Documente Academic

Documente Profesional

Documente Cultură

The Masonry Edge - Warehouse Construction

Încărcat de

Ronald Millán Gonzales0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări2 paginiConcrete Masonry wall provides the structure and the skin at the same time. Fire and sound resistance are built right into the wall, along with impact resistance and security. The goal is an economical building system that will look good, perform well and stand the test of time.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentConcrete Masonry wall provides the structure and the skin at the same time. Fire and sound resistance are built right into the wall, along with impact resistance and security. The goal is an economical building system that will look good, perform well and stand the test of time.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări2 paginiThe Masonry Edge - Warehouse Construction

Încărcat de

Ronald Millán GonzalesConcrete Masonry wall provides the structure and the skin at the same time. Fire and sound resistance are built right into the wall, along with impact resistance and security. The goal is an economical building system that will look good, perform well and stand the test of time.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

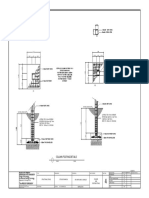

Reinforced Masonry:

One simple system for warehouse construction

THE MASONRY EDGE

STD. horiz. joint

reinf. @ 16 O.C.

#6 vert. rebar 48

O.C. (grout cores

with rebar only)

Cores filled with

foamed in place

insulation

12 Concrete

Masonry unit

Cont. bond beam

w/2 #5 rebar

Bar joist

32

the turn of the century. With another turn of the centu-

ry upon us, perhaps we should observe the benefits of

integrating structure and finish into one element again.

In a steel/precast system the need for structure

is satisfied by steel. The need for cladding is satisfied

by precast panels. Fire proofing (if necessary) is

applied over steel members. The nature of this type of

building is a complex array of dissimilar materials

which must all be fabricated off site and organized into

one complete system.

The best wall system is one that can perform

several functions simultaneously. Areinforced masonry

wall provides the structure and the skin at the same

time. Insulation can simply be foamed into the cores of

the units, or attached to the inside face. Fire and sound

resistance are built right into the wall, along with

impact resistance and security. Aesthetics, of course,

are subjective, but masonry has always been considered

one of the most beautiful building materials available.

Furthermore, the concrete masonry industry offers vir-

tually unlimited styles and textures of blocks, and this

style and texture is not just a painted on finish, its built

right into the wall.

The Chicago industrial market is seeing a sig-

nificant increase in build to suit and speculative ware-

house development. Naturally, developers would like

to provide the highest quality building at the most com-

petitive price possible. Building with concrete mason-

ry provides an economical building, with unsurpassed

hoosing a building system is

not a simple process. It

should be one single answer

to several important questions.

One must consider all the desired

characteristics, such as economy,

durability, appearance and structur-

al stability to name a few. The goal

is an economical building system

that will look good, perform well,

and stand the test of time. The best

choice for a building system is one

that satisfies all of the desired char-

acteristics at the lowest cost.

Reinforced concrete masonry walls

provide all of the desired character-

istics with one simple and cost-

effective load-bearing wall, thus

providing the the greatest effect

with the least effort.

Sometimes when exposed

to a complex question, we see an

even more complex answer. Asolu-

tion we see in the Chicago market

is a steel structure with attached

precast panels as a system. This

separation of structure and finish is

not a new idea. It was one of the

main ideas which sparked the mod-

ernist movement in architecture at

C

The All Concrete Masonry

Warehouse

Project: 32,000 ft

2

warehouse with

32 tall walls, 10 garage

doors, and a double

cantilever corner entry.

Construction: 12 C.M.U. with #6 rebar

@ 48 O.C. per figure 1.

Avg. lead time: 8.7 days

Avg. duration: 24 days

Average cost $8.25 - $8.50 / ft

2

(reg. med. wt.)

of walls: $9.25 - 9.50 / ft

2

( l.w. split face )

Add $0.45 / ft

2

for

foamed in place insulation

Costs are averaged from Chicago area mason contractors estimates

Figure 1

By: Jason Yana

(Over)

Why is concrete masonry an excel-

lent choice for commercial ware-

houses?

Initial costs:

The way that one can create an eco-

nomical warehouse with masonry is

by virtue of simplicity. By taking

advantage of the inherent compres-

sive strength of concrete, and the

tensile strength of reinforcing steel,

one can use this simple system of

reinforced masonry to create tall

slender load bearing walls in excess

of 40 feet. With the deletion of the

perimeter steel framing, additional

cost savings can be realized with

load bearing concrete masonry

walls. The headaches associated

with designing and fabricating a

steel frame and incorporating an

exterior cladding system to match it

can be replaced by one simple sys-

tem.

Durability & Security:

The durability advantage of mason-

ry is quite clear. Well designed

masonry walls can last for centuries,

and can sustain years of wear and

tear. Durability is an important fac-

tor in warehouses where walls may

be subjected to impact and abrasion

from machinery, forklifts, trucks, etc

After Hurricane Andrew in south

Florida, where block is often used,

researchers investigated the integri-

ty of several building systems. They

found that the masonry walls out

performed all other types of con-

struction. This is a clear example of

the inherent strength of concrete

masonry walls.

Lead time:

The effective lead time for a mason-

ry building usually only takes 1 - 2

weeks. For a more complex steel or

precast concrete product, lead time

could be 20 - 24 weeks of stagnation

while costing $8 - $12 / ft

2 .

Aesthetics

The human scale and textural quali-

ties of masonry make it one of the

most aesthetically pleasing building

material available. The myth of bor-

ing concrete blocks has long been

shattered by the concrete masonry

industry. The vast array of different

shapes, sizes, colors and styles of

architectural concrete block place

no limits on aesthetic creativity.

Fire resistance

By using masonry walls, you pro-

vide your clients with maximum fire

protection. When a wood frame

house is destroyed by fire, the only

thing left standing is the masonry

chimney. Block doesnt burn, melt,

twist, or warp when exposed to fire.

The concrete block wall is a fire bar-

rier able to contain a fire to a small

area, protecting the buildings occu-

pants, not to mention the potential

40% savings on annual fire insur-

ance premiums.

When planning your next

industrial building, or any building

for that matter, consider reducing

the problem down to one simple

solution - Concrete Masonry. For

more information contact the

Masonry Advisory Council at

(847)297-6704/ www.maconline.org

quality, looks, and durability, without the

potential 20 - 24 week lead time associated

with other systems.

Agood designer should know the

facts about concrete masonrys potential in

warehouse construction. For this reason

we have designed a 32,000 sq. ft. all

masonry warehouse and obtained esti-

mates from several prominent mason con-

tractors in the Chicago Area. The average

bid for the 32 tall, regular, mediumweight

12 reinforced block was between $8.25 -

$8.50 /ft

2

, with an average lead time of

only 9 days. For a 12 lightweight split

face architectural block, costs averaged

between $9.25 and $9.50 / ft

2

.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Strength of Anchors in Concrete and Masonry Elements: Standard Test Methods ForDocument8 paginiStrength of Anchors in Concrete and Masonry Elements: Standard Test Methods ForRonald Millán Gonzales100% (1)

- Astm e 165 (Liquidos Penetrantes) PDFDocument20 paginiAstm e 165 (Liquidos Penetrantes) PDFAnonymous eB2AZT3Încă nu există evaluări

- Section 13 - AASHTO LRFDDocument42 paginiSection 13 - AASHTO LRFDRonald Millán GonzalesÎncă nu există evaluări

- Integral Abudment BridgesDocument30 paginiIntegral Abudment BridgesRonald Millán GonzalesÎncă nu există evaluări

- Cut Section SAP2000Document3 paginiCut Section SAP2000Ronald Millán Gonzales0% (1)

- EERI - Chile EarthquakeDocument37 paginiEERI - Chile EarthquakeJavsarÎncă nu există evaluări

- Lean Manufacturing PDFDocument29 paginiLean Manufacturing PDFRonald Millán GonzalesÎncă nu există evaluări

- Generation of Spectrum Compatible AccelerogramsDocument11 paginiGeneration of Spectrum Compatible AccelerogramsRonald Millán GonzalesÎncă nu există evaluări

- PIANC Seismic DesignDocument14 paginiPIANC Seismic DesignMMexpÎncă nu există evaluări

- Report On Thermal and Volume Change Effects On Cracking of Mass ConcreteDocument2 paginiReport On Thermal and Volume Change Effects On Cracking of Mass ConcreteRonald Millán Gonzales0% (1)

- Caltrans Standard Specifications GuideDocument872 paginiCaltrans Standard Specifications GuidesloengineerÎncă nu există evaluări

- Seismic ConceptualDocument82 paginiSeismic Conceptualஆனந்த் கிருஷ்ணன்Încă nu există evaluări

- Semi Integral 20 PDFDocument20 paginiSemi Integral 20 PDFRonald Millán GonzalesÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- DLRB Pier OnlyDocument37 paginiDLRB Pier Onlyrvkumar3619690Încă nu există evaluări

- Wall Panel SystemsDocument19 paginiWall Panel SystemsLaura Sacdalan94% (17)

- Steelpac Proposal For Energypac Engineering Ltd. Ltd.Document22 paginiSteelpac Proposal For Energypac Engineering Ltd. Ltd.kaosar alamÎncă nu există evaluări

- 22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Document29 pagini22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Dennis SagaoÎncă nu există evaluări

- C-HW09 Simpson CatalogDocument44 paginiC-HW09 Simpson CatalogLee WinklerÎncă nu există evaluări

- Precast Concrete Pipe Rack DesignDocument43 paginiPrecast Concrete Pipe Rack DesignAmanpreet Singh67% (3)

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed PDFDocument1.108 paginiPrestressed Concrete Analysis and Design Fundamentals 2nd Ed PDFCarlos Alberto Pacheco Sierra100% (1)

- Pushover Analysis of An Existing R.C.CDocument5 paginiPushover Analysis of An Existing R.C.CYuliusRiefAlkhalyÎncă nu există evaluări

- Column Footing Detail-1Document1 paginăColumn Footing Detail-1Dianne EstillerÎncă nu există evaluări

- Construction Methodology For FoundationDocument1 paginăConstruction Methodology For Foundationborkarsd007Încă nu există evaluări

- Building Construction TechniquesDocument2 paginiBuilding Construction TechniquesDharshan KÎncă nu există evaluări

- Web Compression Buckling Capacity Prediction For Unstiffened I-Sections With Opposite Patch LoadingDocument19 paginiWeb Compression Buckling Capacity Prediction For Unstiffened I-Sections With Opposite Patch LoadingGogyÎncă nu există evaluări

- Enhanced Punching Shear MethodDocument4 paginiEnhanced Punching Shear Methodgks6043Încă nu există evaluări

- Site Class B Response Spectrum GraphDocument8 paginiSite Class B Response Spectrum Graphsudhir12345100% (1)

- BRIDGE Cat + Exams-01Document14 paginiBRIDGE Cat + Exams-01SHOTURU PÎncă nu există evaluări

- Nondestructive Testing for Bridge EvaluationDocument11 paginiNondestructive Testing for Bridge EvaluationMichael MatshonaÎncă nu există evaluări

- Prestress BasicDocument70 paginiPrestress Basickingsaurabh1234Încă nu există evaluări

- Lecture-Masonry Part 2 Adobe StoneDocument7 paginiLecture-Masonry Part 2 Adobe StoneJohn Isaac BanaagÎncă nu există evaluări

- Price of KEL Agro Industry FinalDocument89 paginiPrice of KEL Agro Industry FinalMehari GebreyohannesÎncă nu există evaluări

- 2012 Wood Frame 2012 Wood Frame Construction Manual: Construction Manual: Construction Manual: Construction ManualDocument23 pagini2012 Wood Frame 2012 Wood Frame Construction Manual: Construction Manual: Construction Manual: Construction ManualLourdes PaivaÎncă nu există evaluări

- Abcm Case StudyDocument51 paginiAbcm Case StudyShambhavi SawantÎncă nu există evaluări

- MFE Accessories Brochure (Old)Document8 paginiMFE Accessories Brochure (Old)David LawÎncă nu există evaluări

- 00 List of StandardsDocument2 pagini00 List of StandardsDeepak GuptaÎncă nu există evaluări

- Construction Box CulvertDocument4 paginiConstruction Box CulvertKhalid OsmanÎncă nu există evaluări

- Design of Concrete StructuresDocument2 paginiDesign of Concrete StructuresNehaSingh33% (3)

- Load Calculation Met Arm - 2 - EscalatorDocument3 paginiLoad Calculation Met Arm - 2 - Escalatorvrajan1988Încă nu există evaluări

- Anchorage Design with Circular Base PlateDocument5 paginiAnchorage Design with Circular Base PlateGabbo pnukÎncă nu există evaluări

- Major Project 1 REPORT 16mclc15Document62 paginiMajor Project 1 REPORT 16mclc15Jitendra PatelÎncă nu există evaluări

- An Empirical Stress-Intensity Factor Equation For The Surface CrackDocument8 paginiAn Empirical Stress-Intensity Factor Equation For The Surface CrackShaun Raphael LeeÎncă nu există evaluări

- Concept Big Me She SengDocument204 paginiConcept Big Me She SengmulviÎncă nu există evaluări