Documente Academic

Documente Profesional

Documente Cultură

499 Law

Încărcat de

suder0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 paginiBently Nevada has advocated using open interfaces to combine process and machinery data. One such standard is OPC, which is an important new standard that Bently supports. In the second quarter of 1999, DM2000 will be available with the OPC client interface.

Descriere originală:

Titlu original

499law

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBently Nevada has advocated using open interfaces to combine process and machinery data. One such standard is OPC, which is an important new standard that Bently supports. In the second quarter of 1999, DM2000 will be available with the OPC client interface.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 pagini499 Law

Încărcat de

suderBently Nevada has advocated using open interfaces to combine process and machinery data. One such standard is OPC, which is an important new standard that Bently supports. In the second quarter of 1999, DM2000 will be available with the OPC client interface.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

34 Orbit First Quarter 1999

ently Nevada recognizes that

there is tremendous value in

merging the data and infor-

mation from our machinery manage-

ment systems with the process, plant,

asset, business, and other applica-

tions/data that exist in your facility. For

several years, weve advocated using

our open interfaces to combine process

and machinery data. Using open inter-

faces provides a clearer picture of how

the process and machine interact and

affect each other. Our goal is to provide

systems that easily integrate and

exchange data with other systems in

the plant environment, using accepted

and established open standards and

conventions.

In the software world, these standards

tend to evolve rather quickly. Suppliers,

such as Bently Nevada, must identify,

embrace, and incorporate these stan-

dards into their products to make sys-

tems easy-to-use and easy-to-integrate.

One such standard is OPC (an acronym

for OLE for Process Control), which is

an important new standard that Bently

Nevada supports. This article talks

about what OPC is, why Bently Nevada

supports it, and our current and future

product plans for incorporating OPC

interface capabilities.

by Brad Law

Market Manager, Control and

Automation Systems

Bently Nevada Corporation

e-mail: brad.law@bently.com

OPC and Bently Nevada

allow us to participate in the develop-

ment of OPC specifications and to use

OPC technology in our products. It is

our intent to use OPC as our preferred

protocol to interface our machinery

management software products to com-

plementary control and automation

products, such as data historians and

human interface applications.

Bently Nevada Products

Supporting OPC

Bently Nevada provides a data import

(OPC client) interface for our Data

Manager

2000 (DM2000) Software. It

allows us to import the same data that

has historically been obtained using

DM2000s DDE client interface. While

we will continue to provide DDE capa-

bilities and support, our preference is

to use and advocate the OPC interface

whenever possible. This OPC client

interface is available now through

Bently Nevadas System Integration

Engineering (SIE) group. In the second

quarter of this year, DM2000 will be

available with the OPC client interface

as a standard option that can be config-

ured and integrated by the user.

However, we still recommend you con-

sider using Bently Nevadas SIE

expertise to help you install and inte-

grate our products.

In the fourth quarter of 1999, Bently

Nevada will also offer an OPC data

exporter (server). This will allow you

to share data from our machinery man-

agement systems with any software that

can act as an OPC client. In the future,

What is OPC?

OPC is rapidly becoming the pre-

ferred mechanism for exchanging data

between various control and automa-

tion software applications. The intent

of the OPC standard is to replace exist-

ing transfer methods, such as Dynamic

Data Exchange (DDE). In particular,

OPC provides functionality and relia-

bility, not present in current data

exchange methods, which allows it to

be used in a real-time process

environment.

OPC is an open standard administered

by the OPC Foundation. Their charter

is simple:

To develop an open and interoper-

able interface standard, based upon

the functional requirements of

OLE/COM and DCOM technology,

that fosters greater interoperability

between automation/control applica-

tions, field systems/devices, and

business/office applications.

OPC is the fastest-growing data

exchange mechanism in the world, with

over 175 member companies currently

using OPC in more than 150 products.

Clearly, OPC is an important and glob-

ally-accepted open standard. As such,

Bently Nevada has joined OPC, to

Orbit First Quarter 1999 35

possible to assess the impact of the

process on the machinery and the

machinery on the process. Some

examples are inlet gas temperature

and pressure on a compressor or

inlet steam temperature and pressure

on a turbine. Historically, this data

has been gathered from the

Distributed Control System (DCS)

and independent systems, such as

machinery control systems.

We have numerous interfaces

which enable Bently Nevada's

machinery management systems to

integrate with all the commonly used

DCS systems to access this impor-

tant process-related information. We

believe it is a high priority to design

the integration of the control and

associated systems with the machin-

ery management system at the con-

ceptual stage of a new project or

upgrade.

While the additional data needed

by the machinery management sys-

tem will often reside in the process

or machinery control system, this is

not always the case. When parame-

ters are not actively used by the DCS

for process control, but are impor-

tant to machinery management, it is

often appropriate to connect these

parameters directly to the Bently

Nevada 3500 Machinery Protection

System. This allows the information

Historically, Bently Nevada's inter-

est in non-vibration parameters

stemmed from their usefulness as

machinery protection parameters.

These included parameters, such as

bearing metal temperature, seal oil

system pressure, casing movement

and growth, motor winding tempera-

tures, and other critical measure-

ments of machine integrity used to

initiate a shutdown without the need

for human intervention. Today,

Bently Nevada's need for a variety of

data is changing changing because

machinery protection is no longer a

sufficient practice for our customers.

They must also manage their

machinery's condition. To do this,

our systems require a wider variety

of data to fully define the operating

state, condition, and performance of

the machinery. This proactive

approach to machinery allows you to

support decision making in advance

rather than waiting for conditions to

degrade so severely that the machin-

ery protection system is forced to

intervene. While protection is still

necessary, it is inherently a reactive

function focused on protecting your

machinery and your process stream,

not on optimizing their availability

and reliability.

This wider variety of data (some-

times called process data) makes it

to be placed directly into the

machinery management system data-

base where it is needed without

the delays normally encountered in a

process control system. The parame-

ters can then be optimally processed,

validated, and synchronized with

other management parameters; there

is no data acquisition performance

degradation under any plant operat-

ing scenario as may be the case

when relying on a process control

system to acquire and share this

data. Because Bently Nevada

machinery management systems can

export the data in their databases

using standard data exchange mech-

anisms, it can also be shared with

other plant control and automation

systems once in our database.

No matter which way you choose

to integrate your systems, good engi-

neering practice is essential to avoid

difficulty and to ensure that a reli-

able and easily supported solution

results. Bently Nevada's Project

Management and System Integration

Engineering groups have a wealth of

experience gained from numerous

integration projects. We would like

the opportunity to talk to you about

what we have learned and assist you

in your next project.

virtually all of our machinery manage-

ment software products, including

System 1

TM

, will include OPC support.

If you would like more information

What do we mean by Process Data and why is it important?

on OPC, visit our website at www.bent-

ly.com. Youll find information on

products currently supporting OPC,

links to other OPC sites, and exciting

developments about our plans for incor-

porating this important open standard

in our other products.

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Palo Alto Networks Security SolutionDocument52 paginiPalo Alto Networks Security SolutionsuderÎncă nu există evaluări

- Analysis On Various Optimization Techniques Used For Load Frequency Control in Power SystemDocument25 paginiAnalysis On Various Optimization Techniques Used For Load Frequency Control in Power SystemsuderÎncă nu există evaluări

- Firewalls: Laura Mcfall Depaul University School of Computing and Digital MediaDocument84 paginiFirewalls: Laura Mcfall Depaul University School of Computing and Digital MediasuderÎncă nu există evaluări

- Unit 16: Hidden Markov Models: Computational Statistics With Application To BioinformaticsDocument24 paginiUnit 16: Hidden Markov Models: Computational Statistics With Application To BioinformaticssuderÎncă nu există evaluări

- Timeseries MbookDocument350 paginiTimeseries MbooksuderÎncă nu există evaluări

- Mcafee Virusscan Enterprise 8.8 Software: Installation GuideDocument34 paginiMcafee Virusscan Enterprise 8.8 Software: Installation GuidesuderÎncă nu există evaluări

- Unit B01 - Motion in One Dimension: (Unauthorized Copying or Use of Any Part of Any One of These Slides Is Illegal.)Document79 paginiUnit B01 - Motion in One Dimension: (Unauthorized Copying or Use of Any Part of Any One of These Slides Is Illegal.)suderÎncă nu există evaluări

- Endpoint Security For The Enterprise enDocument6 paginiEndpoint Security For The Enterprise ensuderÎncă nu există evaluări

- CEC MG Lessons Learned Workshop PresentationDocument51 paginiCEC MG Lessons Learned Workshop PresentationsuderÎncă nu există evaluări

- PHC 6052 SAS SkillsDocument52 paginiPHC 6052 SAS SkillssuderÎncă nu există evaluări

- Global Reform Oview Epw 066A02 PDFDocument24 paginiGlobal Reform Oview Epw 066A02 PDFsuderÎncă nu există evaluări

- MPW Coal Conf Apc SKM PDFDocument23 paginiMPW Coal Conf Apc SKM PDFsuderÎncă nu există evaluări

- The Methodology For Knowledge Base Compression and Robust Diagnosis: Application To A Steam Boiler PlantDocument12 paginiThe Methodology For Knowledge Base Compression and Robust Diagnosis: Application To A Steam Boiler PlantsuderÎncă nu există evaluări

- Optimizing Sootblow APC SKMDocument10 paginiOptimizing Sootblow APC SKMsuderÎncă nu există evaluări

- Availability Based TariffDocument14 paginiAvailability Based TariffsuderÎncă nu există evaluări

- Basic Dyn Con Exercises FreeDocument103 paginiBasic Dyn Con Exercises FreesuderÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Emm3812 - Static and Dynamic BalancingDocument7 paginiEmm3812 - Static and Dynamic Balancingsyamil100% (3)

- MECH3030 01 Intro Spr2015Document59 paginiMECH3030 01 Intro Spr2015BillyÎncă nu există evaluări

- Textbook of Elements of Mechanical EngineeringDocument30 paginiTextbook of Elements of Mechanical EngineeringSubhÎncă nu există evaluări

- BTech Curriculum 2014Document7 paginiBTech Curriculum 2014Mulu GirmayÎncă nu există evaluări

- Staic ND Dynamic BalancingDocument4 paginiStaic ND Dynamic BalancingShubhangi BansudeÎncă nu există evaluări

- Lesson S02C03-Moncarz P Et Al. (2000)Document5 paginiLesson S02C03-Moncarz P Et Al. (2000)gonzaloÎncă nu există evaluări

- Fixings Fixed GuardsDocument6 paginiFixings Fixed GuardsIVAIRGÎncă nu există evaluări

- Simple Machines by D. J. Dunn Freestudy .Co. UkDocument15 paginiSimple Machines by D. J. Dunn Freestudy .Co. UkJogi Oscar SinagaÎncă nu există evaluări

- Evaluating The Overall Vibration MeasurementsDocument2 paginiEvaluating The Overall Vibration MeasurementssugiantobarusÎncă nu există evaluări

- 286 Couplings HRCDocument2 pagini286 Couplings HRCkeyur1109Încă nu există evaluări

- NZ Guarding of Belt ConveyorsDocument28 paginiNZ Guarding of Belt Conveyors450gasgasÎncă nu există evaluări

- The Effect of Unbalance On Bearing LifeDocument8 paginiThe Effect of Unbalance On Bearing LifejaypallaÎncă nu există evaluări

- Recommended Initial Alram Ge - 872639Document4 paginiRecommended Initial Alram Ge - 872639kjapasha100% (1)

- Accelerometer Tech - InformationDocument24 paginiAccelerometer Tech - InformationDipankar ChakrabortyÎncă nu există evaluări

- Parker Sanitary Valves & Components PDFDocument16 paginiParker Sanitary Valves & Components PDFlyguyenquocduyÎncă nu există evaluări

- Course Beyond SyllabusDocument21 paginiCourse Beyond SyllabuskarthiyuvenÎncă nu există evaluări

- Shock and Vibration DigestDocument50 paginiShock and Vibration DigestArun0% (1)

- Homework 1 SolutionDocument5 paginiHomework 1 SolutionMrinmoy SahaÎncă nu există evaluări

- Rules For Classification and Construction Ship Technology: Seagoing Ships 14 Redundant Propulsion and Steering SystemsDocument18 paginiRules For Classification and Construction Ship Technology: Seagoing Ships 14 Redundant Propulsion and Steering SystemsLastunÎncă nu există evaluări

- Kollmorgen S300 S400 S600 S700 Servo Drive Profibus Communication Manual en Rev07-2014Document52 paginiKollmorgen S300 S400 S600 S700 Servo Drive Profibus Communication Manual en Rev07-2014Sam SchröderÎncă nu există evaluări

- European Standard Norme Européenne Europäische NormDocument14 paginiEuropean Standard Norme Européenne Europäische Normfercho2581Încă nu există evaluări

- DOM Assignment 5Document1 paginăDOM Assignment 5kumar kmÎncă nu există evaluări

- Banner STB Touch ButtonsDocument26 paginiBanner STB Touch ButtonsMemik TylnÎncă nu există evaluări

- Lucasfilm Sound Effects Library Complete Track and Index ListingDocument10 paginiLucasfilm Sound Effects Library Complete Track and Index ListingKALFERÎncă nu există evaluări

- GST Rate & HSN Code For Industrial Machinery - Chapter 84Document9 paginiGST Rate & HSN Code For Industrial Machinery - Chapter 84petergr8t1Încă nu există evaluări

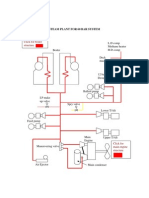

- Steam Power Plant For 60 Bar SystemDocument3 paginiSteam Power Plant For 60 Bar SystemGnana Subramanian ArumugamÎncă nu există evaluări

- Depriciation Rate F.Y 2009 - 2010Document6 paginiDepriciation Rate F.Y 2009 - 2010senthamarai kannan A100% (6)

- Synchro FlexDocument84 paginiSynchro FlexFabrizio Grasso100% (1)

- IRC5-IRC5 Product Reference Manual 3HAC021313-001 - Part2 - Reva - enDocument144 paginiIRC5-IRC5 Product Reference Manual 3HAC021313-001 - Part2 - Reva - enmartinimartiiniÎncă nu există evaluări

- TEMA Standards PDFDocument5 paginiTEMA Standards PDFfuransu777Încă nu există evaluări