Documente Academic

Documente Profesional

Documente Cultură

Et Set 4 Update 14 Screen

Încărcat de

Faizan MotiwalaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Et Set 4 Update 14 Screen

Încărcat de

Faizan MotiwalaDrepturi de autor:

Formate disponibile

an efficiency milestone

Based on the proven design concepts of types 3 and 6, the modern type 4 engines in the 800 to 1,500 kW power range are characterized by a high power

density and outstanding efficiency. The optimized control and monitoring provides easy preventive maintenance and maximum reliability and availability.

J416

Richard van Schie,

Greenhouses Facility;

Monster, The

Netherlands

J420

Landfill site

Bootham Lane;

Doncaster, UK

J420

Hospital;

Padua, Italy

J420

Containerized

solution

Biogas plant SBR;

Kogel, Germany

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Natural gas

Engine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x J416

Electrical output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,260 kW

Thermal output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,806 kW

Commissioning . . . September 2004 (1

st

engine),

July 2007 (2

nd

engine)

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Landfill gas

Engine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x J420

Electrical output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,666 kW

Commissioning. . . . . . . . . . . . May 2001 (1

st

engine),

December 2002 (2

nd

engine)

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Natural gas

Engine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x J420

Electrical output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,832 kW

Thermal output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,576 kW

Commissioning. . . . .February 2002 (1

st

engine),

October 2003 (2

nd

engine)

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Biogas

Engine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 x J420

Electrical output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,413 kW

Thermal output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 751 kW

Steam production. . . . . . . . . . . . 1,037 kg/h at 3 bar

or 698 kW output

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . October 2003

At this greenhouse facility, the Jenbacher cogen-

eration system provides power for artificial lighting,

heating and CO

2

to increase the chrysanthemum

production capabilities. The CO

2

produced from the

engines exhaust gas is used for the fertilization

of the greenhouses, whereas the operator gains

additional economic benefit due to the supply of

the generated electricity to the local grid.

At this site, the methane content of the landfill gas

can drop as low as 35%. The fluctuations in the

methane content can be handled easily by the

Jenbacher engines due to the patented LEANOX*

lean mixture combustion system. Thus these vari-

ations do not cause any reduction in the high out-

put level of our power systems. The installation is

operated by United Utilities Green Energy Limited.

Two Jenbacher cogeneration systems help the

Padua hospital to control its energy costs by

providing power and heat at high efficiency levels.

The electrical efficiency of each engine is 42.3%.

This biogas plant utilizes leftover food from hospitals,

hotels and canteens as well as organic residual

waste from the food industry for producing biogas

that fuels our gas engine. The electricity generated

is entirely fed into the public grid, and the exhaust

gas from the engine is used for steam production.

The steam serves for the pasteurization of the

waste, which can then be used as sterilized fertilizer.

reference installations

model, plant key technical data description

Jenbacher

type 4

The new 4B version

*Trademark of General Electric Company

GE Power & Water

Distributed Power

2

0

1

4

G

E

J

e

n

b

a

c

h

e

r

G

m

b

H

&

C

o

O

G

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

G

E

A

-

1

3

6

9

1

A

technical data

Dimensions l x w x h (mm)

Generator set J412 5,400 x 1,800 x 2,200

J416 6,200 x 1,800 x 2,200

J420 7,100 x 1,900 x 2,200

Cogeneration system J412 6,000 x 1,800 x 2,200

J416 6,700 x 1,800 x 2,200

J420 7,100 x 1,800 x 2,200

Container J412 12,200 x 3,000 x 2,600

J416 12,200 x 3,000 x 2,600

J420 12,200 x 3,000 x 2,600

Weights empty (kg)

J412 J416 J420

Generator set 10,900 12,500 14,400

Cogeneration system 11,500 13,100 15,000

Container (generator set) 28,200 30,300 35,600

Container (cogeneration) 28,800 30,900 35,000

Configuration V 70

Bore (mm) 145

Stroke (mm) 185

Displacement/cylinder (lit) 3.06

Speed (rpm) 1,800 / 1,200 (60 Hz)

1,500 (50 Hz)

Mean piston speed (m/s) 7.4 (1,200 rpm)

9.3 (1,500 rpm)

Scope of supply Generator set, cogeneration system,

generator set/cogeneration in container

Applicable gas types Natural gas, flare gas, biogas, landfill gas,

sewage gas. Special gases (e.g., coal mine

gas, coke gas, wood gas, pyrolysis gas)

Engine type J412 J416 J420

No. of cylinders 12 16 20

Total displacement (lit) 36.7 48.9 61.1

1) Technical data according to ISO 3046

2) Total heat output with a tolerance of +/- 8%, exhaust gas outlet temperature 120C, for biogas exhaust gas outlet temperature 180C

All data according to full load and subject to technical development and modification.

Further engines versions available on request.

technical features

feature description advantages

Heat recovery

Gas dosing valve

Four-valve

cylinder head

Crack connecting rod

Flexible arrangement of heat exchanger, two stage oil plate heat exchanger

on demand

Electronically controlled gas dosing valve with high degree of control

accuracy

Optimized swirl and channel geometry using advanced calculation and

simulation methods (CFD)

Applying a technology tried and tested in the automotive industry in our

powerful stationary engines

- Maximum thermal efficiency, even at high and

fluctuating return temperatures

- Very quick response time

- Rapid adjustment of air/gas ratio

- Large adjustable calorific value range

- Minimized charge-exchange losses

- Central spark-plug position resulting in optimal

cooling and combustion conditions

- High dimensional stability and accuracy

- Reduced connecting rod bearing wear

- Easy to maintain

outputs and efficiencies

Natural gas 1,500 rpm | 50 Hz 1,800 rpm | 60 Hz 1,200 rpm | 60 Hz

NOx < Type Pel (kW)

1

el (%)

1

Pth (kW)

2

th (%)

2

tot (%) Pel (kW)

1

el (%)

1

Pth (kW)

2

th (%)

2

tot (%) Pel (kW)

1

el (%)

1

Pth (kW)

2

th (%)

2

tot (%)

412 889 42.8 918 44.2 87.1 850 41.1 973 47.1 88.2 634 43.0 618 41.9 84.9

500 mg/m

3

N

416 1,189 43.0 1,223 44.2 87.1 1,137 41.3 1.298 47.1 88.4 850 43.3 824 41.9 85.2

420 1,487 43.0 1,528 44.2 87.1 1,426 41.4 1.623 47.1 88.6 1,063 43.3 1,028 41.8 85.1

412 889 42.1 944 44.7 86.9 850 40.0 1.008 47.4 87.4 634 42.1 640 42.5 84.5

250 mg/m

3

N

416 1,189 42.3 1,259 44.7 87.0 1,137 40.1 1.343 47.4 87.5 850 42.3 856 42.6 84.9

420 1,487 42.3 1,573 44.7 87.0 1,426 40.3 1.680 47.4 87.7 1,063 42.3 1,084 43.2 85.5

412 889 42.1 932 44.2 86.3

350 mg/m

3

N

416 1,189 42.3 1,242 44.1 86.4

420 1,486 42.3 1,553 44.1 86.5

Biogas 1,500 rpm | 50 Hz 1,800 rpm | 60 Hz

NOx < Type Pel (kW)

1

el (%)

1

Pth (kW)

2

th (%)

2

tot (%) Pel (kW)

1

el (%)

1

Pth (kW)

2

th (%)

2

tot (%)

412 889 42.0 905 42.8 84.8 850 40.0 944 44.4 84.5

416 1,189 42.1 1,207 42.8 84.9 1,137 40.2 1,259 44.5 84.7

420 1,487 42.2 1,487 42.2 83.2 1,426 40.3 1,572 44.4 84.7

412 889 41.6 918 43.0 84.6 850 39.2 975 44.9 84.1

250 mg/m

3

N

416 1,189 41.7 1,189 42.9 84.7 1,137 39.3 1,302 45.0 84.2

420 1,487 41.8 1,487 41.1 82.9 1,426 39.4 1,627 45.0 84.4

500 mg/m

3

N

GE Power & Water Jenbacher gas engines Austria (main production facility) 6200 Jenbach T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.ge-distributedpower.com

S-ar putea să vă placă și

- Sample Cross-Complaint For Indemnity For CaliforniaDocument4 paginiSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Maintenance Schedule For Gas Genset - GE JENBACHERDocument5 paginiMaintenance Schedule For Gas Genset - GE JENBACHERrajputashi92% (12)

- Perkins 1300 Technical DataDocument12 paginiPerkins 1300 Technical DataAbdul Khaliq100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Perkins 4012-46TWG2-3Document24 paginiPerkins 4012-46TWG2-3Cris_eu09100% (3)

- Perkins 2206c E13tag2 en ItDocument20 paginiPerkins 2206c E13tag2 en Itganesh_d2k6100% (1)

- 2506C E15tag2 PDFDocument14 pagini2506C E15tag2 PDFIvan Dumont67% (3)

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansDe la EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansEvaluare: 4 din 5 stele4/5 (8)

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 paginiParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraÎncă nu există evaluări

- A - PAGE 1 - MergedDocument73 paginiA - PAGE 1 - MergedGenalyn DomantayÎncă nu există evaluări

- Ets Ust 3 Update 14 ScreenDocument2 paginiEts Ust 3 Update 14 ScreenFaizan MotiwalaÎncă nu există evaluări

- 4012-46TWG2A 4012-46TWGA DieselDocument24 pagini4012-46TWG2A 4012-46TWGA DieselJDBORDÎncă nu există evaluări

- Cat cG132: Series Gas Generator SetsDocument8 paginiCat cG132: Series Gas Generator SetsCesário GuimarãesÎncă nu există evaluări

- 4012-46TWG2A - & - 3A Diesel (1250 Kva)Document24 pagini4012-46TWG2A - & - 3A Diesel (1250 Kva)Nate PawangÎncă nu există evaluări

- Perkins 4012 - 46twg2a Briz MotorsDocument18 paginiPerkins 4012 - 46twg2a Briz MotorsRafiee AdityaÎncă nu există evaluări

- Technical Data: 4000 Series 4012-46TWG2A 4012-46TWG3ADocument8 paginiTechnical Data: 4000 Series 4012-46TWG2A 4012-46TWG3Aabo omrÎncă nu există evaluări

- Thông số Perkins 4008TAG1A PDFDocument16 paginiThông số Perkins 4008TAG1A PDFBắc NhậtÎncă nu există evaluări

- Perkins 4008tag1a & Tag2a (Tsl4252e-6)Document16 paginiPerkins 4008tag1a & Tag2a (Tsl4252e-6)Cris_eu09Încă nu există evaluări

- 2206A Series PerkinsDocument20 pagini2206A Series Perkinskodor sinno100% (1)

- Altherma Data BookDocument19 paginiAltherma Data BookDawn RogersÎncă nu există evaluări

- 2206c-E13tag2&3 Tpd1688e4Document20 pagini2206c-E13tag2&3 Tpd1688e4Daniel Graterol100% (2)

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocument18 paginiCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- Tag 2 ADocument17 paginiTag 2 AepicenterrulezÎncă nu există evaluări

- 2506-A E15tag1 Datos TecnicosDocument14 pagini2506-A E15tag1 Datos TecnicosValeddia Beatriz Gutierrez Nina100% (1)

- Jenbacher Type 4: An Efficiency Milestone Reference InstallationsDocument2 paginiJenbacher Type 4: An Efficiency Milestone Reference InstallationsJose FavaÎncă nu există evaluări

- 1106c-E66tag2 (Tpd1619e1) PDFDocument8 pagini1106c-E66tag2 (Tpd1619e1) PDFKelvin FaneyteÎncă nu există evaluări

- 1104 C44 TAG2 TPD1637 Technical Data SheetDocument8 pagini1104 C44 TAG2 TPD1637 Technical Data SheetFarhan JuttÎncă nu există evaluări

- Jenbacher Type 6 Fs en Metric 2016Document2 paginiJenbacher Type 6 Fs en Metric 2016laiquz zamanÎncă nu există evaluări

- Innio BR t6 Update A4 en 2019 Screen Ijb-119006-EnDocument2 paginiInnio BR t6 Update A4 en 2019 Screen Ijb-119006-EnMahdi DehghankarÎncă nu există evaluări

- Jenbacher Type 6: Cutting-Edge TechnologyDocument2 paginiJenbacher Type 6: Cutting-Edge TechnologysxturboÎncă nu există evaluări

- 1106a-70tag2 TPD1857Document10 pagini1106a-70tag2 TPD1857Jan Ahmed100% (1)

- Technical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Document8 paginiTechnical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Ulma HudinÎncă nu există evaluări

- Technical Specifications: CAMDA Perkins Diesel Genset at 60HZ, 1800Rpm, 3ph, 0.8pfDocument16 paginiTechnical Specifications: CAMDA Perkins Diesel Genset at 60HZ, 1800Rpm, 3ph, 0.8pfNisar AhmedÎncă nu există evaluări

- TPD2158E2Document4 paginiTPD2158E2MohamedJaberKutkutMjkÎncă nu există evaluări

- 1104D-E44Tag1 Electropak: SeriesDocument8 pagini1104D-E44Tag1 Electropak: Seriesmahmoud khtaÎncă nu există evaluări

- 1760 KvaDocument16 pagini1760 KvaMarco PideritÎncă nu există evaluări

- Tpd2157en-04 (08-23)Document5 paginiTpd2157en-04 (08-23)ccssaa123Încă nu există evaluări

- Innio BR t6 A4 en 2022 ScreenDocument2 paginiInnio BR t6 A4 en 2022 ScreenAbdelrahman Abo El-KherÎncă nu există evaluări

- TPD2076 1Document7 paginiTPD2076 1Alfonso RivasÎncă nu există evaluări

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 paginiSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudÎncă nu există evaluări

- 10 Generator EbookDocument15 pagini10 Generator EbookPurryWidiarko100% (1)

- 1506A-E88TAG5 - TPD1953 - Dec2014 - 300kVADocument12 pagini1506A-E88TAG5 - TPD1953 - Dec2014 - 300kVAbacÎncă nu există evaluări

- PD750-01 Engine Data Sheet 12-29-20Document4 paginiPD750-01 Engine Data Sheet 12-29-20Service Brags & Hayes, Inc.Încă nu există evaluări

- Part. B.thermal DesignDocument8 paginiPart. B.thermal DesignAhmed GadÎncă nu există evaluări

- Innio Ets t6 A4 en 2023 Screen Ijb-123006-EnDocument2 paginiInnio Ets t6 A4 en 2023 Screen Ijb-123006-Enalexei.lex226iÎncă nu există evaluări

- TBG 620Document4 paginiTBG 620sdiamanÎncă nu există evaluări

- @perkins: 400 Series 403C-15GDocument2 pagini@perkins: 400 Series 403C-15GYaredÎncă nu există evaluări

- Small Wind ProfileDocument11 paginiSmall Wind ProfileChristopher HeathÎncă nu există evaluări

- 1506A-E88TAG5 Oct2016Document3 pagini1506A-E88TAG5 Oct2016Md ShÎncă nu există evaluări

- Perkins 1106A-70TAG2 PDFDocument10 paginiPerkins 1106A-70TAG2 PDFAna Nurul WakhidahÎncă nu există evaluări

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 paginiSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudÎncă nu există evaluări

- Perkins 1104 44tg1 Spec SheetDocument8 paginiPerkins 1104 44tg1 Spec SheetRodrigoThuLokithoPkmzÎncă nu există evaluări

- 1506a E88tag5 - 300 KvaDocument12 pagini1506a E88tag5 - 300 KvaRizki Heru HermawanÎncă nu există evaluări

- Perkins 4000 SeriesDocument16 paginiPerkins 4000 SeriesFuqqi Bhai100% (3)

- 2806A-E18TAG2A Technical DataDocument10 pagini2806A-E18TAG2A Technical DatabereketÎncă nu există evaluări

- Generator 404D-22G ElectropaK PN1912Document2 paginiGenerator 404D-22G ElectropaK PN1912Rizki Rangga DwipuraÎncă nu există evaluări

- Technical Data: @perkinsDocument6 paginiTechnical Data: @perkinsHendra SyalalaÎncă nu există evaluări

- 4006-23tag2a - Tag3aDocument14 pagini4006-23tag2a - Tag3aImran MazharÎncă nu există evaluări

- 400 Series: Diesel Engine - ElectropakDocument2 pagini400 Series: Diesel Engine - ElectropakShahroz ShaikhÎncă nu există evaluări

- eSH Technical Catalog PDFDocument116 paginieSH Technical Catalog PDFRheoserve Industrial SolutionsÎncă nu există evaluări

- DB EKHVX EN tcm135-186767 PDFDocument21 paginiDB EKHVX EN tcm135-186767 PDFdino_pÎncă nu există evaluări

- Perkins Engines 1106A-70TAG4Document10 paginiPerkins Engines 1106A-70TAG4dagimÎncă nu există evaluări

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesDe la EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesEvaluare: 3 din 5 stele3/5 (1)

- Electrical Motor Products: International Energy-Efficiency Standards and Testing MethodsDe la EverandElectrical Motor Products: International Energy-Efficiency Standards and Testing MethodsÎncă nu există evaluări

- CMA Positions: Dawn Sunday October 11, 2015 - Page 4Document27 paginiCMA Positions: Dawn Sunday October 11, 2015 - Page 4Faizan MotiwalaÎncă nu există evaluări

- Custom Tambola Housie Tickets PDFDocument5 paginiCustom Tambola Housie Tickets PDFFaizan MotiwalaÎncă nu există evaluări

- 1-25 BINGO: Safety First!Document17 pagini1-25 BINGO: Safety First!Faizan MotiwalaÎncă nu există evaluări

- License PremiumDocument1 paginăLicense PremiumNguyen Viet Trung (FPL HCMK13.3)100% (1)

- Iris - Help by FBRDocument5 paginiIris - Help by FBRGulzar Ahmad RawnÎncă nu există evaluări

- Pre Post TestDocument7 paginiPre Post TestFaizan MotiwalaÎncă nu există evaluări

- CBE Shedule Quarterly Winter 2015 FinalDocument1 paginăCBE Shedule Quarterly Winter 2015 FinalFaizan MotiwalaÎncă nu există evaluări

- Internship Report MTMDocument45 paginiInternship Report MTMusmanaltafÎncă nu există evaluări

- برنامج حساب زكاه المالDocument3 paginiبرنامج حساب زكاه المالnewlife4me100% (10)

- Business Finance SyllabusDocument68 paginiBusiness Finance SyllabusKhalid Mahmood0% (1)

- MPF Card FormDocument2 paginiMPF Card FormFaizan MotiwalaÎncă nu există evaluări

- Limiting Factor AnalysisDocument5 paginiLimiting Factor AnalysisFaizan MotiwalaÎncă nu există evaluări

- Jumbo Touch Remote ImDocument18 paginiJumbo Touch Remote ImFaizan MotiwalaÎncă nu există evaluări

- Zakat CalculatorDocument3 paginiZakat CalculatorFaizan MotiwalaÎncă nu există evaluări

- Spinning Project Profile FinalDocument23 paginiSpinning Project Profile FinalFaizan Motiwala67% (3)

- Spinning MillDocument6 paginiSpinning MillAnand Arumugam0% (1)

- Chairman's Message: Frequently Asked Questions On The Code of Corporate Governance (Revised)Document26 paginiChairman's Message: Frequently Asked Questions On The Code of Corporate Governance (Revised)Faizan MotiwalaÎncă nu există evaluări

- Appointment of AuditorDocument16 paginiAppointment of Auditorshahnawaz243Încă nu există evaluări

- Budgeting ExampleDocument17 paginiBudgeting ExampleBikrOm BaRuaÎncă nu există evaluări

- ICSP Company Law Paper Suggested Answer 2013Document8 paginiICSP Company Law Paper Suggested Answer 2013Faizan MotiwalaÎncă nu există evaluări

- Formula SheetDocument2 paginiFormula SheetFaizan Motiwala100% (1)

- Sohail ResumeDocument2 paginiSohail ResumeFaizan MotiwalaÎncă nu există evaluări

- Sohail ResumeDocument2 paginiSohail ResumeFaizan MotiwalaÎncă nu există evaluări

- Operations Management IsDocument6 paginiOperations Management IsFaizan MotiwalaÎncă nu există evaluări

- Professional CmaDocument3 paginiProfessional CmarehankhananiÎncă nu există evaluări

- Operations Management IsDocument6 paginiOperations Management IsFaizan MotiwalaÎncă nu există evaluări

- SEC CS Spice Money LTDDocument2 paginiSEC CS Spice Money LTDJulian SofiaÎncă nu există evaluări

- Use of Travelling Waves Principle in Protection Systems and Related AutomationsDocument52 paginiUse of Travelling Waves Principle in Protection Systems and Related AutomationsUtopia BogdanÎncă nu există evaluări

- Ideal Gas Law Lesson Plan FinalDocument5 paginiIdeal Gas Law Lesson Plan FinalLonel SisonÎncă nu există evaluări

- Lecture Notes 3A - Basic Concepts of Crystal Structure 2019Document19 paginiLecture Notes 3A - Basic Concepts of Crystal Structure 2019Lena BacaniÎncă nu există evaluări

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 paginiTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngÎncă nu există evaluări

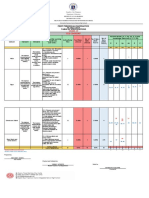

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 paginiRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoÎncă nu există evaluări

- Catálogo MK 2011/2013Document243 paginiCatálogo MK 2011/2013Grupo PriluxÎncă nu există evaluări

- Dialog InggrisDocument4 paginiDialog Inggrisبايو سيتياوانÎncă nu există evaluări

- LicencesDocument5 paginiLicencesstopnaggingmeÎncă nu există evaluări

- JP Selecta IncubatorDocument5 paginiJP Selecta IncubatorAhmed AlkabodyÎncă nu există evaluări

- Activity Evaluation Form: "Where Children Come First"Document1 paginăActivity Evaluation Form: "Where Children Come First"TuTitÎncă nu există evaluări

- Asuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiDocument43 paginiAsuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiCak FirmanÎncă nu există evaluări

- The Piano Lesson Companion Book: Level 1Document17 paginiThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelÎncă nu există evaluări

- Bag Technique and Benedict ToolDocument2 paginiBag Technique and Benedict ToolAriel Delos Reyes100% (1)

- Health and Safety For The Meat Industry: Guidance NotesDocument198 paginiHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicÎncă nu există evaluări

- Microeconomics Term 1 SlidesDocument494 paginiMicroeconomics Term 1 SlidesSidra BhattiÎncă nu există evaluări

- Morse Potential CurveDocument9 paginiMorse Potential Curvejagabandhu_patraÎncă nu există evaluări

- Electric Vehicles PresentationDocument10 paginiElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- War at Sea Clarifications Aug 10Document4 paginiWar at Sea Clarifications Aug 10jdageeÎncă nu există evaluări

- Vedic Maths Edited 2Document9 paginiVedic Maths Edited 2sriram AÎncă nu există evaluări

- Bigbazaar PDFDocument14 paginiBigbazaar PDFazhagu sundaramÎncă nu există evaluări

- Hetal Patel: Team Leader - SalesDocument2 paginiHetal Patel: Team Leader - SalesPrashant kumarÎncă nu există evaluări

- Geotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonDocument7 paginiGeotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonJuan PerezÎncă nu există evaluări

- Technical Data Sheet TR24-3-T USDocument2 paginiTechnical Data Sheet TR24-3-T USDiogo CÎncă nu există evaluări

- Assignment 3Document2 paginiAssignment 3Debopam RayÎncă nu există evaluări

- MECANISMOS de Metais de TransicaoDocument36 paginiMECANISMOS de Metais de TransicaoJoão BarbosaÎncă nu există evaluări