Documente Academic

Documente Profesional

Documente Cultură

Baran Eudesmane Syntheses Tetrahedron 2010

Încărcat de

Victor CiocalteaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Baran Eudesmane Syntheses Tetrahedron 2010

Încărcat de

Victor CiocalteaDrepturi de autor:

Formate disponibile

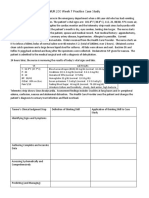

Total synthesis of eudesmane terpenes: cyclase phase

Ke Chen, Yoshihiro Ishihara, Mara Moro n Gala n, Phil S. Baran

*

Department of Chemistry, The Scripps Research Institute, 10550 North Torrey Pines Road, La Jolla, CA 92037, USA

a r t i c l e i n f o

Article history:

Received 16 January 2010

Received in revised form 20 February 2010

Accepted 23 February 2010

Available online 26 February 2010

Dedicated to Professor Brian Stoltz on the

occasion of his receipt of the Tetrahedron

Young Investigator Award

a b s t r a c t

A full account of synthetic efforts toward dihydrojunenol, one of the lowest oxidized members of the

eudesmane family of natural products, is presented. The nal synthetic sequence illustrates a nine-step,

gram-scale, enantioselective route to this bicyclic terpene with excellent stereocontrol and in 21% overall

yield.

2010 Elsevier Ltd. All rights reserved.

1. Introduction

The eudesmanes represent a broad family of sesquiterpenoid

natural products containing approximately 1000 members, many

of which exhibit antifungal, antibacterial, and anticancer activ-

ity.

1

These bicyclic terpenes are characterized by a 2-isopropyl-

4a,8-dimethyldecahydronaphthalene framework, and most of its

members are adorned with a variety of oxidation patterns. In

order to target a variety of members within a class of terpenoid

natural products using a unied synthetic approach, the logic of

a two-phase approach in terpene synthesis was conceived and

demonstrated in the total synthesis of eudesmanes.

2

This design

was inspired by terpene biosynthesis

3

and was executed in two

separate phasesda cyclase phase and an oxidase phase.

4

In the

context of eudesmane total synthesis, four targets were selected

and retrosynthetically traced back to a common precursor bear-

ing a lower oxidation state through the use of a retrosynthetic

pyramid diagram. Thus, dihydrojunenol (1) became the target of

a cyclase phase endpoint, which would then serve as the oxidase

phase starting point toward polyhydroxylated eudesmanes 25

(Fig. 1).

2

In this full account, the evolution of our synthetic

strategy toward 1 is described, culminating in a short, scalable

and enantioselective route to this bicyclic terpene.

Althoughdihydrojunenol (1) was onlyrecentlyisolatedduringthe

study of aroma components of the woody material Bursera graveolens

by Yukawa and co-workers,

5

its structure was reported over 50 years

ago as a result of hydrogenation of another natural product, junenol.

6

Despite its low molecular weight, 1 contains ve contiguous stereo-

centers that pose a challenge for its total synthesis. Consequently,

prior to the communication of this work,

2

it had only been synthe-

sized once in a racemic, stereorandom fashion from farnesol.

7

Semi-

synthesis was the preferred route in the 1960s for the synthesis of 1,

as twosuchroutes weredevisedfromother eudesmane precursors.

6,8

Moreover, 1 could be accessed inone step fromjunenol,

9

and as such,

the three semi-syntheses

6c,10,11

and one racemic total synthesis

12

of

junenol could be considered as being formal syntheses of 1.

13

Early in this program, in order to obtainauthentic samples of 1 for

comparison, we repeated the procedure by Pedro and co-workers,

11

which we had judged to be the most efcient synthesis of either

dihydrojunenol (1) or junenol. Although this nine-step synthesis to-

ward 1 would rely on a natural product as the starting material,

santonin(6) was a relativelycheapandcommerciallyavailable option

(Fig. 2). In our hands, the sequence

9,11

proceeded in 8% overall yield;

along withthe desiredproduct 1, two other isomers 7 and8 were also

obtained and their structures were veried by X-ray crystallography

(crystals obtainedas their p-nitrobenzoyl ester derivatives). Thus, this

route not only provided us with a sample of 1, but also furnished two

valuable stereoisomers that wouldserve as markers for spectroscopic

comparison in our total synthesis endeavors toward 1.

Me

Me

Me

HO

Me

Me

Me

Me

HO HO

Me

2: 4-epi-ajanol

Me

Me

Me

HO

Me

HO

3: dihydroxyeudesmane

(structure reassigned)

1: dihydrojunenol

4: pygmol

Me

Me

Me

HO HO

Me

HO

Me

OH

HO HO

Me

Me

OH

5: eudesmantetraol

"oxidase

phase"

Figure 1. Dihydrojunenol (1), its X-ray structure and the eudesmane family of

terpenes.

* Corresponding author. Tel.: 1 858 784 7373; fax: 1 858 784 7375; e-mail

address: pbaran@scripps.edu (P.S. Baran).

Contents lists available at ScienceDirect

Tetrahedron

j ournal homepage: www. el sevi er. com/ l ocat e/ t et

0040-4020/$ see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.tet.2010.02.088

Tetrahedron 66 (2010) 47384744

2. Results and discussion

2.1. Initial synthetic strategy

Early forays toward the synthesis of dihydrojunenol (1) were

conducted according to a retrosynthetic blueprint that simplied

the target back to commercially available piperitone (dehy-

dromenthone, 9; Fig. 3a). This monocyclic enone can be procured

in both enantiomeric forms and could, in principle, lead to the

desired eudesmane skeleton in as few as three steps:

(1) Substrate-controlled diastereoselective conjugate addition

onto C10; (2) C4C5 bond formation; and (3) net reduction to

forge the stereotriad C4C5C6 (eudesmane numbering,

1

Fig. 3a).

Although such a synthesis would rely entirely on a chiral pool

source, this attractive three-step route would render the pro-

duction of 1 highly efcient and scalable. To this end, alkene- and

alkyne-bearing conjugate addition products were prepared, as

well as some of their derivatives (Fig. 3b). To our dismay, the

desired C4C5 bond-forming reactions did not proceed in our

hands to generate the desired decalin framework, most likely due

to the steric congestion imposed by the adjacent quaternary

center (C10). At this juncture, we devised an alternative strategy

that delayed the introduction of the C14 methyl group until after

the C4C5 bond formation.

O

O

O

Me

Me

Me

HO

Me

Me

Me

Me

HO

Me

Me

Me

Me

HO

Me

(refs 9,11)

6

1 7 8

9 steps, 8%

overall yield

Figure 2. Previously reported semi-synthesis of dihydrojunenol (1) from santonin (6).

9,11

O Me

Me

Me

O Me

Me

Me

O Me

Me

Me

N

2

ML

n

O Me

Me

Me

ML

n

= Rh

2

(OAc)

4

; Rh

2

(OCt)

4

; Rh

2

(cap)

4

; Cu(OTf)

2

O Me

Me

Me

R

Conditions

O Me

Me

Me

Conditions: Pd(CH

3

CN)

2

Cl

2

, TMSCl;

Pd(CH

3

CN)

2

Cl

2

,

Yb(OTf)

3

; MW, 200

C

R = CO

2

Et

O Me

Me

Me

O Me

Me

Me

[O] = I

2

; Cu(2-ethylhexanoate)

2

; K

3

Fe(CN)

6

; Cp

2

FePF

6

a) LHMDS

b) [O]

O Me

Me

Me

O Me

Me

Me

Br R

Me

Conditions: (nBu

3

Sn)

2

; AIBN, nBu

3

SnH

Me OH Me

Me

Me

H

1

b

OR Me

Me

Me

Conditions

O Me

Me

Me

Conditions: MW, 200 C; HgCl

2

, then NaI; AuCl; AuCl

3

;

Au[N(SO

2

CF

3

)

2

]PPh

3

; AuClPPh

3

;

Au(OTf)PPh

3

; AgOTf

R = TMS;

TBS; TIPS

OR Me

Me

Me

O Me

Me

Me

R

Conditions

R = TMS;

TBS; TIPS

Conditions: MW, 200 C; Cu(OAc)

2

; Mn(OAc)

3

; Pd(OAc)

2

;

Pd(CH

3

CN)

2

Cl

2

, benzoquinone;

Pd(OAc)

2

, O

2

; Pd(OAc)

2

, NH

4

HCO

2

Conditions

O Me

Me

Me

M

+

1

10

11

2

3

4

5

6

7

8

9

12

13

14

15

9

M = metal

10

5

6

7

8

9

4

5

6 4

5

6

a

Figure 3. (a) Initial strategy to generate the decalin skeleton; (b) selected approaches.

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4739

2.2. Revised strategy and racemic synthesis

Equipped with the knowledge garnered from failed approaches,

a revised synthetic strategy was conceived (Fig. 4). Retrosyntheti-

cally, net oxidation and C14 methyl group excision from 1 would

lead to dienone 10. With the all-carbon quaternary center at C10 no

longer present, 10 could be disconnected at the C4C5 linkage via

retro-Heck coupling to evoke the monocyclic enone 11. This enone

could then be thought to arise from 2-iodocryptone (13) by

a Grignard addition followed by a Dauben carbonyl transposition.

14

Finally, 13 could be generated from isovaleraldehyde and methyl

vinyl ketone through the well-known Robinson annulation,

followed by an electrophilic iodination.

In the forward direction, methyl vinyl ketone and iso-

valeraldehyde were mixed together in the presence of 20 mol %

(diethylamino)trimethylsilane

15

to generate racemic 2-isopropyl-

5-oxohexanal (14) in 62% yield (Fig. 5a). This known Michael

addition product

16,17

was then treated with base under phase-

transfer conditions

18

to afford racemic cryptone (15) in 87% yield.

An efcient synthesis of 15 has been a long-standing problem, since

it is a useful building block for the construction of various natural

products; although more than a dozen other methods for cryptone

synthesis are known, most of them require more than two steps

and are less efcient, or generate olen-transposed side products

that are difcult to remove.

19,20

This enone procured in multigram

quantities was then iodinated at the a-position in near-quantitative

yield to install a functional group handle that would later become

useful for CC bond formation (Fig. 5b). Iodocryptone 13 thus

generated was further subjected to a two-step alkylative carbonyl

transposition,

14

consisting of pentenylmagnesium bromide addi-

tion followed by PCC oxidation. It is of note here that an unexpected

solvent effect was observed during the Grignard addition, in which

the use of THF or ether led to low (<20%) yields whereas toluene

allowed efcient formation (>75%) of 12 as an inconsequential

mixture of diastereomers. PCC oxidation of this mixture sub-

sequently allowed smooth transformation into the desired mono-

cyclic enone 11 (74% over two steps).

The installation of the necessary functional group handles pro-

vided the opportune moment to forge the previously problematic

C4C5 linkage. Without an adjacent quaternary center hindering

the site of reaction, 11 smoothly underwent intramolecular ring

closure under standard Heck conditions (using catalytic Pd(OAc)

2

and PPh

3

) to generate bicyclic dienone 10 in 74% yield (Fig. 5b). It is

of note that these preliminary reaction conditions gave way to ca.

20% of a 7-endo side product (16). Substituting Pd(OAc)

2

by

Pd

2

(dba)

3

eliminated this side product but did not signicantly

increase the reaction yield; however, the use of a stoichiometric

Ag

2

CO

3

additive

21

improved the formation of 10 to 95% yield. Ac-

cess to bicyclic dienone 10 was thus achieved in short order (six

steps) from cheap (<1 $/g) starting materials in multigram

quantities.

At this point in time, all that separated dienone 10 from the

desired natural product 1 were one methyl group addition and two

strategic reductions, which would set four stereocenters overall.

The remaining C14 methyl group was introduced via copper-

mediated conjugate addition; however, this initially failed to give

product when MeMgBr and CuI were employed (Fig. 6, entry 1).

Substituting the active metal species to Me

2

CuLi in ether allowed

a diastereoselective 1,4-addition to proceed, albeit in abysmal yield.

Employing Me

3

SiCl as an additive

22

improved the reaction yield to

62%, but resulted in a 1:3 mixture of C10 epimers 17 and 18, fa-

voring the undesired stereoisomer 18 (entry 3). Modifying the re-

action medium to toluene surprisingly shut down the reaction

completely, whereas dichloromethane proved to be the solvent of

choice, improving the combined yield to 78% (33% of 17 and 45% of

18). When Me

3

SiCl was eliminated in a control experiment (entry

6), the product ratio drastically changed, providing the 1,4-addition

products as a 3:1 ratio of 17 to 18 in 73% combined yield (with 17%

recovered starting material). These reaction conditions were

eventually adopted as the optimal conditions. Performing this same

reaction at a higher temperature for a shorter amount of time yet

again altered reaction yields, but in unfavorable fashion (entry 7:

44% of 17 and 38% of 18).

OH Me

Me

Me

Me O Me

Me

O Me

Me

I

Me

Me

I

OH

Me

Me

I

O

MgBr O

Me

O Me

Me

10

H

1 11

13 12

Figure 4. Revised strategy to construct the decalin skeleton.

Me

Me

OH

I

O Me

Me

I

O Me

Me

MgBr

Conditions B

I

2

, pyr

(99%) Conditions A

PCC, DCM

3

Me

Me

O

I

Entry Conditions A

a

Yield (%)

1

2

3

4

THF (0.1 M), -78 C, 4 h

a. The Grignard reagent was prepared

as a 0.7 M ether solution; b.

Conversion was low; c. The yield was

based on two steps (after PCC

oxidation).

Et

2

O (0.1 M), -78 C, 2 h

PhMe (0.1 M), -78 C, 4 h

PhMe (0.1 M), -78 C for

30 min; 0 C for 30 min

trace

20

5

b

74

c

Entry Conditions B

d

Yield (%)

1

2

3

Pd(OAc)

2

, PPh

3

, Et

3

N, DMF

d. 0.1 equiv. of Pd(OAc)

2

and 0.3 equiv.

of PPh

3

(or 0.1 equiv. Pd

2

(dba)

3

) were

used, along with 1.2 equiv. of Et

3

N; e. ca.

20% of 16 was obtained.

Pd

2

(dba)

3

, Et

3

N, PhMe

Pd(OAc)

2

, Ag

2

CO

3

(1.0 equiv.),

PPh

3

, Et

3

N, MeCN

74

e

80

95

Me

Me

O

Me

Me

O

Me O

Me

Me

O

O

Et

2

NTMS

MeCN

nBu

4

NOH, KOH

THF/Et

2

O/H

2

O

O

62% 87%

a

b

14 15

15 13 12

16 10 11

Figure 5. (a) Synthesis of racemic cryptone (15); (b) preparation of dienone 10.

O Me

Me

Me O Me

Me

Me

Me O Me

Me

Me

Conditions

Entry Conditions Yield of 17 (%)

1

2

3

4

MeMgBr (2.5 equiv.), CuI (2.5 equiv.), THF (0.1 M), 0 C, 1 h

a. Low conversion; b. Yield of the C10-epimer 18; c. 17% recovered 10 was also obtained.

Me

2

CuLi (0.5 M in Et

2

O, 1.5 equiv.), Et

2

O (0.1 M), 0 C, 2 h

Me

2

CuLi (as entry 2), TMSCl (5.0 equiv), Et

2

O (0.1 M), 0 C, 2 h

Me

2

CuLi (as entry 2), TMSCl (5.0 equiv), toluene (0.1 M), 0 C, 2 h

trace

a

10

a

17 (+ 45

b

)

trace

a

then

aqueous

work-up

5 Me

2

CuLi (as entry 2), TMSCl (5.0 equiv), DCM (0.1 M), 0 C, 2 h 33 (+ 45

b

)

6 Me

2

CuLi (as entry 2), DCM (0.1 M), 0 C, 4 h 56 (+17

b

)

c

7 Me

2

CuLi (as entry 2), DCM (0.1 M), RT, 1 h 44 (+ 38

b

)

10 18 17

+

10 10

14 14

Figure 6. Installation of the C14 methyl group.

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4740

With ample quantities of bicyclic enone 17 in hand, all that was

required to generate dihydrojunenol (1) was to forge three con-

tiguous stereocenters via two net reductions. Although one-step

simultaneous reductions of C]C and C]O bonds in enones are

known, many require harsh conditions such as high-pressure hy-

drogenation

23

or strong electroreduction,

24

and is otherwise non-

selective.

25

Furthermore, the necessity for dihydrogen to add to 17

from the a-face of the C]C bond but from the b-face of the C]O

bond precluded the use of hydrogenation as a means for one-step

double reduction. Ultimately, we resorted to a known two-step

reduction strategy

8

that hydrogenated the olen rst, followed by

a dissolving metal reduction (Fig. 7). Hydrogenation over Pd on

carbon set the stereocenters at C4 and C5, and without isolation,

the resulting ketone was treated with sodium in ethanol, yielding 1

stereoselectively (only a single isomer was observed) in 87% yield

over two steps. The eudesmane thus obtained in nine steps and in

19% overall yield was in excellent spectroscopic agreement with

that reported in the literature.

5

2.3. Enantioselective synthesis

With a short, robust synthesis of racemic 1 in hand, an enan-

tioselective route was sought. Since the synthesis was designed in

such a way that chiral information from the isopropyl-bearing C7

stereocenter is propagated onto the remaining four stereocenters of

the bicyclic molecule, all that was required was the enantioselective

formation of cryptone (15), and in turn, that of the keto-aldehyde

14 (vide supra). Examples of enantioselective Michael additions

26

onto methyl vinyl ketone

17

are known, which even encompassed

our specic substrate.

17c,d

Thus, diphenylprolinol methyl ether 19

27

was used in catalytic quantities (5 mol %) to generate the Michael

adduct 14 in 89% yield and in 9295% ee (Fig. 8). However, this

straightforward enantioselective addition was followed by a chal-

lenging transformation, in which aldol condensation was required

to occur without epimerizing the newly formed stereocenter.

Conditions previously employed upon racemic 14 (see Fig. 5a)

resulted in partial epimerization, thus reducing the enantiopurity

to 56% ee. The use of pyridine at room temperature did not effect

any conversion, whereas the use of LDA or silica gel resulted in

decomposition of 14 (Fig. 8, entries 3 and 4). Assuming that the

thermodynamic conditions required for dehydration were the

cause of loss in enantiopurity, milder two-step procedures for aldol

addition and dehydration were attempted. However, this triggered

losses in bothyield and in enantiopurity (entries 5 and 6). Intrigued

by Chakrabortis report on the use of catalytic LiOH as an efcient

base for ClaisenSchmidt condensations,

28

we became interested

in similar reaction conditions. Thus, addition of 10 mol % LiOH in

THFH

2

O at 0

C, followed by in situ mesylation and elimination,

resulted in a gratifying 78% yield and a retention of 74% ee (entry 7).

Further investigation revealed that a solvent change to methanol

increases the enantiopurity of 15, and this solvent effect could

perhaps be explained by the formation of a lithiumalkoxide species

that serves to deprotonate at the terminal methyl (C5) position

rather than at the more hindered C7 position. Following this logic,

a more bulky alcohol such as 2-propanol was employed, and this

signicantly mitigated the loss of enantiopurity due to epimeriza-

tion (entry 9). In addition, these new conditions obviated the need

for ensuing mesylation and elimination steps, due to the increased

basicity of the active lithium alkoxide species. Consequently, an

asymmetric synthesis of cryptone (15) was achieved in two steps, in

63% overall and in 89% ee, which proved to be superior to previous

syntheses

19

of this simple terpene. Furthermore, this asymmetric

synthesis of 15 fared better than our own racemic counterpart (54%

over two steps; see Fig. 5a). With enantioenriched 15 in hand, the

same synthetic sequence as the racemic synthesis was carried out

(vide supra), resulting in a gram-scale enantioselective total syn-

thesis of dihydrojunenol (1) in nine steps and in 21% overall yield.

3. Conclusion and strategic perspective

In summary, a full account of synthetic efforts toward dihy-

drojunenol (1) has been presented. Failed attempts at forging a CC

bond adjacent to an all-carbon quaternary center have led to a re-

vised route that coupled together simple starting materials, methyl

vinyl ketone and isovaleraldehyde, in enantioselective fashion. Key

steps toward the synthesis of 1 involved an efcient, intramolecular

Heck coupling followed by a copper-mediated conjugate addition

that proceeded with excellent diastereoselectivity. This chemistry

has thus enabled the rst enantioselective total synthesis of 1 in

21% overall yield (Fig. 9). Moreover, this protecting group-free,

nine-step route resulted in a gram-scale preparation of 1, which

allowed for the generation of ample quantities of this bicyclic ter-

pene required for its subsequent use as a starting material in

a systematic exploration of CH oxidation chemistry.

2

The efciency with which the total synthesis of a representative

eudesmane, dihydrojunenol (1), was completed is partly due to the

low oxidation state of the target, which was an intended feature of

this study. Since there is only one heteroatom present in the target

1, protecting group chemistry is destined to be relinquished or, at

the very least, minimized.

29

A great variety of chemistry can be

employed without fear for side reactions, including the use of harsh

organometallic reagents. As demonstrated here, the mere choosing

of a judicious retrosynthetic intermediate (such as 1 in the prepa-

ration of targets 25) can free one fromchemoselectivity issues

30

in

Me O Me

Me

1) Pd/C, H

2

2) Na, EtOH

Me OH Me

Me

Me

H

1

Me

17

(87% overall)

4

5

6

Figure 7. Stereoselective reductions and completion of dihydrojunenol.

8

N/A

a

N/A

b

O

Me

O

Me

Me

N

H OMe

Ph

Ph

(5 mol%)

4 C, 36 h, 89%

92-95% ee

Me

O

Me Me

O

O

Me Me

Conditions

O

Me Me

HO

Entry Conditions Yield (%); ee (%)

1

2

3

4

DBU (1 equiv.), DCM, rt, 1 h; MsCl (5 equiv.), Et

3

N (10 equiv.), rt, 1 h

a. No reaction; b. Decomposition of 14.

TBAF (0.5 equiv.), CH

3

CN, rt, 2 h; then MsCl, Et

3

N (as Entry 5)

nBu

4

NOH, KOH, THF/Et

2

O/H

2

O, 50 C, 30 min

pyridine, rt, 12 h

75; 34

34; 0

87; 56

5

LDA (1.0 equiv.), -78 C, 30 min

6

silica gel (5% v/v), 50 C, 12 h N/A

b

7 LiOH (0.1 equiv.), THF/H

2

O (3:1), 0 C, 30 min; then MsCl, Et

3

N (as Entry 5) 78; 74

8 LiOH (0.1 equiv.), MeOH, 0 C, 30 min; then MsCl, Et

3

N (as Entry 5) 71; 80

9 LiOH (0.1 equiv.), iPrOH, rt, 24 h 71; 89

(S)-14 (S)-15

(S)-19

5

5

6 6

7 7

Figure 8. Enantioselective Michael addition and generation of enantioenriched cryp-

tone (15).

Me

O

O

Me

Me

Me OH Me

Me

Me

H

nine steps

21% overall yield

gram-scale

enantioselective

protecting group-free

1

Figure 9. Summary of the approach.

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4741

terpene synthesis. Finally, the synthesis outlined herein facilitates

an adherence to the principles of redox economy,

31

since the in-

stallation of functional groups, which is commonly plagued by

superuous redox manipulations, is practically unnecessary in 1.

4. Experimental section

4.1. General

All reactions were carried out under a nitrogen atmosphere with

dry solvents using anhydrous conditions unless otherwise stated.

Dry tetrahydrofuran (THF), diethyl ether (Et

2

O), dichloromethane

(DCM), toluene, methanol (MeOH), acetonitrile (MeCN), N,N-dime-

thylformamide (DMF), and triethylamine (Et

3

N) were obtained by

passing these previously degassed solvents through activated alu-

mina columns. Reagents were purchased at the highest commercial

quality and used without further purication, unless otherwise

stated. Yields refer to chromatographically and spectroscopically (

1

H

NMR) homogeneous materials, unless otherwise stated. Reactions

were monitored by thin layer chromatography (TLC) carried out on

0.25 mm E. Merck silica gel plates (60F-254) using UV light as the

visualizing agent and an acidic mixture of anisaldehyde, phospho-

molybdic acid, ceric ammonium molybdate, or basic aqueous

potassium permangante (KMnO

4

), and heat as developing agents. E.

Merck silica gel (60, particle size 0.0430.063 mm) was used for ash

column chromatography. Preparative thin layer chromatography

(PTLC) separations were carried out on 0.25 or 0.5 mmE. Merck silica

gel plates (60F-254). NMR spectra were recorded on Bruker DRX-

600, DRX-500, and AMX-400 or Varian Inova-400 instruments and

calibrated using residual undeuterated solvent as an internal refer-

ence (CHCl

3

at 7.26 ppm in

1

H NMR; 77.0 ppm in

13

C NMR). The

following abbreviations (or combinations thereof) were used to ex-

plain the multiplicities: ssinglet, ddoublet, ttriplet, qquartet,

mmultiplet, brbroad. High-resolution mass spectra (HRMS) were

recorded on Agilent LC/MSD TOF time-of-ight mass spectrometer

by electrospray ionization time-of-ight reectron experiments. IR

spectra were recorded on a Perkin-Elmer Spectrum BX FTIR spec-

trometer. Melting points were recorded on a Fisher-Johns 12-144

melting point apparatus. Optical rotations were obtained on

a Perkin-Elmer 431 Polarimeter.

4.1.1. (rac)-2-Isopropyl-5-oxohexanal (14). In a ame-dried round-

bottom ask, a mixture of freshly distilled isovaleraldehyde

(20.0 mL, 0.18 mol, 1.0 equiv) and (diethylamino)trimethylsilane

(6.9 mL, 0.037 mmol, 0.2 equiv) in MeCN (600 mL) was cooled to

0

C. Freshly distilled methyl vinyl ketone (22.5 mL, 0.28 mol,

1.5 equiv) was added, and the resulting yellow, homogeneous so-

lution was heated at reux under nitrogen for 36 h. The crude

mixture was cooled to room temperature and concentrated in

vacuo, upon which the resulting thick oil was puried by column

chromatography (silica gel, gradient from 10:1 to 1:1 hexanes/

EtOAc) to provide (rac)-14 (17.8 g, 62%), whose spectroscopic data

was identical to previous reports.

15a,16

4.1.2. (S)-2-Isopropyl-5-oxohexanal (14). In a ame-dried round-

bottomask, a mixture of freshly distilled isovaleraldehyde (8.1 mL,

74.8 mmol, 1.0 equiv), prolinol catalyst (S)-19

27

(1.01 g, 3.74 mmol,

0.05 equiv), and co-catalyst ethyl 3,4-dihydroxybenzoate (2.73 g,

15.0 mmol, 0.20 equiv) was cooled to 0

C. Freshly distilled methyl

vinyl ketone (9.1 mL, 112.2 mmol, 1.5 equiv) was then added, and

the resulting brown, homogeneous solution was stirred under ni-

trogen at 4

C for 36 h. The crude material was puried by column

chromatography (silica gel, gradient from 10:1 to 1:1 hexanes/

EtOAc) to provide (S)-14 (10.3 g, 89%), whose spectroscopic data

was identical to the previous report.

15a,16

[Note: This compound

was prepared by following the reported procedure without further

optimization. The enantiomeric excess (9295%) was determined

by

1

H NMR analysis of the corresponding L-valine methyl ester

imine

32

].

4.1.3. (rac)-4-Isopropylcyclohex-2-enone (15). A solution of (rac)-14

(0.50 g, 3.3 mmol, 1.0 equiv) in Et

2

O (30 mL) and THF (10 mL) was

stirred at room temperature. To this solution was added aqueous

KOH solution (30 mL, 0.1 N) and nBu

4

NOH (0.52 mL, 40% aq) in one

portion. The mixture was heated to reux for 3 h before cooling to

room temperature. Et

2

O (50 mL) was then added and the layers

were separated. The aqueous layer was extracted with Et

2

O

(250 mL) and the combined organic layers were dried over

MgSO

4

, ltered, and concentrated in vacuo. Flash chromatography

(silica gel, gradient from 10:1 to 5:1 hexanes/Et

2

O) yielded cryp-

tone, (rac)-15, as a colorless oil (0.39 g, 87%), and its spectroscopic

data was identical to previous reports.

19

4.1.4. (S)-4-Isopropylcyclohex-2-enone (15). A solution of (S)-14

(2.21 g, 14.1 mmol, 1.0 equiv) in 2-propanol (47 mL, 0.3 M) was

stirred at room temperature, upon which LiOH (33.7 mg, 1.4 mmol,

0.10 equiv) was added in one portion. After stirring for 24 h, the

reaction was quenched with saturated aqueous NH

4

Cl (100 mL).

EtOAc (100 mL) was added and the layers were separated. The

aqueous layer was extracted with EtOAc (2100 mL) and the

combined organic layers were dried over MgSO

4

, ltered, and

concentrated in vacuo. Flash chromatography (silica gel, gradient

from 10:1 to 5:1 hexanes/Et

2

O) yielded cryptone, (S)-15, as a col-

orless oil (1.38 g, 71%), whose spectroscopic data was identical to

previous reports.

19

The enantiomeric excess (89%) was determined

by chiral HPLC [AD-H, 2% isopropanol in hexanes, 0.5 mL/min, t

r

12.373 min (major), 13.687 min (minor)].

4.1.5. (S)-2-Iodo-4-isopropylcyclohex-2-enone (13). To a solution of

compound (S)-15 (9.05 g, 65.4 mmol, 1.0 equiv) in DCM (80 mL)

and pyridine (80 mL) at 0

C, iodine (19.9 g, 78.5 mmol, 1.2 equiv)

was added in ve portions over 10 min. After stirring at room

temperature for 12 h, the brown solution was poured into satu-

rated aqueous Na

2

S

2

O

3

(150 mL) and Et

2

O (500 mL). The layers

were separated and the organic phase was washed with aqueous

HCl solution (1 N, 2300 mL), dried over MgSO

4

, ltered, and

concentrated in vacuo. The crude material was ltered through

a short silica plug eluting with DCM to provide 13 as a yellow oil

(17.3 g, 99%). R

f

0.5 (silica gel, 9:1 hexanes/EtOAc); [a]

23

D

26.4

(c 2.19, DCM); IR (lm) n

max

2954, 2358, 1687, 1582, 1322,

1154 cm

1

;

1

H NMR (500 MHz, CDCl

3

) d 7.67 (s, 1H), 2.78 (dt,

J16.5, 3.9 Hz, 1H), 2.412.51 (m, 2H), 2.032.06 (m, 1H),

1.781.85 (m, 2H), 0.97 (d, J7.0 Hz, 3H), 0.95 (d, J7.0 Hz, 3H);

13

C NMR (125 MHz, CDCl

3

) d 192.3, 163.2, 103.9, 47.0, 36.2, 31.4,

25.2, 19.6, 19.4; HRMS (ESI) calcd for C

9

H

13

IO [MNa]

286.9909,

found 286.9906.

4.1.6. (S)-2-Iodo-6-isopropyl-3-(pent-4-enyl)cyclohex-2-enone

(11). In a ame-dried round-bottom ask charged with argon,

iodocryptone 13 (6.04 g, 22.9 mmol, 1.0 equiv) was dissolved in

toluene (229 mL, 0.1 M) at 78

C. A solution of freshly prepared

Grignard reagent in Et

2

O (0.7 M, 49 mL, 1.5 equiv) was added over

5 min. The resulting solution was stirred at 78

C for 30 min and

then the dry-ice bath was replaced with an ice bath. Stirring was

continued for an additional 30 min at 0

C before saturated aqueous

NH

4

Cl (300 mL) was added. The layers were separated and the

aqueous layer was extracted with Et

2

O (2100 mL). The combined

organic layers were washed with brine (50 mL), dried over MgSO

4

,

ltered, and concentrated in vacuo. The crude alcohol thus

obtained (ca. 22 mmol) was then dissolved in DCM (110 mL, 0.2 M).

Molecular sieves (3 , 20 g) and PCC (5.90 g, 27.5 mmol, 1.2 equiv)

were added and the resulting brown mixture was stirred at room

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4742

temperature for 6 h. The dark reaction mixture was then ltered

through a short silica plug eluting with DCM to provide 11 as

a colorless oil (5.64 g, 74% over two steps). R

f

0.4 (silica gel, 1:1

hexanes/DCM); [a]

23

D

26.3 (c 1.14, DCM); IR (lm) n

max

2958, 2356,

1829, 1675, 1587, 1559, 1458, 1158, 911 cm

1

;

1

H NMR (500 MHz,

CDCl

3

) d 5.805.86 (m, 1H), 5.05 (dd, J17.1, 1.5 Hz, 1H), 5.02 (d,

J10.2 Hz, 1H), 2.582.63 (m, 1H), 2.452.52 (m, 3H), 2.352.41 (m,

1H), 2.252.28 (m, 1H), 2.142.17 (m, 2H), 1.941.99 (m, 1H), 1.76

1.82 (m, 1H), 1.581.64 (m, 2H), 0.94 (d, J7.0 Hz, 3H), 0.85 (d,

J6.8 Hz, 3H);

13

C NMR (125 MHz, CDCl

3

) d 194.2, 168.2, 137.9, 115.6,

107.8, 52.1, 44.1, 33.7, 32.0, 27.0, 26.4, 22.9, 20.8, 18.6; HRMS (ESI)

calcd for C

14

H

21

IO [MNa]

355.0535, found 355.0532.

4.1.7. (S)-2-Isopropyl-8-methylene-3,4,5,6,7,8-hexahydronaph-

thalen-1(2H)-one (10). Monocyclic enone 11 (3.43 g, 10.3 mmol,

1.0 equiv), triphenyl phosphine (0.81 g, 3.1 mmol, 0.3 equiv), sil-

ver carbonate (2.84 g, 10.3 mmol, 1.0 equiv), and Et

3

N (1.71 mL,

12.3 mmol, 1.2 equiv) were added to MeCN (100 mL, 0.1 M) and

the resulting mixture was thoroughly degassed with argon. Pal-

ladium (II) acetate (0.23 g, 1.03 mmol, 0.1 equiv) was then added.

The reaction mixture was heated to 70

C, and the homogenous,

brown solution was stirred for 3 h under argon before being

cooled back to room temperature. Aqueous HCl solution (1 N,

300 mL) was then added and the mixture was extracted with Et

2

O

(3100 mL). The combined organic layers were washed with brine

(100 mL), dried over MgSO

4

, ltered, and concentrated in vacuo.

The crude mixture was puried by column chromatography (silica

gel, gradient from 4:1 to 1:2 hexanes/DCM) to provide compound

10 as a colorless oil (2.02 g, 95%). R

f

0.5 (silica gel, DCM); [a]

23

D

9.4 (c 0.32, DCM); IR (lm) n

max

2932, 1675, 1384, 1192 cm

1

;

1

H

NMR (500 MHz, CDCl

3

) d 5.77 (br s, 1H), 5.04 (br s, 1H), 2.282.36

(m, 7H), 2.082.12 (m, 1H), 1.961.98 (m, 1H), 1.731.83 (m, 3H),

0.93 (d, J6.9 Hz, 3H), 0.88 (d, J6.8 Hz, 3H);

13

C NMR (125 MHz,

CDCl

3

) d 201.2, 156.7, 138.3, 130.9, 113.5, 54.2, 34.5, 32.9, 30.8, 26.6,

23.0, 22.9, 21.1, 19.0; HRMS (ESI) calcd for C

14

H

20

O [MNa]

227.1412, found 227.1408.

4.1.8. (2S,4aR)-2-Isopropyl-4a,8-dimethyl-3,4,4a,5,6,7-hexahy-

dronaphthalen-1(2H)-one (17). In a ame-dried round-bottom

ask charged with argon, a solution of 10 (1.97 g, 9.6 mmol,

1.0 equiv) in DCM (96 mL, 0.1 M) was cooled to 0

C. A freshly

prepared Et

2

O solution of lithium dimethylcuprate

33

(0.50 M,

29 ml, 1.5 equiv) was added in one portion. The reaction mixture

was stirred for 4 h before being quenched with saturated aqueous

NH

4

Cl (100 mL). The mixture was extracted with Et

2

O (3200 mL),

and then the combined organic layers were washed with brine

(50 mL), dried over MgSO

4

, ltered, and concentrated in vacuo. The

crude material was puried by column chromatography (silica gel,

gradient from 4:1 to 1:1 hexanes/DCM). The rst fraction provided

the desired compound 17 (1.21 g, 56%). R

f

0.5 (silica gel, DCM); [a]

23

D

106 (c 0.22, DCM); IR (lm) n

max

2931, 2358, 2341, 1684, 1653,

1540, 1457, 1106 cm

1

;

1

H NMR (500 MHz, CDCl

3

) d 2.282.36 (m,

1H), 2.082.12 (m, 1H), 1.992.02 (m, 2H), 1.861.91 (m, 1H), 1.68 (s,

3H), 1.541.75 (m, 6H), 1.361.42 (m, 1H), 0.94 (s, 3H), 0.94 (d,

J6.4 Hz, 3H), 0.89 (d, J6.8 Hz, 3H);

13

C NMR (125 MHz, CDCl

3

)

d 207.7, 140.3, 136.6, 57.8, 40.5, 38.6, 38.3, 33.1, 25.9, 25.3, 21.9, 21.2,

21.1, 18.6, 18.3; HRMS (ESI) calcd for C

15

H

24

O [MNa]

243.1725,

found 243.1715. A more polar fraction afforded recovered starting

material 10 as a colorless oil (334.2 mg, 17%), and a third fraction

consisted of the other diastereomer (2S,4aS)-2-isopropyl-4a,8-di-

methyl-3,4,4a,5,6,7-hexahydronaphthalen-1(2H)-one (18) as a color-

less oil (356.3 mg, 17%). R

f

0.34 (silica gel, DCM); IR (lm) n

max

2946, 2368, 2341, 1684, 1657, 1540, 1163 cm

1

;

1

H NMR (500 MHz,

CDCl

3

) d 1.852.06 (m, 6H), 1.74 (s, 3H), 1.601.72 (m, 3H), 1.541.58

(m, 1H), 1.381.46 (m, 2H), 1.00 (s, 3H), 0.91 (d, J6.2 Hz, 3H), 0.87

(d, J6.2 Hz, 3H);

13

C NMR (125 MHz, CDCl

3

) d 210.7, 139.1, 138.1,

58.6, 38.5, 38.2, 36.0, 33.0, 27.5, 26.3, 23.1, 21.7, 21.1, 20.1, 18.5;

HRMS (ESI) calcd for C

15

H

24

O [MNa]

243.1725, found 243.1719.

4.1.9. Dihydrojunenol (1). Under a blanket of hydrogen gas (1 atm),

a solution of 17 (1.21 g, 5.5 mmol, 1.0 equiv) in EtOAc (55 mL, 0.1 M)

was stirred with palladiumon carbon (0.51 g, 0.55 mmol, 0.1 equiv)

at room temperature for 30 min. The reaction mixture was ltered

through a plug of silica gel topped with Celite (EtOAc elution) to

provide a saturated ketone (ca. 1.4 g). Without further purication,

this ketone was dissolved in anhydrous ethanol (55 mL, 0.1 M)

under argon. Sodium (0.64 g, 27.5 mmol, 5.0 equiv) was added in

ve portions and the reaction mixture was stirred at room tem-

perature for 30 min before being quenched with saturated aqueous

NH

4

Cl solution (50 mL). The quenched mixture was then extracted

with Et

2

O (3100 mL), and the combined organic layers were

washed with brine (50 mL), dried over MgSO

4

, ltered, and con-

centrated in vacuo. The crude material was puried by ltering

through a plug of silica gel (Et

2

O elution) to provide dihydrojunenol

(1) as a colorless oil that slowly solidied at room temperature

(1.07 g, 87% over two steps). This natural product had spectroscopic

data identical to the previous report.

5

R

f

0.50 (silica gel, DCM); [a]

23

D

0 (c 0.70, DCM); lit.

5

0 (c 1.01, CHCl

3

); IR (lm) n

max

3261, 2930, 1472,

1345, 1160 cm

1

;

1

H NMR (500 MHz, CDCl

3

) d 3.52 (dt, J5.4,

10.1 Hz, 1H), 2.182.25 (m, 2H), 1.601.66 (m, 2H), 1.411.49 (m,

2H), 1.341.39 (m, 2H), 1.201.32 (m, 3H), 1.031.16 (m, 4H), 0.97 (d,

J7.5 Hz, 3H), 0.93 (d, J7.0 Hz, 3H), 0.89 (s, 3H), 0.86 (d, J6.9 Hz,

3H);

13

C NMR (125 MHz, CDCl

3

) d 69.4, 53.7, 51.9, 44.2, 42.2, 35.0,

33.5, 27.0, 26.5, 21.3, 20.8, 19.0, 17.3, 16.4, 14.7; HRMS (ESI) calcd for

C

15

H

28

O [MNa]

247.2038, found 247.2038.

4.2. X-ray crystallographic data

Crystallographic data for 1, and for the p-nitrobenzoyl ester de-

rivatives of 7 and 8 have been deposited with the Cambridge Crys-

tallographic Data Centre. Copies of the data can be obtained free of

charge from http://www.ccdc.cam.ac.uk/products/csd/request/

(CCDC #743414 for 1, 766068 for the p-nitrobenzoyl ester derivative

of 7, and 766069 for the p-nitrobenzoyl ester derivative of 8).

Acknowledgements

We thank Dr. D.-H. Huang and Dr. L. Pasternack for NMR spec-

troscopic assistance, Dr. G. Siuzdak for mass spectrometric and Dr.

A. Rheingold (UCSD) for X-ray crystallographic assistance. Financial

support for this work was provided by The Scripps Research In-

stitute and Bristol-Myers Squibb.

References and notes

1. Wu, Q.-X.; Shi, Y.-P.; Jia, Z.-J. Nat. Prod. Rep. 2006, 23, 699734.

2. Chen, K.; Baran, P. S. Nature 2009, 459, 824828.

3. Davis, E. M.; Croteau, R. Top. Curr. Chem. 2000, 209, 5395.

4. Maimone, T. J.; Baran, P. S. Nature Chem. Bio. 2007, 3, 396407.

5. Yukawa, C.; Iwabuchi, H.; Komemushi, S.; Sawabe, A. J. Oleo. Sci. 2004, 53,

343348.

6. For an isolation of junenol and synthesis of dihydrojunenol from junenol, see:

(a) Motl, O.; Herout, V.; Sorm, F. Chemicke listy 1956, 50, 12821288; (b)

Bhattacharyya, S. C.; Rao, A. S.; Shaligram, A. M. Chem. Ind. 1960, 469470; (c)

Shaligram, A. M.; Rao, A. S.; Bhattacharyya, S. C. Tetrahedron 1962, 18, 969977.

7. For an 8-step racemic total synthesis toward dihydrojunenol and a 9-step

synthesis toward junenol, see: Schwartz, M. A.; Crowell, J. D.; Musser, J. H. J. Am.

Chem. Soc. 1972, 94, 43614363.

8. For a 7-step semi-synthesis of dihydrojunenol starting from another eudes-

mane natural product, see: Theobald, D. W. Tetrahedron 1964, 20, 25932600.

9. The one step required to convert junenol into dihydrojunenol employed H

2

and

PtO

2

in CH

3

CO

2

H, which reduced a terminal olen in 94% yield; see Ref. 6c.

10. For a 17-step semi-synthesis of junenol starting from santonin, see the fol-

lowing reference and references within: Niwa, M.; Iguchi, M.; Yamamura, S.

Bull. Chem. Soc. Jpn. 1976, 49, 31453147.

11. For an 8-step semi-synthesis of junenol starting from santonin, see: Cardona, L.;

Garca, B.; Gime nez, J. E.; Pedro, J. R. Tetrahedron 1992, 48, 851860.

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4743

12. For a 14-step total synthesis of junenol, see the following reference and ref-

erences within: Banerjee, A. K.; Hurtado, H. E.; de Carrasco, M. C. J. Chem. Soc.,

Perkin Trans. 1 1982, 25472551.

13. For recent syntheses of eudesmane-based natural products, see: (a) Shimoma,

F.; Kondo, H.; Yuuya, S.; Suzuki, T.; Hagiwara, H.; Ando, M. J. Nat. Prod. 1998, 61,

2228; (b) Zhang, Z.; Li, W.-D. Z.; Li, Y. Org. Lett. 2001, 3, 25552557; (c) Ferraz,

H. M. C.; Souza, A. J. C.; Tenius, B. S. M.; Bianco, G. G. Tetrahedron 2006, 62,

92329236; (d) Levine, S. R.; Krout, M. R.; Stoltz, B. M. Org. Lett. 2009, 11,

289292.

14. Dauben, W. G.; Michno, D. M. J. Org. Chem. 1977, 42, 682685.

15. For the use of Et

2

NSiMe

3

in Michael additions, see: (a) Hagiwara, H.;

Komatsubara, N.; Ono, H.; Okabe, T.; Hoshi, T.; Suzuki, T.; Ando, M.; Kato, M. J.

Chem. Soc., Perkin Trans. 1 2001, 316322; (b) Hagiwara, H.; Ono, H.; Hoshi, T.

Org. Synth. 2003, 80, 195197.

16. Hudlicky, T.; Fleming, A.; Radesca, L. J. Am. Chem. Soc. 1989, 111, 66916707.

17. For examples of enantioselective Michael additions onto methyl vinyl ketone,

see: (a) Melchiorre, P.; Jrgensen, K. A. J. Org. Chem. 2003, 68, 41514157; (b)

Hong, B.-C.; Chen, F.-L.; Chen, S.-H.; Liao, J.-H.; Lee, G.-H. Org. Lett. 2005, 7,

557560; (c) Peelen, T. J.; Chi, Y.; Gellman, S. H. J. Am. Chem. Soc. 2005, 127,

1159811599; (d) Chi, Y.; Gellman, S. H. Org. Lett. 2005, 7, 42534256.

18. Hagiwara, H.; Okabe, T.; Ono, H.; Kamat, V. P.; Hoshi, T.; Suzuki, T.; Ando, M.

J. Chem. Soc., Perkin Trans. 1 2002, 895900.

19. For examples of both racemic and enantioselective syntheses of cryptone, see:

(a) Soffer, M. D.; Jevnik, M. A. J. Am. Chem. Soc. 1955, 77, 10031006; (b) Krishna

Rao, G. S.; Dev, S. J. Indian Chem. Soc. 1956, 33, 539544; (c) Vig, O. P.; Kumar, V.;

Raj, I. J. Indian Chem. Soc. 1962, 39, 432434; (d) Banerjee, R. C. J. Indian Chem.

Soc. 1962, 39, 756758; (e) Mukherji, G.; Ganguly, B. K.; Banerjee, R. C.; Mu-

kherji, D.; Bardhan, J. C. J. Chem. Soc. 1963, 24022407; (f) Stork, G.; Brizzolara,

A.; Landesman, H.; Szmuszkovicz, J.; Terrell, R. J. Am. Chem. Soc. 1963, 85,

207222; (g) Snider, B. B.; Rodini, D. J.; van Straten, J. J. Am. Chem. Soc. 1980, 102,

58725880; (h) Birch, A. J.; Raverty, W. D.; Stephenson, G. R. J. Org. Chem. 1981,

46, 51665172; (i) Ito, Y.; Sawamura, M.; Kominami, K.; Saegusa, T. Tetrahedron

Lett. 1985, 26, 53035306; (j) Shirai, R.; Tanaka, M.; Koga, K. J. Am. Chem. Soc.

1986, 108, 543545; (k) Mancini, I.; Guella, G.; Pietra, F. Gazz. Chim. Ital. 1988,

118, 447449; (l) Hawley, R. C.; Schreiber, S. L. Synth. Commun. 1990, 20,

11591165; (m) Kato, M.; Watanabe, M.; Vogler, B.; Tooyama, Y.; Yoshikoshi, A.

J. Chem. Soc., Chem. Commun. 1990, 17061707; (n) Kato, M.; Watanabe, M.;

Tooyama, Y.; Vogler, B.; Yoshikoshi, A. Synthesis 1992, 10551057; (o) Aoki, K.;

Nakajima, M.; Tomioka, K.; Koga, K. Chem. Pharm. Bull. 1993, 41, 994996; (p)

Evarts, J.; Torres, E.; Fuchs, P. L. J. Am. Chem. Soc. 2002, 124, 1109311101; (q)

Isaksson, D.; Sjo din, K.; Ho gberg, H.-E. Tetrahedron: Asymmetry 2006, 17,

275280; (r) Mori, K. Tetrahedron: Asymmetry 2006, 17, 21332142.

20. For selected examples of cryptone being used as a starting material in total

synthesis, see: (a) Soffer, M. D.; Gu nay, G. E. Tetrahedron Lett. 1965, 6,

13551358; (b) Sakurai, H.; Hosomi, A.; Saito, M.; Sasaki, K.; Iguchi, H.; Sasaki,

J.; Araki, Y. Tetrahedron 1983, 39, 883894; (c) Schreiber, S. L.; Santini, C. J. Am.

Chem. Soc. 1984, 106, 40384039; (d) Tokunaga, Y.; Yagihashi, M.; Ihara, M.;

Fukumoto, K. J. Chem. Soc., Chem. Commun. 1995, 955956; (e) Ye, B.; Nakamura,

H.; Murai, A. Tetrahedron 1996, 52, 63616372; (f) Becker, J.; Bergander, K.;

Fro hlich, R.; Hoppe, D. Angew. Chem. Int. Ed. 2008, 47, 16541657; (g) Findley,

T. J. K.; Sucunza, D.; Miller, L. C.; Davies, D. T.; Procter, D. J. Chem.dEur. J. 2008,

14, 68626865.

21. For an example of Ag

2

CO

3

being an important additive for Heck reactions, see:

Denmark, S. E.; Schnute, M. E. J. Org. Chem. 1995, 60, 10131019.

22. For selected examples describing the role of Me

3

SiCl in conjugate additions,

see: (a) Corey, E. J.; Boaz, N. W. Tetrahedron Lett. 1985, 26, 60156018; (b) Corey,

E. J.; Boaz, N. W. Tetrahedron Lett. 1985, 26, 60196022; (c) Alexakis, A.; Berlan,

J.; Besace, Y. Tetrahedron Lett. 1986, 27, 10471050; (d) Nakamura, E.; Matsu-

zawa, S.; Horiguchi, Y.; Kuwajima, I. Tetrahedron Lett. 1986, 27, 40294032; (e)

Lipshutz, B. H.; Dimock, S. H.; James, B. J. Am. Chem. Soc. 1993, 115, 92839284.

23. Chatterjee, M.; Chatterjee, A.; Raveendran, P.; Ikushima, Y. Green Chem. 2006, 8,

445449.

24. Popp, F. D.; Schultz, H. P. Chem. Rev. 1962, 62, 1940.

25. Sonoda, Y.; Tanoue, Y.; Yamaguchi, M.; Sato, Y. Chem. Pharm. Bull. 1987, 35,

394397.

26. For selected examples of proline-based catalysts used in asymmetric Michael

additions, see: (a) Yamaguchi, M.; Shiraishi, T.; Hirama, M. Angew. Chem., Int. Ed.

Engl. 1993, 32, 11761178; (b) List, B.; Pojarliev, P.; Martin, H. J. Org. Lett. 2001, 3,

24232425; (c) Mase, N.; Watanabe, K.; Yoda, H.; Takabe, K.; Tanaka, F.; Barbas,

C. F., III. J. Am. Chem. Soc. 2006, 128, 49664967; (d) Enders, D.; Hu ttl, M. R. M.;

Grondal, C.; Raabe, G. Nature 2006, 441, 861863; (e) Hayashi, Y.; Itoh, T.;

Ohkubo, M.; Ishikawa, H. Angew. Chem., Int. Ed. 2008, 47, 47224724.

27. Enders, D.; Kipphardt, H.; Gerdes, P.; Brena-Valle, L. J.; Bhushan, V. Bull. Chim.

Soc. Belg. 1988, 97, 691704.

28. Bhagat, S.; Sharma, R.; Sawant, D. M.; Sharma, L.; Chakraborti, A. K. J. Mol. Catal.

A: Chemical 2006, 244, 2024.

29. (a) Baran, P. S.; Maimone, T. J.; Richter, J. M. Nature 2007, 446, 404408; (b)

Young, I. S.; Baran, P. S. Nature Chem. 2009, 1, 193205.

30. Shenvi, R. A.; OMalley, D. P.; Baran, P. S. Acc. Chem. Res. 2009, 42, 530541.

31. (a) Burns, N. Z.; Baran, P. S.; Hoffmann, R. W. Angew. Chem., Int. Ed. 2009, 48,

28542867; (b) Newhouse, T.; Baran, P. S.; Hoffmann, R. W. Chem. Soc. Rev.

2009, 38, 30103021.

32. Chi, Y.; Peelen, T. J.; Gellman, S. H. Org. Lett. 2005, 7, 34693472.

33. House, H. O.; Respess, W. L.; Whitesides, G. M. J. Org. Chem. 1966, 31, 31283141.

K. Chen et al. / Tetrahedron 66 (2010) 47384744 4744

S-ar putea să vă placă și

- 12 Recipes That Will Change The Way You CookDocument24 pagini12 Recipes That Will Change The Way You Cooksayakou78100% (23)

- Adventure Shorts Volume 1 (5e)Document20 paginiAdventure Shorts Volume 1 (5e)admiralpumpkin100% (5)

- Antenna Wave Propagation Lab Manual CSTDocument13 paginiAntenna Wave Propagation Lab Manual CSTPrince Syed100% (3)

- Instructional MediaDocument7 paginiInstructional MediaSakina MawardahÎncă nu există evaluări

- Script For Demo TeachingDocument9 paginiScript For Demo TeachingDindz SurioÎncă nu există evaluări

- MKTG How Analytics Can Drive Growth in Consumer Packaged Goods Trade PromotionsDocument5 paginiMKTG How Analytics Can Drive Growth in Consumer Packaged Goods Trade PromotionsCultura AnimiÎncă nu există evaluări

- Mushoku Tensei Volume 2Document179 paginiMushoku Tensei Volume 2Bismillah Dika2020Încă nu există evaluări

- Comparative Analysis Betwee Fast Restaurats & Five Star Hotels RestaurantsDocument54 paginiComparative Analysis Betwee Fast Restaurats & Five Star Hotels RestaurantsAman RajputÎncă nu există evaluări

- F A T City Workshop NotesDocument3 paginiF A T City Workshop Notesapi-295119035Încă nu există evaluări

- (Elearnica - Ir) - Towards The Total Synthesis of Tashironin Related Allo-Cedrane Natural ProdDocument4 pagini(Elearnica - Ir) - Towards The Total Synthesis of Tashironin Related Allo-Cedrane Natural ProdMohamadMostafaviÎncă nu există evaluări

- Umihara Et Al-2017-Chemistry - A European JournalDocument3 paginiUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaÎncă nu există evaluări

- Synthesis of Heteroaromatic Natural ProductsDocument127 paginiSynthesis of Heteroaromatic Natural ProductsWilly CoioteÎncă nu există evaluări

- A Formal Synthesis of Reserpine: Hydrindane Approach To The Woodward's Ring-E PrecursorDocument6 paginiA Formal Synthesis of Reserpine: Hydrindane Approach To The Woodward's Ring-E PrecursorwandadwilestariÎncă nu există evaluări

- A Practical Synthesis of (-) - Kainic AcidDocument11 paginiA Practical Synthesis of (-) - Kainic AcidNikhil SarpateÎncă nu există evaluări

- Angew Chem Int Ed - 2015 - Pan - Total Synthesis of Diterpenoid Steenkrotin ADocument4 paginiAngew Chem Int Ed - 2015 - Pan - Total Synthesis of Diterpenoid Steenkrotin Azhang quanÎncă nu există evaluări

- Despre MoleculeDocument14 paginiDespre MoleculeAlexa IordacheÎncă nu există evaluări

- Poly EneDocument3 paginiPoly EneMohammed TarekÎncă nu există evaluări

- Op4 PDFDocument6 paginiOp4 PDFPaula Andrea GutiérrezÎncă nu există evaluări

- Acros Organics Acta N°006Document20 paginiAcros Organics Acta N°006Atomer FormationÎncă nu există evaluări

- Enantioselective Total Synthesis of (+) - Wortmannin: Yinliang Guo, Tianfei Quan, Yandong Lu, and Tuoping LuoDocument4 paginiEnantioselective Total Synthesis of (+) - Wortmannin: Yinliang Guo, Tianfei Quan, Yandong Lu, and Tuoping LuoLê MinhÎncă nu există evaluări

- CarmegliptinDocument12 paginiCarmegliptinQuân MinhÎncă nu există evaluări

- Synthesis of N-Chloroquinolines and N-Ethynylquinolines (nZ2, 4, 8) : Homo and Heterocoupling Reactions.Document10 paginiSynthesis of N-Chloroquinolines and N-Ethynylquinolines (nZ2, 4, 8) : Homo and Heterocoupling Reactions.kawtherahmedÎncă nu există evaluări

- Angewandte Chemie, Vol. 46 Nb. 7 (2007) P. 1066 - 1070Document5 paginiAngewandte Chemie, Vol. 46 Nb. 7 (2007) P. 1066 - 1070rrgodboleÎncă nu există evaluări

- Lindsey Methods of DPM FORMYLATION SynthesisDocument11 paginiLindsey Methods of DPM FORMYLATION SynthesisPULAKESH BORAHÎncă nu există evaluări

- NorrisolidetDocument4 paginiNorrisolidetOscar Martin OrdoñezÎncă nu există evaluări

- Uses of 2-Ethoxy-4 (3H) Quinazolinone in Synthesis of Quinazoline and Quinazolinone Derivatives of Antimicrobial Activity: The Solvent EffectDocument12 paginiUses of 2-Ethoxy-4 (3H) Quinazolinone in Synthesis of Quinazoline and Quinazolinone Derivatives of Antimicrobial Activity: The Solvent Effectkhaliddarwish1962Încă nu există evaluări

- Tetrahedron Letters: Olugbeminiyi O. Fadeyi, R. Nathan Daniels, Sean M. Deguire, Craig W. LindsleyDocument4 paginiTetrahedron Letters: Olugbeminiyi O. Fadeyi, R. Nathan Daniels, Sean M. Deguire, Craig W. LindsleyNopasantiÎncă nu există evaluări

- Dyes and Pigments-2016-New Class of Hyperpolarizable Push-Pull Organic Chromophores by Applying A Novel and Convenient Synthetic StrategyDocument5 paginiDyes and Pigments-2016-New Class of Hyperpolarizable Push-Pull Organic Chromophores by Applying A Novel and Convenient Synthetic StrategyELKIN ALFONSO RODRIGUEZ AGUALIMPIAÎncă nu există evaluări

- Total Synthesis of Sordaricin: Lewis N. Mander and Regan J. ThomsonDocument4 paginiTotal Synthesis of Sordaricin: Lewis N. Mander and Regan J. ThomsonOskar Martin OrdoñezÎncă nu există evaluări

- Jacs AsapDocument2 paginiJacs AsapMohamadMostafaviÎncă nu există evaluări

- COM 08 11328asdfdsDocument9 paginiCOM 08 11328asdfdsVictor NgÎncă nu există evaluări

- TricicloclavupdfDocument2 paginiTricicloclavupdfOscar Martin OrdoñezÎncă nu există evaluări

- Tetrahedron 2010 66 10 01902 - 01910 CiclicoDocument9 paginiTetrahedron 2010 66 10 01902 - 01910 Ciclicoteodoro11Încă nu există evaluări

- Total Synthesis of Crenulatan Diterpenes: Strategy and Stereocontrolled Construction of A Bicyclic Keto-Lactone Building BlockDocument12 paginiTotal Synthesis of Crenulatan Diterpenes: Strategy and Stereocontrolled Construction of A Bicyclic Keto-Lactone Building BlockLibre Joel IanÎncă nu există evaluări

- Dihydrocoronatine Promising Candidate For A Chemical Probe To Study Coronatine Jasmonoid and Octadecanoid Binding ProteinDocument5 paginiDihydrocoronatine Promising Candidate For A Chemical Probe To Study Coronatine Jasmonoid and Octadecanoid Binding ProteinQuenguan FranklinÎncă nu există evaluări

- Annulation of Imidazolines With Bis-Electrophiles: Synthesis of Imidazo (1,2-A) PyridinesDocument10 paginiAnnulation of Imidazolines With Bis-Electrophiles: Synthesis of Imidazo (1,2-A) PyridinesboksabbÎncă nu există evaluări

- Room Temperature C P Bond Formation Enabled by Merging Nickel Catalysis and Visible Light Induced Photoredox Catalysis - CompressDocument5 paginiRoom Temperature C P Bond Formation Enabled by Merging Nickel Catalysis and Visible Light Induced Photoredox Catalysis - CompressshankhadeepawsÎncă nu există evaluări

- Anthony R. Lingham Et Al - Studies Towards The Synthesis of Salvinorin ADocument9 paginiAnthony R. Lingham Et Al - Studies Towards The Synthesis of Salvinorin ABic0000Încă nu există evaluări

- Hapilindoles BDocument6 paginiHapilindoles BQuân MinhÎncă nu există evaluări

- Synthesis of (2-Nitro-1-Phenoxypropane-1, 3-Diyl) Dibenzene Compounds From Baylis - Hillman DerivativesDocument6 paginiSynthesis of (2-Nitro-1-Phenoxypropane-1, 3-Diyl) Dibenzene Compounds From Baylis - Hillman DerivativesIAEME PublicationÎncă nu există evaluări

- Harzialactone TA 2005 LuDocument3 paginiHarzialactone TA 2005 LuhloicÎncă nu există evaluări

- Nakanishi 2014Document7 paginiNakanishi 2014Abhishek PareekÎncă nu există evaluări

- 815 824 PDFDocument10 pagini815 824 PDFDiogo DiasÎncă nu există evaluări

- Jo 000853Document8 paginiJo 000853natali.pfernandezÎncă nu există evaluări

- Trans Imminazione Beta ControllataDocument2 paginiTrans Imminazione Beta ControllatafuturichimiciÎncă nu există evaluări

- Diastereoselective Synthesis of Homo-N, O-NucleosidesDocument8 paginiDiastereoselective Synthesis of Homo-N, O-Nucleosidesapi-19793040Încă nu există evaluări

- Polycyclic AlkenesDocument8 paginiPolycyclic AlkenesDieter ScheibelÎncă nu există evaluări

- Paper: Microwave Methods For The Synthesis of Paddlewheel Diruthenium Compounds With N, N-Donor LigandsDocument6 paginiPaper: Microwave Methods For The Synthesis of Paddlewheel Diruthenium Compounds With N, N-Donor LigandshttmaiÎncă nu există evaluări

- Qi1999 Article SynthesisOfCyclicPrecursorsOfPDocument5 paginiQi1999 Article SynthesisOfCyclicPrecursorsOfPMorkizgaÎncă nu există evaluări

- Asian J. Org. Chem. 2021,10, 2152-2156Document5 paginiAsian J. Org. Chem. 2021,10, 2152-2156NoimurÎncă nu există evaluări

- Epoxide Chemistry - Guided Inquiry Experiment.Document3 paginiEpoxide Chemistry - Guided Inquiry Experiment.Jamal RafiqueÎncă nu există evaluări

- PDC Dea Hydrodeoxygenation PhenolsDocument11 paginiPDC Dea Hydrodeoxygenation Phenolsvell1234Încă nu există evaluări

- Li BerkeleyoneDocument6 paginiLi BerkeleyoneVõ Quốc CườngÎncă nu există evaluări

- Benzyne CyclizationDocument13 paginiBenzyne Cyclizationcobalt59Încă nu există evaluări

- Synthesis of Bromo and Chloro Derivatives of Baylis-Hillman AdductsDocument5 paginiSynthesis of Bromo and Chloro Derivatives of Baylis-Hillman AdductsIAEME PublicationÎncă nu există evaluări

- Merino 2002Document18 paginiMerino 2002محمد بلحوتÎncă nu există evaluări

- Current+Organic+Chemistry +2008, 12,+1116-1183Document96 paginiCurrent+Organic+Chemistry +2008, 12,+1116-1183Murali Venkat NagÎncă nu există evaluări

- A Wittig-olefination-Claisen-rearrangement Approach To The 3-Methylquinoline-4-Carbaldehyde SynthesisDocument5 paginiA Wittig-olefination-Claisen-rearrangement Approach To The 3-Methylquinoline-4-Carbaldehyde SynthesisMuhammad Mirza HardiansyahÎncă nu există evaluări

- JLCR 2580270809 PDFDocument11 paginiJLCR 2580270809 PDFPaula LomboÎncă nu există evaluări

- Cha 2011Document4 paginiCha 2011Bùi Nguyên DươngÎncă nu există evaluări

- Franz H. Kohnke and J. Fraser Stoddart - The Evolution of Molecular Belts and CollarsDocument6 paginiFranz H. Kohnke and J. Fraser Stoddart - The Evolution of Molecular Belts and CollarsCogsmsÎncă nu există evaluări

- Chemical Synthesis of Oligonucleotides PDFDocument12 paginiChemical Synthesis of Oligonucleotides PDFMuhammad AhmedÎncă nu există evaluări

- Chemical Synthesis of OligosDocument12 paginiChemical Synthesis of OligosJulia JimenezÎncă nu există evaluări

- An Improved Asymmetric Synthetic Route To D-Biotin Via Hoffmann-Roche Lactone-Thiolactone ApproachDocument4 paginiAn Improved Asymmetric Synthetic Route To D-Biotin Via Hoffmann-Roche Lactone-Thiolactone ApproachPaulo HenriqueÎncă nu există evaluări

- Sinteza BussealinDocument3 paginiSinteza BussealinGheorghe CobuzÎncă nu există evaluări

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeDe la EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeÎncă nu există evaluări

- Total Synthesis of (+) - Laurencin. Use of Acetal-Vinyl Sulfide Cyclizations For Forming Highly Functionalized Eight-Membered Cyclic EthersDocument9 paginiTotal Synthesis of (+) - Laurencin. Use of Acetal-Vinyl Sulfide Cyclizations For Forming Highly Functionalized Eight-Membered Cyclic EtherspravitaÎncă nu există evaluări

- 1515667147CHE P14 M12 EtextDocument14 pagini1515667147CHE P14 M12 Etextsavitha KadencheriÎncă nu există evaluări

- A Simple, Green and One-Pot Four-Component Synthesis of 1,4-Dihydropyridines and Their AromatizationDocument6 paginiA Simple, Green and One-Pot Four-Component Synthesis of 1,4-Dihydropyridines and Their AromatizationEdgar HernándezÎncă nu există evaluări

- Program at A Glance: Day 1 May 2, 2022Document3 paginiProgram at A Glance: Day 1 May 2, 2022Victor CiocalteaÎncă nu există evaluări

- ILN 1910-06-11 P. 940Document1 paginăILN 1910-06-11 P. 940Victor CiocalteaÎncă nu există evaluări

- TMM With Oxindoles and Cyano DonorDocument2 paginiTMM With Oxindoles and Cyano DonorVictor CiocalteaÎncă nu există evaluări

- AAA With Acylsilanes Dai JACS 2010Document3 paginiAAA With Acylsilanes Dai JACS 2010Victor CiocalteaÎncă nu există evaluări

- Nyt Planas - Scores - at - ChessDocument1 paginăNyt Planas - Scores - at - ChessVictor CiocalteaÎncă nu există evaluări

- Canadian Interuniversity Chess Championship 2008 InformationDocument3 paginiCanadian Interuniversity Chess Championship 2008 InformationVictor CiocalteaÎncă nu există evaluări

- Williams OL 1999 PCy3 Branched RegioselectivityDocument3 paginiWilliams OL 1999 PCy3 Branched RegioselectivityVictor CiocalteaÎncă nu există evaluări

- Trost Charley Alpha Hydroxy Aldehydes by DAAA JACS 2006Document2 paginiTrost Charley Alpha Hydroxy Aldehydes by DAAA JACS 2006Victor CiocalteaÎncă nu există evaluări

- Trost Charley Ketone Enolates JACS 2004Document2 paginiTrost Charley Ketone Enolates JACS 2004Victor CiocalteaÎncă nu există evaluări

- Fiaud Mulleron TL 1981 Symmetry of PD Allyl ComplexDocument4 paginiFiaud Mulleron TL 1981 Symmetry of PD Allyl ComplexVictor CiocalteaÎncă nu există evaluări

- Trost Charley DAAA Full Paper JACS 2009Document15 paginiTrost Charley DAAA Full Paper JACS 2009Victor CiocalteaÎncă nu există evaluări

- Stoltz Decarboxylative Asymmetric AA To Form Tertiary and Quaternary StereocentresDocument5 paginiStoltz Decarboxylative Asymmetric AA To Form Tertiary and Quaternary StereocentresVictor CiocalteaÎncă nu există evaluări

- Yu PGP Efflux Review 2017Document16 paginiYu PGP Efflux Review 2017Victor CiocalteaÎncă nu există evaluări

- Mayo V Iancu, 938 F.3d 1343 (CAFC 2019)Document21 paginiMayo V Iancu, 938 F.3d 1343 (CAFC 2019)Victor CiocalteaÎncă nu există evaluări

- Trost Jiayi Alpha Oxy Ketones by Decarboxylative AAA JACS 2008Document2 paginiTrost Jiayi Alpha Oxy Ketones by Decarboxylative AAA JACS 2008Victor CiocalteaÎncă nu există evaluări

- Holland ABCG2 Inhibition BJPH 2007Document10 paginiHolland ABCG2 Inhibition BJPH 2007Victor CiocalteaÎncă nu există evaluări

- Guo Vit E TPGS RV EJPS 2013Document12 paginiGuo Vit E TPGS RV EJPS 2013Victor CiocalteaÎncă nu există evaluări

- Ru-Catalyzed Decarboxylative TMM Cycloaddition With Alkylidene Dicarbonyl Compounds OLDocument3 paginiRu-Catalyzed Decarboxylative TMM Cycloaddition With Alkylidene Dicarbonyl Compounds OLVictor CiocalteaÎncă nu există evaluări

- Reddy PGP Drug Distribution in Brain 2016Document9 paginiReddy PGP Drug Distribution in Brain 2016Victor CiocalteaÎncă nu există evaluări

- Elgart SNEDDS P-GP Efflux Pharm Res 2013Document16 paginiElgart SNEDDS P-GP Efflux Pharm Res 2013Victor CiocalteaÎncă nu există evaluări

- Times of India 1928-02-27Document1 paginăTimes of India 1928-02-27Victor CiocalteaÎncă nu există evaluări

- Abdallah PGP Efflux Inhibition Review 2015Document18 paginiAbdallah PGP Efflux Inhibition Review 2015Victor CiocalteaÎncă nu există evaluări

- Stoltz Decarboxylative Asymmetric AA To Form Tertiary and Quaternary StereocentresDocument5 paginiStoltz Decarboxylative Asymmetric AA To Form Tertiary and Quaternary StereocentresVictor CiocalteaÎncă nu există evaluări

- Decarboxylative AAA Review PDFDocument3 paginiDecarboxylative AAA Review PDFVictor CiocalteaÎncă nu există evaluări

- Decarboxylative Asymmetric Allylic Alkylation of Vinylogous Esters and ThioestersDocument4 paginiDecarboxylative Asymmetric Allylic Alkylation of Vinylogous Esters and ThioestersVictor CiocalteaÎncă nu există evaluări

- Racemic Decarboxylative Allylation of Nitriles OLDocument4 paginiRacemic Decarboxylative Allylation of Nitriles OLVictor CiocalteaÎncă nu există evaluări

- Racemic Decarboxylative Allylation of Phenols OLDocument3 paginiRacemic Decarboxylative Allylation of Phenols OLVictor CiocalteaÎncă nu există evaluări

- Decarboxylative Asymmetric Allylic Alkylation ReviewDocument3 paginiDecarboxylative Asymmetric Allylic Alkylation ReviewVictor CiocalteaÎncă nu există evaluări

- Decarboxylative Allylic Alkylation of NitroalkanesDocument3 paginiDecarboxylative Allylic Alkylation of NitroalkanesVictor CiocalteaÎncă nu există evaluări

- ABHI Network List As On 30-06-2023Document3.401 paginiABHI Network List As On 30-06-20233uifbcsktÎncă nu există evaluări

- By Nur Fatin Najihah Binti NoruddinDocument7 paginiBy Nur Fatin Najihah Binti NoruddinNajihah NoruddinÎncă nu există evaluări

- Data Sheet Physics 1 Module 10BDocument2 paginiData Sheet Physics 1 Module 10BBryanHarold BrooÎncă nu există evaluări

- Glgq1g10 Sci Las Set 4 ColoredDocument4 paginiGlgq1g10 Sci Las Set 4 ColoredPogi AkoÎncă nu există evaluări

- Revision Notes On Section 1.6 - Belief, Uncertainty & UnbeliefDocument5 paginiRevision Notes On Section 1.6 - Belief, Uncertainty & Unbeliefnisalielisha rodrigoÎncă nu există evaluări

- Icmap Newsletter June 2017Document7 paginiIcmap Newsletter June 2017GoopÎncă nu există evaluări

- Colour Communication With PSD: Printing The Expected With Process Standard Digital!Document22 paginiColour Communication With PSD: Printing The Expected With Process Standard Digital!bonafide1978Încă nu există evaluări

- Mactor Report - Taller de Prospectiva D 2Document39 paginiMactor Report - Taller de Prospectiva D 2Giovani Alexis Saez VegaÎncă nu există evaluări

- SOCI 223 Traditional Ghanaian Social Institutions: Session 1 - Overview of The CourseDocument11 paginiSOCI 223 Traditional Ghanaian Social Institutions: Session 1 - Overview of The CourseMonicaÎncă nu există evaluări

- Integrating Intuition and Analysis Edward Deming Once SaidDocument2 paginiIntegrating Intuition and Analysis Edward Deming Once SaidRimsha Noor ChaudaryÎncă nu există evaluări

- Lsp404 How To Write An Argumentative Essay NewDocument52 paginiLsp404 How To Write An Argumentative Essay Newagegae aegaegÎncă nu există evaluări

- Part 4 Basic ConsolidationDocument3 paginiPart 4 Basic Consolidationtαtmαn dє grєαtÎncă nu există evaluări

- Lista Materijala WordDocument8 paginiLista Materijala WordAdis MacanovicÎncă nu există evaluări

- NUR 200 Week 7 Practice Case StudyDocument2 paginiNUR 200 Week 7 Practice Case StudyJB NicoleÎncă nu există evaluări

- A Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattDocument5 paginiA Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattAmory JimenezÎncă nu există evaluări

- 2.2 Push and Pull Sources of InnovationDocument16 pagini2.2 Push and Pull Sources of Innovationbclarke113Încă nu există evaluări

- Accounting For Employee Stock OptionsDocument22 paginiAccounting For Employee Stock OptionsQuant TradingÎncă nu există evaluări

- Mock Exam 2Document18 paginiMock Exam 2Anna StacyÎncă nu există evaluări

- Bnblist3559 PDFDocument430 paginiBnblist3559 PDFJagroopSinghBalhraÎncă nu există evaluări

- SjshagavDocument6 paginiSjshagavindah ayu lestariÎncă nu există evaluări

- Scanned - National Learning CampDocument2 paginiScanned - National Learning CampJOHN JORICO JARABAÎncă nu există evaluări

- Villa VeronicaDocument12 paginiVilla Veronicacj fontzÎncă nu există evaluări