Documente Academic

Documente Profesional

Documente Cultură

Aircraft Engine

Încărcat de

Damy ManesiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aircraft Engine

Încărcat de

Damy ManesiDrepturi de autor:

Formate disponibile

Aircraft engine

Sumber : http://en.wikipedia.org/wiki/Aircraft_engine#In-line_engine

From Wikipedia, the free encyclopedia

A Rolls-Royce Merlin installed in a preserved Avro York

Part of a series on

Aircraft propulsion

Shaft engines :

driving propellers, rotors, ducted fans, orpropfans

Internal combustion engines:

Piston engine

Wankel engine

Turbines:

Turboprop

Turboshaft

External combustion engines:

Steam-powered

Reaction engines

Turbines:

Turbojet

Turbofan

Propfan

Rocket-powered

Motorjet

Pulsejet

Ramjet

Scramjet

Others

Human-powered

Electric

Nuclear

Hydrogen

V

T

E

An aircraft engine is the component of the propulsion system for an aircraft that generates

mechanical power. Aircraft engines are almost always either lightweight piston engines or gas

turbines.

Contents

[hide]

1 Aircraft Engine Manufacturing Industry

2 Timeline of aircraft engine development

3 Shaft engines

o 3.1 Reciprocating (piston) engines

3.1.1 In-line engine

3.1.2 V-type engine

3.1.3 Horizontally opposed engine

3.1.4 H configuration engine

3.1.5 Radial engine

3.1.6 Rotary engine

o 3.2 Turbine-powered

3.2.1 Turboprop

3.2.2 Turboshaft

4 Reaction engines

o 4.1 Jets

4.1.1 Turbojet

4.1.2 Turbofan

o 4.2 Pulse jets

o 4.3 Rocket

5 Newer engine types

o 5.1 Wankel engine

o 5.2 Diesel engine

o 5.3 Precooled jet engines

o 5.4 Electric

6 Fuel

7 See also

8 Notes

9 References

10 External links

Aircraft Engine Manufacturing Industry[edit]

As of 2012, the size of the aircraft engine manufacturing market was almost $40 billion.

[1]

There

are over 350 manufacturing companies in the United States employing over 70 thousand. For a

list of all manufacturers in the world see the List of aircraft engines.

Timeline of aircraft engine development[edit]

Wright vertical 4-cylinder engine

See also: Timeline of jet power

1848: John Stringfellow made a steam engine capable of powering a model, albeit with

negligible payload.

1903: Charlie Taylor built an inline aeroengine for the Wright Flyer (12 horsepower).

1903: Manly-Balzer engine sets standards for later radial engines.

[2]

1906: Lon Levavasseur produces a successful water-cooled V8 engine for aircraft use.

1908: Ren Lorin patents a design for the ramjet engine.

1908: Gnome Omega designed the world's first rotary engine to be produced in quantity. In

1909 a Gnome powered Farman III aircraft won the prize for the greatest non-stop distance

flown at the Reims Grande Semaine d'Aviation setting a world record for endurance of 180

kilometres (110 mi).

1910: Coand-1910, an unsuccessful ducted fan aircraft exhibited at Paris Aero Salon,

powered by a piston engine. The aircraft never flew, but a patent was filed for routing

exhaust gases into the duct to augment thrust.

[3][4][5][6]

1914: Auguste Rateau suggests using exhaust-powered compressor a turbocharger to

improve high-altitude performance;

[2]

not accepted after the tests

[7]

1917-18 - The Idflieg-numbered R.30/16 example of the Imperial

German Luftstreitkrfte's Zeppelin-Staaken R.VI heavy bomber becomes the earliest known

supercharger-equipped aircraft to fly, with a Mercedes D.II straight-six engine placed in the

central fuselage to power a Brown-Boveri mechanical supercharger for the R.30/16's quartet

ofMercedes D.IVa powerplants.

1918: Sanford Alexander Moss picks Rateau's idea and creates the first successful

turbocharger

[2][8]

1926: Armstrong Siddeley Jaguar IV (S), the first series-produced supercharged engine for

aircraft use;

[9][nb 1]

two-row radial with a gear-driven centrifugal supercharger.

1930: Frank Whittle submitted his first patent for turbojet engine.

June 1939: Heinkel He 176 is the first successful aircraft to fly powered solely by a liquid-

fueled rocket engine.

August 1939: Heinkel HeS 3 turbojet propels the pioneering German Heinkel He 178 aircraft.

1940: Jendrassik Cs-1, the world's first run of the turboprop engine. It is not put into service.

1944: Messerschmitt Me 163B Komet, the world's first rocket propelled combat aircraft

deployed.

1945: First turboprop powered aircraft flies, a Gloster Meteor with two Rolls-Royce Trent

1947: Bell X-1 rocket propelled aircraft exceeds the speed of sound.

1948: 100 shp 782, the first turboshaft engine to be applied to aircraft use; in 1950 used to

develop the larger 280 shp (210 kW) Turbomeca Artouste.

1949: Leduc 010, the world's first ramjet-powered aircraft flight.

1950: Rolls-Royce Conway, the world's first production turbofan, enters service.

1960s: General Electric TF39 high bypass turbofan enters service delivering greater thrust

and much better efficiency.

2002: HyShot scramjet flew in dive.

2004: Hyper-X, the first scramjet to maintain altitude.

Shaft engines[edit]

Ranger L-440 air-cooled, six-cylinder, inverted, in-line engine used inFairchild PT-19

Reciprocating (piston) engines[edit]

Main article: reciprocating engine

In-line engine[edit]

Main article: Straight engine

This type of engine has cylinders lined up in one row. It typically has an even number of

cylinders, but there are instances of three- and five- cylinder engines. The greatest advantage of

an inline engine is that it allows the aircraft to be designed with a low frontal area to minimise

drag. If the engine crankshaft is located above the cylinders, it is called an inverted inline engine:

this allows the propeller to be mounted high up to increase ground clearance, enabling shorter

landing gear. The disadvantages of an inline engine include a poorpower-to-weight ratio,

because the crankcase and crankshaft are long and thus heavy. An in-line engine may be either

air-cooled or liquid-cooled, but liquid-cooling is more common because it is difficult to get enough

air-flow to cool the rear cylinders directly. Inline engines were common in early aircraft; one was

used in the Wright Flyer, the aircraft that made the first controlled powered flight. However, the

inherent disadvantages of the design soon became apparent, and the inline design was

abandoned, becoming a rarity in modern aviation.

V-type engine[edit]

A Rolls-Royce Merlin V-12 Engine

Main article: V engine

Cylinders in this engine are arranged in two in-line banks, typically tilted 60-90 degrees apart

from each other and driving a common crankshaft. The vast majority of V engines are water-

cooled. The V design provides a higher power-to-weight ratio than an inline engine, while still

providing a small frontal area. Perhaps the most famous example of this design is the

legendary Rolls-Royce Merlin engine, a 27-litre (1649 in

3

) 60 V12 engine used in, among others,

the Spitfires that played a major role in the Battle of Britain.

Horizontally opposed engine[edit]

Main article: Flat engine

A ULPower UL260i horizontally opposed air-cooled aero engine

A horizontally opposed engine, also called a flat or boxer engine, has two banks of cylinders on

opposite sides of a centrally located crankcase. The engine is either air-cooled or liquid-cooled,

but air-cooled versions predominate. Opposed engines are mounted with the crankshaft

horizontal in airplanes, but may be mounted with the crankshaft vertical in helicopters. Due to the

cylinder layout, reciprocating forces tend to cancel, resulting in a smooth running engine.

Opposed, air-cooled four- and six-cylinder piston engines are by far the most common engines

used in small general aviation aircraft requiring up to 400 horsepower (300 kW) per engine.

Aircraft that require more than 400 horsepower (300 kW) per engine tend to be powered

by turbine engines.

H configuration engine[edit]

Main article: H engine

An H configuration engine is essentially a pair of horizontally opposed engines placed together,

with the two crankshafts geared together.

Radial engine[edit]

A Pratt & Whitney R-2800 engine

Main article: Radial engine

This type of engine has one or more rows of cylinders arranged around a centrally

located crankcase. Each row generally has an odd number of cylinders to produce smooth

operation. A radial engine has only one crank throw per row and a relatively small crankcase,

resulting in a favorable power-to-weight ratio. Because the cylinder arrangement exposes a large

amount of the engine's heat-radiating surfaces to the air and tends to cancel reciprocating forces,

radials tend to cool evenly and run smoothly. The lower cylinders, which are under the

crankcase, may collect oil when the engine has been stopped for an extended period. If this oil is

not cleared from the cylinders prior to starting the engine, serious damage due to hydrostatic

lock may occur.

Most radial engines have the cylinders arranged evenly around the crankshaft, although some

early engines, sometimes called semi-radials or fan configuration engines, had an uneven

arrangement. The best known engine of this type is the Anzani engine, which was fitted to

the Bleriot XI used for the first flight across the English Channel in 1909. This arrangement had

the drawback of needing a heavy counterbalance for the crankshaft, but was used to avoid

the spark plugs oiling up.

In military aircraft designs, the large frontal area of the engine acted as an extra layer of armor

for the pilot. Also air-cooled engines, without vulnerable radiators, are slightly less prone to battle

damage, and on occasion would continue running even with one or more cylinders shot away.

However, the large frontal area also resulted in an aircraft with an aerodynamically

inefficient increased frontal area.

Rotary engine[edit]

Le Rhone 9C rotary aircraft engine

Main article: Rotary engine

Rotary engines have the cylinders in a circle around the crankcase, as in a radial engine, (see

above), but the crankshaft is fixed to the airframe and the propeller is fixed to the engine case, so

that the crankcase and cylinders rotate. The advantage of this arrangement is that a satisfactory

flow of cooling air is maintained even at low airspeeds, retaining the weight advantage and

simplicity of a conventional air-cooled engine without one of their major drawbacks. The first

practical rotary engine was the Gnome Omega designed by the Seguin brothers and first flown in

1909. Its relative reliability and good power to weight ratio changed aviation

dramatically.

[10]

Before the first World War most speed records were gained using Gnome-

engined aircraft, and in the early years of the war rotary engines were dominant in aircraft types

for which speed and agility were paramount. To increase power, engines with two rows of

cylinders were built.

However, the gyroscopic effects of the heavy rotating engine produced handling problems in

aircraft and the engines also consumed large amounts of oil since they used total loss

lubrication, the oil being mixed with the fuel and ejected with the exhaust gases. Castor oil was

used for lubrication, since it is not soluble in petrol, and the resultant fumes were nauseating to

the pilots. Engine designers had always been aware of the many limitations of the rotary engine

so when the static style engines became more reliable and gave better specific weights and fuel

consumption, the days of the rotary engine were numbered.

Turbine-powered[edit]

Turboprop[edit]

Cutaway view of a Garrett TPE-331turboprop engine showing the gearbox at the front of the engine

Main article: Turboprop

While military fighters require very high speeds, many civil airplanes do not. Yet, civil aircraft

designers wanted to benefit from the high power and low maintenance that a gas turbine engine

offered. Thus was born the idea to mate a turbine engine to a traditional propeller. Because gas

turbines optimally spin at high speed, a turboprop features a gearbox to lower the speed of the

shaft so that the propeller tips don't reach supersonic speeds. Often the turbines that drive the

propeller are separate from the rest of the rotating components so that they can rotate at their

own best speed (referred to as a free-turbine engine). A turboprop is very efficient when operated

within the realm of cruise speeds it was designed for, which is typically 200 to 400 mph (320 to

640 km/h).

Turboshaft[edit]

A Rolls-Royce Model 250 turboshaft engine common to many types of helicopters

Main article: Turboshaft

Turboshaft engines are used primarily for helicopters and auxiliary power units. A turboshaft

engine is similar in principle, but in a turboprop the propeller is supported by the engine and the

engine is bolted to the airframe: in a turboshaft, the engine does not provide any direct physical

support to the helicopter's rotors. The rotor is connected to a transmission which is bolted to the

airframe, and the turboshaft engine drives the transmission. The distinction is seen by some as

slim, as in some cases aircraft companies make both turboprop and turboshaft engines based on

the same design.

Reaction engines[edit]

Main article: Jet engine

Reaction engines generate the thrust to propel an aircraft by ejecting the exhaust gases at high

velocity from the engine, the resultantreaction of forces driving the aircraft forwards. The most

common reaction propulsion engines flown are turbojets, turbofans and rockets. Other types

such as pulsejets, ramjets,scramjets and Pulse Detonation Engines have also flown. In jet

engines the oxygen necessary for fuel combustion comes from the air, while rockets carry

oxygen in some form as part of the fuel load, permitting their use in space.

Jets[edit]

Turbojet[edit]

A General Electric J85-GE-17A turbojet engine. This cutaway clearly shows the 8 stages of axial compressor at the front (left side of the picture),

the combustion chambers in the middle, and the two stages ofturbines at the rear of the engine.

Main article: Turbojet

A turbojet is a type of gas turbine engine that was originally developed for

military fighters during World War II. A turbojet is the simplest of all aircraft gas turbines. It

consists of a compressor to draw air in and compress it, a combustion section where fuel is

added and ignited, one or more turbines that extract power from the expanding exhaust gases to

drive the compressor, and an exhaust nozzle that accelerates the exhaust gases out the back of

the engine to create thrust. When turbojets were introduced, the top speed of fighter aircraft

equipped with them was at least 100 miles per hour faster than competing piston-driven aircraft.

In the years after the war, the drawbacks of the turbojet gradually became apparent. Below about

Mach 2, turbojets are very fuel inefficient and create tremendous amounts of noise. Early designs

also respond very slowly to power changes, a fact that killed many experienced pilots when they

attempted the transition to jets. These drawbacks eventually led to the downfall of the pure

turbojet, and only a handful of types are still in production. The last airliner that used turbojets

was the Concorde, whose Mach 2 airspeed permitted the engine to be highly efficient.

Turbofan[edit]

A cutaway of a CFM56-3 turbofan engine

Main article: Turbofan

A turbofan engine is much the same as a turbojet, but with an enlarged fan at the front that

provides thrust in much the same way as a ducted propeller, resulting in improved fuel-efficiency.

Though the fan creates thrust like a propeller, the surrounding duct frees it from many of the

restrictions that limit propeller performance. This operation is a more efficient way to provide

thrust than simply using the jet nozzle alone and turbofans are more efficient than propellers in

the trans-sonic range of aircraft speeds, and can operate in the supersonic realm. A turbofan

typically has extra turbine stages to turn the fan. Turbofans were among the first engines to use

multiple spoolsconcentric shafts that are free to rotate at their own speedto let the engine

react more quickly to changing power requirements. Turbofans are coarsely split into low-bypass

and high-bypass categories. Bypass air flows through the fan, but around the jet core, not mixing

with fuel and burning. The ratio of this air to the amount of air flowing through the engine core is

the bypass ratio. Low-bypass engines are preferred for military applications such as fighters due

to high thrust-to-weight ratio, while high-bypass engines are preferred for civil use for good fuel

efficiency and low noise. High-bypass turbofans are usually most efficient when the aircraft is

traveling at 500 to 550 miles per hour (800 to 885 km/h), the cruise speed of most large airliners.

Low-bypass turbofans can reach supersonic speeds, though normally only when fitted

with afterburners.

Pulse jets[edit]

Main article: Pulse jet engine

Pulse jets are mechanically simple devices thatin a repeating cycledraw air through a no-

return valve at the front of the engine into a combustion chamber and ignited it. The combustion

forces the exhaust gases out the back of the engine. It produces power as a series of pulses

rather than as a steady output, hence the name. The only application of this type of engine was

the German unmanned V1 flying bomb of World War II. Though the same engines were also

used experimentally for ersatz fighter aircraft, the extremely loud noise generated by the engines

caused mechanical damage to the airframe that was sufficient to make the idea unworkable.

Rocket[edit]

An XLR99

Main article: Rocket engine

A few aircraft have used rocket engines for main thrust or attitude control, notably the Bell X-

1 and North American X-15. Rocket engines are not used for most aircraft as the energy and

propellant efficiency is very poor except at high speeds, but have been employed for short bursts

of speed and takeoff. Rocket engines are very efficient only at very high speeds, although they

are useful because they produce very large amounts of thrust and weigh very little.

Newer engine types[edit]

Wankel engine[edit]

Main article: Wankel engine

Powerplant from aSchleicher ASH 26e self-launching motor glider, removed from the glider and mounted on a test stand for maintenance at the Alexander

Schleicher GmbH & Co inPoppenhausen, Germany. Counter-clockwise from top left: propeller hub, mast with belt guide, radiator, Wankel engine, muffler

shroud.

Another promising design for aircraft use was the Wankel rotary engine. The Wankel engine is

about one half the weight and size of a traditionalfour-stroke cycle piston engine of equal power

output, and much lower in complexity. In an aircraft application, the power-to-weight ratio is very

important, making the Wankel engine a good choice. Because the engine is typically constructed

with an aluminium housing and a steel rotor, and aluminium expands more than steel when

heated, a Wankel engine does not seize when overheated, unlike a piston engine. This is an

important safety factor for aeronautical use. Considerable development of these designs started

after World War II, but at the time the aircraft industry favored the use of turbine engines. It was

believed that turbojet or turboprop engines could power all aircraft, from the largest to smallest

designs. The Wankel engine did not find many applications in aircraft, but was used by Mazda in

a popular line of sports cars. Recently, the Wankel engine has been developed for use in motor

gliders where the small size, light weight, and low vibration are especially important.

[11]

Wankel engines are becoming increasingly popular in homebuilt experimental aircraft, due to a

number of factors. Most are Mazda 12A and 13B engines, removed from automobiles and

converted to aviation use. This is a very cost-effective alternative to certified aircraft engines,

providing engines ranging from 100 to 300 horsepower (220 kW) at a fraction of the cost of

traditional engines. These conversions first took place in the early 1970s, and with hundreds or

even thousands of these engines mounted on aircraft, as of 10 December 2006 the National

Transportation Safety Board has only seven reports of incidents involving aircraft with Mazda

engines, and none of these is of a failure due to design or manufacturing flaws. During the same

time frame, they have reports of several thousand reports of broken crankshafts and connecting

rods, failed pistons and incidents caused by other components not found in the Wankel engines.

Rotary engine enthusiasts refer to piston aircraft engines as "Reciprosaurs," and point out that

their designs are essentially unchanged since the 1930s, with only minor differences in

manufacturing processes and variation in engine displacement.

Diesel engine[edit]

Main article: Aircraft Diesel engine

Most aircraft engines use spark ignition, generally using gasoline as a fuel. Starting in the 1930s

attempts were made to produce a compression ignition Diesel engine for aviation use. In general,

Diesel engines are more reliable and much better suited to running for long periods of time at

medium power settings, which is why they are widely used in, for example, trucks and ships. The

lightweight alloys of the 1930s were not up to the task of handling the much higher compression

ratios of diesel engines, so they generally had poor power-to-weight ratios and were uncommon

for that reason, although the Clerget 14F Diesel radial engine (1939) has the same power to

weight ratio as a gasoline radial. Improvements in Diesel technology in automobiles (leading to

much better power-weight ratios), the Diesel's much better fuel efficiency and the high relative

taxation of AVGAS compared to Jet A1 in Europe have all seen a revival of interest in the use of

diesels for aircraft. Thielert Aircraft Engines converted Mercedes Diesel automotive engines,

certified them for aircraft use, and became an OEM provider to Diamond Aviation for their light

twin. Financial problems have plagued Thielert, so Diamond's affiliate Austro Engine

developed the new AE300 turbodiesel, also based on a Mercedes engine.

[12]

Competing new

Diesel engines may bring fuel efficiency and lead-free emissions to small aircraft, representing

the biggest change in light aircraft engines in decades. Wilksch Airmotive build 2-stroke Diesel

engine (same power to weight as a gasoline engine) for experimental aircraft: WAM 100

(100 hp), WAM 120 (120 hp) and WAM 160 (160 hp)

Diesel engines may also be carving out a niche among low- and medium-altitude unmanned

aircraft. The U.S. Army's MQ-1C Grey Eagle employs a heavy-fuel diesel engine which has the

advantages of extended range, more time on station, and fuel commonality among the vehicle

fleet, as compared to gasoline-powered piston engines or turbine engines. A smaller but similar

UAV also using a heavy-fuel diesel engine is Unmammed Aerial Systems Inc.'s Nightwind IVB.

Precooled jet engines[edit]

Main article: Precooled jet engine

For very high supersonic/low hypersonic flight speeds inserting a cooling system into the air duct

of a hydrogen jet engine permits greater fuel injection at high speed and obviates the need for

the duct to be made of refractory or actively cooled materials. This greatly improves the

thrust/weight ratio of the engine at high speed.

It is thought that this design of engine could permit sufficient performance for antipodal flight at

Mach 5, or even permit a single stage to orbit vehicle to be practical.

Electric[edit]

About 60 electrically powered aircraft, such as the QinetiQ Zephyr, have been designed since the

1960s.

[13][14]

Some are used as military drones.

[15]

In France in late 2007, a conventional light

aircraft powered by an 18 kW electric motor using lithium polymer batteries was flown, covering

more than 50 kilometers (31 mi), the first electric airplane to receive a certificate of

airworthiness.

[13]

Limited experiments with solar electric propulsion have been performed, notably the

manned Solar Challenger and Solar Impulse and the unmanned NASA Pathfinder aircraft.

Fuel[edit]

This section does not cite any references or sources. Please help improve this section by adding citations to

reliable sources. Unsourced material may be challenged and removed. (September 2010)

This section possibly contains original research. Please improve it by verifying the claims made and adding inline

citations. Statements consisting only of original research should be removed. (September 2010)

All aviation fuel is produced to stringent quality standards to avoid fuel-related engine failures.

Aviation standards are much more strict than those for road vehicle fuel because an aircraft

engine must meet a strictly defined level of performance under known conditions. These high

standards mean that aviation fuel costs much more than fuel used for road vehicles.

Aircraft reciprocating (piston) engines are typically designed to run on aviation gasoline. Avgas

has a higher octane rating than automotive gasoline to allow higher compression ratios, power

output and efficiency at higher altitudes. Currently the most common Avgas is 100LL that refers

to the octane rating (100 octane) and the lead content (LL = low lead).

Refineries blend Avgas with tetraethyllead (TEL) to achieve these high octane ratings, a practice

that governments no longer permit for road vehicle gasoline. The shrinking supply of TEL and the

possibility of environmental legislation banning its use has made a search for replacement fuels

for general aviation aircraft a priority for pilot's organizations.

[16]

Turbine engines and aircraft Diesel engines burn various grades of jet fuel. Jet fuel is a relatively

heavy and less volatile petroleum derivative based on kerosene, but certified to strict aviation

standards, with additional additives.

See also[edit]

Air safety

Aircraft engine position number

Engine configuration

Hyper engine

List of aircraft engines

Model engine

United States military aero engine designations

Notes[edit]

1. Jump up^ The world's first series-produced cars with superchargers came earlier than aircraft. These were Mercedes 6/25/40 hp

and Mercedes 10/40/65 hp, both models introduced in 1921 and used Roots superchargers. G.N. Georgano, ed. (1982). The new

encyclopedia of motorcars 1885 to the present (3rd ed.). New York: Dutton. p. 415. ISBN 0-525-93254-2.

References[edit]

1. Jump up^ "Pell Research Aircraft Engine Manufacturing Industry Report". Pellresearch.com. Retrieved 7 April 2013.

2. ^ Jump up to:

a

b

c

Ian McNeil, ed. (1990). Encyclopedia of the History of Technology. London: Routledge. pp. 31521. ISBN 0-203-

19211-7.

3. Jump up^ Gibbs-Smith, Charles Harvard (1970). Aviation: an historical survey from its origins to the end of World War II.

London: Her Majesty's Stationery Office.

4. Jump up^ Gibbs-Smith, Charles Harvard (1960). The Aeroplane: An Historical Survey of Its Origins and Development. London: Her

Majesty's Stationery Office.

5. Jump up^ Winter, Frank H. (December 1980). "Ducted Fan or the World's First Jet Plane? The Coanda claim re-examined". The

Aeronautical Journal (Royal Aeronautical Society) 84.

6. Jump up^ Antoniu, Dan; Cico, Geroge; Buiu, Ioan-Vasile; Bartoc, Alexandru; utic, Robert. Henri Coand and his technical work

during 19061918 (in Romanian). Bucharest: Editura Anima.ISBN 978-973-7729-61-3.

7. Jump up^ Guttman, Jon (2009). SPAD XIII vs. Fokker D VII: Western Front 1918 (1st ed.). Oxford: Osprey. pp. 2425. ISBN 1-

84603-432-9.

8. Jump up^ Powell, Hickman (Jun 1941). "He Harnessed a Tornado...". Popular Science.

9. Jump up^ Anderson, John D (2002). The airplane: A history of its technology.. Reston, VA, USA: American Institute of Aeronautics

and Astronautics. pp. 25253. ISBN 1-56347-525-1.

10. Jump up^ Gibbs-Smith, C.H. (2003). Aviation. London: NMSO. p. 175. ISBN 1 9007 4752 9.

11. Jump up^ "ASH 26 E Information". DE: Alexander Schleicher. Archived from the original on 2006-10-08. Retrieved 2006-11-24.

12. Jump up^ "Diamond Twins Reborn". Flying Mag. Retrieved 2010-06-14.

13. ^ Jump up to:

a

b

Worldwide premire: first aircraft flight with electrical engine, Association pour la Promotion des Aronefs

Motorisation lectrique, December 23, 2007.

14. Jump up^ Superconducting Turbojet, Physorg.com.

15. Jump up^ Voyeur, Litemachines.

16. Jump up^ "EAA'S Earl Lawrence Elected Secretary of International Aviation Fuel Committee" (Press release).

[dead link]

External links[edit]

Wikimedia Commons

has media related

to Aircraft engines.

Look up aircraft

enginein Wiktionary,

the free dictionary.

Aircraft Engines and Aircraft Engine Theory (includes links to diagrams)

The Aircraft Engine Historical Society

Jet Engine Specification Database

Aircraft Engine Efficiency: Comparison of Counter-rotating and Axial Aircraft LP Turbines

The History of Aircraft Power Plants Briefly Reviewed : From the " 7 lb. per h.p" Days to the "

1 lb. per h.p" of To-day

"The Quest for Power" a 1954 Flight article by Bill Gunston

Aircraft engine position number

From Wikipedia, the free encyclopedia

Aircraft engine position numbering

Thrust levers in a Boeing 727 with the engine number on each lever

On multi-engined aircraft, aircraft engine positions are numbered from left to right from the

view of the pilot looking forward.

[1]

Contents

[hide]

1 Wing and rear-mounted engines

o 1.1 Twin-engined aircraft

o 1.2 Three-engined aircraft

o 1.3 Four-engined aircraft

o 1.4 Six-engined aircraft

2 Other configurations

o 2.1 Centerline

3 References

Wing and rear-mounted engines[edit]

Twin-engined aircraft[edit]

#1 - port - on the left

#2 - starboard - on the right

Three-engined aircraft[edit]

#1 - port - on the left

#2 - centre - on the centerline

#3 - starboard - on the right

Four-engined aircraft[edit]

#1 - port outer - on the left furthest from the fuselage

#2 - port inner - on the left nearest to the fuselage

#3 - starboard inner - on the right nearest to the fuselage

#4 - starboard outer - on the right furthest from the fuselage

Six-engined aircraft[edit]

#1 - port outer - on the left furthest from the fuselage

#2 - port middle - on the left between #1 and #3

#3 - port inner - on the left nearest to the fuselage

#4 - starboard inner - on the right nearest to the fuselage

#5 - starboard middle - on the right between #4 and #6

#6 - starboard outer - on the right furthest from the fuselage

Other configurations[edit]

Centerline[edit]

The English Electric Lightning has two jet engines on the centerline one above the other.

[2]

#1 - below and to the front of #2

#2 - above and to the rear of #1

References[edit]

1. Jump up^ National Business Aircraft Association (1952). Skyways for business. Henry Publications. p. 52.

2. Jump up^ Power Plants

Engine configuration

From Wikipedia, the free encyclopedia

This article does not cite any references or sources. Please help improve this article by adding citations to

reliable sources. Unsourced material may be challenged and removed. (September 2007)

Wikimedia Commons

has media related

to Engines by cylinder

layout.

Engine configuration is an engineering term for the layout of the major components of

a reciprocating piston internal combustion engine. These components are

the cylinders and crankshafts in particular but also, sometimes, the camshaft(s).

Many apparently 'standard' names for configurations are historic, arbitrary, or overlapping. For

example, the 180 V engine is so named because the crankshaft is related to a V engine more

closely than it is related to other opposed-piston engines such as the boxer. Others would

consider it a flat engine because of its shape.

The names W engine and rotary engine have each been used for several unconnected designs.

The H-4 and H-6 engines produced by Subaru are not H engines at all, but boxer engines. The

Subaru H-4 and H-6 designs are so named because they are horizontally opposed pistons.

Contents

[hide]

1 Categorisation by piston motion

2 Other categorizations

o 2.1 By valve placement

o 2.2 By camshaft placement

3 References

Categorisation by piston motion[edit]

See also: Multi-cylinder engine

Engine types include:

Single-cylinder engines

Inline engine designs:

Straight engine, with all of the cylinders placed in a single row

U engine, two separate straight engines with crankshafts linked by a central gear.

The square four is a U engine where the two straight engines have two

cylinders each.

V engine, with two banks of cylinders at an angle, most commonly 60 or 90 degrees.

Flat engine, two banks of cylinders directly opposite each other on either side of the

crankshaft.

H engine, two crankshafts.

W engine. Combination of V and straight, giving 3 banks, or two V's intertwined giving 4

banks.

Opposed piston engine, with multiple crankshafts, an example being:

Delta engines, with three banks of cylinders and three crankshafts

X engine.

Radial designs, including most:

Rotary engine designs. Mostly seen on pre-|WWII aircraft.

Pistonless rotary engines, notably:

Wankel engine.

The standard names for some configurations are historic, arbitrary, or both, with some overlap.

For example, the cylinder banks of a 180 V engine do not in any way form a V, but it is regarded

as a V engine because of its crankshaft and big end configuration, which result in performance

characteristics similar to a V engine. But it is also considered a flat engine because of its shape.

On the other hand, some engines which have none of the typical V engine crankshaft design

features and consequent performance characteristics are also regarded as V engines, purely

because of their shape. Similarly, the Volkswagen Group VR6 engine is a hybrid of the V

engine and the straight engine, and can not be definitively labeled as either.

Other categorizations[edit]

By valve placement[edit]

The majority of four stroke engines have poppet valves, although some aircraft engines

have sleeve valves. Valves may be located in the cylinder block (side valves), or in the cylinder

head (overhead valves). Modern engines are invariably of the latter design. There may be two,

three, four or five valves per cylinder, with the intake valves outnumbering the exhaust valves in

case of an odd number.

By camshaft placement[edit]

Poppet valves are opened by means of a camshaft which revolves at half the crankshaft speed.

This can be either chain, gear or toothed belt driven from the crankshaft, and can be located in

the crankcase (where it may serve one or more banks of cylinders) or in the cylinder head.

If the camshaft is located in the crankcase, a valve train of pushrods and rocker arms will be

required to operate overhead valves. Mechanically simpler are side valves, where the valve

stems rested directly on the camshaft. However, this gives poor gas flows within the cylinder

head as well as heat problems and fell out of favor for automobile use, seeflathead engine.

The majority of modern automobile engines place the camshaft on the cylinder head in

an overhead camshaft (OHC) design. There may be one or two camshafts in the cylinder head; a

single camshaft design is called single overhead camshaft (SOHC). A design with two camshafts

per cylinder head is called double overhead camshaft (DOHC). Note that the camshafts are

counted per cylinder head, so a V engine with one camshaft in each of its two cylinder heads is

still an SOHC design, and a V engine with two camshafts per cylinder head is DOHC, or

informally a "quad cam" engine.

With overhead camshafts, the valvetrain will be shorter and lighter, as no pushrods are required.

Some overhead camshaft designs still have rocker arms; this facilitates adjustment of

mechanical clearances.

If there are two camshafts in the cylinder head, the cams can sometimes bear directly on cam

followers on the valve stems (tappets). This is the usual arrangement for a four-valves-per-

cylinder design. This latter arrangement is the most inertia free, allows the most unimpeded gas

flows in the engine and is the usual arrangement for high performance automobile engines. It

also permits the spark plug to be located in the center of the cylinder head, which promotes

better combustion characteristics. Beyond a certain number of valves, the effective area

covered decreases, so four is the common-most number. Odd numbers of valves necessarily

means the intake or exhaust side must have one valve more. In practice this is invariably the

intake valves - even in even-numbered head designs, inlet valves are often larger in size than

exhaust.

Very large engines (e.g. marine engines) can have either extra camshafts or extra lobes on the

camshaft to enable the engine to run in either direction. Furthermore other manipulations of

valves can be used for e.g. engine braking, such as in a Jake brake.

A disadvantage of overhead cams is that a much longer chain (or belt) is needed to drive the

cams than with a camshaft located in the cylinder block, usually a tensioner is also needed. A

break in the belt may destroy the engine if pistons touch open valves at top dead center.

References[edit]

[hide]

V

T

E

Reciprocating engines and configurations

Type

Bourke

Deltic

Orbital

Piston

Pistonless (Wankel)

Radial

Rotary

Split cycle

Stelzer

Tschudi

Stroke cycles

Two-stroke

Four-stroke

Six-stroke

Configurations and number of cylinders

Single cylinder

Single

Split-single

Inline / straight

I2

I3

I4

I5

I6

I7

I8

I9

I10

I12

I14

Flat

F2

F4

F6

F8

F10

F12

F16

V / Vee

V2

V3

V4

V5

V6

V8

V10

V12

V14

V16

V18

V20

V24

W

W8

W12

W16

W18

Other inline

H

U

Square four

VR

Opposed

X

Components

Valves

Cylinder head porting

Corliss

Intake

Exhaust

Multi

Overhead

Piston

Poppet

Side

Sleeve

Slide

Rotary valve

Variable valve timing

Camless

Desmodromic

Fuel supplies

Carburetor

Gasoline direct injection

Common rail

Mechanisms Cam

Camshaft

Overhead camshaft

Connecting rod

Crank

Crankshaft

Scotch Yoke

Swashplate

Rhombic drive

Linkages

PeaucellierLipkin

Watt's (parallel)

Other

Hemi

Recuperator

Turbo-compounding

[hide]

V

T

E

Automotive engine

Part of the Automobile series

Basic terminology

Bore

Compression ratio

Crank

Cylinder

Dead centre

Diesel engine

Dry sump

Engine balance

Engine configuration

Engine displacement

Engine knocking

Firing order

Hydrolock

Petrol engine

Power band

Redline

Spark-ignition engine

Stroke

Stroke ratio

Wet sump

Main components

Connecting rod

Crankcase

Crankpin

Crankshaft

Crossflow cylinder head

Crossplane

Cylinder bank

Cylinder block

Cylinder head

Flywheel

Head gasket

Hypereutectic piston

Main bearing

Piston

Piston ring

Reverse-flow cylinder head

Starter ring gear

Sump

Valvetrain

Cam

Cam follower

Camshaft

Desmodromic valve

Hydraulic tappet

Multi-valve

Overhead camshaft

Overhead valve

Pneumatic valve springs

Poppet valve

Pushrod

Rocker arm

Sleeve valve

Tappet

Timing belt

Timing mark

Valve float

Variable valve timing

Aspiration

Air filter

Blowoff valve

Boost controller

Butterfly valve

Centrifugal-type supercharger

Cold air intake

Dump valve

Electronic throttle control

Forced induction

Inlet manifold

Intake

Intercooler

Manifold vacuum

Naturally aspirated engine

Ram-air intake

Scroll-type supercharger

Short ram air intake

Supercharger

Throttle

Throttle body

Turbocharger

Twin-turbo

Variable-geometry turbocharger

Variable-length intake manifold

Warm air intake

Fuel system Carburetor

Common rail

Direct injection

Fuel filter

Fuel injection

Fuel pump

Fuel tank

Gasoline direct injection

Indirect injection

Injection pump

Lean burn

Unit injector

Ignition

Contact breaker

Magneto

Distributor

Electrical ballast

High tension leads

Ignition coil

Spark plug

Wasted spark

Electrics and engine

management

Airfuel ratio meter

Alternator

Automatic Performance Control

Car battery (leadacid battery)

Crankshaft position sensor

Dynamo

Drive by wire

Electronic control unit

Engine control unit

Engine coolant temperature sensor

Glow plug

Idle air control actuator

MAP sensor

Mass flow sensor

Oxygen sensor

Starter motor

Throttle position sensor

Exhaust system

Automobile emissions control

Catalytic converter

Diesel particulate filter

Exhaust manifold

Glasspack

Muffler

Engine cooling

Air cooling

Antifreeze (ethylene glycol)

Core plug

Electric fan

Fan belt

Radiator

Thermostat

Water cooling

Viscous fan (fan clutch)

Other components

Balance shaft

Block heater

Combustion chamber

Cylinder head porting

Gasket

Motor oil

Oil filter

Oil pump

Oil sludge

PCV valve

Seal

Synthetic oil

Underdrive pulleys

Portal

Category

[hide]

V

T

E

Automobile configuration

Part of the Automobile series

Car body style and

classification

2 plus 2

Antique car

Cabrio coach

Cabriolet

City car

Classic car

Compact car

Compact executive car

Compact MPV

Compact SUV

Convertible

Coup

Coup utility

Crossover SUV

Custom car

Delivery

Delivery Truck

Drophead coupe

Executive car

Fastback

Family car

Full-size car

Grand tourer

Hardtop

Hatchback

Hot hatch

Hot rod

Kei car

Large family car

Leisure activity vehicle

Lead sled

Liftback

Limousine

Luxury vehicle

Microcar

Mid-size car

Mini MPV

Mini SUV

Minivan

Muscle car

Pony car

Notchback

Panel van

Personal luxury car

Pickup truck

Quad coup

Retractable hardtop

Roadster

Saloon

Sedan

Sport compact

Sport utility vehicle

Sports car

Station wagon

Street rod

Supercar

Supermini

Targa top

Taxicab

Touring car

Town car

T-top

Tow truck

Ute

Van

Voiturette

Specialized vehicles

Amphibious vehicle

Driverless car (autonomous car)

Flying car

Gyrocar

Propulsion

Internal combustion engine

Electric vehicle

Battery electric vehicle

Neighborhood Electric Vehicle

Hybrid vehicle (plug-in)

Hydrogen vehicle

Fuel cell

Steam car

Alternative fuel vehicle

Autogas

Biodiesel

Common ethanol fuel mixtures (E85)

Gasoline direct injection

Homogeneous charge compression ignition

Liquid nitrogen

Drive wheels

Front-wheel drive

Rear-wheel drive

Two-wheel drive

Four-wheel drive

Six-wheel drive

Eight-wheel drive

Engine positioning

Front-engine

Rear-engine

Mid-engine

Layout

Front-engine, front-wheel-drive

Rear-engine, front-wheel-drive

Front-engine, rear-wheel-drive

Rear mid-engine, rear-wheel-drive

Mid-engine, front-wheel-drive

Rear-engine, rear-wheel-drive

Front-engine, four-wheel-drive

Rear-engine, four-wheel-drive

Mid-engine, four-wheel-drive

Engine configuration

(internal combustion

engines only)

Boxer engine

Flat engine

Flathead engine

Four-stroke engine

H engine

Inline engine

Pushrod engine

Reciprocating engine

Single-cylinder engine

Straight engine

Straight-six engine

Two-stroke engine

V engine

W engine

Wankel engine

Engine fuel type

Diesel

Electric

Gasoline (petrol)

Hybrid

Hydrogen

Steam

Portal

Category

Categories:

Engine technology

Engines

Hyper engine

From Wikipedia, the free encyclopedia

Liberty L-12 engine

Liberty L-12 engine, from which Hyper Engine No.1 was derived

Type One cylinder converted into "Hyper Engine No.

1"

National origin United States

Manufacturer Continental Motors

Designed by Sam Heron

First run 1932

Major applications Experimental Engine

Number built 1

The hyper engine was a 1930s study project by the United States Army Air Corps (USAAC) to

develop a high-performance aircraft engine that would be equal to or better than the aircraft and

engines then under development in Europe. The project goal was to produce an engine that was

capable of delivering 1 hp/in

3

(46 kW/L) of engine displacement for a weight of less than 1 lb/hp

delivered. The ultimate design goal was an increased power-to-weight ratio suitable for long-

range airliners and bombers.

At the time, no production engine could come close to the requirements, although this milestone

had been met by special modified or purpose-built racing engines such as the Napier

Lion and Rolls-Royce R. A typical large engine of the era, thePratt & Whitney R-1830 Twin

Wasp radial developed about 1,200 hp (895 kW) from 1,830 in

3

(30 L) so an advance of at least

50% would be needed. Simply scaling up an existing design would not solve the problem. While

it would have increased the total available power, it would not have any significant effect on the

power-to-weight ratio; for that, more radical changes were needed.

[1]

Several engines were built as part of the hyper program, but for a variety of reasons none of

these saw production use. Air-cooled engines from a variety of US companies were delivering

similar power ratings by the early 1940s, and the licensed production of the Rolls-Royce

Merlin as the Packard V-1650 provided hyper-like performance from an inline while the Allison V-

1710 did the same from a US design, one produced as a private effort outside the hyper

program.

Contents

[hide]

1 Design and development

o 1.1 Hyper No.1

o 1.2 Hyper No.2

o 1.3 Continental O/V/IV/XIV-1430

2 Request for data R40-C

o 2.1 FY 1940

o 2.2 FY 1941

3 Program end

4 See also

5 References

o 5.1 Notes

o 5.2 Bibliography

o 5.3 Further reading

Design and development[edit]

Improvements in construction and lighter materials had already delivered some benefits on the

way to higher power-to-weight ratios. Aluminum was being introduced in place of steel as the

quality and strength of aluminum alloys improved during the 1930s; this lowered engine weight

noticeably, but not enough to achieve a 50% overall improvement. To reach that goal, the power

of the engine would also need to be increased. Power is a combination of energy and the rate it

is delivered, so to improve the power-to-weight ratio, one would need to increase the operating

pressures of the engine, the operating speed, or a combination of both. Further gains could be

made by eliminating losses like friction, combustion inefficiencies and scavenging losses,

delivering more of the theoretical power to the propeller.

[2]

The USAAC engineers determined that it would study all three improvements. Before long, they

concluded that increasing the combustion temperature and scavenging efficiency promised the

greatest increases of all of the possibilities. To meet that goal, increasing engine speed seemed

to be the most attractive solution. However, there were a number of practical problems that were

impeding progress in these areas.

Increasing the compression ratio is an easy change that improves the mean effective

pressure (MEP), but leads to engine knocking from inconsistent detonation. Uncontrolled, knock

can damage the engine and was a major block on the way to improved power settings. This

change would also increase the operating temperatures, which presented a problem with the

valves. Valves were already reaching temperatures that would cause pre-ignition of the fuel as it

flowed past them.

Increasing operational speed is also, theoretically, a simple change to the engine design.

However, at high operating speeds the valves do not completely close before the cam opens

them again, a problem called "valve float". Valve float allows gases in the cylinder to escape

through the partially open valve, reducing the engine efficiency. Increasing valve spring pressure

to close the valves faster led to rapid cam wear and increased friction, reducing overall

performance by more than any horsepower gained.

[3]

As valves were a key issue in both approaches to improved performance, they had been a major

area of research in the 1920s and 30s. In the UK, Harry Ricardo had written an influential paper

on the sleeve valve system for exactly these reasons, claiming it was the only way forward. He

had some success in selling this idea, most notably to Bristol Aeroplane Company Engines,

where Roy Fedden became "a believer". Ricardo's friendly competitor, Frank Halford, designed

his own sleeve valve engine with Napier & Son, another prominent British engine maker.

[4]

The USAAC was not so convinced that the sleeve valve was the only solution. Ironically it was

one of Ricardo's papers on the sleeve valve design that led to the USAAC's hyper engine efforts.

In one late 1920s paper he claimed that the 1 hp/in goal was impossible to achieve with poppet

valve type engines. The USAAC engineering team at Wright Field decided to test this claim by

beating it. They proposed an engine of about 1200 cubic inches (20 L), hoping the engine's

smaller size would lead to reduced drag and hence improved range.

Hyper No.1[edit]

Sam Heron, head of development at Wright Field and a former colleague of Ricardo while Heron

had been working at the Royal Aircraft Factory, Farnborough, started working on the problem

with a single-cylinder test engine that he converted to liquid cooling, using a Liberty L-12 engine

cylinder. He pushed the power to 480 psi Brake Mean Effective Pressure, and the coolant

temperature to 300 F (149 C) before reaching the magic numbers. By 1932, the USAAC's

encouraging efforts led the Army to sign a development contract with Continental Motors

Company for the continued development of the engine design. The contract limited Continental's

role to construction and testing, leaving the actual engineering development to the Army.

[5]

Starting with the L-12-cylinder, they decreased the stroke from 7 in to 5 in in order to allow higher

engine speeds, and then decreased the bore from 5 in to 4.62 in, creating the 84 in cylinder.

This would be used in a V-12 engine of 1008 in displacement.

[6]

They used the L-12's overhead

camshaft to operate multiple valves of smaller size, which would improve charging

and scavenging efficiency. Continental's first test engine, the single-cylinder Hyper No.1, first ran

in 1933.

They eventually determined that exhaust valves could run cooler when a hollow core filled

with sodium is used - the sodium liquefies and considerably increases the heat transfer from the

valve's head to its stem and then to the relatively cooler cylinder head where the liquid coolant

picks it up.

[6]

Liquid cooling systems at that time used plain water, which limited operating temperatures to

about 180 F (82 C). The engineers proposed using ethylene glycol, which would allow

temperatures up to 280 F. At first they proposed using 100% glycol, but there was little

improvement due to the lower specific heat of the glycol (about 2/3 that of water). They

eventually determined that a 50/50 mixture (by volume) of water and glycol provided optimal heat

removal.

[6]

Hyper No.2[edit]

A second cylinder was added to Hyper No. 1 to make a horizontal opposed engine for evaluation

of an opposed-piston 12-cylinder engine. After running the modified engine with different

combinations of cylinder bore and stroke, it was found that the high coolant temperatures

required to maintain the required output was impractical. A third high-performance single-cylinder

engine was then constructed with lower operating parameters. This engine was designated

"Hyper No. 2", and became the test bed for developing the cylinders that would become the O-

1430-1.

[6]

Continental O/V/IV/XIV-1430[edit]

Main article: Continental I-1430

IV-1430-9 in the National Museum of the United States Air Force

The Army apparently became concerned about the development of a suitable supercharger for

high-altitude use, and for further development in 1934 they asked for a newer cylinder with

slightly less performance and an increased volume of 118.8 in

3

from its 5.5 in (140 mm) bore and

5.0 in (130 mm) stroke. This size cylinder would then be used in a 1,425 in

3

12-cylinder engine,

delivering the same 1,000 hp, with a performance of 0.7 hp/in

3

. This placed its performance on a

par with newer experimental engines from Europe like theRolls-Royce PV-12, at least when

running on the higher-octane fuels the Army planned to use.

[7]

Another change was to the engine layout. The Army, convinced that future aircraft designs would

use engines buried in the wings for additional streamlining, asked Continental to design a full-

sized flat-opposed-piston engine for installation inside a wing. The resulting engine was the

Continental O-1430, which would require a ten year development period which changed the

layout to first an upright V-12 engine and later, an inverted V-12 engine before becoming reliable

enough to consider for full production as the Continental IV-1430 in 1943. By then other engines

had already passed its 1,600 hp (1,200 kW) rating, and although the IV-1430 had a better power-

to-weight ratio, there was little else to suggest setting up production in the middle of the war was

worthwhile.

[7]

The project was eventually guided by the requirements in the "Request for data R40-C", which

was included as a part of the Financial Year 1940 aircraft procurement program.

Request for data R40-C[edit]

As 1938 came to an end, the war in Europe heated to its boiling point. At this point, European

aircraft had greatly surpassed US designs.

[8]

The two top USAAC fighters, theSeversky P-35 and

the Curtiss P-36A, were just able to hit 300 mph (480 km/h). Against the 340+

mph Messerschmitt Bf 109 they would be completely outclassed. The twin-engined Lockheed

XP-38 was entering an extended test program.

Although the XP-38 was able to fly at speeds in excess of 413 mph, it was big and heavy, and

was therefore not as maneuverable as its stablemates.

[9]

The XP-38 also had a newly introduced

liquid-cooled engine, the Allison V-1710. The Allison's in-line vee cylinder arrangement allowed

for a narrow aerodynamic shape that had much less drag than the air-cooled radial engine

fighters that predominated America at the time.

[10]

The fighter aircraft procurement program for FY 1940 was contained in a document that was

approved by Assistant Secretary of War Louis K. Johnson on 9 June 1939. That document was

the "Request for Data R40-C", and unlike previous aircraft procurement requests, it was sent to

only a limited number of aircraft manufacturers. The original document was to be sent to:

[11]

Bell Aircraft Corporation

Consolidated Aircraft Corporation

Curtiss-Wright Corporation Curtiss Airplane Division

Curtiss-Wright Corporation, St. Louis Airplane Division

Grumman Aircraft Engineering Corporation

Lockheed Aircraft Corporation

Republic Aviation Corporation

Vought-Sikorsky Aircraft Division, United Aircraft Corporation

Vultee Aircraft Division, Aviation Manufacturing Corporation

After final review and approval as Air Corps Type Specification XC-622, a further four

manufacturers were added to the distribution:

Hughes Aircraft Corporation

McDonnell Aircraft Company

Boeing Aircraft Company

Northrop Aircraft, Incorporated

These companies had only ten days to agree to the terms of the document, and only 30 days to

submit their designs.

FY 1940[edit]

A total of 26 designs, with a mix of 16 engine models from six engine companies, were submitted

by seven of the selected companies. These engines became known as the "Hyper Engines", a

contraction of High-performance engines. The submitted designs were graded using a "Figure of

merit" (FOM) rating system, and then, using the FOM results (which ranged from 444.12 for the

Allison V-1710-E8 to 817.90 for the Pratt and Whitney X-1800-A4G), they were separated into

one of three groups.

Those placed in the first group were little more than modifications to existing designs. They

were not considered to be sufficiently advanced.

Those placed in the third group proposed using an engine that was unlikely to be developed

into flying condition by the time the airframe was ready to fly. They were not considered to be

viable in the time frame allowed.

The remaining ten designs were placed in the second group: those that were an

advancement in aeronautical engineering, with an engine that would be ready to fly, when

needed.

Only three of these ten designs were approved, and contracts were made for a limited prototype

run of three aircraft for each.

[12]

The three aircraft/engine combinations that were selected:

[13]

1. Vultee Aircraft's Model 70 Alternate 2, (FOM score: 817.9), which became the Vultee XP-

54, powered by the Pratt & Whitney X-1800-A4G engine

2. Curtiss-Wright St Louis' Model P248C, (FOM score: 770.6), which became the Curtiss-

Wright XP-55 Ascender, powered by the Continental IV-1430-3 engine

3. Northrop's Model N2-B (FOM score: 725.8), which became the Northrop XP-56 Black

Bullet, powered by the Pratt & Whitney X-1800-A3G engine

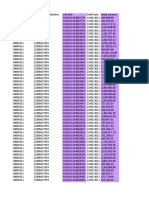

The high-performance engines of FY 1940

[13]

Engine Model Configuration Displacement Horsepower

Specific

horsepower

Weight

Power to

weight ratio

Continental IV-1430-3 inverted V-12 1,430 in 1,600 hp at 3,200 rpm 1.12 hp/in 1,615 lb .99 hp/lb

Pratt & Whitney X-1800-A3G 24 cylinder H-block 2,600 in 2,200 hp .85 hp/in 3,250 lb .68 hp/lb

Pratt & Whitney X-1800-A4G 24-cylinder H-block 2,600 in 2,200 hp .85 hp/in 3,250 lb .68 hp/lb

FY 1941[edit]

Three additional high-performance engines were considered for the USAAC's FY 1942 "Hyper"

engine procurement program. They were:

[13]

Wright R-2160 "Tornado"

Pratt & Whitney H-3130

Allison V-3420

Not to be left out, the US Navy selected the Lycoming XH-2470 for funding in FY 1942 as well.

[13]

The high-performance engines of FY 1941

[13]

Engine Model Configuration Displacement Horsepower

Specific

horsepower

Weight

Power to

weight

ratio

Allison V-3420 24-cylinder W engine 3,421.2 in 2,100 hp .61 hp/in

2,600 lb

(1,200 kg)

.81 hp/lb

Lycoming XH-2470

24-cylinder horizontal

opposed

2,470 in 2,300 hp .93 hp/in

2,430 lb

(1,100 kg)

.96 hp/lb

Pratt & Whitney XH-

3130

24-cylinder H-block 3,130 in 2,650 hp .84 hp/in

3,250 lb

(1,470 kg)

.82 hp/lb

Wright R-2160 42-cylinder 6-row 2,160 in 2,350 hp 1.09 hp/in

2,400 lb

.98 hp/lb

(1,100 kg)

Program end[edit]

In the end, all of these programs were canceled, and the surviving engines became museum

pieces. One survivor, a Continental IV-1430, is privately owned, and is displayed publicly from

time to time.

Ironically, engines that were not considered under the program; the Allison V-1710, Pratt &

Whitney R-2800 Double Wasp, Wright R-3350 Duplex-Cyclone and Pratt & Whitney R-4360

Wasp Major, all surpassed the USAAC requirements, and continue flying into the 21st century,

primarily flying restored warbird aircraft.

See also[edit]

Bomber B, the German Luftwaffe's advanced medium bomber program that used similar

high-output aviation powerplants.

References[edit]

Notes[edit]

1. Jump up^ White p 211

2. Jump up^ Biermann pp 16, 17

3. Jump up^ Taylor p 64

4. Jump up^ Bingham pg 49

5. Jump up^ White p 375

6. ^ Jump up to:

a

b

c

d

Balzer p.28

7. ^ Jump up to:

a

b

White p 376

8. Jump up^ Balzer p 7

9. Jump up^ Balzer pp 9, 10

10. Jump up^ Schlaifer p 253

11. Jump up^ Balzer p 13

12. Jump up^ Balzer p 15

13. ^ Jump up to:

a

b

c

d

e

Balzer p.24

Bibliography[edit]

Balzer, Gerald H. (2008). American Secret Pusher Fighters of World War II. Specialty Press. ISBN 978-1-58007-125-3.

Biermann, Arnold E, Corrington, Lester C. and Harries, Myron L. (1942). Effects of Additions of Aromatics on Knocking Characteristics of

Several 100-octane Fuels at Two Engine Speeds. Cleveland, Ohio, May,: Aircraft Engine Research Laboratory.

Bingham, Victor. Major Piston Aero Engines of World War II. Airlife Publishing. ISBN 1-84037-012-2.

Schlaifer, Robert and Herron S.D. Development of Aircraft Engines and Development of Aviation Fuels. Harvard University.

Taylor, C. Fayette (1971). Aircraft Propulsion, Smithsonian Press, GPO.

White, Graham (1995). Allied Piston Engines of World War II. SAE International. ISBN 1-56091-855-9 Check |isbn= value (help).

S-ar putea să vă placă și

- Mechanical Radial EngineDocument11 paginiMechanical Radial EngineAnindam DebÎncă nu există evaluări

- Piston Engine FundamentalDocument62 paginiPiston Engine Fundamentalkp subedi100% (1)

- 100 Years Aircraft EngineDocument11 pagini100 Years Aircraft Enginemkhairuladha100% (1)

- Jet EngineDocument14 paginiJet EngineعبداللهأحمدÎncă nu există evaluări

- Jet Engine Lubrication SystemDocument23 paginiJet Engine Lubrication SystemJimmy Haddad100% (1)

- Sub Scale Flight TestingDocument10 paginiSub Scale Flight TestingRajeuv GovindanÎncă nu există evaluări

- 480B EC120 ComparisonDocument6 pagini480B EC120 ComparisonJuan Carlos Letona100% (1)

- Piston Engines, GasTurbine Engines, Propellers PDFDocument141 paginiPiston Engines, GasTurbine Engines, Propellers PDFAakash SawaimoonÎncă nu există evaluări

- A 373340Document8 paginiA 373340Christian ZevahcÎncă nu există evaluări

- Turbofan Engine FullDocument29 paginiTurbofan Engine FullPramodPradhanÎncă nu există evaluări

- Development of HelicoptersDocument20 paginiDevelopment of HelicoptersLove KushwahÎncă nu există evaluări

- Lycoming TG ST SteDocument115 paginiLycoming TG ST StehankthedogÎncă nu există evaluări

- Turbo Jet EngineDocument15 paginiTurbo Jet EngineMuhammad Bin RiazÎncă nu există evaluări

- Rolls Royce MerlinDocument6 paginiRolls Royce Merlinkty2924Încă nu există evaluări

- 021 06-00-00 Pneumatic - Pressurisation and Air Cond Amend0Document29 pagini021 06-00-00 Pneumatic - Pressurisation and Air Cond Amend0kashimotocomotuyaÎncă nu există evaluări

- Engine Design ClassificationDocument76 paginiEngine Design ClassificationLuis NunesÎncă nu există evaluări

- Arnold-Inverse Pressure Gradient MatchingDocument7 paginiArnold-Inverse Pressure Gradient MatchingredxusÎncă nu există evaluări

- FLYER EurofoxDocument6 paginiFLYER EurofoxMashrekin HossainÎncă nu există evaluări

- 4) AC 65-15 Airframe HandbookDocument620 pagini4) AC 65-15 Airframe HandbookWarren Dhez FortunatoÎncă nu există evaluări

- Seddon Basic Helicopter AerodynamicsDocument79 paginiSeddon Basic Helicopter AerodynamicsKamal Kumar GuptaÎncă nu există evaluări

- Jet PropulsionDocument40 paginiJet PropulsionDileep Kumar Manjhi100% (1)

- 4 Controles de VueloDocument42 pagini4 Controles de Vuelojulian duqueÎncă nu există evaluări

- Mantenaice Manual RotaxDocument184 paginiMantenaice Manual RotaxAndresLopezMllan100% (1)

- FlapsDocument22 paginiFlapsDexterydÎncă nu există evaluări

- RC Amphibious Aircraft Report - Construction, Calculation & Project ManagementDocument107 paginiRC Amphibious Aircraft Report - Construction, Calculation & Project ManagementKazi Faisal100% (1)

- Aircraft Recognition PowerPoint PDFDocument11 paginiAircraft Recognition PowerPoint PDFNick TsangÎncă nu există evaluări

- Auxiliary Power UnitDocument1 paginăAuxiliary Power UnitGoswamirishabhÎncă nu există evaluări

- Quick Build MIG-29 Instruction ManualDocument9 paginiQuick Build MIG-29 Instruction Manual6mmflyrc100% (1)

- Development of The R-2800 CrankshaftDocument34 paginiDevelopment of The R-2800 Crankshaftmrcdexterward100% (2)

- Anatomy of A STOL AircraftDocument11 paginiAnatomy of A STOL AircraftAEROWORKERÎncă nu există evaluări

- Airfoil: American English British English Wing Propeller Screw Sail Fluid Lift Downforce CamberDocument27 paginiAirfoil: American English British English Wing Propeller Screw Sail Fluid Lift Downforce Cambermanoj chauhanÎncă nu există evaluări

- The Little Engine That CouldnDocument8 paginiThe Little Engine That CouldnMorgen Gump100% (1)

- 1.-Cap Aeronave GeneralDocument53 pagini1.-Cap Aeronave GeneralArturo Zugarazo ZaragozaÎncă nu există evaluări

- Mm-Io-360-N1a - 3-31-2016Document207 paginiMm-Io-360-N1a - 3-31-2016Shirley CruzÎncă nu există evaluări

- A Wood Propeller For Your HomebuiltDocument3 paginiA Wood Propeller For Your HomebuiltRicardo VilhenaÎncă nu există evaluări

- P08 Curtiss ElectricDocument10 paginiP08 Curtiss Electricvinnman87100% (1)

- LycomingDocument56 paginiLycomingQuality DepartmentÎncă nu există evaluări

- Falco F8LDocument13 paginiFalco F8LPredrag PavlovićÎncă nu există evaluări

- Too Small of A PlaneDocument22 paginiToo Small of A PlaneFridayFunStuffÎncă nu există evaluări

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 paginiGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENÎncă nu există evaluări

- AS350 B3 UtilityDocument4 paginiAS350 B3 Utilitygarcheti100% (1)

- Piaggio P180 M Avanti PapermodelDocument14 paginiPiaggio P180 M Avanti PapermodelJosé Antonio NevesÎncă nu există evaluări

- GE 109: Introduction To Engineering Product: Week 1Document22 paginiGE 109: Introduction To Engineering Product: Week 1Hemant MeenaÎncă nu există evaluări

- How Do Airplanes FlyDocument4 paginiHow Do Airplanes FlyPradeep DevatagalÎncă nu există evaluări

- Rolls Royce GriffonDocument13 paginiRolls Royce GriffonDaniel Armstrong100% (1)

- Rolls Royce Merlin 61 EngineDocument5 paginiRolls Royce Merlin 61 EngineIvan Kopić100% (2)

- V12 Engine by SreejithDocument16 paginiV12 Engine by SreejithSreejith BabuÎncă nu există evaluări

- Collected Articles From Flight Training News 2006-2011De la EverandCollected Articles From Flight Training News 2006-2011Încă nu există evaluări

- Jet - The story of jet propulsion: The inventors The aircraft The companiesDe la EverandJet - The story of jet propulsion: The inventors The aircraft The companiesÎncă nu există evaluări

- Wing Theory in Supersonic Flow: International Series of Monographs in Aeronautics and AstronauticsDe la EverandWing Theory in Supersonic Flow: International Series of Monographs in Aeronautics and AstronauticsÎncă nu există evaluări

- Aircraft Engine - Wikipedia, The Free EncyclopediaDocument11 paginiAircraft Engine - Wikipedia, The Free EncyclopediaReetGillÎncă nu există evaluări

- Aircraft Engine - WikipediaDocument67 paginiAircraft Engine - WikipediaLAliÎncă nu există evaluări

- Kurva Tegangan Regangan Kawat Gitar Akustik: Strees (KG/MM )Document8 paginiKurva Tegangan Regangan Kawat Gitar Akustik: Strees (KG/MM )Damy ManesiÎncă nu există evaluări

- Hotel Registration FormDocument4 paginiHotel Registration FormDamy Manesi50% (2)

- Oi Mate C Maintenance ManualDocument774 paginiOi Mate C Maintenance ManualDamy ManesiÎncă nu există evaluări

- Airport FacilitiesDocument15 paginiAirport FacilitiesDamy Manesi100% (3)

- From This MomentDocument1 paginăFrom This MomentDamy ManesiÎncă nu există evaluări

- Test ReportDocument11 paginiTest ReportDamy ManesiÎncă nu există evaluări

- Set Up Dialog MillingDocument19 paginiSet Up Dialog MillingDamy ManesiÎncă nu există evaluări

- TopCAM CAD IntroductionDocument14 paginiTopCAM CAD IntroductionDamy ManesiÎncă nu există evaluări

- Astm A1007Document3 paginiAstm A1007Damy ManesiÎncă nu există evaluări

- International Journal ReviewDocument6 paginiInternational Journal ReviewDamy ManesiÎncă nu există evaluări

- Advance Thermodynamics 1Document16 paginiAdvance Thermodynamics 1T975Încă nu există evaluări

- A Space Tribology Handbook: ESTL, AEA Technology, Warrington, UKDocument5 paginiA Space Tribology Handbook: ESTL, AEA Technology, Warrington, UKDamy ManesiÎncă nu există evaluări

- Step 1 Engine Electrical Bhs Indo)Document105 paginiStep 1 Engine Electrical Bhs Indo)rrhakim100% (6)

- Matlab Programming Strategy For Vle With EosDocument7 paginiMatlab Programming Strategy For Vle With Eosmatheus735Încă nu există evaluări

- Strategy For Solving Vle Problems With PR - EosDocument13 paginiStrategy For Solving Vle Problems With PR - EosDamy ManesiÎncă nu există evaluări

- Teknik P & G - 1 - GhurriDocument42 paginiTeknik P & G - 1 - GhurriDamy ManesiÎncă nu există evaluări

- Advance Thermodynamics 1Document16 paginiAdvance Thermodynamics 1T975Încă nu există evaluări

- AdvanceThermodynamics Materi 6Document28 paginiAdvanceThermodynamics Materi 6Damy ManesiÎncă nu există evaluări

- Advance Thermodynamics 1Document16 paginiAdvance Thermodynamics 1T975Încă nu există evaluări

- Love EeeeDocument580 paginiLove EeeeDamy ManesiÎncă nu există evaluări

- Graduate Courses Faq (English-Korean)Document10 paginiGraduate Courses Faq (English-Korean)Damy ManesiÎncă nu există evaluări

- Frekuensi: Senar Notasi Saintis Notasi UmumDocument2 paginiFrekuensi: Senar Notasi Saintis Notasi UmumDamy ManesiÎncă nu există evaluări

- Two Tank Study MaterialDocument28 paginiTwo Tank Study MaterialLi XueÎncă nu există evaluări

- Aircraft EngineDocument37 paginiAircraft EngineDamy Manesi100% (1)

- Keseimbangan PartikelDocument11 paginiKeseimbangan PartikelDamy ManesiÎncă nu există evaluări

- Momen Dan KopelDocument14 paginiMomen Dan KopelDamy ManesiÎncă nu există evaluări

- Boiler CalculationsDocument16 paginiBoiler CalculationsBilly Moerdani100% (1)

- Management and Energy OptimizationDocument13 paginiManagement and Energy OptimizationDamy ManesiÎncă nu există evaluări

- Steam TablesDocument16 paginiSteam TablesSantosh KumarÎncă nu există evaluări

- PERKINS Industrial Engine 4016-61 TRG Operation and Maintenance ManualDocument82 paginiPERKINS Industrial Engine 4016-61 TRG Operation and Maintenance Manualahmedalgalo0% (1)

- 7FH2 Gen Fund ConstructionDocument30 pagini7FH2 Gen Fund ConstructionRamon de Oliveira100% (2)

- Equipment RentalsDocument1 paginăEquipment RentalsShielagil CailoÎncă nu există evaluări

- Matehan Catalog 06 PDFDocument92 paginiMatehan Catalog 06 PDFNAMRAJ SHARMAÎncă nu există evaluări

- MODULE 17 All QuestionDocument75 paginiMODULE 17 All QuestionSatyam100% (1)

- Compressors: Select Criterion For ServiceDocument34 paginiCompressors: Select Criterion For ServiceZoran TrajkovicÎncă nu există evaluări

- RR Avon 1534 2Document3 paginiRR Avon 1534 2frdn100% (1)

- DAF Truck en b4511Document119 paginiDAF Truck en b4511Ashraf MostafaÎncă nu există evaluări

- Engineering Aspects of Turbomolecular Pump DesignDocument5 paginiEngineering Aspects of Turbomolecular Pump DesignvirgilioÎncă nu există evaluări

- India Import Data of PressureDocument8 paginiIndia Import Data of PressureCamila PenhaÎncă nu există evaluări

- Integrated Chassis ManagementDocument1 paginăIntegrated Chassis ManagementOliver AlfaroÎncă nu există evaluări

- PipefitterDocument4 paginiPipefitterapi-78684586Încă nu există evaluări

- International - DT570 (2004-06) - 000Document9 paginiInternational - DT570 (2004-06) - 000Harlinton descalziÎncă nu există evaluări

- Land Rover V8: and ToolDocument56 paginiLand Rover V8: and ToolAntonio OliveiraÎncă nu există evaluări

- A319/A320/A321 Technical Training Manual General Familiarization Course 29 Hydraulic PowerDocument38 paginiA319/A320/A321 Technical Training Manual General Familiarization Course 29 Hydraulic PowerAnas AbandehÎncă nu există evaluări

- 067 735 Cylinder 1st Compression StageDocument8 pagini067 735 Cylinder 1st Compression StageNitesh MakwanaÎncă nu există evaluări

- Assembly Instructions: Limit Switches DKUN 1Document24 paginiAssembly Instructions: Limit Switches DKUN 1Bang OchimÎncă nu există evaluări

- DOOSAN 460 SKID STEER LOADER Service Repair Manual PDFDocument35 paginiDOOSAN 460 SKID STEER LOADER Service Repair Manual PDFdfjjskemmdm100% (1)

- Leave It To The Experts Who Built Your Engine!Document4 paginiLeave It To The Experts Who Built Your Engine!guichen wangÎncă nu există evaluări

- Gas Turbine CoolingDocument13 paginiGas Turbine CoolingHimanshu DahireÎncă nu există evaluări

- RSP CodeDocument18 paginiRSP CodeHolly LarsonÎncă nu există evaluări

- Chapter 8B - Gas Power Plant Brayton CycleDocument17 paginiChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Man Turbo THM Gas TurbineDocument51 paginiMan Turbo THM Gas Turbineaiabbasi9615100% (1)