Documente Academic

Documente Profesional

Documente Cultură

Designing PV Systems for Grid Connection

Încărcat de

Jose Antonio AbadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Designing PV Systems for Grid Connection

Încărcat de

Jose Antonio AbadDrepturi de autor:

Formate disponibile

Renewable Energy 31 (2006) 20422062

Design of grid connected PV systems considering

electrical, economical and environmental aspects:

A practical case

Alberto Ferna ndez-Infantes

a

, Javier Contreras

a,

,

Jose L. Bernal-Agust n

b

a

E.T.S. de Ingenieros Industriales, University of Castilla-La Mancha, Avda. Camilo Jose Cela s/n.,

13071 Ciudad Real, Spain

b

Department of Electrical Engineering, University of Zaragoza, Calle Mara de Luna, 3., 50018 Zaragoza, Spain

Received 5 August 2005; accepted 28 September 2005

Available online 2 November 2005

Abstract

This paper presents the complete design of a photovoltaic installation that may be either used for

internal electric consumption or for sale using the premium subsidy awarded by the Spanish

Government. Electric optimization strategies are detailed in the project, as well as the sizing of the

photovoltaic installation and economic and nancial issues related to it. The project optimizes the

electricity demand, improving reactive power and studying the convenience of hourly discrimination

fees in addition to the design of the photovoltaic installation. A specic computer application for the

automated calculation of all relevant parameters of the installationphysical, electrical, economical

as well as ecologicalhas been developed to make the process of calculating photovoltaic

installations easier and to reduce the design development time. Moreover, the budget of the

photovoltaic installation is included, as well as its corresponding nancial ratios and payback

periods. Finally, the conclusions reached in the technical and economic design of the installation are

shown.

r 2005 Elsevier Ltd. All rights reserved.

Keywords: Photovoltaic energy; Power optimization; Renewable energies; Computer application

ARTICLE IN PRESS

www.elsevier.com/locate/renene

0960-1481/$ - see front matter r 2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.renene.2005.09.028

Corresponding author. Tel.: +34 926 295464; fax: +34 926 295361.

E-mail address: Javier.Contreras@uclm.es (J. Contreras).

1. A brief history of the project

The project starts as a response to the inquiry placed by the High School Ojos del

Guadiana (Fig. 1) in Daimiel, Ciudad Real, Spain, to the Industrial Engineering School

at Ciudad Real to study the feasibility of a photovoltaic installation within their premises.

Preliminary studies begin in September 2004 and the project is nished in March 2005.

Within these 6 months, the forecasted electric demand, the available surface to place the

solar arrays, overall funding, and other relevant data are exhaustively studied in order to

build a design according to the needs of the Centre. The main innovation of this project

resides in the development of a computer application to design the photovoltaic

installation connected to the grid. This application considers all relevant parameters,

allowing for an interactive design that takes into account all the electric, nancial and

economic data simultaneously. In addition, we have reduced the development time and run

several sensitivity analysis studies to compare different solutions.

2. Proposals for optimizing the electricity consumption

The activities oriented to optimize the electricity consumption have produced the results

described in the following subsections.

2.1. Feasibility study of the electricity demand of the Centre

The results of the preliminary study of the electrical consumption conrm a worrying

increase in the demand: from 32,200 kWh and 23,200 kVArh in year 2000 to 44,070 kWh

and 28,900 kVArh in 2004, as shown in Fig. 2. In 2005, the trend is even sharper. With the

beginning of the construction of a new annex building equipped with 2 classrooms and a

library, demand forecasts are even bigger. The prediction of electric demand for 2005 is

48,100 kWh and 32,000 kVArh. Thus, we plan a strategy based on three key points to

reduce the electricity bill:

1. Optimization of the current electricity consumption studying the possibility of including

reactive compensation equipment and the convenience of signing for different hourly

price discrimination fees.

ARTICLE IN PRESS

Fig. 1. Computer simulation of the High School Ojos del Guadiana building in Daimiel, Ciudad Real, Spain.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2043

2. Reduction of the electric demand in the next years, proposing basic rules for saving

energy and the selection of new electrical equipment in the future.

3. Feasibility study of a photovoltaic installation connected to the low voltage network

that would cover part of the annual demand of the Centre with solar energy.

To calculate the demand for each bimonthly period, or even for a monthly period, is a

complex task, due to the presence of seasonality, with peaks during the months of January

and February (corresponding to the March invoice) and troughs during July and August,

in which the Centre is closed (September invoice). The most precise way to adjust all data is

to use a moving averages model of 6 periods (equivalent to 1 year).

To predict the electricity demand for 2005 we proceed to seasonalize and deseasonalize

the consumption data from 2000 to 2005, using the centred and non-centred 6-point

moving averages model [1] as shown below:

Pm

t

=

P

t6

i=t

T

i

6

, (1)

Pmc

t

=

Pm

t

Pm

t1

2

, (2)

IE

t

=

T

t

Pmc

t

, (3)

where T

i

is the demand in the bimonthly period i. Assuming that the active and reactive

energy consumptions for a 2-month period are known, we calculate the moving averages

values for 6 periods, as indicated in (1); later, we nd the centred moving average value,

Pmc

i

, from Pm

i

and Pm

i1

, as shown in (2). And from the moving averaged value centred

in period i and the demand of that period, we obtain the seasonality index of period T

i

,

IE

i

, as shown in (3).

Since the algorithm based on moving averages condenses all the data of the year in a few

values, we use linear interpolation for year 2005 to approximate more accurately. From

available data of the JanuaryFebruary periods for the years 20002004, we extrapolate

the same data for the year 2005, and the same process is repeated for all bimonthly periods.

With the actual data from 2000 to 2004 and the rst forecast for 2005 we proceed to

ARTICLE IN PRESS

0

10000

20000

30000

40000

50000

60000

k

W

h

/

k

V

A

r

h

Active Energy Reactive Energy

2000 2001 2002 2003 2004 2005

Year

Fig. 2. Annual development of the electricity demand of the Centre and future trend obtained using interpolation.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2044

calculate the seasonality indexes for each of the periods. Once this is done, we order the

seasonality indexes in columns and we calculate the seasonality indexes corresponding to

each of the bimonthly periods, so that the sum of all of them is equal to 6, which is the

number of periods considered in a yearly cycle. With this we obtain the factors to weigh the

linear estimation for the complete year (obtained from the overall consumption data in

previous years, as shown in Fig. 3). In this way, we obtain the weighted demand for each of

the bimonthly periods. To approximate the demand prole even more, we have distributed

the result for each bimonthly period between the two months, using a smooth distribution

function that considers the number of working days of the month.

2.2. Compensation of reactive energy

The compensation of reactive energy may result in a 4% bonus in the electricity bill, as

opposed to the current 5% penalty, if it were possible compensate between 90% and 98%

of the total reactive energy demand. Currently, for every billing period, the average value

of the power factor cos j is given by

cos j =

E

a

E

2

a

E

2

r

q , (4)

where E

a

and E

r

are the values of the active and reactive energy demands, respectively,

during the billing period.

Using Eq. (5) we can calculate the penalty or the bonus applied by Spanish law; it is

limited to 47% in case of penalty, and to 4% in case of bonus:

k

r

(%) =

17

cos

2

j

p 21. (5)

In our calculations we specically take this fact into account for the year 2005. Later, we

compare the bills with and without compensation to obtain the annual savings.

Likewise, we calculate the reactive power of the equipment necessary to compensate the

reactive demand, based on the total amount of the demand (with the exception of a base

level demand of the entire year, which is consumed by static equipment and concentrated

within the daily 8 h with the highest demand). Thus, a piece of equipment of 17.5 kVAr

should meet the demand 100% of the time, smaller units ranging from 12.5 to 15 kVAr

ARTICLE IN PRESS

C

o

s

0

2000

4000

6000

8000

10000

12000

Jan-00 May-00 Sep-00 Jan-01 May-01 Sep-01 Jan-02 May-02 Sep-02 Jan-03 May-03 Sep-03 Jan-04 May-04 Sep-04 Jan-05

k

V

A

h

/

k

V

A

r

h

0.00

0.20

0.40

0.60

0.80

1.00

1.20

Active Energy Reactive Energy Cos

Fig. 3. Development of the active and reactive electricity demands of the Centre, showing seasonalities.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2045

may be unable to meet the demand sometimes, and the compensation would not be

optimal (98% of reactive demand).

2.3. Reduction of electricity consumption

We present a series of actions for the following years, especially for 2005, where the

demand shows a marked trend to increase. The suggested actions are fundamental to keep

a certain level of independence with respect to the future incomes obtained from

photovoltaic generation. The actions can be reduced to the following ones:

+ Rational use of energy.

+ Replacement of obsolete equipment of high consumption whenever possible.

+ Progressive renewal of current lighting equipment by new equipment with reectors and

electronic ballasts.

+ Discarding the use of electricity for heating (furnaces, convectors, accumulators, etc.),

only allowing it for heat pumps and refrigerators.

+ Adaptation of the computer equipment: selection of moderate consumption feeders and

LCD-type screens.

+ Publicity campaign oriented to the students promoting consumption moderation and

environmental consciousness in public and in private.

+ Periodic reporting of the energy savings results.

3. Photovoltaic installation design method

Once the convenience of having a solar photovoltaic installation has been decided, we have

to consider the limited economic funds available to the Centre. Thus, instead of choosing a

traditional design based on power from generators and inverters we seek a more exible design

method that takes into account all the parameters that can have an inuence on: performance,

production, nancial data, available subsidies, remuneration for selling electricity, taxes

applied to the remuneration, annual quota in concept of repayment once the electricity sales

income is discounted, etc. This custom-made concept is the most innovative feature of this

project; Fig. 4 reects the main differences between both design philosophies.

In this way, our automated calculation of the solar photovoltaic installation generates

numerous advantages compared to a traditional design method:

+ It considers many more parameters, in fact, more than 60.

+ It allows for a better-adjusted design where we can alter parameters such as power,

surface, orientation, production of energy, protability, etc.

+ Fast sensitivity analysis of inuential parameters.

+ Faster design process with many scenarios that reect particular needs.

+ For a quick modication of the parameters we link our application to a database that

includes the main features of the most popular photovoltaic panels and inverters; by

typing the code and the number of units, the application collects all data necessary to

proceed with the calculations.

The main factors considered in our computer application that affect the performance of

the photovoltaic generators are described in following subsections.

ARTICLE IN PRESS

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2046

3.1. Solar irradiation data variability

While the Atlas of Solar Radiation in Spain provides the most optimistic data, the most

conservative data come from the NASA web site [2], showing a standard deviation of 3.6%

and a variability greater than 7%. We use data from NASA Surface Meteorology and Solar

Tables (SSE). As shown in Table 1 obtained from [3], it can be observed that actual

readings obtained in the same place by different sources provide results that vary around

10%. Thus, we consider adequate using the most pessimistic available data.

ARTICLE IN PRESS

Fig. 4. Diagram comparing the traditional design process versus our exible calculation method.

Table 1

February and yearly averages of the daily horizontal global irradiation in Algiers, according to different sources

Information source February G

d

(0) (kWh/m

2

) Yearly average (kWh/m

2

)

CDER 3.03 4.23

Capde rou 3.20 4.60

Censolar 3.00 4.37

NASA 2.90 4.45

Meteonorm 3.00 4.52

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2047

3.2. Losses due to shading over the PV panels

They can be due to distant shading (trees, posts, nearby buildings, etc.) if shadows

interpose between the sun and the panels during the day, or due to direct shading, if there

are several rows of panels arranged in the same horizontal plane.

Losses can be important, because of that, the location must be carefully chosen to avoid

distant shading as much as possible, whereas, to avoid direct shading, we can opt to split

each row of panels arranged in the same plane, or to elevate them on an inclined surface.

To estimate losses due to distant shading we use the method proposed by the Institute for

diversication and energy savings (IDAE) [4] of Spain, by superposing the prole of visible

obstacles observed from the installation point to a graph of solar trajectories (see Fig. 5).

Each sector of the graph has an associated loss coefcient that varies according to the

orientation and the slope of the panels. We calculate each of the sectors intercepted by the

shading prole and we add up the corresponding coefcients obtained from a table,

depending on the orientation and slope of the panels. This results in a loss percentage for a

particular location. This is the only loss contribution that is not automated in our

program; Fig. 5 shows that there are no obstacles in the solar trajectory and losses are

negligible (0.2%).

On the other hand, losses due direct shading are estimated to be around 2% [4]. Lower

values cannot be considered for a at-grounded placement, even if the distance between

two consecutive rows is greater than the one shown in (6), such that

d

min

=

h

vertical

k

, (6)

where coefcient k is calculated as [tan(611latitude)]

1

. The latitude of the location is 391

05

/

N; therefore coefcient k is: [tan(61139105

/

)]

1

= [tan(21155

/

)]

1

= 2.4855.

We obtain the height of the panel, according to its dimensions and optimal slopes, from

Eq. (7). Also, we can deduce the minimum spacing between rows of modules using Eq. (8).

h

vertical

= L

mod

sin(b) h

sup

, (7)

d

min

= k[L

mod

sin(b) h

sup

] = 2:4855 [1:593 sin(30:67

) 0]

2:55[m], (8)

ARTICLE IN PRESS

Fig. 5. Superposition of the solar trajectories diagram to a panoramic view of the roof for shading calculation.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2048

where b is the inclination angle that turns out to be 30.671, as shown in Section 3.4. See

Fig. 6 for a pictorial description of the calculations.

3.3. Losses due to electric conductors

These losses are important in DC, when the voltage is low. It is crucial to conveniently

size the conductor sections so that the voltage drop is less than 1.5%. It is also important:

to place the generators close to the inverters, to work at the maximum DC voltage that the

panels and the inverters can withstand, to increase the conversion performance, and to

reduce ohmic losses. Depending on the conductor section considered, our computer

application calculates losses due to voltage drop in DC.

3.4. Slope, orientation and glass surface reexivity of the PV panels

Usually, if the PV panels are not perfectly oriented to the south (azimuth 01 in the

northern hemisphere), their orientation can originate a considerable loss of efciency.

Likewise, the slope of the panels should be changed two to four times a year to maximize

the solar absorption, since the optimum slope in the summer is not the same as the

optimum one in the winter.

Glass surface reexivity protects the panels from the accumulation of dirt in the surface;

a dirty glass reects a percentage of energy that increases with the divergence of the

incidence angle with respect to a perpendicular line to the glass surface plane (a glass

reects more light and looks dirtier when you observe it from the side). This causes the

panels to reect part of the direct radiation and the majority of the diffuse radiation

available. Rain can solve this problem, but in the summer season the efciency of the

radiation is signicantly reduced unless the surface of the panels is cleaned on a regular

basis.

We use Eq. (9) to calculate the optimal slope [5]:

b

opt

= 3:7

0:69 f, (9)

where b

opt

is the inclination angle that optimizes the incident radiation over the panel

surface for a year, and f is the latitude of the location point. The optimal angle that is

obtained from Eq. (9) is 30.671.

ARTICLE IN PRESS

Fig. 6. Minimum spacing between two consecutive rows of panels as a function of the geometric parameters.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2049

Provided the optimal angle and the annual irradiation over a horizontal surface, (G

a

(0)),

it is possible to calculate the value of the annual irradiation for the optimal angle b

opt

using

G

a

(b

opt

) =

G

a

(0)

[1 4:46 10

4

b

opt

1:19 10

4

b

2

opt

]

. (10)

Finally, we calculate the incident effective annual irradiation over the generators surface,

denoted by G

eff

(b; a), using Eqs. (11) and (12) proposed in [5], including orientation, slope,

and reexivity due to dirt on the surface of the glass

G

eff

(b; a)

G

a

(b

opt

)

= g

1

(b b

opt

)

2

g

2

(b b

opt

) g

3

, (11)

g

i

= g

1i

[a[

2

g

2i

[a[ g

3i

; i = 1; 2; 3, (12)

where a is the azimuth, and the coefcients g

1i

, g

2i

, g

3i

depend on the degree of dirtiness of

the panel. For a medium-dirtiness case, the values of these coefcients correspond to the

ones shown in Table 2.

3.5. Efciency of the inverters

Despite being electrical equipment of high performance in DC/AC conversion, they

never reach 100% efciency [6]; they reach their optimum performance in the range of

8596% efciency for power values close to the nominal rating, while for the generation of

small amounts of powerin conditions of cloudiness, start-ups, sunrise and sunsetthe

efciency can diminish considerably. Spanish law [7] makes the use of inverters with a

minimum efciency at 25% of the nominal power compulsory, which means selecting good

equipment turns out to be fundamental. Also, the monitoring of the point of maximum

power and the adaptation to the variable conditions of generation involves a small loss of

power during normal operation conditions. For single-phase inverters, the sum of all the

losses can be about 820% of the total energy generated, depending on the quality of the

equipment. The data provided by the manufacturers for each model is included in the

database of the computer application; we also consider a loss factor by monitoring the

Maximum Power Point (MPP) and the start-up/shutdown of the inverters.

3.6. Actual power produced by the PV panels

It is usually lower than the nominal value in catalogues [8]. Spanish law [7] establishes

that the power, measured in standard conditions, cannot be lower than 90% of the

ARTICLE IN PRESS

Table 2

Coefcients used in (11), with 97% transmittance due to dirt

T

dirty

(0)=T

clean

(0) = 0:97

Coefcients i = 1 i = 2 i = 3

g

i1

8 109 3.8 10

7

1.218 10

4

g

i2

4.27 107 8.2 10

6

2.892 10

4

g

i3

2.5 105 1.034 10

4

0.9314

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2050

nominal power value in catalogues. A breach of contract could be reason for refund

(almost all the manufacturers freely replace the panels if they do not comply with the

specication of the 90% of power), but one must consider that the standard conditions:

1000 W/m

2

, 25 1C in the surface of the cells and spectral distribution 1.5 AM, in which the

nominal power is measured, do not correspond to the real working conditions.

To reach a temperature of 25 1C in the cells of the panel, it is necessary that the ambient

temperature is, approximately, 5 1C. Provided that the ambient temperature is usually

greater than this value, there can be a decrease in the power delivered by the panels because

the open circuit voltage and the maximum power voltage diminish when the temperature

increases with respect to the nominal condition (25 1C). However, the current delivered by

the panel does not signicantly depend on the temperature. Therefore, the power delivered

by the panels is usually lower than the nominal one.

Our computer application considers the nominal power minus 10%, or the maximum

percentage guaranteed by the manufacturer, if it were smaller. Then, it is multiplied by a

variable coefcient [8] that takes into account: (i) the average temperature at noon for each

month in the considered location and (ii) the decrease of power due to temperature, as

explained above.

The relation between the power output of the panels and the nominal power of the PV is

calculated in

P

real

= P

nom

100 dev

nom

(%)

100

100 DP (25 T

cell

)

100

, (13)

where dev

nom

(%) is the maximum deviation of power guaranteed by the provider [W], DP

is the power variation for each degree increase in the temperature with respect to the 25 1C

nominal value [W/1C], and T

cell

is the average temperature of the cell during operating

conditions (atmospheric temperature while the sun is at its zenith plus an empirical

increment between 8 and 20 1C, depending on the climate).

Note that ageing and degeneration of the modules causes them to slightly decrease their

performance each year: due to UV irradiation, severe temperature changes have a

cumulative effect over the electrical production.

4. Final design of the grid connected PV installation

Once all data described in Section 3 are considered, we proceed to obtain the overall

electricity production for each monthly period, according to the longitude and latitude

data obtained, using Eq. (14) [5].

E

month

= P

nom

G

effect

G

+

F

Shadow

F

eff

kWh

month

, (14)

where P

nom

is the nominal power, as indicated by the manufacturer of the photovoltaic

panels in standard conditions, G

effect

is the effective annual incident irradiation over the

panel surface considering the orientation angle and the panel slope, G

+

is the value of the

irradiation for which P

max

is measured: 1000 W/m

2

, 25 1C, F

Shadow

is a factor that considers

the losses due to shading in the panel, F

eff

is an efciency factor including the losses in the

inverter, the losses in the generators at temperatures greater than 25 1C, and the voltage

drops in the lines.

ARTICLE IN PRESS

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2051

With all this, F

eff

oscillates between 0.7and 0.9 for a standard installation, and mainly

depends on the quality of the equipment selected. If F

eff

were lower than 0.7 it would imply

a decient performance of one or several components.

The optimal dimension of the photovoltaic installation that meets all High School

requirements is a plant composed of 72 modules, each module with a peak production of

160 peak power or Wp (total production is 11,520 Wp). The plant is arranged in 12 groups

of 6 modules, where each group produces 960 Wp. The modules are connected in series and

operate at 210 V and 4.55 A in nominal rate. Every 3 groups of 6 modules are also

connected to the inverter through a pair of wires, so each pair of wires (4 pairs in total)

operates at 210 V, 13.65 A and 2880 W (nominal rate). See Fig. 7 for details. The panels are

oriented to the south forming an angle of 11.231 with respect to the main orientation of the

roofs of the building. The modules are manually mounted on inclinable supports to

maximize the electric power generation. The optimum slope in case of xed supports is

30.671, as calculated in Eq. (9).

As shown in Fig. 8, the generation plant is connected to 3 single-phase inverters; two of

them withstand 2600 W during nominal operation, and the other one withstands 4600/

5200 W. The latter can be connected either to 5 or to 6 basic groups of 6 photovoltaic

modules to reduce total investment without modifying the optimal performance

ARTICLE IN PRESS

Fig. 7. Arrangement and connections of the photovoltaic modules.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2052

conditions. Each inverter comes with its own electrical protections and is connected to one

of the phases (R, S, T) of the low voltage grid, delivering power ranging from 9800 to

10,400 W. To ensure the optimal protection of the electrical equipment and the inverters

from their environment, they are located within a 1.50 2.50 m brick-made shelter placed

beside the High Schools gym, conveniently insulated against rain and humidity and

adequately ventilated. See Fig. 9 for an overall 3D view of the installation, including the

inverters shelter, and Fig. 10 for a detailed view of the solar panels.

The power ratio (P

Generator

=P

Inverters

) is near 1.10. The efciency of the inverters is

typically 94% (maximum efciency is 96%). The section of the cables has been enlarged by

design to reduce DC losses, and the location of the power lines and inverters has been

chosen to reduce the distance to the MV/LV transformer substation. The lines from the

modules to the inverters are aerial, whereas the three-phase line to the main grid is buried

underground.

The electrical production of the installation would approximately meet 29% of the

estimated demand for 2005, as shown in Fig. 11, but it would have met 43% of it in the

year 2000, 42% in 2001, 35% in 2002, and 32% in 2003. That is why it is equally important

to take actions to also reduce the electric consumption, as detailed in Section 3.2. The

calculation of the photovoltaic power production is automated in our computer

application from data inputs. Fig. 12 compares the forecast of the photovoltaic generated

energy versus the forecast of electrical demand of the High School per month. The energy

produced per kWp in such conditions is about 1207 kWh per year. This data is far from the

optimistic forecasts of many photovoltaic manufacturers, who predict values between 1300

and 1500 kWh per year. Note that our installation is optimized for normal operation and

does not have shading effects [9].

ARTICLE IN PRESS

Fig. 8. One-line diagram of the proposed photovoltaic plant.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2053

5. Environmental analysis

The nal design has resulted in an electric power plant composed of photovoltaic

modules based on polycrystalline silicon technology with a peak power of 11,520 Wp and 3

single-phase inverters, one of 5200 W and two of 2600 W, totaling 10,400 W in nominal

operation. Each inverter injects its current to one of the phases (R, S, T) of the low voltage

grid. The area of each photovoltaic module is 1.26 m

2

(1.16 m

2

of active area) so that the 72

projected modules add up to a collector area of 90.57 m

2

, whose active area is

approximately 83.61 m

2

.

The estimated electrical efciency of the modules is approximately 13.5%, losses related

to orientation, slope and dirt of the modules are estimated around 6.88%, losses due to

indirect shading are negligible and direct shading losses are around 2%. In addition, power

losses due to temperature are around 4.42%, assuming that the cells surface temperature is

12 1C higher than the monthly average temperature when the sun is at its zenith. Power

losses due to voltage drops are estimated around 1%, due to oversized cable sections. All

things considered, the power plant generates an average of 1.287 MWh each month, as

shown in detail in Table 3.

On average, 1.158 MWh are injected to the grid per month, considering all types of

losses, with an 85% efciency factor. Compared to the thermal data, the electric

production is equivalent to the combustion of 1.195 Tons of Oil Equivalents (TOE) or 1.708

Tons of Coal Equivalents (TCE), even after assuming a 100% efciency factor in

generation, transformation and distribution of the electric power. Considering a more

realistic scenario and assuming that:

(1) The electricity would be generated from a combined cycle or an equivalent technology

whose efciency factor could be around 50% on the average.

(2) A 95% efciency factor in each successive voltage adjustment: from 12,000 V-

250,000 V, from 250,000 V-20,000 V and from 20,000 V-380 V.

(3) Additional losses of 5% in low voltage distribution, then, we would have an

approximate overall efciency factor of 40%.

ARTICLE IN PRESS

Fig. 9. 3D view of the installation showing the DC circuit and the location of the inverters shelter.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2054

ARTICLE IN PRESS

August 3%

July 4%

June 4%

May 3%

April 3%

March 2%

February 2%

Forecast 71%

September 3%

October 2%

December 1%

November 1%

January 1%

Fig. 11. Monthly PV generation forecast vs. annual electric demand of the Centre.

Fig. 10. 3D detail view of the solar panels arrangement on the roof.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2055

So, to generate the same electric power using fossil fuel [10], it would be necessary to

burn up to 2.934 TOE or up to 4.197 TCE every year, even without considering the cost

and power needed to extract, rene and deliver the fuel, which would increase prices even

more.

All of this implies that, throughout a life-span of 25 years for the entire installation, the

photovoltaic modules would produce the same power as 73.35 tons of oil or 104.93 tons of

coal, with the subsequent reduction in emissions of CO

2

, NO

X

and SO

X

. So, the

consideration of the environmental impact changes the global appreciation of the

installation [11], especially if we take into account the relatively small dimensions and

the power produced in the plant.

6. Complete budget of the PV installation: economic and nancial case studies

We show in Table 4 the complete budget of the PV installation.

Current legislation in Spain [12] regarding the production of electrical energy originated

from renewable energy sources, waste and cogeneration, allows all the energy generated by

the PV system to be injected into the grid. In addition, the energy consumed by the PV

system can be bought back at a much lower price than the one paid to the PV system for its

production.

For installations with less than 100 kW of installed power, the energy tariff is established

at 575% of the average electric tariff, or the reference tariff (updated yearly) for the rst 25

years of the installation, decreasing to 460% in the following years.

We carry out two different economic and nancial case studies using the methodology

in [10]. In the rst case study we assume that the investment is nanced through a loan

of 90% of the total value, and the remaining 10% comes from the Centres own funds. In

the second case study, the investment is completely nanced with external funds from

a loan that covers the part of the investment that is not subsidized by the Spanish

Government [13].

Next, we present the nancial parameters:

+ Required investment without Value Added Tax (VAT): 64,577 h.

+ VAT: 16% (10,332 h). Taxes not related to subsidies are 8472 h, they are refundable a

year later.

ARTICLE IN PRESS

0

1000

2000

3000

4000

5000

6000

7000

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

[

k

W

h

/

m

o

n

t

h

]

PV Generation

Electric Demand

Fig. 12. Monthly PV generation forecast vs. monthly electric demand of the Centre.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2056

ARTICLE IN PRESS

T

a

b

l

e

3

A

v

e

r

a

g

e

s

o

l

a

r

i

r

r

a

d

i

a

t

i

o

n

,

t

e

m

p

e

r

a

t

u

r

e

-

r

e

l

a

t

e

d

l

o

s

s

e

s

,

g

e

n

e

r

a

t

e

d

a

n

d

g

r

i

d

-

d

e

l

i

v

e

r

e

d

p

o

w

e

r

a

n

d

i

n

c

o

m

e

f

r

o

m

e

l

e

c

t

r

i

c

i

t

y

s

a

l

e

s

o

f

t

h

e

p

r

o

p

o

s

e

d

i

n

s

t

a

l

l

a

t

i

o

n

(

a

m

i

n

u

s

s

i

g

n

i

n

d

i

c

a

t

e

s

p

o

s

i

t

i

v

e

e

a

r

n

i

n

g

s

)

M

o

n

t

h

I

r

r

a

d

i

a

t

i

o

n

G

e

f

f

(

b

,

a

)

(

k

W

h

/

m

2

m

o

n

t

h

)

T

e

m

p

e

r

a

t

u

r

e

l

o

s

s

e

s

c

o

e

f

c

i

e

n

t

P

h

o

t

o

v

o

l

t

a

i

c

g

e

n

.

p

o

w

e

r

(

k

W

h

/

m

o

n

t

h

)

G

r

i

d

d

e

l

i

v

e

r

e

d

p

o

w

e

r

(

k

W

h

/

m

o

n

t

h

)

E

c

o

n

o

m

i

c

r

e

m

u

n

e

r

a

t

i

o

n

a

(

h

)

E

l

e

c

t

r

i

c

i

t

y

b

i

l

l

(

h

)

M

o

n

t

h

l

y

d

i

f

f

e

r

e

n

c

e

a

(

h

)

J

a

n

u

a

r

y

6

8

.

0

0

1

.

0

2

7

6

6

5

.

4

9

5

9

8

.

9

4

2

8

8

.

3

5

5

6

0

.

5

8

2

7

2

.

2

3

F

e

b

r

u

a

r

y

8

5

.

5

7

1

.

0

1

5

8

2

7

.

4

9

7

4

4

.

7

4

3

5

8

.

5

4

6

7

3

.

8

5

3

1

5

.

3

0

M

a

r

c

h

1

3

8

.

3

2

1

.

0

0

1

1

3

1

9

.

0

5

1

1

8

7

.

1

5

5

7

1

.

5

4

5

7

5

.

8

5

4

.

3

2

A

p

r

i

l

1

5

9

.

4

1

0

.

9

9

0

1

5

0

4

.

2

7

1

3

5

3

.

8

4

6

5

1

.

7

9

4

6

3

.

3

6

1

8

8

.

4

3

M

a

y

1

9

5

.

7

6

0

.

9

7

1

1

8

1

1

.

7

8

1

6

3

0

.

6

0

7

8

5

.

0

3

4

2

3

.

4

7

3

6

1

.

5

6

J

u

n

e

2

1

1

.

4

9

0

.

9

4

1

1

8

9

5

.

8

6

1

7

0

6

.

2

8

8

2

1

.

4

6

3

8

1

.

2

9

4

4

0

.

1

8

J

u

l

y

2

3

8

.

0

1

0

.

9

0

4

2

0

5

0

.

8

5

1

8

4

5

.

7

7

8

8

8

.

6

2

2

6

3

.

4

5

6

2

5

.

1

7

A

u

g

u

s

t

2

1

0

.

9

4

0

.

9

0

2

1

8

1

3

.

5

9

1

6

3

2

.

2

3

7

8

5

.

8

1

1

9

2

.

5

9

5

9

3

.

2

2

S

e

p

t

e

m

b

e

r

1

5

9

.

4

1

0

.

9

2

3

1

4

0

1

.

7

1

1

2

6

1

.

5

4

6

0

7

.

3

5

4

1

7

.

7

4

1

8

9

.

6

1

O

c

t

o

b

e

r

1

0

4

.

9

8

0

.

9

6

6

9

6

6

.

5

7

8

6

9

.

9

2

4

1

8

.

8

1

5

3

7

.

1

8

1

1

8

.

3

7

N

o

v

e

m

b

e

r

6

7

.

0

9

1

.

0

0

1

6

3

9

.

7

7

5

7

5

.

8

0

2

7

7

.

2

1

5

8

9

.

7

2

3

1

2

.

5

1

D

e

c

e

m

b

e

r

5

6

.

7

8

1

.

0

2

2

5

5

3

.

1

1

4

9

7

.

8

0

2

3

9

.

6

6

4

4

1

.

0

7

2

0

1

.

4

1

T

o

t

a

l

1

6

9

5

.

7

9

1

5

,

4

4

9

.

5

5

1

3

,

9

0

4

.

5

9

6

6

9

4

.

1

7

5

5

2

0

.

1

5

1

1

7

4

.

0

2

M

o

n

t

h

l

y

a

v

e

r

a

g

e

1

4

1

.

3

2

0

.

9

7

1

2

8

7

.

4

6

1

1

5

8

.

7

2

5

5

7

.

8

5

4

6

0

.

0

1

9

7

.

8

4

a

W

i

t

h

o

u

t

V

A

T

.

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2057

+ Depreciation period of the investment: 20 consecutive years.

+ Total electrical power produced by the photovoltaic modules: 11,520 Wp.

+ Inverter estimated production: 10,400 W.

+ Photovoltaic estimated production: 13,904 kWh/year.

+ Electric reference tariff (ERT): 0.083728 h/kWh, as shown in the Ofcial State Bulletin

of Spain, BOE (12/31/2004).

+ Electric remuneration (h/kWh): 575% of the ERT during 25 years; 460% of the ERT

until the end-of-life of the installation.

+ EURIBOR interest rate for a 6 months loan (%): 2.5% yearly.

+ Period to pay back the subsidized loan: 7 years.

+ Amount of the subsidized loan: 57,494 h (90% of total investment minus the total value of a

diesel-engine alternator which could generate the same power for 8000h of use/year).

+ Non-recoverable subsidy given by IDAE: 20% of the subsidized amount, or 11,499 h.

+ Inter-annual ination: 2.5%.

+ Inter-annual energy ination: 2%.

+ Self-nanced investment: 6457 h.

+ VAT return: 8472 h.

+ Period to return the VAT of the installation: 7 years.

+ Economic Activity Tax (EAT): 0.7212 h/installed kWp; nevertheless, the installation

would be free of this tax since it would not reach 37.24 h (corresponding to a 51 kWp

installation).

+ State taxes: 35% of net prot (excluding depreciation of equipment+VAT).

+ Estimated maintenance costs: 0.018 h/generated kWh.

+ Insurance cost to cover defective equipment: 0.4% of the installation value each year.

+ Investment required to generate an equivalent amount of electric power using a diesel-

engine alternator: 801 h for a 1.74 kW engine working 8000 h/year.

+ Depreciation of the equipment: Although it is expected that the photovoltaic modules

can be operative after 25 years of use, its salvage value is 0 h.

+ Considering all the costs involved, earnings from electricity sales (after taxes) for the

two studied cases are shown as follows.

Scenario 1: mixed nancing: 10% self-funding, 90% external funding.

+ Internal rate of return (IRR): 14.65%.

+ Payback period: 6 years and 6 months.

ARTICLE IN PRESS

Table 4

Complete budget of the PV installation

Description Total (h)

Photovoltaic modules, supports and accessories 49,720.08

DC circuit, connection to the grid and grounding 883.70

Inverters and related devices 6980.95

Civil engineering project work 2593.80

Labor costs and equipment installation 2060.30

Civil engineering project management work 1805.36

Total 64,044.41

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2058

+ Aggregate prot: 110,916.80 h.

+ Net Present Value (NPV): 73,696.31 h.

+ Costbenet ratio: 0.46 in 10 years, 1.24 in 15 years, 2.08 in 20 years, and 2.85 in 25

years.

Scenario 2: 100% external nancing.

+ Internal rate of return (IRR): 16.00%.

+ Payback period: 7 years and 2 months.

+ Aggregate prot: 109,561.07 h.

+ Net present value (NPV): 73,079.76 h.

+ Costbenet ratio: 0.42 in 10 years, 1.20 in 15 years, 2.05 in 20 years, and 2.82 in 25 years.

In the second case study, the cash ow is basically the same as in the rst one; only the

development of the income varies: the aggregate prot during the payback period (rst 7

years) is less positive compared to the rst case. Also, the IRR has a higher value because

the interest of the loan (subsidized by IDAE) is not affected by ination; in addition, the

interest of the consumer credit does not affect the NPV and the aggregate prot value,

since high interest rates of up to 20% have been tested without signicant variation in the

aggregate prot.

To conclude, Fig. 13 depicts the annual cash ow for scenarios 1 and 2, which is almost

identical in both cases. Figs. 14 and 15 present the development of the annual incomes for

scenarios 1 and 2, respectively.

7. Conclusions

After calculating the dimensions of the PV installation, the estimated power production,

the total budget and two nancial case studies, these are the main conclusions that we have

reached:

+ The installation requires an initial investment several times greater than the cost

of diesel-engine alternator equipment that can generate the same amount of power in

1 year.

+ Economic incentives, like subsidies for part of the investment, and the chance to sell all

the electricity generated at 6 times its market price, are required to make a photovoltaic

installation protable.

+ An even greater investment is necessary to generate the electricity required to meet the

demand of the Centre completely only using photovoltaic energy, since the installation

can only meet 30% of the annual electrical demand. Nevertheless, the income from sales

of the electricity generated is greater than the amount of the electricity bills.

+ Developing an installation of this type promotes the use of environmentally conscious

sources of energy and motivates students to use renewable energies.

+ With the subsidized loans given by the IDAE, the installation becomes viable in a

reasonable period (nearly 8 years) and generates prots from the beginning; these prots

can be used to partially pay the Centres electric bills. Once the investment has been

repaid, the annual earnings from PV electric generation can fully compensate the

electricity bill, which would allow for considerable budget savings.

ARTICLE IN PRESS

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2059

+ The remuneration given to PV electric generation in Spain (575% of the ERT

established by law for a 25 years period) allows making a prot from the investment in

the long term. Also, non-recoverable subsidies reduce the payback period. The actual

cost of this remuneration scheme represents just 2% of the special electricity taxes,

approximately 0.08% of the electricity bill, whereas the nuclear moratorium tax almost

absorbs 40%, or 1.6% of the electricity bill.

+ The aggregate prot in the long term, 2025 years, doubles the initial value of the

installation. The NPV is also positive and the IRR guarantees that an increase in

ination will not affect the protability of the installation.

ARTICLE IN PRESS

-10000

-5000

0

5000

10000

15000

0 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Years

Economic ActivityTax

Financing installments

VAT

Electricity income

1

Fig. 13. Annual cash ow components for scenarios 1 and 2.

-8000

-6000

-4000

-2000

0

2000

4000

6000

0 4 3 2 1 5 9 8 7 6 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Years

Fig. 14. Annual income development for scenario 1 (mixed nancing: 10% self-funding, 90% external-funding).

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2060

+ The durability of the equipment guarantees optimal operation for 25 years, except

accidents, for which a specic insurance can be purchased until the installation is totally

repaid in about 8 years, just after the subsidized loans are fully repaid.

+ Finally, the remuneration obtained from the sale of PV-generated electricity can

produce prots that can both repay the necessary loans to get the installation started

and also the electricity bill, even if the electric consumption remains constant during the

following years.

References

[1] Newbold P. Statistics for business and economics, 5th ed. Englewood Cliffs, NJ: Prentice-Hall; 2002.

[2] National Aeronautics and Space Administration. http://www.nasa.gov

[3] Labed S, Lorenzo E. The impact of solar radiation variability and data discrepancy on the design of PV

systems. Renewable Energy 2004;29:100722.

[4] Technical conditions for PV installations connected to the grid [in Spanish]. Report available from the

publication services of the Institute for Diversication and Energy Savings, Spain. http://www.idae.es, 2002.

[5] Lorenzo E. Energy collected and delivered by PV modules. In: Luque A, Hegedus S, editors. Handbook of

photovoltaic science and engineering. West Sussex, UK: Wiley; 2003. p. 90570.

[6] Caaman o E, Lorenzo E. Inverters in PV grid connected systems: an assessment on the proper selection. In:

Proceedings of the 13th European photovoltaic solar energy conference, Nice, France, October 1995.

p. 19001903.

[7] Royal Decree 1663/2000 on the connection of photovoltaic installations to the low voltage network [in

Spanish]. September 29, 2000. Available at http://www.boe.es

[8] Caaman o E. Grid connected photovoltaic buildings: characterisation and analysis. PhD thesis, Polytechnic

University of Madrid, Superior Technical School of Telecommunication Engineers, Madrid, Spain, 1998 [in

Spanish].

[9] Caaman o E, Lorenzo E. Photovoltaics in grid-connected buildings: energy ow and economic aspects. Prog

Photovoltaics: Res Appl 1995;3:13543.

[10] Bernal-Agust n, JL, Dufo-Lo pez, R. Economical and environmental analysis of grid connected photovoltaic

systems in Spain. Renewable Energy, in press, doi:10.1016/j.renene.2005.06.004.

[11] Spiegel RJ, Kern EC, Greenberg DL. Demonstration of the environmental and demand-side management

benets of grid-connected photovoltaic power systems. Sol Energy 1998;62(5):34558.

ARTICLE IN PRESS

-2000

-1000

0

1000

2000

3000

4000

5000

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Years

Fig. 15. Annual income development for scenario 2 (100% external nancing).

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2061

[12] Royal Decree 436/2004 establishing the methodology for the update and systematisation of the legal and

economic regime of the activity of production of electrical energy in special regimes [in Spanish]. March 12,

2004. Available at http://www.boe.es

[13] Line of nancing ICO-IDAE for renewable energies and power efciency projects [in Spanish], 2005.

Available at http://www.idae.es

ARTICLE IN PRESS

A. Fernandez-Infantes et al. / Renewable Energy 31 (2006) 20422062 2062

S-ar putea să vă placă și

- ArtículOperation Results of A Photovoltaic System Interconnected To The Low Voltage Grid in Bogotá, Colombiao Florencia 2015Document5 paginiArtículOperation Results of A Photovoltaic System Interconnected To The Low Voltage Grid in Bogotá, Colombiao Florencia 2015Andres Julian AristizabalÎncă nu există evaluări

- Short-term forecasting model for electric power production of small-hydro power plants (SHPPsDocument8 paginiShort-term forecasting model for electric power production of small-hydro power plants (SHPPsNuno LeaoÎncă nu există evaluări

- Levelized Cost of Electricity For The Deployment of Solar Photovoltaic Plants: The Region of León (Spain) As Case StudyDocument5 paginiLevelized Cost of Electricity For The Deployment of Solar Photovoltaic Plants: The Region of León (Spain) As Case StudybetyÎncă nu există evaluări

- EnergyPLAN Model DocumentationDocument62 paginiEnergyPLAN Model DocumentationSboÎncă nu există evaluări

- Reducing Peak Electricity Demand in Building Climate Control Using Real-Time Pricing and Model Predictive ControlDocument6 paginiReducing Peak Electricity Demand in Building Climate Control Using Real-Time Pricing and Model Predictive ControlSandy TondoloÎncă nu există evaluări

- Kaggle Competition PDFDocument19 paginiKaggle Competition PDFTeodor von BurgÎncă nu există evaluări

- 1 s2.0 S0306261915006030 MainDocument8 pagini1 s2.0 S0306261915006030 Mainufu_santosÎncă nu există evaluări

- Energies 13 03680Document23 paginiEnergies 13 03680jhonÎncă nu există evaluări

- 10 1016@j Energy 2015 03 031 PDFDocument11 pagini10 1016@j Energy 2015 03 031 PDFMax SteeleÎncă nu există evaluări

- Thesis On Grid Connected PV SystemDocument8 paginiThesis On Grid Connected PV SystemWriteMyCustomPaperWarren100% (2)

- EU China Energy Magazine 2022 March Issue: 2022, #2De la EverandEU China Energy Magazine 2022 March Issue: 2022, #2Încă nu există evaluări

- Renewable Energy Scenarios in The Portuguese Electricity SystemDocument14 paginiRenewable Energy Scenarios in The Portuguese Electricity SystemMEV CEOÎncă nu există evaluări

- A Simple Model For Sizing Stand Alone PHOTOVOLTAIC SYSTEMSDocument16 paginiA Simple Model For Sizing Stand Alone PHOTOVOLTAIC SYSTEMSspam spamÎncă nu există evaluări

- Heat Pump Report Final PDFDocument66 paginiHeat Pump Report Final PDFIna Rodica PricăÎncă nu există evaluări

- Adaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesDocument6 paginiAdaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesMario SammyÎncă nu există evaluări

- Forecasting Next-Day Electricity Prices by Time Series ModelsDocument7 paginiForecasting Next-Day Electricity Prices by Time Series Modelsmail_205402752Încă nu există evaluări

- Probability Density Function Characterization For Aggregated Large-Scale Wind Power Based On Weibull MixturesDocument15 paginiProbability Density Function Characterization For Aggregated Large-Scale Wind Power Based On Weibull Mixturesocha890Încă nu există evaluări

- Electrical Energy Audit A Case Study: Gousia Sultana, Harsha.H.UDocument6 paginiElectrical Energy Audit A Case Study: Gousia Sultana, Harsha.H.UtaksasÎncă nu există evaluări

- An Innovative Control Framework for District HeatingDocument15 paginiAn Innovative Control Framework for District HeatingVedantham Lakshmi SrinivasÎncă nu există evaluări

- Research ArticleDocument13 paginiResearch ArticlegiovanaÎncă nu există evaluări

- Articulo 2Document13 paginiArticulo 2ALEJANDRO RIVERAÎncă nu există evaluări

- La Supervisión de Las Energías Renovables y El Control Real de Tiempo de Producción en EspañaDocument6 paginiLa Supervisión de Las Energías Renovables y El Control Real de Tiempo de Producción en EspañaMiguel Angel Miranda UgarteÎncă nu există evaluări

- Processes: Inverter E Power Estimation Using Solar RadiationDocument19 paginiProcesses: Inverter E Power Estimation Using Solar RadiationSujeet KumarÎncă nu există evaluări

- Modelling The Load Curve of Aggregate Electricity Consumption Using Principal ComponentsDocument42 paginiModelling The Load Curve of Aggregate Electricity Consumption Using Principal ComponentsMuhammad SulaimanÎncă nu există evaluări

- Assessing Electrical Energy Use in HVAC Systems: ArticlesDocument6 paginiAssessing Electrical Energy Use in HVAC Systems: Articleskash30Încă nu există evaluări

- Energies: Implementation of IEC 61400-27-1 Type 3 Model: Performance Analysis Under Different Modeling ApproachesDocument23 paginiEnergies: Implementation of IEC 61400-27-1 Type 3 Model: Performance Analysis Under Different Modeling ApproachesLuis FebresÎncă nu există evaluări

- Pensar !!!Document6 paginiPensar !!!Jamerson RamosÎncă nu există evaluări

- Energy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet KurbanDocument13 paginiEnergy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet Kurbanakash_chandraya4200Încă nu există evaluări

- Small PV Power PlantDocument6 paginiSmall PV Power PlantAbeer ElhadyÎncă nu există evaluări

- COMBINED FINANCIAL AND ENVIRONMENTAL OPTIMIZATION OF A Trigeneration SystemDocument13 paginiCOMBINED FINANCIAL AND ENVIRONMENTAL OPTIMIZATION OF A Trigeneration SystemAlvaro Antonio Ochoa VillaÎncă nu există evaluări

- PDFDocument10 paginiPDFAhmed WestministerÎncă nu există evaluări

- Energies: Graphical Diagnosis of Performances in Photovoltaic Systems: A Case Study in Southern SpainDocument26 paginiEnergies: Graphical Diagnosis of Performances in Photovoltaic Systems: A Case Study in Southern SpainHassen BrahimÎncă nu există evaluări

- Fuzzy Based Ev Charging With Reduced Power Fluctuation Under Renewable Power Consumption ConstraintDocument16 paginiFuzzy Based Ev Charging With Reduced Power Fluctuation Under Renewable Power Consumption ConstraintkesavantÎncă nu există evaluări

- 1paper Title: Author's Affiliation, CountryDocument7 pagini1paper Title: Author's Affiliation, CountryEfrat NainggolanÎncă nu există evaluări

- SVR Model Predicts Turkey's Electricity ConsumptionDocument8 paginiSVR Model Predicts Turkey's Electricity Consumptionblack272727Încă nu există evaluări

- Wrec8 AmarDocument6 paginiWrec8 AmarOmar Barrios AÎncă nu există evaluări

- ENTSO-E Grid Planning Modelling Showcase for China: Joint Statement Report Series, #4De la EverandENTSO-E Grid Planning Modelling Showcase for China: Joint Statement Report Series, #4Încă nu există evaluări

- Plants: Energy Efficiency Improvement in Thermal PowerDocument6 paginiPlants: Energy Efficiency Improvement in Thermal Powerhendra_01Încă nu există evaluări

- 4.2 Luxamérica 2012Document7 pagini4.2 Luxamérica 2012Energía Citec UabcÎncă nu există evaluări

- Impacts of Solar PV, Battery Storage and HVAC Set Point Adjustments On Energy Savings and Peak Demand Reduction Potentials in BuildingsDocument8 paginiImpacts of Solar PV, Battery Storage and HVAC Set Point Adjustments On Energy Savings and Peak Demand Reduction Potentials in BuildingsFirma PurbantoroÎncă nu există evaluări

- Optimal Generation Scheduling of Hydropower Plant With Pumped Storage UnitDocument8 paginiOptimal Generation Scheduling of Hydropower Plant With Pumped Storage UnitAlexander DeckerÎncă nu există evaluări

- SECH SpainDocument75 paginiSECH SpainTy PhanÎncă nu există evaluări

- Elsevier Rubio MathematicsDocument28 paginiElsevier Rubio MathematicsCristianÎncă nu există evaluări

- 1 s2.0 S2352484722012203 MainDocument16 pagini1 s2.0 S2352484722012203 Mainluis trujilloÎncă nu există evaluări

- Error Assessment of Solar Irradiance Forecasts and AC Power From Energy Conversion Model in Grid-Connected Photovoltaic SystemsDocument27 paginiError Assessment of Solar Irradiance Forecasts and AC Power From Energy Conversion Model in Grid-Connected Photovoltaic Systemsmohd hazimÎncă nu există evaluări

- Residential Energy Audit VelascoDocument25 paginiResidential Energy Audit VelascoNaason VelascoÎncă nu există evaluări

- Determination of Sustainable Energy Mix To Meet Nigeria Vision 20:2020 On Power Using Linear ProgrammingDocument7 paginiDetermination of Sustainable Energy Mix To Meet Nigeria Vision 20:2020 On Power Using Linear ProgrammingAZOJETEÎncă nu există evaluări

- Energies 12 00766 v2Document11 paginiEnergies 12 00766 v2Τζίνα ΓιαννοπούλουÎncă nu există evaluări

- Household Electricity End-Use ConsumptionDocument22 paginiHousehold Electricity End-Use ConsumptionEva ViskadourakiÎncă nu există evaluări

- J.asela Liyanage - (DMX9403 - Assignment)Document17 paginiJ.asela Liyanage - (DMX9403 - Assignment)sithegeÎncă nu există evaluări

- Optimized Clusters For Disaggregated Electricity Load ForecastingDocument20 paginiOptimized Clusters For Disaggregated Electricity Load ForecastingKalthoum ZaoualiÎncă nu există evaluări

- Rail Bhawan ReportDocument34 paginiRail Bhawan ReportNikhil MohiteÎncă nu există evaluări

- Electricity Consumption and Generation Forecasting With Artificial Neural NetworksDocument22 paginiElectricity Consumption and Generation Forecasting With Artificial Neural Networksjerrymcguire2024Încă nu există evaluări

- A Simple Procedure To Size Active Solar Heating Schemes For Low-Energy Building DesignDocument9 paginiA Simple Procedure To Size Active Solar Heating Schemes For Low-Energy Building DesignmohammudpÎncă nu există evaluări

- energies-12-00773Document15 paginienergies-12-00773kmlhectorseth94Încă nu există evaluări

- 1 s2.0 S0360544221009270 MainDocument15 pagini1 s2.0 S0360544221009270 Mainsanketdesalecr7Încă nu există evaluări

- Power Plant Capital CostDocument201 paginiPower Plant Capital Costsringgodani100% (1)

- Phase1_Sample_fileDocument10 paginiPhase1_Sample_filekomalkajal804Încă nu există evaluări

- Grid Connected PV System ThesisDocument5 paginiGrid Connected PV System Thesisafktlrreerdihj100% (2)

- Smart GridDocument10 paginiSmart GridAnand SreekumarÎncă nu există evaluări

- What is Operations ResearchDocument10 paginiWhat is Operations ResearchSHILPA GOPINATHANÎncă nu există evaluări

- DBO News Release DFPI 9 25 2020Document2 paginiDBO News Release DFPI 9 25 2020ForkLogÎncă nu există evaluări

- Merchant of Venice Act 2 Part 2Document25 paginiMerchant of Venice Act 2 Part 2Verna Santos-NafradaÎncă nu există evaluări

- Auditing and Assurance Services A Systematic Approach 10th Edition Messier Test Bank 1Document62 paginiAuditing and Assurance Services A Systematic Approach 10th Edition Messier Test Bank 1willie100% (36)

- ST 2 PDFDocument2 paginiST 2 PDFEbenezer SamedwinÎncă nu există evaluări

- Bharti Airtel Services LTD.: Your Account Summary This Month'S ChargesDocument4 paginiBharti Airtel Services LTD.: Your Account Summary This Month'S ChargesVinesh SinghÎncă nu există evaluări

- Research Proposal On Challenges of Local GovernmentDocument26 paginiResearch Proposal On Challenges of Local GovernmentNegash LelisaÎncă nu există evaluări

- Fria MCQDocument13 paginiFria MCQJemima LalaweÎncă nu există evaluări

- Palepu - Chapter 5Document33 paginiPalepu - Chapter 5Dương Quốc TuấnÎncă nu există evaluări

- FBL Annual Report 2019Document130 paginiFBL Annual Report 2019Fuaad DodooÎncă nu există evaluări

- Finance ProblemsDocument5 paginiFinance Problemsstannis69420Încă nu există evaluări

- Draft Dispossessory Appeal OptionsDocument12 paginiDraft Dispossessory Appeal Optionswekesamadzimoyo1Încă nu există evaluări

- GEM/2022/B/2723659 Bid CorrigendumDocument2 paginiGEM/2022/B/2723659 Bid CorrigendumAnmol JainÎncă nu există evaluări

- Office Stationery Manufacturing in The US Industry ReportDocument40 paginiOffice Stationery Manufacturing in The US Industry Reportdr_digital100% (1)

- Real Estate - Understanding U.S. Real Estate DebtDocument16 paginiReal Estate - Understanding U.S. Real Estate DebtgarchevÎncă nu există evaluări

- Yodlee User Guide PDFDocument211 paginiYodlee User Guide PDFy2kmvrÎncă nu există evaluări

- 2010 Financial Information John Keells Holdings PLCDocument59 pagini2010 Financial Information John Keells Holdings PLCPrasanna Lanka DasanayakeÎncă nu există evaluări

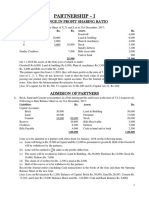

- Partnership - I: Change in Profit Sharing RatioDocument33 paginiPartnership - I: Change in Profit Sharing RatioUjjwal BeriwalÎncă nu există evaluări

- Gram Yojana (Gram Priya) 10 Years Rural Postal Life Insurance Age at Entry Yrs Annual Rs Halfyearly Rs Quarterly Rs Monthly Age at Entry YrsDocument2 paginiGram Yojana (Gram Priya) 10 Years Rural Postal Life Insurance Age at Entry Yrs Annual Rs Halfyearly Rs Quarterly Rs Monthly Age at Entry YrsPriya Ranjan KumarÎncă nu există evaluări

- A Study On Investors Buying Behaviour Towards Mutual Fund PDF FreeDocument143 paginiA Study On Investors Buying Behaviour Towards Mutual Fund PDF FreeRathod JayeshÎncă nu există evaluări

- Bank Mandiri ProfileDocument2 paginiBank Mandiri ProfileTee's O-RamaÎncă nu există evaluări

- s6 Econ (Public Finance and Fiscal Policy)Document50 paginis6 Econ (Public Finance and Fiscal Policy)juniormugarura5Încă nu există evaluări

- IDirect Zomato IPOReviewDocument13 paginiIDirect Zomato IPOReviewSnehashree SahooÎncă nu există evaluări

- 15968615919016284WDocument2 pagini15968615919016284WSourya MitraÎncă nu există evaluări

- Artist Village Detroit Revitalizes Neighborhood Through Creative EnterpriseDocument6 paginiArtist Village Detroit Revitalizes Neighborhood Through Creative EnterpriseVaishali JoshiÎncă nu există evaluări

- Inventory Trading SampleDocument28 paginiInventory Trading SampleRonald Victor Galarza Hermitaño0% (1)

- Accounting and FinanceDocument5 paginiAccounting and FinanceHtoo Wai Lin AungÎncă nu există evaluări

- Saral Gyan Stocks Past Performance 050113Document13 paginiSaral Gyan Stocks Past Performance 050113saptarshidas21Încă nu există evaluări

- Ch.3 Size of BusinessDocument5 paginiCh.3 Size of BusinessRosina KaneÎncă nu există evaluări