Documente Academic

Documente Profesional

Documente Cultură

Examen Parcial - Ingeniería Térmica - 3ITI - 1213 - SOLUCIÓN

Încărcat de

Kais Garchi CasalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Examen Parcial - Ingeniería Térmica - 3ITI - 1213 - SOLUCIÓN

Încărcat de

Kais Garchi CasalDrepturi de autor:

Formate disponibile

1

Asignatura: IME105 - Ingeniera Trmica

Cuatrimestre: 1 Examen: Parcial Convocatoria: Ordinaria

Grupo: 3 ITI 3 ME-AUT Curso: 2012/2013 Fecha: 8 de noviembre de 2012

CUESTIONES (puntuacin entre parntesis en cada cuestin).

1.- (1 punto) Un fuel se quema durante un proceso estacionario de combustin. Una

cantidad de calor por unidad de tiempo de 1120 kW se pierde en los

alrededores que se encuentran a 300 K. La entropa de los reactivos que

entran por unidad de tiempo es 17 kW/K y la de los productos es

15 kW/K. Calcule el ratio total de irreversibilidad o exerga destruida por

unidad de tiempo (kW).

Solucin: 520 kW

To=300 "K"

Q_out=1120 "kW"

S_react=17 "kW'K"

S_prod= 15 "kW/K"

S_react-S_prod-Q_out/To+S_gen=0 "Entropy balance for steady state

operation, Sin-Sout+Sgen=0"

X_dest=To*S_gen

"Some Wrong Solutions with Common Mistakes:"

W1_Xdest=S_gen "Taking Sgen as exergy destruction"

W2_Xdest=To*S_gen1; S_react-S_prod-S_gen1=0 "Ignoring Q_out/To"

2.- (1.5 puntos) Benceno gas (C

6

H

6

) se quema con un 95% de aire terico (se forma

algo de CO) durante un proceso de combustin en rgimen

estacionario. Calcule la fraccin molar del CO en los productos.

Solucin: 2.1%

n_C=6

n_H=6

a_th=n_C+n_H/4

coeff=0.95 "coeff=1 for theoretical combustion, 1.5 for 50% excess air"

"Assuming all the H burns to H2O, the combustion equation is

C6H6+coeff*a_th(O2+3.76N2)----- (n_CO2) CO2+(n_CO)CO+(n_H2O)

H2O+(n_N2) N2"

n_O2=coeff*a_th

n_N2=3.76*n_O2

n_H2O=n_H/2

n_CO2+n_CO=n_C

2*n_CO2+n_CO+n_H2O=2*n_O2 "Oxygen balance"

n_prod=n_CO2+n_CO+n_H2O+n_N2 "Total mole numbers of product gases"

y_CO=n_CO/n_prod "mole fraction of CO in product gases"

"Some Wrong Solutions with Common Mistakes:"

DI I N

2

W1_yCO=n_CO/n1_prod; n1_prod=n_CO2+n_CO+n_H2O "Not including N2 in

n_prod"

W2_yCO=(n_CO2+n_CO)/n_prod "Using both CO and CO2 in calculations"

3.- (1.5 puntos) Aire en un ciclo ideal Diesel se comprime de 2 litros a 0.13 litros, y

despus se expande durante el proceso de adicin de calor a presin

constante hasta 0.30 litros. Bajo suposiciones de aire fro estndar,

calcule la eficiencia trmica del ciclo.

Solucin: 59%

V1=2 "L"

V2= 0.13 "L"

V3= 0.30 "L"

r=V1/V2

rc=V3/V2

k=1.4

Eta_Diesel=1-(1/r^(k-1))*(rc^k-1)/k/(rc-1)

"Some Wrong Solutions with Common Mistakes:"

W1_Eta = 1-(1/r1^(k-1))*(rc^k-1)/k/(rc-1); r1=V1/V3 "Wrong r value"

W2_Eta = 1-Eta_Diesel "Using incorrect relation"

W3_Eta = 1-(1/r^(k1-1))*(rc^k1-1)/k1/(rc-1); k1=1.667 "Using wrong k value"

W4_Eta = 1-1/r^(k-1) "Using Otto cycle efficiency"

PROBLEMAS (puntuacin entre parntesis).

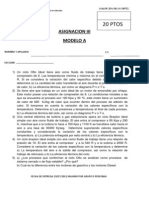

PE1. (3 puntos) En una cmara de combustin entra n-octano (C

8

H

18

) a 25C y 1 atm,

donde se mezcla y quema con un 100% de exceso de aire que entra a la cmara

de combustin en las mismas condiciones, como se indica en la figura adjunta.

Un anlisis de los gases de combustin revela Si la temperatura de salida de los

gases de combustin es 257C, se pide determinar:

1. Las reacciones de combustin con aire terico y con exceso de aire

ajustadas.

2. La tasa de transferencia de calor de la cmara de combustin en

kJ/kmol octano y en kJ/kg octano.

Products

257C

C

8

H

18

25C

100% excess air

25C

Q

out

Combustion

chamber

P = 1 atm

3

PE2.- (3 puntos) Un ciclo de Otto ideal tiene una relacin de compresin de 9.2. Al

principio del proceso de compresin, el aire se encuentra a 98 kPa y 27C, y se

sabe que la presin mxima del ciclo duplica la presin del punto 2 (final del

proceso de compresin isentrpica). Tome en cuenta la variacin de los calores

especficos con la temperatura (condiciones SAE), y determine:

1. Diagramas T-s y P-v del ciclo.

2. Presin y temperatura mximas del ciclo.

3. La salida neta de trabajo.

4. La eficiencia trmica.

5. La presin media efectiva para el ciclo.

15-58 n-Octane is burned with 100 percent excess air. The heat transfer per kilogram of fuel burned for a

product temperature of 257C is to be determined.

Assumptions 1 Steady operating conditions exist. 2 Air and combustion gases are ideal

gases. 3 Kinetic and potential energies are negligible. 4 Combustion is complete. 5 The

fuel is in vapor phase.

Properties The molar masses of propane and air are 44 kg/kmol and 29 kg/kmol,

respectively (Table A-1).

Analysis The combustion reaction for stoichiometric air is

| |

2 2 2 2 2 18 8

3.76)N (12.5 O H 9 CO 8 3.76N O 5 . 12 H C + + + +

The combustion equation with 100% excess air is

| |

2 2 2 2 2 2 18 8

N 94 O 5 . 12 O 9H 8CO 3.76N O 25 H C + + + + +

The heat transfer for this combustion

process is determined from the energy

balance

system out in

E E E A = applied on

the combustion chamber with W = 0. It

reduces to

( ) ( )

+ + =

R

f R

P

f P

h h h N h h h N Q

out

Assuming the air and the combustion products to be ideal gases, we have h = h(T).

From the tables,

Substance

f

h

kJ/kmol

K 298

h

kJ/kmol

K 530

h

kJ/kmol

C

8

H

18

(g) -208,450 --- ---

O

2

0 8682 15,708

N

2

0 8669 15,469

H

2

O (g) -241,820 9904 17,889

CO

2

-393,520 9364 19,029

Substituting,

Product

s

257C

C

8

H

18

25C

100% excess

air

25C

Q

out

Combustion

chamber

P = 1 atm

4

( )( ) ( )( ) ( )( )

( )( ) ( )( )

18 8

out

H C kmol kJ 880 , 239 , 4

0 0 450 , 208 1 8669 469 , 15 0 94

8682 708 , 15 0 5 . 12 9904 889 , 17 820 , 241 9 9364 029 , 19 520 , 393 8

/ =

+ +

+ + + + + = Q

or

18 8 out

H C kmol kJ 880 , 239 , 4 / = Q

Then the heat transfer per kg of fuel is

18 8

H C kJ/kg 37,200 = = =

kg/kmol 114

fuel kJ/kmol 880 , 239 , 4

fuel

out

out

M

Q

Q

9-169 An ideal Otto cycle with air as the working fluid with a compression ratio of 9.2

is considered. The amount of heat transferred to the air, the net work output, the thermal

efficiency, and the mean effective pressure are to be determined.

Assumptions 1 The air-standard assumptions are applicable. 2 Kinetic and potential

energy changes are negligible. 3 Air is an ideal gas with variable specific heats.

Properties The gas constant of air is R = 0.287 kJ/kg K (Table A-1). The properties of

air are given in Table A-17.

Analysis (a) Process 1-2: isentropic compression.

( )

( ) ( ) kPa 2129 kPa 98

K 300

K 708.3

9.2

kJ/kg 9 . 518

K 3 . 708 52 . 67 2 . 621

2 . 9

1 1

2 . 621

kJ/kg 214.07 K 300

1

1

2

2

1

2

1

1 1

2

2 2

2

2

1

2

1 1

1 1 2

1

=

|

|

.

|

\

|

= = =

=

= = = = =

=

= =

P

T

T

P

T

P

T

P

u

T

r

u T

r r r

r

v

v v v

v v

v

v

v

v

Process 2-3: v = constant heat addition.

( )( )

kJ/kg 609.8 9 . 518 7 . 1128

593 . 8

kJ/kg 1128.7 K 1416.6 3 . 708 2 2

2 3

3 2 2

2

3

3

2

2 2

3

3 3

3

= = =

=

= = = = = =

u u q

u T T

P

P

T

T

P

T

P

in

r

v

v v

(b) Process 3-4: isentropic expansion.

( )( ) kJ/kg 487.75 06 . 79 593 . 8 2 . 9

4

3

4

3 3 4

= = = = = u r

r r r

v v

v

v

v

Process 4-1: v = constant heat rejection.

kJ/kg 336.1 7 . 273 8 . 609

kJ/kg 273.7 07 . 214 75 . 487

out in net

1 4 out

= = =

= = =

q q w

u u q

(c) 55.1% = = =

kJ/kg 609.8

kJ/kg 336.1

in

net

th

q

w

q

v

v

P

4

1

3

2

q

in

q

out

5

(d)

( )( )

( )

( )( )

kPa 429

kJ 1

m kPa 1

1/9.2 1 /kg m 0.879

kJ/kg 336.1

/ 1 1

MEP

/kg m 0.879

kPa 98

K 300 K /kg m kPa 0.287

3

3

1

net

2 1

net

max

2 min

3

3

1

1

1 max

=

|

|

.

|

\

|

=

= =

=

= = =

r

w w

r

P

RT

v v v

v

v v

v v

S-ar putea să vă placă și

- Examen Parcial - Ingeniería Térmica - 3ME - 3AUT - 1213 - SOLUCIÓNDocument4 paginiExamen Parcial - Ingeniería Térmica - 3ME - 3AUT - 1213 - SOLUCIÓNKais Garchi CasalÎncă nu există evaluări

- Examen Ordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNDocument9 paginiExamen Ordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNKais Garchi CasalÎncă nu există evaluări

- Examen Extraordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNDocument7 paginiExamen Extraordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNKais Garchi CasalÎncă nu există evaluări

- Practica 2 Kais GarchiDocument6 paginiPractica 2 Kais GarchiKais Garchi CasalÎncă nu există evaluări

- Practica 1 Kais GarchiDocument3 paginiPractica 1 Kais GarchiKais Garchi CasalÎncă nu există evaluări

- Proceso SDocument7 paginiProceso SKais Garchi CasalÎncă nu există evaluări

- Tema 6. Ingeniería TérmicaDocument0 paginiTema 6. Ingeniería TérmicaKais Garchi CasalÎncă nu există evaluări

- Asignacion 3 Tema III Sec 12 I 2012Document2 paginiAsignacion 3 Tema III Sec 12 I 2012Kais Garchi CasalÎncă nu există evaluări

- Ciclos TermodinamicosDocument17 paginiCiclos TermodinamicosRomeritho JC Vsqz VgÎncă nu există evaluări

- Formulario - Ingeniería TérmicaDocument0 paginiFormulario - Ingeniería TérmicaKais Garchi CasalÎncă nu există evaluări

- Compuestos Quimicos InorganicosDocument2 paginiCompuestos Quimicos InorganicosAdrianHaro100% (2)

- Carta Campamento 2018Document5 paginiCarta Campamento 2018Justin BergÎncă nu există evaluări

- Actividad Física y SaludDocument21 paginiActividad Física y SaludGisbellAcostaVillasmilÎncă nu există evaluări

- Agentes Contaminantes y Su ProcedenciaDocument5 paginiAgentes Contaminantes y Su ProcedenciaFatima SanchezÎncă nu există evaluări

- Fases de PerforaciónDocument2 paginiFases de Perforaciónarianna ulloaÎncă nu există evaluări

- SEM 05 Nomenclatura Inorgánica IDocument4 paginiSEM 05 Nomenclatura Inorgánica Iesbin mayder inga fernandezÎncă nu există evaluări

- Biogas A Partir de PollinazaDocument15 paginiBiogas A Partir de Pollinazaledatintaya100% (1)

- Derrame Pleural 1Document11 paginiDerrame Pleural 1Nauro CaballeroÎncă nu există evaluări

- Deficit de Atencion Kim PDFDocument10 paginiDeficit de Atencion Kim PDFKimberli HernandezÎncă nu există evaluări

- TecnologiaDocument1 paginăTecnologiaAdam Boyd0% (1)

- AlgasDocument3 paginiAlgasNicolle Andrea Morales CárdenasÎncă nu există evaluări

- Guía Metodológica para El Rociado DomiciliarioDocument30 paginiGuía Metodológica para El Rociado DomiciliarioBioyoga mente.cuerpo.espirituÎncă nu există evaluări

- +evaluacion Multiaxial en DSM PDFDocument1 pagină+evaluacion Multiaxial en DSM PDFDanielaÎncă nu există evaluări

- TALLER#2 GeologiaDocument4 paginiTALLER#2 GeologiaAndres Felipe Novoa SilvaÎncă nu există evaluări

- Casa Materna CalhuitzDocument33 paginiCasa Materna CalhuitzWuqu' KawoqÎncă nu există evaluări

- 10 SedimentacionDocument21 pagini10 SedimentacionJhon GomezÎncă nu există evaluări

- Guia de Ejercicios 5 (Cultivo Continuo) 1Document2 paginiGuia de Ejercicios 5 (Cultivo Continuo) 1sebastianscribd2014Încă nu există evaluări

- El Sentido de La VidaDocument12 paginiEl Sentido de La VidaRolando JiménezÎncă nu există evaluări

- 2 Introducción A Las TurbomáquinasDocument69 pagini2 Introducción A Las TurbomáquinasJesus Alberto Gomez VegaÎncă nu există evaluări

- Memorias de Un Librero PornógrafoDocument224 paginiMemorias de Un Librero Pornógraforafaelki100% (2)

- Unidad 3Document9 paginiUnidad 3julietaaleromero629Încă nu există evaluări

- reportePDF CUS FSE 007Document55 paginireportePDF CUS FSE 007Jhon Edinson MosqueraÎncă nu există evaluări

- La Bruja NegraDocument384 paginiLa Bruja NegraMantilla Fernando esteban88% (8)

- Ejemplo Cuadrado Latino Octubre 2020Document6 paginiEjemplo Cuadrado Latino Octubre 2020delvis sanchez diasÎncă nu există evaluări

- TaliaDocument4 paginiTaliaemersonÎncă nu există evaluări

- Moniciones para La Misa Del 7 de Septiembre 2018Document6 paginiMoniciones para La Misa Del 7 de Septiembre 2018NORSAID NORAIMA Y SAIDÎncă nu există evaluări

- Yesenia Garfias ZegarraDocument5 paginiYesenia Garfias ZegarraWILFREDO JEANPIERS BOZA SICOSÎncă nu există evaluări

- RESUMEN Moda y Hogar SostenibleDocument7 paginiRESUMEN Moda y Hogar SostenibleJuliana CastellanosÎncă nu există evaluări

- Destilacion Quimica OrganicaDocument18 paginiDestilacion Quimica OrganicaRobertÎncă nu există evaluări

- 3° A y B - Taller de Lectura - El Dengue y La Fiebre Chikungunyaucar - Prof. Yanina AlfaroDocument3 pagini3° A y B - Taller de Lectura - El Dengue y La Fiebre Chikungunyaucar - Prof. Yanina AlfaroALVARO GAMBOAÎncă nu există evaluări