellers, which have the ability to cool parts

of the press, which are in contact with seeds and oil to control the temperature

during processing (38).

Figure 5. Processing of axseed to produce cold-pressed ax oil.

290 FLAX OIL AND HIGH LINOLENIC OILS

Oil from expeller is ltered, packaged under nitrogen or other neutral gas into bot-

tles protecting from light exposure, and ready for distribution. Flax oil is very suscep-

tible to oxidative deterioration, and treatment to eliminate oxygen needs to be

applied. On the North American continent, ax oil is considered as a health food oil.

When ax oil is processed for industrial use, standard processing steps are

applied as described in Figure 6. Flaxseeds are tampered and then aked, passing

through a set of smooth rolls. Flaked seeds are sent to a cooker where they are

heated to a temperature of 80100

C to inactivate enzymes and help release the

oil during pressing. At this stage, formation of toxic substances is prevented. The

cooked seeds are transferred to the expeller, and expelled oil through ltration is

placed in a storage tank, where it is combined with oil from solvent extraction.

Cake/meal after pressing is fed to the solvent extractor, where hexane is used as

Figure 6. Processing of axseed to produce rened, bleached, and deodorized ax oil.

FLAX 291

a solvent. From the extractor, cake is moved to the desolvatizer where the solvent

is removed at 100

C. Meal is then cooled and used as an animal feed ingredient.

Combined oils are puried by the standard rening process, typical to all vegetable

oils (7). Degumming is applied to remove phospholipids, rening to lower the

content of free fatty acids, bleaching to eliminate chlorophylls and other pigments

as well as to decompose hydroperoxides, and deodorizing to make the oil

odorless through elimination of oxidation products (Figure 6). Processing of

low linolenic axseed oil is similar to that described for ax oil and other com-

modity oils.

3. PERILLA OIL

3.1. Origin and Application

Perilla, Perilla frutescens, L. Britton, is a member of the mint family, Lamiaceae

(Labiatae). This plant is a common annual weed in the eastern United States (1). In

Asia, perilla is considered a commercial crop where seeds are used to produce oil

and plant parts are used as garnish, avoring, and sources of nutritional components

in combination with cereals or vegetables. In the United States, perilla food pro-

ducts are available in the Korean ethnic markets, and red-leafed plants are used

in landscaping. After the Second World War, the United States imported perilla

oil, which was used as a drying oil (1). Perilla plant and seed is used in Asia as

seeds for birds and human consumption; seed oil is used as a fuel, a drying oil,

or a cooking oil; leaves are used as a pot-herb, for medicine, food coloring, avor-

ing dishes, and source of functional nutrients; foliage is distilled to produce an

essential oil for avoring.

Wilson et al. (39) isolated the toxin, perilla ketone, which causes pulmonary

edema (uid in the lung cavity) in many animal species, although not in pigs

and dogs (40). In Japan, 2050% of long-term workers in the perilla industry devel-

oped dermatitis on their hands because of contact with perillaldehyde (41). Small

amounts of these components have been detected in perilla oil where it works as an

efcient antioxidant.

Perilla was never grown commercially as an oilseed in the United States; how-

ever, several agronomists have investigated the crop (42, 43). Rabak and Lowman

(43) determined that perilla is well adapted to the climate of the southeastern

United States; it would be unprotable to cultivate it, unless seed shattering can

be controlled. Seed yields ranged from 220 to 1400 kg/ha in Illinois (44), 1020

to 1440 kg/ha in Korea (45), and 1110 to 1670 kg/ha in Japan agricultural produc-

tion (41). Perilla was also experimentally grown as a crop in many parts of the

British Empire (46, 47). Production of perilla seeds and oil has been continued

in Korea for a long time (48, 45). Annual production of perilla seed is approxi-

mately 40,000 MT, and perilla oil is the third largest among edible oils used in

the Korean market (49). Perilla plant and seed is widely used in Asian countries

as food ingredients, including Japan, China, and India.

292 FLAX OIL AND HIGH LINOLENIC OILS

3.2. Perilla Seed and Oil

The seed of perilla contains 3151% of oil, which is similar in composition to

axseed oil, with a higher contribution of PUFA of over 70% (Table 4). The

oil is highly unsaturated, with an iodine value of 192208-g iodine /100-g oil

(Table 4). Perilla oil contains over 60% linolenic acid with equal amounts of

both linoleic and oleic acids (Table 4). Specic gravity of this oil is higher than

ax oil because of a higher contribution of PUFA. Other physical parameters of

this oil reect the composition of its fatty acids.

TABLE 4. Composition and Properties of Perilla, Camelina, and Chia Oils.

Parameter Perilla

a

Camelina

b

Chia

c

Fatty Acids (%)

C16:0 7 6 6

C18:0 2 2 3

C18:1 14 13 7

C18:2 17 16 20

C18:3 61 39 63

Saturated 8 12 9

Monounsaturated 14 34 8

Polyunsaturated 78 54 83

Tocopherols (ppm)

a-Tocopherol 31 46

g-Tocopherol 461 420

d-Tocopherol 7 10

Total 499 500

Lipid Classes (%)

Sterol Esters 2

Glycerides 91 97

Glycolipids 4 2

Phospholipids 2 0.9

Sterols (%)

Cholesterol 5

Brassicasterol 4

Campesterol 25

Stigmasterol 3

b-Sitosterol 52

5

-Avenasterol 11

Total Sterols (mg/kg) 3604

Physicochemical Properties

Refractive Index (n

D

20

C) 1.4761 1.4698 1.4753

Specic Gravity (at 15.5

C/15.5

C) 0.937 0.925 0.936

Iodine Value 192208 127155 190199

Saponication Value (mgKOH/g) 188197 180190 180192

Unsaponiable Matter (%) 1.31.5 1.21.5 1.11.3

Oil Content (%) 3550 3542 3240

Protein Content (%) 1728 2530 2030

Camelina contains 15% of eicosenoic acid (C20:1) and 35% of erucic acid (C22:1).

Source:

a

(49);

b

(50, 51);

c

(5054).

PERILLA OIL 293

The amount of tocopherols in perilla oil is higher compared with ax oil, and a

similar contribution of gamma-tocopherol, above 90%, was observed (Table 4).

Shin and Kim (49) analyzed perilla oil for lipid composition and established that

it contained more than 90% triacylglycerols, 4% glycolipids, and 2% of each phos-

pholipids and sterol esters.

Perilla oil has been used as a drying oil in paints, varnishes, linoleum, printing

ink, lacquers, and for protective waterproof coatings on cloth. It has also been used

for cooking and as fuel (56). The meal produced after oil extraction is often used as

an animal feed ingredient.

3.3. Perilla Oil Processing

Perilla oil in Korea is processed like other cold-pressed oils, where pressing and

ltration are the main processing steps. To improve the avor of perilla oil used

in food applications, roasting of seeds is practiced. This will provide oil with a

distinctive roasted, nutty avor and improved stability. Roasting of perilla seeds

is often applied in Korea and China (57). Kim et al. (57) analyzed different

parameters of roasting and established that temperature above 170

C provided

the best avor and stability for the oil. Nonenzymatic browning components are

mainly responsible for avor and antioxidant activity (52). When perilla oil is pro-

duced for the industrial applications, additional processing such as rening, bleach-

ing, and deodorization is carried out (58).

4. CAMELINA

Standard oilseed crops are not often suitable to marginal lands where factors such

as low moisture, low fertility, and saline soils play an important role in the possible

crop to be grown. In recent years, there has been increasing interest in developing

agronomic systems with low requirements for fertilizer, pesticides, and energy,

which provide better soil erosion control than conventional systems. Camelina

can grow in these extreme conditions and provide oilseed with enhanced nutritional

value (59, 60).

4.1. Origin

Camelina sativa (L.) Crantz., plant from the Brassicaceae family, known as false

ax, linseed dodder, and Gold-of-Pleasure, originated in the Mediterranean area

and Central Asia (61). Seeds are small (0.7 mm1.5 mm), pale yellow-brown,

oblong, rough, and with a ridged surface. Camelina is listed as being adapted to

the ax-growing region on the Prairies, in Europe, and other countries (59, 62).

It is primarily a minor weed in ax, which does not have seed dormancy (63).

Camelina is short-seasoned, 85100 days, so it could be incorporated into double

cropping systems during cool periods in warmer environments (55).

Cultivation of camelina probably began in Neolithic times, and by the Iron Age

in Europe, when the number of crop plants approximately doubled, this crop was

294 FLAX OIL AND HIGH LINOLENIC OILS

commonly used as an oil-supplying plant. Cultivation, as evidenced from carbo-

nized seed, has been shown to occur in regions surrounding the North Sea during

the Bronze Age (64). Camelina monoculture occurred in the Rhine River Valley as

early as 600 B.C. Camelina probably spread in mixtures with ax and as monocul-

tures, similar to small grains, which also often spread as crop mixtures. It was cul-

tivated in antiquity from Rome to Southeastern Europe and the Southwestern Asian

(64).

Camelina production declined during medieval times because of unknown fac-

tors, but it continued to coevolve as a weed with ax, and this is the possible intro-

duction of it to the Americas. Like rapeseed oil, camelina oil has been used as an

industrial oil after the industrial revolution (64). The seeds have been fed to caged

birds, and the straw has been used for ber. There has been scattered production of

camelina in Europe in modern times, mostly in Germany, Poland, and the USSR. In

the 1980s, breeding and germplasma screening were applied to modify fatty acid

composition and the content of glucosinolates in camelina seeds (6569).

Camelina has been evaluated in Canada, North Dakota, and Minnesota for its

agronomical performance (63, 70, 50). Recent interest in the species is mainly

because of the demand for alternative low-input oilseed crops with the potential

for food and nonfood utilization of the seed oil (60, 71). Unique agronomic features

such as compatibility with reduced tillage and cover crop and competitiveness with

weeds or winter surface seeding showed suitability of camelina for sustainable agri-

culture systems. Furthermore, the species has a potential as a low-cost crop for

green manuring (60).

Long-term yield of camelina cultivars in North America has been averaging

from 1100 to 1200 kg/ha with a maximum of about 2000 kg/ha. It should be noted

that the yield of many commodity oilseeds, especially B. napus, has been improved

through plant breeding, whereas camelina has not been modied yet (63).

4.2. Seed Composition

The oil content of camelina seed ranges from 29% to 45% in North American

crops, and in Germany, it is between 37% and 44%. The seed protein content varies

from 23% to 30% (60, 50, 71, 72). Camelina protein content and composition is

similar to ax, although higher sulfur content has been observed for camelina oil

(63). Camelina meal is comparable with soybean meal, containing 4547% crude

protein and 1011% ber (73). Like other cruciferous plants, camelina meal con-

tains glucosinolates at levels of 1520 mmol/g (74). This is a low content of gluco-

sinolates compared with other brassicaceous species, hence making the utilization

of meals easier (73, 75).

4.3. Fatty Acid Composition and Use of the Oil

Camelina oil has a unique fatty acid pattern and is characterized by a linolenic

acid (C18:3) content ranging from 30% to 40%, eicosenic acid (C20:1) content

CAMELINA 295

of around 15%, and less than 4% erucic acid (21). The fatty acids in camelina oil are

primarily unsaturated, with only about 12% being saturated (Table 4). About 54%

of the fatty acids are polyunsaturated, primarily linoleic (18:2) and linolenic (18:3),

and 34% are monounsaturated, primarily oleic (18:1) and eicosenoic (20:1).

The fatty acid composition of camelina oil can be inuenced by both environ-

ment and variety, although the effects detected were small. Nine varieties were

tested, and the maximum differences between oleic, linoleic and linolenic acid

levels were 3%, 2.4%, and 2.2%, respectively (76). Also, a 2% less linolenic

acid was observed in camelina grown during a dry warm year compared with the

normal year. Although these differences are statistically signicant, they are rela-

tively small in absolute terms and have no signicant effect on the properties of the

extracted oil (68, 50, 76).

With its high contribution of polyunsaturated fatty acids, mainly linoleic and

linolenic, and relatively low saturated fatty acid content, camelina oil could be con-

sidered a high-quality edible oil. Camelina oil is less unsaturated than ax oil but

more than sunower or canola oils (Tables 2 and 4). This oil seems to be unique

among vegetable oils in having a high content of 11-eicosenoic acid. Most of the

camelina lines assessed contain 24% erucic acid (Table 4), which is higher than

the maximum limits for canola-quality rapeseed oil. However, screened germplasm

of camelina showed that lines with zero erucic acid content are available and,

through plant breeding, zero erucic varieties can be obtained.

Plant sterols identied in this oil consist mainly of b-sitosterol and campesterol

(Table 4). About 4% brassicasterol was detected in the oil, which is typical for

Brassica family plants (51). The total content of sterols in oil is comparable with

other commercial oils (Tables 2 and 4). The presence of cholesterol in camelina oil

makes it unique among vegetable oils, where only a trace has been detected in some

tropical oils (51).

Composition and content of tocopherols in camelina oil was similar to perilla

oil, where more than 80% of all tocopherols were gamma isomer (Table 4). Alpha

and delta tocopherols were detected as minor antioxidants (77). The total content of

tocopherols was comparable with perilla oil, and higher than that in ax oil (Tables

4 and 2). The total content of tocopherols in camelina oil is higher than canola, ax,

soybean, and sunower.

4.4. Processing of Camelina Seed, Oil Stability, and Utilization

Cold-pressed camelina oil had an attractive yellow color, a mustard-like taste, and a

characteristic pleasant odor. This type of avor is acceptable in India and other

Asian countries, but in Europe and North America, it is difcult to nd acceptability

among consumers, mainly because of a different expectation from vegetable oils.

However, commercial camelina oil needs to be rened and deodorized to produce

an odorless and colorless product as expected by consumers (76). Crude camelina

oil, rened following typical steps as described for ax oil (Figure 6), afforded a

product similar to typical commercial oils (76).

296 FLAX OIL AND HIGH LINOLENIC OILS

To establish storage stability of camelina oil, an accelerated Schaal Oven storage

test was carried out at 65

C with crude and rened canola and linseed and camelina

oils (76). Conjugated dienes, peroxide, and p-anisidine values were determined.

The results indicated that the storage stability of camelina oil was similar to ax

oil, but it was less stable than canola oil. Crude camelina oil showed a higher

oxidative stability than the rened product (76). During storage, rened camelina

oil had a 30% higher peroxide level when compared with crude camelina oil (76).

Comparison with sh oil, which is rich in omega-3 fatty acids, proved that camelina

oil is much more resistant to oxidative deterioration than sh oil (76). At room

temperature, crude camelina oil was far more stable than could be expected

from its high linolenic acid content. This unusual oxidative stability can be attrib-

uted to the presence of natural antioxidants. However, the content of tocopherols

discussed above was in the middle range compared with other commercial

oils but slightly higher than that of ax oil (Tables 2 and 4). Oxidative stability

is not only related to the content and composition of tocopherols, but also to pre-

sence of other components, such as phenolic acids and polyphenols. The content of

antioxidants in oils is also affected by the processing, and the amounts of antiox-

idants can be lowered even by 50% when particular processing conditions are

applied (15).

The frying performance of camelina oil was compared with soybean oil and

assessed under deep frying conditions. Oil deterioration was monitored by asses-

sing changes in viscosities, free fatty acids, p-anisidine values, and the formation

of oxidized triacylglycerols (76). During the rst 5 days of frying, camelina oil

deterioration was similar to that of soybean oil. After that time of frying, camelina

oil deteriorated much faster than soybean oil, probably because its antioxidants

were depleted. In fact, after 7 days of frying, the levels of oxidized triacylglycerols

in camelina oil reached the level permitted in Europe, 25%, and in soybean the

amount of these components was at 14% (76). Similarly, viscosity of camelina

oil increased 100% by the end of the heating period, whereas in soybean oil, it

increased only by 30%. Total carbonyl level, measured by p-anisidine values,

was three times higher in camelina oil than in soybean oil. In addition, deterioration

of camelina oil during 5 days of potato frying caused formation of the strong and

objectionable paint-like avor (76).

Rened camelina oil was blended into fat phase to produce margarines and

spreads enriched in omega-3 fatty acids. The resulting spreads had physical proper-

ties similar to a product based on typical commercial oils. The stability of the new

product was satisfactory, and off-avors were not detected after 6 months of storage

(76).

Camelina oil was also included in formulation of salad dressings. Produced dres-

sings showed a similar stability to conventional products during several months of

storage at ambient temperature without off-avor formation (76).

Taking into consideration that camelina oil production will be less expensive and

the oil is more stable than sh oil, this oil can be an excellent ingredient to enrich

spreads, margarines, and other fat-containing food products, in omega-3 fatty acids,

and by this way change the ratio of omega-3 to omega-6 fatty acids.

CAMELINA 297

5. CHIA

5.1. Origin

Chia (Salvia hispanica L.) is an annual herbaceous plant from the mint family,

Labiatae, and it is native to southern Mexico, northern Guatemala, and can be

grown in South America and the Southwestern United States (52). This plant

was used by the Aztec and other tribes of Central America as an important crop

not only for food, but also for medicine and paint. Chia oil is a century-old ingre-

dient that has been rediscovered today as a potential ingredient for cosmetic and

food industries (52). Although chia has been cultivated for several centuries, pre-

sently it is cultivated only in some states in Mexico. The total area cultivated is less

than 450 hectares per year. Trials to adopt this cultivar to other regions of America

have been done with positive results (52). Chia seeds and oil are available on the

American continent in health food stores.

5.2. Oil and Seed Composition

Chia seed contains 2540% oil and 1830% protein. The chia meal is high in pro-

tein and ber similar to axseed and soybean (52, 53). Chia seed, oil, and meal can

be used as ingredients with high nutritional value for human food and animal feed.

Chia seed contains mucilage and water-soluble ber, may possibly contain lignans,

and is similar to ax (53). Trials conducted in 1995 and 1996 showed yield and

oil contents to be affected by growing conditions and harvested yields were up to

1500 kg/ha (52).

Chia oil is high in polyunsaturated fatty acids, particularly a-linolenic acid; the

content of this fatty acid is higher than ax oil (Table 4). Linoleic acid is the sec-

ond-most abundant acid in chia with a contribution of 1726%, which gives PUFA

content of 83%, the highest amount among edible oils. Additionally, chia oil has the

lowest content of saturated fatty acids (Tables 2 and 4).

The physical properties of chia oil are similar to perilla and camelina with

the same effect of PUFA discussed above. Lipid class composition in chia oil is

also typical for vegetable oils where triacylglycerols are the main components

(Table 4)(52).

REFERENCES

1. J. M. Hagemann, F. R. Earle, and I. A. Wolff, Lipids, 2, 371 (1967).

2. Q. Pan, Flax Production, Utilization and Research in China, 53, 5963 (1990).

3. T. P. Freeman, in S. C. Cunnane and L. U. Thompson, eds., Flaxseed in Human Nutrition,

AOCS Press, Champaign, Illinois, 1995, pp. 1121.

4. T. L. Krawczyk, Inform, 10, 1029 (1999).

5. Canada Grains Council, Statistical Handbook, 2001.

6. A. G. Green and D. R. Marshall, Aust. J. Agric. Res., 32, 599 (1981).

298 FLAX OIL AND HIGH LINOLENIC OILS

7. N. A. M. Eskin, B. E. McDonald, R. Przybylski, L. J. Malcolmson, R. Scarth, T. Mag,

K. Ward, and D. Adolph, in Y. H. Hui, ed., Baileys Industrial Oil and Fat Products, Wiley,

New York, 1996, p. 1.

8. E. N. Frankel, Trends Food Sci. Technol., 4, 220 (1993).

9. A. G. Green, and P. J. C. Dribnenki, Lipid Technol., 6, 29 (1994).

10. F. D. Gunstone, J. L. Harwood, and F. B. Padley, eds., The Lipid Handbook, Chapman and

Hall, London, 1994.

11. D. R. Declercq, J. K. Daun, and K. H. Tipples, in Crop Bulletin, Canadian Grain

Commission, Winnipeg, Manitoba, Canada, No. 202, 1992, p. 1.

12. N. S. Hettiarachy, G. A. Hareland, A. Ostenson, and G. Baldner-Shank, in Proceedings of

the 53rd Annual Flax Institute of the US Meeting, Fargo, North Dakota, 1990, p. 36.

13. D. G. Dorrell, Fette Seifen Anstrichm., 77, 258 (9175).

14. A. G. Green, Crop Sci., 26, 961 (1986).

15. D. Olejnik, M. Gogolewski, and M. Nogala-Kalucka, Nahrung, 41, 101104 (1997).

16. N. A. M. Eskin and R. Przybylski, in N. A. M. Eskin and D. S. Robinson, eds., Food Shelf

Life Stability, CRC Press, Boca Raton, Florida, 2001, p. 175.

17. R. B. Tarandjiiska, I. N. Mrekov, B. M. N. Damyanova, and B. S. Amidzhin, J. Sci Food

Agric., 72, 403 (1996).

18. L. U. Thompson, P. Robb, M. Serraino, and F. Cheung, Nutr. Cancer, 16, 43 (1991).

19. M. Axelson, J. Sjovall, B. E. Gustafsson, and K. D. R. Setchell, Nature, 298, 659 (1982).

20. K. D. R. Setchell, in S. C. Cunnane and L. U. Thompson, eds., Flaxseed in Human

Nutrition, AOCS Press, Champaign, Illinois, 1995, p. 82.

21. L. U. Thompson, S. E. Rickard, L. J. Orcheson, and M. M. Seidl, Carcinogenesis, 17, 1373

(1996).

22. L. U. Thompson, M. M. Seidl, S. Rickard, L. Orcheson, and H. H. S. Fong, Nutr. Cancer,

26, 159 (1996).

23. W. R. Phipps, M. C. Martini, J. W. Lampe, J. L. Slavin, and M. S. Kurzer, J. Clin.

Endocrinol., 77, 1215 (1993).

24. Y. Mousavi and H. Adlercreutz, J. Steroid. Biochem. Mol. Biol., 41, 615 (1992).

25. M. E. Martin, M. Haourigui, C. Pelissero, C. Benassayag, and E. A. Nunez, Life Sci., 58,

429 (1996).

26. T. Fotsis, M. Pepper, and H. Adlercreutz, Proc. Natl. Acad. Sci. USA, 90, 2690 (1993).

27. T. Hirano, K. Fukuoka, K. Oka, and Y. Matsumoto, Cancer Invest., 9, 145 (1991).

28. K. Prasad, Mol. Cell Biochem., 168, 17 (1997).

29. G. Block, B. Patterson, and A. Subar, Nutr. Cancer, 50, 207 (1992).

30. D. M. Parkin, C. S. Muir, S. L. Whelan, Y. Gao, J. Ferlay, and J. Powell, in Cancer

Incidence in Five Continents, Vol VI, International Agency for Research on Cancer, Lyon,

France, 1992, p. 865.

31. H. Adlercreutz, T. Fotsis, and J. Lampe, Scand. J. Clin. Lab. Invest., 53, 5 (1993).

32. H. Adlercreutz, H. R. Heikkinen, and M. Woods, Lancet, 2, 1295 (1982).

33. K. D. R. Setchell and H. Adlercreutz, in I. R. Rowland, ed., Role of the Gut Flora in

Toxicity and Cancer, Academic Press, London, 1988, pp. 315345.

34. J. E. Vanderveen, in S. C. Cunnane and L. U. Thompson, eds., Flaxseed in Human

Nutrition, AOCS Press, Champaign, Illinois, 1995, p. 363.

REFERENCES 299

35. B. F. Haumann, Inform, 1, 934 (1990).

36. E. A.Weiss, Oils & Fat Int., 9, 23 (1993).

37. Inform, 9, 628 (1998).

38. P. P. Kolodziejczyk and P. Fedec, in S. C. Cunnane and L. U. Thompson, eds., Flaxseed in

Human Nutrition, AOCS Press, Champaign, Illinois, 1995, p. 261.

39. B. J. Wilson, J. E. Garst, R. D. Linnabary, and R. B. Channell, Britton. Sci., 197, 573

(1977).

40. J. E. Garst, W. C. Wilson, N. C. Kristensen, P. C. Harrison, J. E. Corbin, J. Simon, R. M.

Philpot, and R. R. Szabo, Anim. Sci., 60, 248 (1985).

41. N. Okazaki, M. Matsunaka, M. Kondo, and K. Okamoto, Skin Res., 24, 250 (1982).

42. H. A. Gardener, U.S. Cir., 52, 1 (1917).

43. Rabak, F. and M. S. Lowman, in Perilla, USDA, Agriculture Research Administration,

Bureau of Plant Industry, Soils, and Agricultural Engineering, Beltsville, Maryland, 1945.

44. R. O. Weibel and W. L. Burlison, Soybean Dig., 8, 14 (1948).

45. I. S. Choi, S. Y. Son, and O. H. Kwon, Korean Soc. Hort. Sci., 25, 68 (1980).

46. Imperial Institute, Bul. Imp. Inst., 18, 479 (1920).

47. Imperial Institute, Bul. Imp. Inst., 24, 205 (1926).

48. Yu, I. S. and S. K. Oh, Res. Rpt. Off. Rural Dev., 18, 187 (1976).

49. H. S. Shin and S. W. Kim, J. Amer. Oil Chem. Soc., 71, 619 (1994).

50. E. C. Leonard, Inform, 9, 831 (1998).

51. V. K. S. Shukla, P. C. Dutta, and W. E. Artz, J. Amer. Oil Chem. Soc., 79, 965 (2002).

52. W. Coates, and R. Ayerza, J. Amer. Oil. Chem. Soc., 75, 1417 (1998).

53. A. A. Bushway, A. M. Wilson, L. Houston, and R. J. Bushway, J. Food Sci., 49, 555 (1984).

54. R. Ayerza, J. Amer. Oil Chem. Soc, 72, 1079 (1995).

55. H. S. Park, J. G. Kim, and M. J. Cho, J. Korean Agric. Chem. Soc., 24, 224 (1981).

56. Publications and Information Directorate, in The Wealth of India, Vol.7, New Delhi, India,

1966.

57. S. J.Kim, H. N. Yoon, and J. S. Rhee, J. Amer. Oil Chem. Soc., 77, 451 (2000).

58. S. J. Kim, S. H. Song, H. N. Yoon, and U. Y. Kong, Inform, 6, 514 (1995).

59. National Research Council (NRC), in Alternative Agriculture/Committee on the Role of

Alternative Farming Methods in Modern Production Agriculture, National Academy

Press, Washington, D.C., 1989.

60. D. H. Putnam, J. T. Budin, L. A. Field, and W. M. Breene, in J. Janick and J. E. Simon, eds.,

New Crops, Wiley, New York, 1993, pp. 314322.

61. J. Schultze-Motel, Archaeo-Physika, 8, 267 (1979).

62. North Central Regional Technical Committee NC-121, Weeds of the North Central States,

North Central Regional Res. Pub. 281, Bul. 772, Agr. Expt. Sta., Univ. Illinois, Urbana-

Champaign, Illinois, 1981.

63. R. G. Robinson, Minnesota Agr. Expt. Sta. Bull., 579 (1987).

64. K. H. Knorzer, Bererichte der Deutschen Botanischen Gesellschaft, 91, 187 (1978).

65. R. Seehuber and M. Dambroth, Landbauforschung Voelkenrode, 37, 219 (1987).

66. G. Enge and G. Olsson, Sveriges Utsadesforenings Tidskrift, 96, 220 (1986).

67. B. G. Kartamyshev, Selektsiya i Semenovodstvo, 6, 9 (1985).

300 FLAX OIL AND HIGH LINOLENIC OILS

68. R. Seehuber and M. Dambroth, Landbauforschung Volkenrode, 33, 183 (1983).

69. R. Seehuber and M. Dambroth, Landbauforschung Volkenrode, 34, 174 (1984).

70. R. K. Downey, J. Amer. Oil Chem. Soc., 48, 718 (1971).

71. R. Seehuber, Fette-Seifen-Anstrichmittel, 86, 177 (1984).

72. R. Marquard and H. Kuhlmann, Fette Seifen Anstrichmittel, 88, 245 (1986).

73. G. O. Korsrud, M. O. Keith, and J. M. Bell, Can. J. Anim. Sci., 58, 493 (1978).

74. J. Zubr, Indust. Crops Products, 6, 113 (1997).

75. R. Lange, W. Schumann, M. Petrzika, H. Busch, and R. Marquard, Fat Sci. Technol., 97,

146 (1995).

76. J. G. Crowley and A. Frohlich. (2002, November 29). Factors Affecting the Composition

and Use of Camelina. Technical Report, Crops Research Centre, Oak Park, Carlow,

Ireland. Available: http://www.teagasc.ie/research/reports/crops/4319/eopr-4319.htm.

77. J. T. Budin, W. M. Breene, and D. H. Putnam, J. Amer. Oil Chem. Soc., 72, 309 (1995).

REFERENCES 301

S-ar putea să vă placă și

- Canola OilDocument8 paginiCanola OilDonald VernonÎncă nu există evaluări

- Materials Today Communications: SciencedirectDocument12 paginiMaterials Today Communications: Sciencedirectsook mun100% (2)

- Properties of Oil and FatDocument51 paginiProperties of Oil and FatPramudyaÎncă nu există evaluări

- Grow+Taller+4+Idiots+PDF+ +eBook+Exercise+Free+Download+Full+Version+Darwin+SmithDocument29 paginiGrow+Taller+4+Idiots+PDF+ +eBook+Exercise+Free+Download+Full+Version+Darwin+SmithMegaV100% (2)

- Marketing StrategyDocument16 paginiMarketing StrategyPraveen Kumar100% (1)

- Oil and Fat Technology Lectures IDocument27 paginiOil and Fat Technology Lectures Iaulger100% (4)

- Refining and Degumming For OilDocument7 paginiRefining and Degumming For Oiljaymie_llanera100% (1)

- Gourmet and Health-Promoting Specialty OilsDe la EverandGourmet and Health-Promoting Specialty OilsRobert MoreauEvaluare: 3 din 5 stele3/5 (1)

- Refinery of Palm OilDocument36 paginiRefinery of Palm Oildoshi_ritesh100% (6)

- Olive Oil: Chemistry and TechnologyDe la EverandOlive Oil: Chemistry and TechnologyDimitrios BoskouEvaluare: 3.5 din 5 stele3.5/5 (2)

- Economic Analysis of Processing and Marketing of Palm Oil in Afikpo NorthDocument8 paginiEconomic Analysis of Processing and Marketing of Palm Oil in Afikpo NorthMajesty100% (1)

- Refinery of Palm OilDocument14 paginiRefinery of Palm OilEvantono Balin Christianto100% (1)

- Palm Oil in FryingDocument73 paginiPalm Oil in FryingGenesis Custodio100% (1)

- Extraction and Physicochemical Properties of Low Free Fatty Acid CrudeDocument18 paginiExtraction and Physicochemical Properties of Low Free Fatty Acid CrudeDinda IntanÎncă nu există evaluări

- 9772 35859 3 PB PDFDocument18 pagini9772 35859 3 PB PDFJim TsikasÎncă nu există evaluări

- Chapter One 1.1 Background of The StudyDocument23 paginiChapter One 1.1 Background of The StudyUshie IsraelÎncă nu există evaluări

- Field Crops 2Document164 paginiField Crops 2Gary Bhullar0% (2)

- 8 2 Introduction To Biodiesel ProductionDocument7 pagini8 2 Introduction To Biodiesel ProductionshawonscribdÎncă nu există evaluări

- Agro301 PDFDocument164 paginiAgro301 PDFNihar YeluriÎncă nu există evaluări

- Anga Geoffrey EzhimDocument63 paginiAnga Geoffrey EzhimGEOFFREY ANGAÎncă nu există evaluări

- A Comparative Study of Chemical Analysis of Palm Kernel OilDocument41 paginiA Comparative Study of Chemical Analysis of Palm Kernel OilAhmad Jaelani ManurungÎncă nu există evaluări

- 164 Sahar Abrehdari PDFDocument8 pagini164 Sahar Abrehdari PDFНаталья СанягинаÎncă nu există evaluări

- Palm Oil Is An Edible: Elaeis Guineensis Elaeis Oleifera Attalea MaripaDocument1 paginăPalm Oil Is An Edible: Elaeis Guineensis Elaeis Oleifera Attalea MaripaKishyorr KarthikÎncă nu există evaluări

- Castor Oil - ProDocument23 paginiCastor Oil - Prozin berÎncă nu există evaluări

- Dhanaa Full ProjectDocument34 paginiDhanaa Full ProjectSimon Peter100% (1)

- Details For Black BookDocument62 paginiDetails For Black BookSagar PatilÎncă nu există evaluări

- 01 Fats and OilsDocument81 pagini01 Fats and Oilsኢትዮጵያ ሐገሬÎncă nu există evaluări

- Transgenic OilsDocument20 paginiTransgenic OilsHerdiwan Novindra0% (1)

- Assignment by Manish Chaudhary (32016313)Document15 paginiAssignment by Manish Chaudhary (32016313)Manish ChaudharyÎncă nu există evaluări

- Palm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewDocument24 paginiPalm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewCarlos RomanÎncă nu există evaluări

- Vegetable OilsDocument40 paginiVegetable OilsMasrie AlemÎncă nu există evaluări

- About Palm OilDocument5 paginiAbout Palm OilheldyÎncă nu există evaluări

- Analysis of The Physical and Chemical Characteristics of Edible Vegetable Blended OilDocument6 paginiAnalysis of The Physical and Chemical Characteristics of Edible Vegetable Blended OilAlvina SuryadinataÎncă nu există evaluări

- Maulana Ainul Yaqin EASDocument15 paginiMaulana Ainul Yaqin EASAndyllo RichieÎncă nu există evaluări

- Pecan TabelaDocument12 paginiPecan TabelaRama ShaktiÎncă nu există evaluări

- Microbial LipidsDocument10 paginiMicrobial LipidsSharif M Mizanur RahmanÎncă nu există evaluări

- Liu 1997Document89 paginiLiu 1997Hary PrasetyaÎncă nu există evaluări

- Castor Oil (Ricinus Communis) - A Review On The Chemical Composition and Physicochemical PropertiesDocument15 paginiCastor Oil (Ricinus Communis) - A Review On The Chemical Composition and Physicochemical PropertiesDidier SanonÎncă nu există evaluări

- Agr 321 PDFDocument164 paginiAgr 321 PDFDiwakar KumarÎncă nu există evaluări

- Chapter-1: Brassica Juncea Is A Highly Variable SpeciesDocument10 paginiChapter-1: Brassica Juncea Is A Highly Variable SpeciesNeenu RajputÎncă nu există evaluări

- 1 Production and Trade of Vegetable Oils: Frank D. GunstoneDocument5 pagini1 Production and Trade of Vegetable Oils: Frank D. GunstoneAlfonso RuizÎncă nu există evaluări

- Biochemical Characteristics of India HempDocument4 paginiBiochemical Characteristics of India HempRemi OsanyinlusiÎncă nu există evaluări

- Braking DownDocument4 paginiBraking DownSalman Khan ProcessengineerÎncă nu există evaluări

- KiceDocument22 paginiKiceThian SiahaanÎncă nu există evaluări

- Palm Oil (Q&A) 2013Document5 paginiPalm Oil (Q&A) 2013labendetÎncă nu există evaluări

- Sustainable Processing Oils in Low RR Tread Compounds - Flanigan Beyer Klekamp Rohweder Stuck Terrill.sDocument22 paginiSustainable Processing Oils in Low RR Tread Compounds - Flanigan Beyer Klekamp Rohweder Stuck Terrill.sREZAÎncă nu există evaluări

- IOSR JournalsDocument4 paginiIOSR JournalsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Oil Seed CropsDocument21 paginiOil Seed CropsGreg BillÎncă nu există evaluări

- Africa Sunflower Cake PDFDocument13 paginiAfrica Sunflower Cake PDFKarthikeyan DevarajÎncă nu există evaluări

- 1988 Kiritsakis Olive OilDocument30 pagini1988 Kiritsakis Olive Oilel_bhuoÎncă nu există evaluări

- For Thesis'Document3 paginiFor Thesis'Gracilla ElmidoÎncă nu există evaluări

- Introduction To Palm OilDocument12 paginiIntroduction To Palm Oilshahira_zakariaÎncă nu există evaluări

- Aceite de TrigoDocument5 paginiAceite de Trigovanessa mamani churaÎncă nu există evaluări

- 09 Chapter2 PDFDocument31 pagini09 Chapter2 PDFRamÎncă nu există evaluări

- Soybean Oil Extraction and Processing: Andrew ProctorDocument2 paginiSoybean Oil Extraction and Processing: Andrew ProctorASHIN DASÎncă nu există evaluări

- Richie Andyllo Stefanus EASDocument14 paginiRichie Andyllo Stefanus EASAndyllo RichieÎncă nu există evaluări

- Corn Oil. An Emerging Industrial Product: January 2012Document40 paginiCorn Oil. An Emerging Industrial Product: January 2012dimas nuriyan efendiÎncă nu există evaluări

- Lit 7Document12 paginiLit 7basireddykasireddy005Încă nu există evaluări

- Trait-Modified Oils in FoodsDe la EverandTrait-Modified Oils in FoodsFrank T. OrthoeferÎncă nu există evaluări

- the Nature of Healthcare: Essential Oils Effects, Risks and Patient SafetyDe la Everandthe Nature of Healthcare: Essential Oils Effects, Risks and Patient SafetyÎncă nu există evaluări

- Single Cell Oils: Microbial and Algal OilsDe la EverandSingle Cell Oils: Microbial and Algal OilsZvi CohenÎncă nu există evaluări

- Tib A004Document32 paginiTib A004Pranab BhattacharyaÎncă nu există evaluări

- GRANTED ABROAD (Based On E-Mail of IPU Dated (11/june/2021)Document18 paginiGRANTED ABROAD (Based On E-Mail of IPU Dated (11/june/2021)Charowar HussainÎncă nu există evaluări

- Aditi VosDocument1 paginăAditi VosXELIXCELINÎncă nu există evaluări

- Biological Importance of Carbohydrates and LipidsDocument17 paginiBiological Importance of Carbohydrates and LipidsAnaitum SharmaÎncă nu există evaluări

- Moraxella Lacunata (Morax Axenfeld Bacillus or Haemophilus Duplex)Document4 paginiMoraxella Lacunata (Morax Axenfeld Bacillus or Haemophilus Duplex)Mare5Der5Încă nu există evaluări

- Hetrocyclic Compounds: SyllabusDocument23 paginiHetrocyclic Compounds: SyllabusVISHNU RAJ VÎncă nu există evaluări

- Study Material: Downloaded From VedantuDocument6 paginiStudy Material: Downloaded From VedantuPUNEETHÎncă nu există evaluări

- 2015 Chandra - Basic Concepts of BiotechnologyDocument518 pagini2015 Chandra - Basic Concepts of BiotechnologyPavani ReddyÎncă nu există evaluări

- 7 Most Common Motor Enclosure Types Defined by NEMA StandardsDocument4 pagini7 Most Common Motor Enclosure Types Defined by NEMA Standardsap1948100% (1)

- Assignment 2Document3 paginiAssignment 2edelyn telewikÎncă nu există evaluări

- Guia de Proveedores de PinturasDocument28 paginiGuia de Proveedores de PinturasEDGrog100% (1)

- Effect of Natural Zeolite As Substrate Filler On The Properties of NBREPDM BlendDocument8 paginiEffect of Natural Zeolite As Substrate Filler On The Properties of NBREPDM BlendhesÎncă nu există evaluări

- Defix: Linacol MedicalDocument2 paginiDefix: Linacol MedicalMohammed Al-YagoobÎncă nu există evaluări

- Enzymatic Cell Wall Degradation of Chlorella Vulgaris and Other Microalgae For Biofuels Production 2012Document15 paginiEnzymatic Cell Wall Degradation of Chlorella Vulgaris and Other Microalgae For Biofuels Production 2012Ryan AsyhariÎncă nu există evaluări

- (Doi 10.1016 - B978!1!63067-065-8.50003-7) George, Edmund D. - Soap Manufacturing Technology - Formulation of Traditional Soap Cleansing SystemsDocument18 pagini(Doi 10.1016 - B978!1!63067-065-8.50003-7) George, Edmund D. - Soap Manufacturing Technology - Formulation of Traditional Soap Cleansing Systemsyonna afriliaÎncă nu există evaluări

- Factors Affecting Crop ProductionDocument40 paginiFactors Affecting Crop ProductionKarl Sean Garma UbinaÎncă nu există evaluări

- Industrial Biotechnology 1Document29 paginiIndustrial Biotechnology 1Abdul Al RajaÎncă nu există evaluări

- Skripsi Tanpa PembahasanDocument47 paginiSkripsi Tanpa Pembahasanmuhammad fahriÎncă nu există evaluări

- CHM 510 Experiment 3Document12 paginiCHM 510 Experiment 3Nabilah100% (1)

- Natural FabricsDocument20 paginiNatural FabricsSantosh BishtÎncă nu există evaluări

- Research Paper 2Document45 paginiResearch Paper 2SushmaSahuÎncă nu există evaluări

- Martin Biel Et Al - Hyperpolarization-Activated Cation Channels: From Genes To FunctionDocument40 paginiMartin Biel Et Al - Hyperpolarization-Activated Cation Channels: From Genes To FunctionFedrmÎncă nu există evaluări

- Msds BenzeneDocument32 paginiMsds BenzeneMertcan AslanÎncă nu există evaluări

- CHAP 1 and 2Document10 paginiCHAP 1 and 2pink osallaÎncă nu există evaluări

- Ltalmatch Solutions For Pulp and PaperDocument26 paginiLtalmatch Solutions For Pulp and PaperparagÎncă nu există evaluări

- Viton FreflowDocument8 paginiViton FreflowGopal ChavanÎncă nu există evaluări

- Bicycle Track Coating SystemDocument3 paginiBicycle Track Coating SystemjovindhaÎncă nu există evaluări

- Life Processes Noted For Class10Document43 paginiLife Processes Noted For Class10MIN. Dr. Tanaji sawant officeÎncă nu există evaluări