Documente Academic

Documente Profesional

Documente Cultură

Design and Production Practice of the New Designed Multi-tube Film Sulfonation Reactor

Încărcat de

masthan6y100%(1)100% au considerat acest document util (1 vot)

74 vizualizări3 paginiThe document describes a new multi-tube film sulfonation reactor designed by Kani Chemical Co. Ltd. to address disadvantages of existing designs. Key features of the new reactor include: 1) Using high-precision rotameters to control organic flow in each tube within 1.5% accuracy regardless of tube number; 2) Utilizing a balance wind to increase SO3 concentration and improve temperature control; 3) Adopting a circular baffle and claw plates to strengthen cooling effects. Production tests showed the new reactor improves productivity, reduces energy use, and yields products meeting higher quality standards.

Descriere originală:

SLES Reactor

Titlu original

SLES Reactor

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document describes a new multi-tube film sulfonation reactor designed by Kani Chemical Co. Ltd. to address disadvantages of existing designs. Key features of the new reactor include: 1) Using high-precision rotameters to control organic flow in each tube within 1.5% accuracy regardless of tube number; 2) Utilizing a balance wind to increase SO3 concentration and improve temperature control; 3) Adopting a circular baffle and claw plates to strengthen cooling effects. Production tests showed the new reactor improves productivity, reduces energy use, and yields products meeting higher quality standards.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

74 vizualizări3 paginiDesign and Production Practice of the New Designed Multi-tube Film Sulfonation Reactor

Încărcat de

masthan6yThe document describes a new multi-tube film sulfonation reactor designed by Kani Chemical Co. Ltd. to address disadvantages of existing designs. Key features of the new reactor include: 1) Using high-precision rotameters to control organic flow in each tube within 1.5% accuracy regardless of tube number; 2) Utilizing a balance wind to increase SO3 concentration and improve temperature control; 3) Adopting a circular baffle and claw plates to strengthen cooling effects. Production tests showed the new reactor improves productivity, reduces energy use, and yields products meeting higher quality standards.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

Design and Production Practice of the New Designed Multi-tube Film

Sulfonation Reactor Huiben Zhang (Nanjing Kani Co. Ltd)

I. Foreword

At present, most of the multi-tube film sulfonation reactors in use nationally were designed by Ballestra

Societ Per Azioni, or are replicas manufactured by this company. After many years of practice, we found

some disadvantages of the design per se

1. The organic flow in each reaction tube is adjusted by gasket, which will result in low adjustment accuracy

and long adjustment time. As the flow in reaction tubes increases, the adjustment becomes harder and

harder. When the reaction tubes are corroded after prolonged use, they cannot even be adjusted properly.

2. Also, the organic flow cannot be controlled; thus, it might affect the product quality. Decision on whether

the errors fall within the acceptable range can be made only if each organic flow is demarcated. Failure to

do so will adversely affect the manufacturing procedure. Lock ring is used as the seal between the

sulfonation reactors organic raw material feed chamber and the cooling water jacket. The jacket cannot

withstand high water pressure and thus requires the cooling water to go back to its normal condition.

However, even though the above condition is met, the cooling water may still leak to the organic raw

material feed chamber and result in emulsification of raw materials which cannot be sulfonated anymore.

3. When SO3 enters into the sulfonation, it will contact and corrode the sulfonation reactor heads gland

nuts, gaskets, nozzles, and other parts. It is difficult to uninstall, assemble, or adjust when the thread of

gland nuts was corroded. Recognizing the above problems with Ballestras sulfonation reactors, we, a team

of experts at Kani Chemical Co. Ltd., designed a new type of multi-tubes sulfonation reactor, which is more

reasonable for its structure, convenience in use, and better product quality. Additionally, the way it is

designed makes it robust enough to withstand reaction with various raw materials for sulfonation or

sulfation, even after prolonged use.

II. The Design Ideas

The SO3 sulfonation and sulfation is a diffusion-based extremely fast reaction, which will produce huge

heat, while the product has a high thermo-sensitivity. Therefore, the film sulfonation reactor is required to

effectively control the diffusion rate of SO3. At the beginning of sulfonation reaction (about 0 ~ 1.5meters),

the unit conversion rate of organic materials should have a large cooling area, so that the Moore ratio

between SO3 and organic material can be accurately controlled. The organic material flow should be

accurately controlled in each tube so that the error of organic materials among tubes can be less than

1.5%. The thickness of the organic film around the reaction tube should be consistent, for example, for a

reaction tube with which inner diameter of 25mm and length of 6 meters, the deviation between the upper

and lower concentricity should be less than 2mm, while any length of each reaction tube should be vertical.

It is required that the cooling heat transfer coefficient is improved, so that the reaction temperature can be

effectively controlled. According to the requirements above, we designed a new type of multi-tube film

sulfonation reactor, which works effectively in practice.

III. The Feature of the New Multi-tube Film Sulfonation Reactor

1. The organic feed of each tube needs to be controlled by high-precision rotameter, with 1.5% control

accuracy regardless of the changes of tube numbers. The high-precision rotameter needs to be easy to

adjust. With the increase of number of the tubes, this advantage is more obvious. Meanwhile, in the

process of production, the organic flow can be observed anytime, which indirectly helps understand

whether there is any coking phenomenon in any of the reaction tube.

2. The sulfonation reactor utilizes the balance wind, which can be adjusted by the external piping and

valves, or by changing the diameters of each SO3 nozzles (this method is limited to the process which can

offer high gas concentration, such as liquid SO3 evaporation process) to reduce the diameters of the SO3

nozzles, so that the input air gap area increases between the SO3 nozzle diameter and nozzle. As a result,

the ratio between SO3 and balance wind decreases. The SO3 nozzle plugs into the organic film directly

from the head of sulfonation reactor. SO3 and the balance wind pass the concentric circle together through

organic film (The channel of balance wind is cyclic because the structure needs to ensure a consistent

concentricity between the concentric circle.) and eject out together.

Utilizing the balance wind can help increase SO3 concentration. At the beginning of the reaction, given the

same conversion ratio, there is a longer reaction interval by using balance wind than that of not using it.

Therefore, given the same reaction heat, using the balance wind can help increase the cooling area and

better control the peak value of reaction temperature. This was approved in practice.

In addition, SO3 nozzle directly plugs into the organic film, which avoids the contact with the nut, washer

and nozzles; meanwhile, the balance wind also isolates the SO3 when it goes through pressed nuts and

nozzles, so that corrosion is prevented. Without corrosion, it is very easy to uninstall and assemble. Due to

the use of balance wind, which improves the SO3 gas concentration at the entrance, it is more productive

when LABSA is produced. For example, given the standard condition, LAB is fed into the reaction tube, to

reach 0.58kg/mm, it costs 1450M3 dry air to produce one ton of LABSA. However, if our sulfonation reactor

is used, 19ton/day of SA can be produced, with Roots wind of 19.3m3/min. With the increase of production

in each single tube, the pressure in sulfonation reactor also increases, which reach 0.0350.04mp,

compared to Ballestras reactor which can reach 0.0250.03mp.

3. In order to strengthen the cooling effect, instead of using the baffle with a 1/4 gap (such kind of baffle can

cause death of flow rate, which in turn will affect the cooling effect), we adopted the circle baffle. The baffle

hole is greater than the reaction tube diameter; if a three-clawed or four-clawed plate is set in the between

of reaction tube and baffle, it will improve the heat transfer coefficients, the cooling effect, as well as the

impact of water flow towards the reaction tube.

4. Since organic raw material is fed individually into each reaction tube, it remains completely isolated with

the cooling water system. Therefore, the possibility of cooling water leaking into organic raw materials is

greatly minimized. The cooling water at the head of sulfonation reactor can go back with pressure, which

can go directly to the cooling water system of the sulfonation plant.

IV. Design Parameters

1. The reaction tube internal diameter is 25mm, outer diameter is 29mm, internal diameter deviation is

25mm0.05, internal diameter ovality < 0.01mm. The finish of the inner tube of the reactor is greater than

V8the length of the tube is 6mmaterial316L. The internal diameter of Ballestra is 25.4mm.

2. The designed tube air speed is 43m/s, mass transfer coefficient: kg=1.310-1m/s

3. The initial film thickness is 0.3mm, exports of the film thickness is 3mm. The residence time is about

35ms.

4. The pressure of the entrance of the cooling water tube is 0.3Mp. The heat transfer coefficient is

kw20KJ/m2h-.

5. Balance wind: SO3 ventilation area equals 0.4:1.

V. Production Practice

The new multi-tube film sulfonation reactor has been used in many sulfonated field, such as the sulfation of

fatty alcohol and ether, the acidification of the fatty acids. In the process of Alkylbenzene sulfonation, it

improves the productivity, reduces the energy consumption, as well as improves the product quality.

The index is: actives96.5% (i.e.: Jiale Nanjing Co., Ltd.)

Free oil1.5%

Inorganic acid1.3%

Color25klett

If the SO3 filter adopts the provisioning shower defogger, the inorganic acid can be dropped to less than

1%, actives up to more than 97%. Produce K12 powder

The index is: Actives94%i.e.: Jinling Nanjing Co., Ltd.

Inorganic salts1.2%

No sulfonate1.0%

Color10klett

In the sulfonation of the fatty acids to the formic acids, the Moore rate between SO3 and the formic acids is

1.15 ~ 1.2:1, the temperature at the exit of the sulfonation reactor is 60, aging temperature is between

8590, the conversion rate of fatty acids to formic acids is greater than 96%.

VI. Conclusion

1. The new multi-tube film sulfonation reactor is improved in many ways. Not only it can meet various

requirements for producing sulfonation and sulfation, it can also improve the quantity and quality of the

product, and save the costs compared to the already existing sulfonation reactor in the market.

2. The new multi-tube sulfonation reactor can be applied to practice effectively. With the increase of the

number of tubes, it does not affect the accuracy of raw material quantity, or the product quality. The product

quality is better from multi-tube sulfonation reactorthe more tube number, the better the quantity. The

new multi-tube sulfonation reactor is easy to use and can provide stable product quality. Compared with

other sulfonated reactors, it can improve the product quantity by 45% (limited to LABSA). It can also

improve yield of other products like ether and the fat sulfated quantity by 5 to10%.

Auto Control System

Take an example of the configuration of 5 ton/hour sulfonation equipment. Personal Computer (PC) and

Programmable Logic Controllers (PLC) based control system consists of two Computer Operator Stations,

one set of PLC Controller Station, four MCC control cabinet, and one high-voltage power supply (HVPS)

control cabinet, etc. Using SIEMENS Win CC 7.0 (Windows Control Center) as the human-machine

interface software, the Computer Operator Station integrating with monitoring software which is developed

by our company can display and control the following procedures through computer screen: the sulfonation

dynamic process, the input of technology parameters, system status monitoring, error alarm reminding,

historic data saving, and report printing, etc. SIEMENS S7-300 being the main system structure, PLC

Control Station is responsible for the control of sulfonation equipment. 3152PN/DP being the central

processing unit (CPU), it monitors and transmits data through internet. The Computer Operator Station is

mainly responsible for monitoring the status of the sulfonation equipment. The main functions of Computer

Operation Station are as follows:

1. Display the sulfonation equipment process,

2. Display the real-time system pressure, temperature, and density value collected by the instrument,

3. Set and adjust parameters of proportional-integral-derivative (PID) control loop,

4. Display the running status and alarm status of each motor as well as their start-stop operation,

5. Display and record the alarm information in the production process,

6. Display and record parameters of running system

7. Record, archive, and print the feedback value curve from instrument.

Temperature and pressure parameters of each collected point in the control system are tested and

displayed by the instrument utilizing bi-metal thermometers and pressure gauges. Thermal resistance and

pressure sensors are used to test temperature and pressure in the testing locations of measuring main

temperature, pressure, and high temperature, through cable access PLC control module in the combined

MCC cabinet.

The electric control configures four sets of modular MCC cabinets. Each cabinet is configured by using a

DS cabinet type, 4,000mm*2,000mm*500mm (width*height*depth), a RAL7035 computer-based white

color, and an IP54 protection level. The cabinet is equipped with a filtered ventilation system and light,

which can protect the component service life efficiently. The internal of the cabinet integrates PLC control

station with sulfonation equipment control unit.

In the control loop, Roots Blower adopts soft starter. Frequency Converter adopts VCON NSL series high-

performance Frequency Converter from Finland. Control units adopt domestic products with a brand name

of CHNT or DELIXI, with reliable quality and performance. The low-capacity motor adopts a new type of

NS2 series power machine protection circuit breaker, which can protect the motor reliably and efficiently.

The advantages of the above configuration include: operating staff can master the process operation

quickly through process images, the system can later gradually increase the automatic control units of

sulfonation system as well as extend the control units which is beyond sulfonation board.

S-ar putea să vă placă și

- Boiler Preservation Methods Dry and WetDocument14 paginiBoiler Preservation Methods Dry and WetTin Aung KyiÎncă nu există evaluări

- 150 Chemical Engineering Interview QuestionsDocument40 pagini150 Chemical Engineering Interview QuestionsCheenee SiringanÎncă nu există evaluări

- Full TextDocument3 paginiFull Textvishesh_kumar_7Încă nu există evaluări

- Activated carbon columns designDocument21 paginiActivated carbon columns designnurrahman.auliaÎncă nu există evaluări

- Sulfonation of by So3Document4 paginiSulfonation of by So3International Journal of Advance Research and Innovative Ideas in EducationÎncă nu există evaluări

- Chemical and Mechanical DesignDocument460 paginiChemical and Mechanical DesignNuriman K-monÎncă nu există evaluări

- Heat and Mass TransferDocument23 paginiHeat and Mass TransferMaria Cecille Sarmiento GarciaÎncă nu există evaluări

- How to Maintain and Troubleshoot Boilers and EvaporatorsDocument5 paginiHow to Maintain and Troubleshoot Boilers and EvaporatorsAishÎncă nu există evaluări

- BGD 886-S Cyclic Corrosion Test CCT CabinetsDocument5 paginiBGD 886-S Cyclic Corrosion Test CCT CabinetsAbhinandan AdmutheÎncă nu există evaluări

- Steaming Procedure For Carbon and Sulpur Removal-JMCDocument7 paginiSteaming Procedure For Carbon and Sulpur Removal-JMCAzee TitouÎncă nu există evaluări

- Kerala BOE-2014 Paper-2 SolutionDocument15 paginiKerala BOE-2014 Paper-2 SolutionAlok DoshiÎncă nu există evaluări

- K Brian & E RochaisDocument16 paginiK Brian & E RochaisLuigi Andrew MercadoÎncă nu există evaluări

- Very Poor Poor Good Very Good Excellen TDocument11 paginiVery Poor Poor Good Very Good Excellen TNanthan DevÎncă nu există evaluări

- Boiler Preservation NalcoDocument4 paginiBoiler Preservation NalcoSushil Kumar71% (7)

- Cleaning of CondenserDocument16 paginiCleaning of CondenserKrizia Meiahn CatalonÎncă nu există evaluări

- Purification KATALCO Mar 07Document16 paginiPurification KATALCO Mar 07SimEnzÎncă nu există evaluări

- Project Presentation On Butadiene SulfoneDocument69 paginiProject Presentation On Butadiene SulfoneDinesh DinnuÎncă nu există evaluări

- Rotary Vacuum Drum Filters for Solid-Liquid SeparationDocument6 paginiRotary Vacuum Drum Filters for Solid-Liquid SeparationSiraj AL sharifÎncă nu există evaluări

- Rotary Vacum Drum Filter (Jurnal)Document7 paginiRotary Vacum Drum Filter (Jurnal)Shofiyah Bannan100% (2)

- GwaderaM AdsorptionWaterDocument11 paginiGwaderaM AdsorptionWaterhortalemosÎncă nu există evaluări

- Molecular Sieves PresentationDocument19 paginiMolecular Sieves PresentationVasant Kumar Varma100% (1)

- Morin 1993Document41 paginiMorin 1993muhammad fattah RomdhoniÎncă nu există evaluări

- Bioprocess Principles Chapter1Document96 paginiBioprocess Principles Chapter1Catharanthus9Încă nu există evaluări

- B Tech Monthly Test on BoilersDocument5 paginiB Tech Monthly Test on BoilersRishav Raj100% (1)

- MgO - SiO2 - H2ODocument12 paginiMgO - SiO2 - H2Oaemp2009100% (1)

- Climbing FilmDocument34 paginiClimbing FilmTunji Aminu100% (1)

- FERMENTOR AND BIOREACTOR Design and ControlDocument27 paginiFERMENTOR AND BIOREACTOR Design and ControlnotewalakijayÎncă nu există evaluări

- Meth06 CleanDocument13 paginiMeth06 CleanKhalDrogo886Încă nu există evaluări

- Control Lime Kiln Production Using PID LoopsDocument4 paginiControl Lime Kiln Production Using PID LoopsA Sar BanÎncă nu există evaluări

- Condenser Tube Cleaning Using Bullet Shot MethodDocument6 paginiCondenser Tube Cleaning Using Bullet Shot MethodCharu Chhabra50% (2)

- Thin Film Deposition TechniquesDocument13 paginiThin Film Deposition TechniquesGaganpreetSinghÎncă nu există evaluări

- Guidelines On FCC Fractionator Bottoms System Rev2Document5 paginiGuidelines On FCC Fractionator Bottoms System Rev2M Scott GreenÎncă nu există evaluări

- Enumerate The Different Impurities Found in Raw Water. Describe The Ill Effect of Each Item in Relation To Boiler OperationDocument6 paginiEnumerate The Different Impurities Found in Raw Water. Describe The Ill Effect of Each Item in Relation To Boiler OperationThan AnthonyÎncă nu există evaluări

- 1 PBDocument12 pagini1 PBscata1117Încă nu există evaluări

- Boiler Q&A FurtherDocument7 paginiBoiler Q&A FurtherRachitÎncă nu există evaluări

- 3.10 Water For The BoilerDocument12 pagini3.10 Water For The BoilerJhonathan AlejandroÎncă nu există evaluări

- AP BOE-2013 Paper-1 SolutionDocument9 paginiAP BOE-2013 Paper-1 SolutionAlok Doshi50% (2)

- Characterisation and Optimisation of Ladle Stirring Systems - EUDocument223 paginiCharacterisation and Optimisation of Ladle Stirring Systems - EUJarek PlaszczycaÎncă nu există evaluări

- What Is The Aerosol Fire Extinguishing Systems?Document3 paginiWhat Is The Aerosol Fire Extinguishing Systems?Sooraj VsÎncă nu există evaluări

- Vacuum Distillation of Plutonium Spent SaltsDocument12 paginiVacuum Distillation of Plutonium Spent SaltsJohn Mar OrnaÎncă nu există evaluări

- Top 10 HPLC Column MythsDocument8 paginiTop 10 HPLC Column MythsananedallÎncă nu există evaluări

- v111n11p759 Fluid Roasting ZincDocument7 paginiv111n11p759 Fluid Roasting ZincergfaradÎncă nu există evaluări

- Particulate Emissions Control Technologies OverviewDocument14 paginiParticulate Emissions Control Technologies OverviewAnup NairÎncă nu există evaluări

- Fermentors Bioreactors - Protocol - 039 - BioFlo 320 - Measuring Oxygen Transfer Rate OTR Eppendorf Fermentation VesselsDocument4 paginiFermentors Bioreactors - Protocol - 039 - BioFlo 320 - Measuring Oxygen Transfer Rate OTR Eppendorf Fermentation VesselsTommy HiroÎncă nu există evaluări

- Manufacture OF Producer GasDocument36 paginiManufacture OF Producer GasSai PavanÎncă nu există evaluări

- FCSG For SAGDDocument7 paginiFCSG For SAGDaugur886Încă nu există evaluări

- TP1028ENDocument21 paginiTP1028ENramkeshmit_413125668Încă nu există evaluări

- ZLD Evaporation Crystallization For Waste Water TreatmentDocument6 paginiZLD Evaporation Crystallization For Waste Water Treatmentkosmc123Încă nu există evaluări

- VaporizerDocument11 paginiVaporizerIhteshamÎncă nu există evaluări

- Sootblowing OptimizationDocument9 paginiSootblowing OptimizationvnchromeÎncă nu există evaluări

- Experimental modeling of Sugarcane Flash Bagasse Dryer moisture controlDocument25 paginiExperimental modeling of Sugarcane Flash Bagasse Dryer moisture controlMathusuthanan MariilayarajaÎncă nu există evaluări

- Basic Techniques for Experimental Methods in Air-Sensitive ChemistryDocument30 paginiBasic Techniques for Experimental Methods in Air-Sensitive ChemistryJoe Vito Morabito100% (1)

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmDocument21 paginiProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperÎncă nu există evaluări

- ABSA 4th Class B HelpDocument53 paginiABSA 4th Class B HelpAnonymous eMaZdX9100% (1)

- SF6 Gas Sampling ProcedureDocument4 paginiSF6 Gas Sampling ProcedureMohsin YasinÎncă nu există evaluări

- Method 6 Determination of Sulfur Dioxide Emissions From Stationary SourcesDocument13 paginiMethod 6 Determination of Sulfur Dioxide Emissions From Stationary Sourcesl kÎncă nu există evaluări

- Scientific American Supplement, No. 446, July 19, 1884De la EverandScientific American Supplement, No. 446, July 19, 1884Încă nu există evaluări

- Laboratory Manual of Glass-BlowingDe la EverandLaboratory Manual of Glass-BlowingEvaluare: 5 din 5 stele5/5 (1)

- Audit Observation PDocument23 paginiAudit Observation Pmasthan6y100% (1)

- ABC PoemDocument2 paginiABC Poemmasthan6yÎncă nu există evaluări

- Product Informations:: Tube MachineryDocument1 paginăProduct Informations:: Tube Machinerymasthan6yÎncă nu există evaluări

- Managing Trade Customs China 201107Document32 paginiManaging Trade Customs China 201107ssingaram1965Încă nu există evaluări

- Scan ReportDocument2 paginiScan Reportmasthan6yÎncă nu există evaluări

- ABC PoemDocument3 paginiABC Poemmasthan6yÎncă nu există evaluări

- Yakub AnwarDocument3 paginiYakub Anwarmasthan6yÎncă nu există evaluări

- Eu Sme Centre Guideline - Importing Pharma Products Update - Jul 2014Document26 paginiEu Sme Centre Guideline - Importing Pharma Products Update - Jul 2014masthan6yÎncă nu există evaluări

- 2.2 Primary Criteria 1 - DemandDocument10 pagini2.2 Primary Criteria 1 - Demandmasthan6yÎncă nu există evaluări

- Importacao de Farmaceuticos Na China en EusmecenterDocument12 paginiImportacao de Farmaceuticos Na China en Eusmecentermasthan6yÎncă nu există evaluări

- Eu Sme Centre Guideline - Importing Pharma Products Update - Jul 2014Document26 paginiEu Sme Centre Guideline - Importing Pharma Products Update - Jul 2014masthan6yÎncă nu există evaluări

- Check List For Suspension File FoldersDocument1 paginăCheck List For Suspension File Foldersmasthan6yÎncă nu există evaluări

- Is Allah One or ThreeDocument140 paginiIs Allah One or Threemarmar92Încă nu există evaluări

- LLC StatementDocument14 paginiLLC Statementmasthan6yÎncă nu există evaluări

- Penetration Tests According To The ISO 11140Document41 paginiPenetration Tests According To The ISO 11140masthan6yÎncă nu există evaluări

- Purification of MethanolDocument2 paginiPurification of Methanolmasthan6yÎncă nu există evaluări

- AlfuzosinDocument4 paginiAlfuzosinmasthan6yÎncă nu există evaluări

- Company Profile TemplateDocument5 paginiCompany Profile TemplateIbnu Ali100% (3)

- Methanol Production and UseDocument403 paginiMethanol Production and UseEvin Joy92% (13)

- Stock Filters All NewDocument8 paginiStock Filters All Newmasthan6yÎncă nu există evaluări

- Wasaa'il Al-Thabaat Means of Steadfastness: Standing Firm in IslamDocument26 paginiWasaa'il Al-Thabaat Means of Steadfastness: Standing Firm in IslamROJÎncă nu există evaluări

- ABC PoemDocument4 paginiABC Poemmasthan6yÎncă nu există evaluări

- What Does Islam Say About LifeDocument5 paginiWhat Does Islam Say About Lifemasthan6yÎncă nu există evaluări

- Purification of MethanolDocument2 paginiPurification of Methanolmasthan6yÎncă nu există evaluări

- Our Training Section IncludesDocument1 paginăOur Training Section Includesmasthan6yÎncă nu există evaluări

- WH Transfer DateDocument2 paginiWH Transfer Datemasthan6yÎncă nu există evaluări

- H R D Chemicals: Surfactant Specialities LimitedDocument4 paginiH R D Chemicals: Surfactant Specialities LimitedDick n DockÎncă nu există evaluări

- Date: 01 December 2014 To: Mr. Amjad Ganma Sr. Quality Unit Manager Thru: The Proper Channel Sub: Housing AllowanceDocument1 paginăDate: 01 December 2014 To: Mr. Amjad Ganma Sr. Quality Unit Manager Thru: The Proper Channel Sub: Housing Allowancemasthan6yÎncă nu există evaluări

- NEW NEW NEW NEW NEW: Amlodipine BesylateDocument4 paginiNEW NEW NEW NEW NEW: Amlodipine Besylatemasthan6yÎncă nu există evaluări

- Daher PromotionDocument1 paginăDaher Promotionmasthan6yÎncă nu există evaluări

- Epow KS10H KS20HDocument6 paginiEpow KS10H KS20HstrahinjaÎncă nu există evaluări

- Set Up & Instruction Manual REV. 0.2 Set Up & Instruction Manual REV. 0.8Document39 paginiSet Up & Instruction Manual REV. 0.2 Set Up & Instruction Manual REV. 0.8LuisÎncă nu există evaluări

- Packing in Outbound DeliveryDocument10 paginiPacking in Outbound DeliveryIshan AgrawalÎncă nu există evaluări

- Accessing VDIs and logging into NetScaler GatewayDocument7 paginiAccessing VDIs and logging into NetScaler GatewayMohsin ModiÎncă nu există evaluări

- "Impact of E-Commerce On Marketing": A Summer Training Project Report ONDocument104 pagini"Impact of E-Commerce On Marketing": A Summer Training Project Report ONkavimahi2310Încă nu există evaluări

- Ece4009 - Wireless and Mobile Communication Review 2 Group Members Slot 1. 2. 3. TitleDocument10 paginiEce4009 - Wireless and Mobile Communication Review 2 Group Members Slot 1. 2. 3. TitledwijaÎncă nu există evaluări

- Patriot LPV SpecDocument4 paginiPatriot LPV SpecFederico Pérez de LeónÎncă nu există evaluări

- Training Devices and Addressing ......................................................................... 1-2Document12 paginiTraining Devices and Addressing ......................................................................... 1-2Julian David Arevalo GarciaÎncă nu există evaluări

- Test Unit 1: Vocabulary GrammarDocument4 paginiTest Unit 1: Vocabulary GrammarEstiveenRodriguezÎncă nu există evaluări

- Modern Statistics GuideDocument4 paginiModern Statistics GuideErille Julianne (Rielianne)100% (1)

- Scott Cunningham - Causal Inference (2020) PDFDocument591 paginiScott Cunningham - Causal Inference (2020) PDFRoger Mario Lopez0% (1)

- Bsitay2018 PDFDocument2 paginiBsitay2018 PDFDavidÎncă nu există evaluări

- Applications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationDocument2 paginiApplications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationWarkaÎncă nu există evaluări

- 1000-400-933 - D-X8000 Light Source Service GuideDocument84 pagini1000-400-933 - D-X8000 Light Source Service GuideHichem NaghmouchiÎncă nu există evaluări

- FortiManager-7 4 0-Administration - GuideDocument937 paginiFortiManager-7 4 0-Administration - GuideJosé PabloÎncă nu există evaluări

- Audiocodes Mediant Sbcs For Service ProvidersDocument9 paginiAudiocodes Mediant Sbcs For Service ProvidersrAVIÎncă nu există evaluări

- Fujitsu Desktop Esprimo Q956: Data SheetDocument9 paginiFujitsu Desktop Esprimo Q956: Data SheetFederico SanchezÎncă nu există evaluări

- SLP Konstanter 320W - Technical Data SheetDocument8 paginiSLP Konstanter 320W - Technical Data SheetMihai CherechesÎncă nu există evaluări

- Css Gradient ColorDocument3 paginiCss Gradient ColorAhmadÎncă nu există evaluări

- Cyber Security Course in MalappuramDocument10 paginiCyber Security Course in MalappurammarketerakmÎncă nu există evaluări

- Sample User Profile QuestionnaireDocument6 paginiSample User Profile QuestionnairemuzammilsiddiquiÎncă nu există evaluări

- JSP 2 Struts Eclipse 3 DAO ANSI SQL DB and More With ExamplesDocument250 paginiJSP 2 Struts Eclipse 3 DAO ANSI SQL DB and More With Examplesapi-3696230Încă nu există evaluări

- SN 75114Document11 paginiSN 75114Hector LopezÎncă nu există evaluări

- Karbon MobilesDocument7 paginiKarbon Mobilessac_444kumarÎncă nu există evaluări

- CHRMP Generative AI Sept 2023 1Document19 paginiCHRMP Generative AI Sept 2023 1shajmalikÎncă nu există evaluări

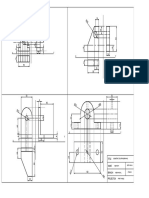

- ISO ORTHO ModelDocument1 paginăISO ORTHO Modelavishal ramÎncă nu există evaluări

- 8251 PciDocument14 pagini8251 PciSoham ChatterjeeÎncă nu există evaluări

- Course Syllabus Data Structures and AlgorithmDocument11 paginiCourse Syllabus Data Structures and AlgorithmCarl GloriosoÎncă nu există evaluări

- HW To HV A Beautiful Mind-Edward de Bono PDFDocument124 paginiHW To HV A Beautiful Mind-Edward de Bono PDFPradeepVemuri100% (1)

- CAE BrochureDocument8 paginiCAE BrochurecimasukÎncă nu există evaluări