Documente Academic

Documente Profesional

Documente Cultură

Is.13311.2.1992 Rebound Hammer

Încărcat de

ChockalingamDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Is.13311.2.1992 Rebound Hammer

Încărcat de

ChockalingamDrepturi de autor:

Formate disponibile

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 13311-2 (1992): Method of non-destructive testing of

concret-methods of test, Part 2: Rebound hammer [CED 2:

Cement and Concrete]

I ndian Standard

NON-DESTRUCTWETESTINGOF

CONCRETE-METHODSOFTEST

PART 2 REBOUND HAMMER

( First Reprint JUNE 1995)

tJDC 666.972 : 620*179*1

Q BI S 1992

BUREAU OF INDIAN STANDARDS

MqNAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

April 1992

Pr i c e Gr oop 3

( Reaffirmed 2004 )

Cement and Concrete Sectional Committee, CED 2

FOREWORD

This Indian Standard was adopted by the Rureau of Indian Standards, after the draft finalized by the

Cement and Coacrete Sectional Committee bad been approved bg&+fivil Engineering Division

Council.

There are occasions when the various perfortiance characteristics of concrete in a structure are

required to be assessed. In most of the cases, an estimate of strength of concrete in the structure is

needed, although parameters like overall quality, uniformity, etc, also become important in others.

The various methods that can be adopted for in-situ assessnhent of strength properties of concrete

depend upon the particular aspect of strength in question. For example, if the load-carrying capacity

of structural ensemble is to be assessed, carrying out a full-scale load test 8s per IS 456 : 1978 Code of

practice for plain and reinforced concrete ( third revision ) or IS 1343: 1980 Code of practice for

prestressed concrete (first revision ) is the most direct way; on the other hand when the actual com-

pressive strength of a concrete in the structure is to be measured, core testing as per IS 516 : 1959

&Method of test for strength of concrete is more reliable. However, both these methods are relatively

cumbersome and the latter method may leave the structure damaged locally in some cases, Use is,

therefore, made of suitable non-destructive tests, which not only provide an estimate of the relative

strength and overall quality of concrete in the structures, but also help in deciding whether more

rigorous tests like load testing or core drilling at selected locations are required.

There are various such non-destructive testing methods which can be broadly classified as those which

measure the overall quality of concrete, for example dynamic or vibration methods like resonance

frequency and ultrasonic pulse velocity tests; and those which involve measurement of parameters like

surface hardness, rebound, penetration, pull-out strength, etc, and are believed to be indirectly related

to the compressive strength of concrete. In addition, radiographic, radiometric, nuclear, magnetic

and electrical methods are also available. Since such non-destructive tests are at best indirect methods

of monitoring the particular characteristic of concrete and the measurements are influenced by

materials, mix and environmental factors, proper interpretation of the results calls for ce1 tain degree

of expertise. It is more so, when the data on the materials and mix proportions used in the construc-

tion are not available as is often the case.

In view of the limitations of the method for predicting the strength of concrete in the structure, it is

preferable that both ultrasonic pulse velocity given in Part 1 of the standard and rebound hammer

method are used in combination to alleviate the errors arising out of influence of material, mix and

environmental parameters on the respective measurements. Relationships between pulse velocity,

rebound number and compressive strength of concrete are obtained by multiple regression of the

measured values on laboratory test specimens. However, this approach has the limitation that the

correlations are valid only for the materials and mix proportions used in the trials. The intrinsic

difference between the laboratory test specimens and in-situ concrete, for example surface texture,

moisture condition, presence of reinforcement, etc, also affect the accuracy of results. The correlation

is valid only within the range of values of pulse velocity, rebound number and compressive strength

employed and any extrapolation beyond these is open to question. The rebound hammer test is not

intended as a substitute for standard compression test, but as a method for determining the uniformity

of concrete in the structure and comparing one concrete with another.

Because of the above limitations, the combined use of these two methods is made in another way. In

this, if the quality of concrete is assessed to be excellent or good by pulse velocity method, only then

the compressive strength is assessed from the rebound hammer indices, and this is taken as indicative

of strength of concrete in the entire cross-section of the concrete member. When the quality assessed

is medium, the estimation of compressive strength by rebound indices is extended to the entire mass

only on the basis of other colateral measurements, for example, strength of site concrete cubes, cement

content in the concrete or core testing. When the quality of concrete is doubtful, no assessment of

concrete strength is made from rebound indices.

In most of the situations, the records ?f the original materials or mix proportions used in the strut_ /

ture are not available. Therefore, cqnslderable improvisation has to be done in evolving the testing

scheme and use is made of comparafive measurements made on adjoining portions of the structures

or even other structures in the vicmlty of the one in question. In doing so, an approach is taken t

the same materials and similar mix proportions and level of workmanship were employed for the t

at

hw,

( Contitzued on\ third cover )

I s 13311( Part 2 ) : 1992

I ndian Standard

NON-DESTRUCTIVE TESTING OF

CONCRETE-METHODSOFTEST

PART 2 REBOUND HAMMER

1 SCOPE

This standard covers the object, principle,

apparatus and procedure of rebound hammer

test method. In addition, influence of test

conditions and some general guidance on the

interpretation of test results are also given.

NOTE - In view of the limitations of each method

of non-destructive testing of concrete, it is essential

that the results of tests obtained by one method

.should be complimented by other tests and each

method should be adopted very carefully.

2 REFERENCES

rebound is read off along a graduated scale and

is designated as the rebound number or rebound

index.

4 APPARATUS

4.1 The Rebound Hammer

It consists of a spring controlled mass that

slides on a plunger within a tubular housing.

The impact energy required for rebound

hammers for different applications is given in

Table 1.

The following Indian standards are necessary

adjuncts to this standard.

IS No. Title

516 : 1959 Method of test for strength of

concrete

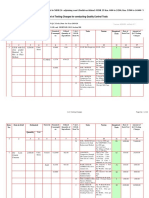

Table 1 Impact Energy for Rebound Hammers

for Different Applications

( Clause 4.1 )

Sl No. Application Approximate Impact

Energy Required

8900 : 1978 Criteria for rejection of outlying

observations

3 OBJECT AND PRINCIPLE OF TAXST

3.1 Object

The rebound hammer method could be used for:

i)

ii)

iii)

i) assessing the likely compressive strength

of concrete with the help of suitable co-

relations between rebound index and

compressive strength,

for th Reiound

Hammers ( Nm 1

For testing normal weight 225

concrete

For light-weight concrete or 075

small and impact sensitive

parts of concrete

For testing mass concrete, 3000

for example in roads, air-

fields pavements and hydrau-

lic structures

5 CMJXKING OF APPARATUS

ii) assessing the uniformity of concrete,

iii) assessing the quality of the concrete in

relation to standard requirements, and

iv) assessing the quality of one element of

concrete in relation to another.

NOTE - The rebound hammer method can be used

with greater confidence for differentiating between

the questionable and acceptable parts of a structure

or for relative comparison between two different

structures.

3.2 Principle of Test

5.1 It is necessary that the rebound hammer is

checked against the testing anvil before com-

mencement of a test to ensure reliable results.

The testing anvil should be of steel having

Brine11 hardness of about 5 000 N/mms. The

supplier/manufacturer of the rebound hammer

should indicate the range of readings on the

anvil suitable for diRerent types of rebound

hammers.

5.2 Procedure of Obtaioing Correlation Betaeeu

Compressive Strength of Concrete and Rebound

Number

When the plunger of rebound hammer is pressed

against the surface of the concrete, the spring-

The most satisfactory way of establishing a

controlled mass rebounds and the extent of

correlation between compressive strength of

concrete and its rebound number is to measure

such rebound depends upon the surface hard-

ness of concrete. The surface hardness and

both the properties simultaneously on concrete

therefore the rebound is taken to be related to

cubes. The concrete cube specimens are held

in a compression testing machine under a fixed

the compressive strength of the concrete. The load, measurements of rebound number taken

1

I S 13311( Part 2 ) : 1992

and then the compressive strength determined

as per IS 516 : 1959. The fixed load required is

of the order of 7 N/mm8 when the impact

energy of the hammer is about 2.2 Nm. The

load should be increased for calibrating rebound

hammers of greater impact energy and decreas-

ed for calibrating rebound hammers of lesser

impact energy. The test specimens should be as

large a mass as possible in order to minimise

the size effect on the test result of a full scale

structure. 150 mm cube specimens are preferred

for calibrating rebound hammers of lower

impact energy ( 2.2 Nm ), whereas for rebound

hammers of higher impact energy, for example

30 Nm, the test cubes should not be smaller

than 300 mm.

If the specimens are wet cured, they should be

removed from wet storage and kept in the

laboratory atmosphere for about 24 hours

before testing. To obtain a correlation between

rebound numbers and strength of wet cured and

wet tested cubes, it is necessary to establish a

correlation between the strength of wet tested

cubes and the strength of dry tested cubes on

which rebound readings are taken. A direct

correlation between rebound numbers on wet

cubes and the strength of wet cubes is not

recommended. Only the vertical faces of the

cube as cast should be tested. At least nine read-

ings should be taken on each of the two vertical

faces accessible in the compression testing

machine when using the rebound hammers. The

points of impact on the specimen must not be

nearer an edge than 20 mm and should be not

less than 20 mm from each other. The same

points must not be impacted more than once.

6 PROCEDURE

6.1 For testing, smooth, clean and dry surface

is to be selected. If loosely adhering scale is

present, this should be rubbed of with a grind-

ing wheel or stone. Rough surfaces resulting

from incomplete compaction, loss of grout,

spalled or tooled surfaces do not give reliable

results and should be avoided.

6.2 The point of impact should be at least

20 mm away from any edge or shape disconti-

nuity.

6.3 For taking a measurement, the rebound

hammer should be held at right angles to the

surface of the concrete member. The test can

-thus be conducted horizontally on vertical

surfaces or vertically upwards or downwards on

horizontal surfaces. If the situation demands,

the rebound hammer can be held at intermediate

angles also, but in each case, the rebound

number will be different for the same concrete.

surfaces are thoroughly cleaned before taking

any measurement. Around each point of observa-

tion, six readings of rebound indices are taken

2nd average of these readings after de!eting

outliers as per IS 8900 : 1978 becomes the

rebound index for the point of observation.

7 INFLUENCE OF TEST CONDITIONS

7.1 The rebound numbers are influenced by a

number of factors like types of cement and

aggregate, surface condition and moisture con-

tent, age of concrete and extent of carbonation

of concrete.

7.1.1 I nfluence of Type of Cement

Concretes made with high alumina cement can

give strengths 100 percent higher than that with

ordinary Portland cement. Concretes made with

supersulphated cement can give 50 percent

lower strength than that with ordinary Portland

cement.

7.1.2 I nfluence of Type of Aggregate

Different types of aggregate used in concrete

give different correlations between compressive

strength and rebound numbers. Normal aggre-

gates such as gravels and crushed rock aggre-

gates give similar correlations, but concrete

made with lightweight aggregates require

special calibration.

7.1.3 I nfluence of Surface Condition and Moisture

Content of Concrete

The rebound hammer method is suitable only

for close texture concrete. Open texture con-

crete typical of masonry blocks, honeycombed

concrete or no-fines concrete are unsuitable

for this test. All correlaticns assume full com-

pactjon, as the strength of partially compacted

concrete bears no unique relationship to the

rebound numbers. Trowelled and floated sur-

faces are harder than moulded surfaces, and

tend to overestimate the strength of concrete.

A wet surface will give rise to underestimation

of the strength of concrete calibrated under

dry conditions. In structural concrete, this can

be about 20 percent lower than in an equivalent

dry concrete.

7.1.4 I njuence of Curing and Age of Concrete

The relationship between hardness and strength

varies as a function of time. Variations in

initial rate of hardening, subsequent curing

and conditions of exposure also influence the

Lelationship. Separate calibration curves are

required for different curing regimes but the

effect of age can generally be ignored for

concrete between 3 days and 3 months old.

6.4 Rebound hammer test is conducted around

all the points of observation on all accessible

7.1.5 I nfluence of Carbonation of Concrete Surface

faces of the structural element. Concrete The influence of carbonation of concrete

IS 1331.1 ( Part 2 ) : I992

surface on the rebound number is very

significant. Carbonated concrete gives an over-

estimate of strength which in extreme cases can

be up to 50 percent. It is possible to establish

correction factors by removing the carbonated

layer and testing the concrete with the rebound

hammer on the uncarbonated concrete.

$ INTERPRETATION OF RESULTS

8.1 The rebound hammer method provides a

convenient and rapid indication of the com-

pressive strength of concrete by means of

establishing a suitable correlation between the

rebound index and the compressive strength of

concrete. The procedure of obtaining such

correlation is given in 5.2. In general, the

rebound number increases as the strength

increases but it is also affected by a number of

parameters as mentioned in 7.1.

It is also pointed out that rebound indices are

indicative of compressive strength of concrete

to a limited depth from the surface. If the con-

crete in a particular member has internal micro-

cracking, flaws or heterogeneity across the

cross-section, rebound hammer indices will not

indicate the same.

As such, the estimation of strength of concrete

by rebound hammer method cannot be held to

be very accurate and probable accuracy of

prediction of concrete strength in a structure

is & 25 percent. If the relationship between

rebound index and compressive strength can be

checked by tests on core samples obtained from

the structure or standard specimens made with

the same concrete materials and mix proportion,

then the accuracy of results and confidence

thereon are greatly increased.

3

l!s 13311( Part 2 ) : 1992

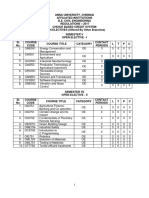

ANNEX A

Cement and Concrete Sectional Committee, CED 2

ChahRun

Da H. C. VI SVB~VABAYA

Members

SEEI B. R. BHABTI KA~

SHBI U. N. RATH ( Alternate )

SHEI H. BFI ATTACEABYA

DB A. K. CEATTEXJ EE

SEBI S. H. SUBBAXANI AX ( Alternate )

CHI EF EN~I NEBX ( DESI GNS )

SUPEBI NTENDI N~ENQI NEEB

IPIpIIsrnling

I n personal capacity ( Univardy of Roorkw, Roorkee 247 667 )

B. G. Shirke & Co, Pune

Orissa Cement Limited, New Delhi

The Associated Cement Companies Ltd, Bombay

Central Public Works Departmeot, New Delhi

( S&S ) ( AlturMts )

CEIEB ENGINEER, NAVAC+ABX DAM Sardar Sarovar Narmada Nigam Ltd, Gandhioagar

SI J PERI NT~DI NQ ENOI NI CEB, QCC ( Alternate )

CHIEF ENQXNEEX ( RESEABOH-CUM-DI REOTOI ~)

RESEARCH O&ICEB ( CONCRETE-

TECHNOLOQY ) ( Altcrnatc )

DIRECYOR

I rrigation and Power Research I nstitute, Amritsar

J OINT DI RECTOR ( AI tcrnatc )

DI RECTOR ( CMDD ) ( N & W )

DEPI XCY DI RECTOR (CMDD) (N W & S )

( Alternate )

SHRI K. H. GANQWAL

SRRI V. PATTABHI ( Altcrnatc )

SHRI V. K. GI I ANEKAR

SERI S. GOP~NATI X

SHBI R. I AMI LAKABAN (Altarnate )

SHBI S. I i. GUEA TEAKUBTA

SHRI J . P. SANKARANARAYANAN

( Alternate )

DB I BSHAD MASOOD

DI L MD KHALID ( Alternute )

J OI NT DI RECTOR, STANDARDS ( B & S) ( CB-I )

J OI NT DI RECTOR STANDARDS ( B & S )

( CB-I I ) ( Altsrnatr )

SHBI N. G. J OSHI

SHBI P. D. KELKAB ( Alternuts )

SEBI D. K. KANUNQO

SHRI B. R. MEENA ( Alfsrnate)

SHBI P. KHI SHNAYURTHY

SHRI S. CHAKBAVARTHY ( Altcrnate )

SHRI A. K. LAL

SHEI T. R. BHATI A ( Alfernnfs)

SHBI G. K. MAJ UMDAR

SHRI S. 0. RANQARI ( Alternuts 1

SHBI M. K. MUKHEBJ EE

SHRI M. K. GHOSH ( Alternate )

SHRI P. N. MEHTA

SHRI J . S. SAN~ANERI A ( Al&ate )

MEXBER SECRETARY

DI I ~ECTOR ( CI VI L ) ( Alternate )

SBRI NIRVAL SINQH

SHRI S. S. MI ~LANI ( Alternate )

SHRI R. C. PARATE

COL R. K. SINQH ( Alterwtr)

SHRI H. S. PASRI CHA

SHRI Y. R. P~OLL

SHBI S. S. SEEHBA ( Alternate )

SHRI Y. R. PHULL

SHRI R. H. SHARMA ( Alternuts )

DR C. RAJ KUXAB

DR S. C. AHLUWALI A ( Alternate )

Sam G. RAMDAS

SERI R. C. SHABMA ( Alternate )

DR M. RAXAI AH

DR A. G. MADHAVA RAO ( Alternats )

REPRESENTATI VE

SHXI A. U. RI J H~I NGI HANI

SHRI C. S. SHAR~A ( Alternate )

A. P. Engineering Research Laboratories, Hyderabad

Central Water Commission, New Delhi

Hyderabad I ndustries Limited, Hyderabad

Structural Engineering Research Ceotre ( CSI R ), Ghaziabad

The I ndia Cements Ltd, Madras

Gannon Dunkerley & Company Limited, Bombay

Central Building Research J ostitute ( CSI R ), Roorkee

Rese;;c,oy;igos & Standards Organization ( Ministry of Railways ).

I ndian Hume Pipes Co Ltd, Bombay

National Test House, Calcutta

Larsen and Tourbo Limited, Bombay

National Buildings Organization, New Delhi

Hospital Services Consultancy Corporation ( I ndia ) Ltd, New Delhi

Ministry of Transport, Department of Surface Transport ( Roadr-

Wing ), New Delhi

Geological Survey of I ndia, Calcutta

Central Board of I rrigation and Power, New Delhi

Development Commissioner for Cement I ndustry ( Ministry of

I ndustry )

Engineer-in-Chiefs Branch, Army Headquarters

Hindustao Prefab Ltd, New Delhi

Central Road Research I nstitute ( CSI R ), New Delhi

I ndian Roads Congress, New Delhi

National Council for Cement and Building Materials, New Delhi

Directorate General of Supplies and Disposals, New Delhi

Structural Engineering Research Centre ( CSI R ), Madras

Builders Association of I odia, Bombay

Cement Corporation of I ndia, New Delhi

( Continued on page 5 f

4

lS 13311( Part 2 ) : 1992

( Continued from fuags 4 )

Msmbsrs

SARI T. N. SUBBA RAN

SHEI S. A. REDDI ( Alfanafr )

SUPT ENQINE~~( D~ls~o~s )

EXECUTIVE ENGINEER ( S. M. R. DIVISION

( Altarnot6 )

SHRI S. B. SURI

SHRI N. CHANDEAS~K~AN ( Allrrnotr )

DR H. C. VISVESVAXAYA

SHRI D. C. CHATTURVEDI ( Allrrnota )

SHRI G. RAXAN

Director ( Civil Engg )

Rcpr6srnfing

Gammon India Limited, Bombay

)

Public Works Department, Government of Tamilnadu

Central Soil and Materials Research Station, New Delhi

The Institution of Engineers ( India ), Calcutta

Director General, BIS ( Ex-ojicio Mcmbsr )

Sccrcfary

SHBI N. C. BANDYOPADHYAY

J oint Director ( Civil Engg ), BIS

Concrete Subcommittee, CED 2 : 2

ConzJ ancr

DB A. K. MULLJ CK

M6mbcrs

SHEI C. R. ALIXCHANDANI

SHRI S. RAN~ARAJ AN (Ak6rnak )

DE P. C. CHOWDHUBY

DR C. S. VISWANATEA (&atnote )

DEPUTY DIRECTOR ( EH )

ASSISTANT DIREOTOB ( EH ) ( A~fcrnafc )

DIEEOTOR (C & MDD )

DEPUTY DIRECTOR ( .=&fnata )

DIRECYOR

J OINT DIRECTOR ( A~tsrtkI fs )

SHR~ V. K. GHANEKAB

SHRI D. S. PRAKASK RAO ( &6fnafs )

SERI B. S. GUPTA u

SHRI S. K. GUHA THAKIJ BTA

SHRI S. P. SANKKRNARAYANAN ( Al t6rnaf6 )

SHRI G. R, HARIDAS

SHRI N. PRABHAKAR ( A~t6ri i afs )

SHRI J . S. HINQORANI

SHRI A. P. REMEDIOS ( Aftsmut )

SHRI LALIT KUUAR J AIN

J OINT DIRECTOR ( STANDAEDS ) ( B & S )/CB-1

J OINT DIRECTOR ( STANDARDS ) ( B & S )I

CB-II ( Aftarnatr )

%RI K. C. KARAMCBANDANI

SHRI N. K. GUPTA ( Al f6rnafs )

PROP S. KRISBNAYOORTHY

SHXI K: K. NAYAR ( &fcrnntc )

SERI V. M. MAD~E

SHRI S. B. MALEKAIZ ( df6rnak )

DE S. c. MAIJ X

MANAC+IN~DIRECTOU

SHBI M. KUNDD ( &6rnal6 )

SHRI N. V. MERANI

SH~I M. K. MVKHERJ I~~

SHRI N. K. SINEA I hf6fnUf6 1

SHR~B.V.B.PU

SERI A. D. KETK~B ( Allrrmatc J

SHSI Y. R. PHIL

SHRI S. S. SE~HBA ( &mat6 )

SHEI A. S. PRASADA RAN

SEEI K. MINI ( Al&maf# )

SUPEBINTENDINO EN~II~~~B ( D~IPNS )

EXECUTIVE ENCUN~~~B ( DB~I~NS )

111 ( Alf6rnofr)

SHBI B. T. UNWALLA

BRIO ( DB ) S. G. VOMBATKABP

SEIRI ?I. K. BEATTAOHAILYA ( &mat6 )

National Council for Cement and Building Materials, New Delhi

Stup Consultants Limited, Bombay

Torsteel Research Foundation in India, Calcutta

National Building Organization, New Delhi

Central Water Commission, New Delhi

A. P. Engiaeering Research Laboratories, Hyderabad

Structural Engineering Research Centre ( CSIR ), Ghaziabad

Central Building Research Institute ( CSIR ), Roorkee

Ganuon Dunkarley & Company Limited, Bombay

Gammon India Limited, Bombay

Associated Consulting Services, Bombay

In Personal Capacity ( 36 Sneh Nagar, Wardha Road, Nagpur-15 )

Research Designs and Standards Organization,

( Ministry of Railways ), Lucknow

Engineers India Limited, New Delhi

Indian Institute of Technology, New Delhi

The Hindustan Construction Co Ltd, Bombay

National Council for Cement and Building Materials, New Delhi

Hindustan Prefab Limited, New Delhi

Public Works Department, Bombay

Ministry of Transport ( Roads Wing ), New Delhi

The Associated Cement Companies Limited, Bombay

Central Road Research Institute, New Delhi

Structural Engineering tiesearch Centre ( CSIR ), Madras

Central Public Works Department, New Delhi

ID Personal Capacity ( 15/g, Rustom Baug, Victoria Road, @mby-27 ,

Enginee&n.Chiefs Branch, Army Headquarters, New Delhi

5

( Continued from second cover )

situations, any significant di f f erence in the ultrasonic pulse velocity or rebound indices between them

must be due to some inherent differences in the overall quality. If the nominal grades of concrete or

mix proportions are known to be different in either case, suitable allowance is made for the same in

interpretation of results.

The test results on ultrasonic pulse velocity and rebound indices are analysed statistically and plotted

as histograms and the lower fractiles of results are taken for assessing the quality or characteristic

strength of concrete, in line with the current limit state concepts of design.

The composition of the technical committee responsible for the formulation of this standard is given

at Annex A.

For the purpose of deciding whether a particular requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in

accordance with IS 2 : 1960 Rules for rounding off numerical values ( revised). The number of

significant places retained in the rounded off value should be the same as that of the specified value in

this standard.

Bureau of Indian Standards

BIS is a statutory institution established under the &treau of I ndian Stundurds Act, 2986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that

no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users

of Indian Standards should ascertain that they are in possession of the latest amendments or edition by

referring to the latest issue of BIS Handbook and Standards Monthly Additions.

This Indian Standard has been developed from Dot : No CED 2 t 3890 )

Amendments Isshed Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telegrams : Manaksanstha

Telephones : 3310131,331 13 75 (Common to all offices)

Regional Offices : Telephone

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern : l/14 C. LT. Scheme VII M, V. I. P. Road, Maniktola

CALCUTTA 700054

Northern : SC0 335-336, Sector 34-A CHANDIGARH 160022

Southern : C. I . T. Campus, IV Cross Road, MADRAS 600113

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

BOMBAY 4fKKl93

{

3310131

331 13 75

{

378499,378561

378626,378662

-c

603843

602025

{

235 02 16,235 04 42

235 15 19,235 23 15

632 92 95,632 78 58

632 78 91,632 78 92

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD.

JAIPUR. KANPUR. LUCKNOW. PATNA. THIRUVANANTHAPURAM.

Printed at Printograph, New Delhi-5 (INDIA)

S-ar putea să vă placă și

- Som Lab Manual NnceDocument39 paginiSom Lab Manual Nncelogeshboy007Încă nu există evaluări

- Road Construction Project ReportDocument41 paginiRoad Construction Project ReportmukeshÎncă nu există evaluări

- Nandpur Mairi Road M-15 Mix Design of ConcreteDocument8 paginiNandpur Mairi Road M-15 Mix Design of ConcreteAnkush PatialÎncă nu există evaluări

- DBM Job MixDocument3 paginiDBM Job MixSOIGNE ENGINEERING CONSULTANTSÎncă nu există evaluări

- BITUMEN LAB TEST CHARGESDocument7 paginiBITUMEN LAB TEST CHARGESRenga PandiÎncă nu există evaluări

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 paginiSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarÎncă nu există evaluări

- Cement Concrtet Mix Design of M-20 Grade For RCC WorkDocument7 paginiCement Concrtet Mix Design of M-20 Grade For RCC WorkSandip Roy100% (1)

- Calculations For Safe Bearing CapacityDocument3 paginiCalculations For Safe Bearing Capacityimran khanÎncă nu există evaluări

- DLC & WMM Belending (Z-1)Document9 paginiDLC & WMM Belending (Z-1)End EndÎncă nu există evaluări

- 2015 Estimating MDD and OMCDocument9 pagini2015 Estimating MDD and OMCKrmt Goji SamaratunggadewaÎncă nu există evaluări

- Bituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Document4 paginiBituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Mozibur RahmanÎncă nu există evaluări

- National Highways Authority of India: Bitumen Extraction TestDocument2 paginiNational Highways Authority of India: Bitumen Extraction Testmanish upadhyayÎncă nu există evaluări

- Compressive Strength of AAC BlockDocument11 paginiCompressive Strength of AAC BlockImran KhanÎncă nu există evaluări

- Mastic-Mix DesignDocument10 paginiMastic-Mix DesignVaasu KotyadaÎncă nu există evaluări

- Test Reports PDFDocument25 paginiTest Reports PDFAbdelhamid ElgasaierÎncă nu există evaluări

- Density, Porosity, and Compaction of Sedimentary RocksDocument24 paginiDensity, Porosity, and Compaction of Sedimentary RocksnewmetroÎncă nu există evaluări

- Study of Strength Properties of Polyester Fibre Reinforced ConcreteDocument5 paginiStudy of Strength Properties of Polyester Fibre Reinforced ConcreteJournal 4 ResearchÎncă nu există evaluări

- Six Lanning of Delhi Agra Section Wet Mix Macadam CalibrationDocument12 paginiSix Lanning of Delhi Agra Section Wet Mix Macadam CalibrationRSBIPL NH17 LABÎncă nu există evaluări

- Sieve Analysis For Fine Aggregate - Kico ProjectDocument1 paginăSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanÎncă nu există evaluări

- Quality TestDocument22 paginiQuality TestUmair Shaikh100% (1)

- Sieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Document1 paginăSieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Mitendra Kumar ChauhanÎncă nu există evaluări

- KSR Job Mix DBM II - pdf-1Document6 paginiKSR Job Mix DBM II - pdf-1Ankur BarsainyaÎncă nu există evaluări

- DBM Dencity CalculationDocument3 paginiDBM Dencity Calculationer_kenedyÎncă nu există evaluări

- Value Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8Document2 paginiValue Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8vishal gupta0% (1)

- Field Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02Document1 paginăField Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02zealbalaÎncă nu există evaluări

- Quality Control Format For MPR Ex Dsc-2Document7 paginiQuality Control Format For MPR Ex Dsc-2Rahmat mulyadiÎncă nu există evaluări

- Effect of Fly-Ash On Geotechnical Characteristics of Black Cotton SoilDocument5 paginiEffect of Fly-Ash On Geotechnical Characteristics of Black Cotton SoilIJIRSTÎncă nu există evaluări

- Hammer Test ReportDocument1 paginăHammer Test ReportMostafizur RahmanÎncă nu există evaluări

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 paginiDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaÎncă nu există evaluări

- Concrete MIx Design SummaryDocument4 paginiConcrete MIx Design SummaryAmarÎncă nu există evaluări

- Shree Balaji Test House Pvt. Ltd. Geotechnical ReportDocument64 paginiShree Balaji Test House Pvt. Ltd. Geotechnical ReportPhani Krishna BadipatiÎncă nu există evaluări

- Itp - RoadDocument5 paginiItp - RoadBiswajit BarikÎncă nu există evaluări

- Sr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDDocument6 paginiSr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDAyan DuttaÎncă nu există evaluări

- Model I.R. - GSB+WBM GR - II+CC - 20.01.2014Document38 paginiModel I.R. - GSB+WBM GR - II+CC - 20.01.2014yedlasÎncă nu există evaluări

- Dense Bituminous MacadamDocument22 paginiDense Bituminous MacadamahmadsulÎncă nu există evaluări

- GSB (Coarse Graded) Summary Sheet: Physical PropertiesDocument10 paginiGSB (Coarse Graded) Summary Sheet: Physical PropertiesjitendraÎncă nu există evaluări

- Liquid Limit TestsDocument41 paginiLiquid Limit Testsindu_lidooÎncă nu există evaluări

- Concrete Roads Mix Design Per IRC CodeDocument11 paginiConcrete Roads Mix Design Per IRC CodeAnonymous MaSR3PÎncă nu există evaluări

- Test Report Volume - 2 PDFDocument495 paginiTest Report Volume - 2 PDFakilan100% (1)

- Bitumen Content TestingDocument9 paginiBitumen Content TestingjaffnaÎncă nu există evaluări

- Determination of Field Density of Soil by Core Cutter MethodDocument3 paginiDetermination of Field Density of Soil by Core Cutter MethodsiddiqueakbarÎncă nu există evaluări

- CompressiveStrength (ASTM-C39) Test ReportDocument21 paginiCompressiveStrength (ASTM-C39) Test ReportNadira PervinÎncă nu există evaluări

- of Standard Penetration TestDocument19 paginiof Standard Penetration Testrishav baishyaÎncă nu există evaluări

- Methodology of UPVDocument3 paginiMethodology of UPVAnonymous eKt1FCDÎncă nu există evaluări

- Summary of Quality Control Tests Required For BridgesDocument4 paginiSummary of Quality Control Tests Required For BridgesJakka LakshmikanthÎncă nu există evaluări

- SBPROTECH LUCKNOW METRO METHOD STATEMENTDocument5 paginiSBPROTECH LUCKNOW METRO METHOD STATEMENTDeepak GareraÎncă nu există evaluări

- Results of Compressive Strength of Concrete / Grout CubesDocument1 paginăResults of Compressive Strength of Concrete / Grout CubesSABEASNÎncă nu există evaluări

- ETHIOPIAN CONSTRUCTION LAB TESTINGDocument2 paginiETHIOPIAN CONSTRUCTION LAB TESTINGBikaZeeÎncă nu există evaluări

- Experimental Study on Permeable Concrete Pavement for Storm Water ManagementDocument28 paginiExperimental Study on Permeable Concrete Pavement for Storm Water ManagementVaidyanathan SivasubramanianÎncă nu există evaluări

- Quality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteDocument9 paginiQuality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteRadhakrishna KPÎncă nu există evaluări

- Asphalt Concrete Ingredient, Design, Production and LayingDocument17 paginiAsphalt Concrete Ingredient, Design, Production and LayingKali Bahadur ShahiÎncă nu există evaluări

- Ayni-Panjakent-Uzbekistan Border Road: List of Test FormsDocument58 paginiAyni-Panjakent-Uzbekistan Border Road: List of Test FormsGolam Masud100% (1)

- Hardness of RockDocument7 paginiHardness of RockPushpendra ChouhanÎncă nu există evaluări

- Road Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All MaterialsDocument53 paginiRoad Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All Materialssunil kuldeepÎncă nu există evaluări

- Concrete Methods of Test Fresh ConcreteDocument4 paginiConcrete Methods of Test Fresh Concretecevivekt0% (1)

- Theoretical Blending: EPC Contractor ClientDocument4 paginiTheoretical Blending: EPC Contractor ClientDeepakÎncă nu există evaluări

- Use of Waste Plastic in Bituminous Concrete MixDocument51 paginiUse of Waste Plastic in Bituminous Concrete MixRahul KumarÎncă nu există evaluări

- Sieve Analysis of Coarse AggDocument10 paginiSieve Analysis of Coarse AggcaddÎncă nu există evaluări

- FDT Part 1Document1 paginăFDT Part 1bilalÎncă nu există evaluări

- Is 13311.2.1992 PDFDocument12 paginiIs 13311.2.1992 PDFTayyab AnwarÎncă nu există evaluări

- Benefits and Limitation of Concretes With SCMsDocument19 paginiBenefits and Limitation of Concretes With SCMsChockalingamÎncă nu există evaluări

- Highway Planning Alignment SEODocument17 paginiHighway Planning Alignment SEOChockalingamÎncă nu există evaluări

- Ae - Notification - Final - PDF 2168Document57 paginiAe - Notification - Final - PDF 2168Sathya PatcheappinÎncă nu există evaluări

- Springer Text Books: S.No. Book Title Author Edition OpenurlDocument21 paginiSpringer Text Books: S.No. Book Title Author Edition OpenurlGustavo ReyesÎncă nu există evaluări

- Evaluation and Maintenance of Pavements - MCQDocument5 paginiEvaluation and Maintenance of Pavements - MCQChockalingamÎncă nu există evaluări

- Final Manual For Specification StandardsDocument192 paginiFinal Manual For Specification Standardsbhargavraparti100% (1)

- Highway Construction Materials and Practice - MCQDocument7 paginiHighway Construction Materials and Practice - MCQChockalingamÎncă nu există evaluări

- Different MaterialsDocument15 paginiDifferent MaterialsChockalingamÎncă nu există evaluări

- X10834 (Oce751)Document2 paginiX10834 (Oce751)Chockalingam100% (4)

- Is 10262 - 2019 NewDocument44 paginiIs 10262 - 2019 NewAkshay dabke100% (1)

- X10834 (Oce751)Document2 paginiX10834 (Oce751)Chockalingam100% (4)

- Different MaterialsDocument15 paginiDifferent MaterialsChockalingamÎncă nu există evaluări

- EIA Project Assessment and ManagementDocument1 paginăEIA Project Assessment and ManagementChockalingam64% (14)

- Highway Engineering QuestionsDocument26 paginiHighway Engineering QuestionsChockalingamÎncă nu există evaluări

- SOM & Soil - GATE QuestionsDocument23 paginiSOM & Soil - GATE QuestionsChockalingamÎncă nu există evaluări

- Modul Kawalan KebisinganDocument66 paginiModul Kawalan KebisinganHafiz Sabri100% (1)

- Mechanical Properties of No Fines Concrete For PathwaysDocument14 paginiMechanical Properties of No Fines Concrete For PathwaysChockalingamÎncă nu există evaluări

- Anna University Annexure 1 Journals 2019Document232 paginiAnna University Annexure 1 Journals 2019Hasib Al-ariki54% (13)

- PSU's Recruiting Thro' GATE 2020 For CivilDocument6 paginiPSU's Recruiting Thro' GATE 2020 For CivilChockalingamÎncă nu există evaluări

- Studies On The Properties of Pervious Fly Ash-Cement Concrete As A Pavement MaterialDocument17 paginiStudies On The Properties of Pervious Fly Ash-Cement Concrete As A Pavement MaterialChockalingamÎncă nu există evaluări

- OCE551 AIR POLLUTION CONTROL ENGINEERINGDocument1 paginăOCE551 AIR POLLUTION CONTROL ENGINEERINGChockalingam100% (1)

- 02.civil - Open Elective SyllabusDocument20 pagini02.civil - Open Elective SyllabusChockalingamÎncă nu există evaluări

- Code of Practice (Part - 1) Cross Section: Institute of Urban TransportDocument78 paginiCode of Practice (Part - 1) Cross Section: Institute of Urban TransportchharingÎncă nu există evaluări

- Construction and Building Materials: Bradley J. Putman, Andrew I. NeptuneDocument6 paginiConstruction and Building Materials: Bradley J. Putman, Andrew I. NeptunemargarethsmÎncă nu există evaluări

- Ground Water Level Scenario in India Premonsoon 2017Document43 paginiGround Water Level Scenario in India Premonsoon 2017Govindarajan BangaruÎncă nu există evaluări

- Final Manual For Specification StandardsDocument192 paginiFinal Manual For Specification Standardsbhargavraparti100% (1)

- Unit-2 Chemical and Mineral AdmixturesDocument3 paginiUnit-2 Chemical and Mineral AdmixturesChockalingamÎncă nu există evaluări

- Construction and Building Materials: Bradley J. Putman, Andrew I. NeptuneDocument6 paginiConstruction and Building Materials: Bradley J. Putman, Andrew I. NeptunemargarethsmÎncă nu există evaluări

- URKUND Plagiarism HandbookDocument16 paginiURKUND Plagiarism HandbookNaGi Sincera D CorazonÎncă nu există evaluări

- Urkundfaq PDFDocument5 paginiUrkundfaq PDFChockalingamÎncă nu există evaluări

- UTAR Faculty of Science Chemistry Lab SessionsDocument3 paginiUTAR Faculty of Science Chemistry Lab SessionsYong LiÎncă nu există evaluări

- Test Questions GRADE 9 NAIL CAREDocument2 paginiTest Questions GRADE 9 NAIL CARESharmaine ManigosÎncă nu există evaluări

- Impact of Monetary Incentives On Employees' Performance in Federal Polytechnic NasarawaDocument45 paginiImpact of Monetary Incentives On Employees' Performance in Federal Polytechnic NasarawaChida EzekielÎncă nu există evaluări

- Bbi 2420 Assignment 1 PortfolioDocument19 paginiBbi 2420 Assignment 1 PortfolioJamili NordinÎncă nu există evaluări

- Machine Learning Assignment Differences Between Linear And Logistic RegressionDocument4 paginiMachine Learning Assignment Differences Between Linear And Logistic Regressionbharti goyalÎncă nu există evaluări

- Echosounder Series HD370 380 390 ManualDocument54 paginiEchosounder Series HD370 380 390 Manuallo5tboy5Încă nu există evaluări

- ARBITRATION Project File LLB-4th Sem PDFDocument3 paginiARBITRATION Project File LLB-4th Sem PDFmeenakshi kaur0% (9)

- At-Home Edition!: Darryl'S HP (Happy Parent) Restoring Tonic Recipe Glenn Asks: What Is A Lock, Really?Document9 paginiAt-Home Edition!: Darryl'S HP (Happy Parent) Restoring Tonic Recipe Glenn Asks: What Is A Lock, Really?Howdy Magic RodeoÎncă nu există evaluări

- WCW - 1993 Training + Contracts 1994Document65 paginiWCW - 1993 Training + Contracts 1994Col. O'NeillÎncă nu există evaluări

- INTEGMED1Document17 paginiINTEGMED1Nica RTÎncă nu există evaluări

- 30 SUMITA-SINHA Political-ScienceDocument13 pagini30 SUMITA-SINHA Political-ScienceNicole OliverÎncă nu există evaluări

- Axioms Are Objects, Too - Ontology Engineering Beyond The Modeling of Concepts and RelationsDocument16 paginiAxioms Are Objects, Too - Ontology Engineering Beyond The Modeling of Concepts and RelationsJose Marcelo SchiesslÎncă nu există evaluări

- Scope of Work - Flow Line SurveyDocument2 paginiScope of Work - Flow Line SurveyrutujaÎncă nu există evaluări

- Proceedings RAD 2012Document402 paginiProceedings RAD 2012Ngôn NguyễnÎncă nu există evaluări

- Sartorius YDP20-0CE PrinterDocument116 paginiSartorius YDP20-0CE Printerblockhead135399Încă nu există evaluări

- Affect and Cognition As Psychological ResponsesDocument17 paginiAffect and Cognition As Psychological ResponsesHarley David Reyes BlancoÎncă nu există evaluări

- Case Study 4: Rescuing NissanDocument3 paginiCase Study 4: Rescuing NissanAngel GondaÎncă nu există evaluări

- Anemia ProjectDocument33 paginiAnemia ProjectNilesh BagalÎncă nu există evaluări

- State of New Jersey Department of Labor and Workforce DevelopmentDocument52 paginiState of New Jersey Department of Labor and Workforce DevelopmentMaria EÎncă nu există evaluări

- MRO Accreditation MC186 - For PostingDocument5 paginiMRO Accreditation MC186 - For PostingNairdna P Led OirasorÎncă nu există evaluări

- BT0062Document21 paginiBT0062Icaii InfotechÎncă nu există evaluări

- MXenes 2D Materials Properties ApplicationsDocument7 paginiMXenes 2D Materials Properties ApplicationsSalman KhanÎncă nu există evaluări

- ProPath Selected As Medical Director For Baylor Scott & White Medical Center - SunnyvaleDocument3 paginiProPath Selected As Medical Director For Baylor Scott & White Medical Center - SunnyvalePR.comÎncă nu există evaluări

- HarnWorld d20 - Harn GuideDocument44 paginiHarnWorld d20 - Harn GuideJamesBirmingham100% (1)

- Cassava Grindier Project PDFDocument9 paginiCassava Grindier Project PDFChuku EbubeÎncă nu există evaluări

- CV For UnescoDocument6 paginiCV For UnescoArpan BhujuÎncă nu există evaluări

- Ventilator Emvie 9+Document6 paginiVentilator Emvie 9+dedezagita_1_laelyÎncă nu există evaluări

- 2018 Analisis Perbandingan Pendapatan Usahatani Padi Organik Dan Anorganik Di Kecamatan Seputih Banyak Kabupaten Lampung Tengah (Leksono, Tri Budi., Supriyadi., Dan Zulkarnain)Document11 pagini2018 Analisis Perbandingan Pendapatan Usahatani Padi Organik Dan Anorganik Di Kecamatan Seputih Banyak Kabupaten Lampung Tengah (Leksono, Tri Budi., Supriyadi., Dan Zulkarnain)Bagus gunawanÎncă nu există evaluări

- Bizhub C360i C300i C250i SeriesDocument16 paginiBizhub C360i C300i C250i SeriesCCS HHYDÎncă nu există evaluări

- Vol II Tech Spec Sct1367Document490 paginiVol II Tech Spec Sct1367ashish.mathur1Încă nu există evaluări