Documente Academic

Documente Profesional

Documente Cultură

Reg MC 08 Rastelli

Încărcat de

nitoxxx666Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Reg MC 08 Rastelli

Încărcat de

nitoxxx666Drepturi de autor:

Formate disponibile

2006 UOP LLC. All rights reserved.

Extending Molecular Sieve Life in

Natural Gas Dehydration Units

Extending Molecular Sieve Life in

Natural Gas Dehydration Units

Henry (Hank) Rastelli

Julie Stiltner Shadden

UOP LLC

Henry (Hank) Rastelli

Julie Stiltner Shadden

UOP LLC

Mid-Continent Annual GPA

April 17, 2008

2007 UOP LLC. All rights reserved.

UOP 4733-01

Outline

Outline

Introduction

Introduction

-

-

Why molecular sieves for dehydration?

Why molecular sieves for dehydration?

-

-

What are molecular sieves?

What are molecular sieves?

Type (Structure & Cation) Type (Structure & Cation)

Formed Versions Formed Versions

Discussion

Discussion

-

-

Problems encountered in service

Problems encountered in service

Liquid entrainment Liquid entrainment

Regeneration at high temperature and pressure Regeneration at high temperature and pressure

-

-

Solutions

Solutions

Process Process

Product Product

-

- Case Histories Case Histories

Summary

Summary

UOP 4733-02

Molecular Sieves Required for Low H

Molecular Sieves Required for Low H

2 2

O Dew Points

O Dew Points

Introduction

Introduction

Why dehydrate natural gas?

Why dehydrate natural gas?

-

-

Pipeline Transmission

Pipeline Transmission

usually glycol treating is

usually glycol treating is

sufficient

sufficient

-

-

Hydrocarbon Recovery

Hydrocarbon Recovery

Cryogenic Refrigeration (D.P. < Cryogenic Refrigeration (D.P. < - -100 100 C) C)

-

-

LNG production (D.P. <

LNG production (D.P. <

-

-

100

100

C)

C)

Peak shavers (H Peak shavers (H

2 2

O, CO O, CO

2 2

removal) removal)

Base load (H Base load (H

2 2

O) O)

-

-

Helium Recovery (D.P. <

Helium Recovery (D.P. <

-

-

162

162

C)

C)

UOP 4733-03

Introduction

What are molecular sieves

What are molecular sieves

-

-

Microporous crystalline alumino

Microporous crystalline alumino

-

-

silicates

silicates

-

-

Commercially synthesized with uniform properties

Commercially synthesized with uniform properties

-

-

Possess high surface area (500

Possess high surface area (500

-

-

1000 m

1000 m

2 2

/g)

/g)

-

-

Pore aperture controls adsorption

Pore aperture controls adsorption

-

-

Alkaline / alkaline earth cations balance surface charge

Alkaline / alkaline earth cations balance surface charge

-

-

Type of cation affects the aperture size (i.e. 3A, 4A, 5A)

Type of cation affects the aperture size (i.e. 3A, 4A, 5A)

-

-

By using a binder (clay, silica, alumina, etc.), molecular

By using a binder (clay, silica, alumina, etc.), molecular

sieves are produced in different aggregates (beads,

sieves are produced in different aggregates (beads,

pellets, mesh)

pellets, mesh)

-

-

Binder choice critical to performance

Binder choice critical to performance

UOP 4733-04

Linde Type A Zeolite Linde Type A Zeolite Microporous, crystalline, alumino Microporous, crystalline, alumino- -silicate silicate

LTA = Zeolite A LTA = Zeolite A

UOP 4733-05

Introduction

Introduction

Why molecular sieves for NG dehydration

Why molecular sieves for NG dehydration

-

-

Strongly polar surface is selective for polar

Strongly polar surface is selective for polar

molecules (H

molecules (H

2 2

O, CO

O, CO

2 2

, H

, H

2 2

S, et.)

S, et.)

-

-

Non

Non

-

-

polar compounds (i.e. hydrocarbons) are not

polar compounds (i.e. hydrocarbons) are not

strongly adsorbed

strongly adsorbed

-

-

Water dew points of <

Water dew points of <

-

-

100

100

C easily achieved

C easily achieved

Molecular Sieves are I deally Suited for

Molecular Sieves are I deally Suited for

Natural Gas Dehydration and Treating

Natural Gas Dehydration and Treating

UOP 4733-06

Discussion

Discussion

Problems encountered in service

Problems encountered in service

-

-

Liquid entrainment

Liquid entrainment

glycols, amines, heavy

glycols, amines, heavy

hydrocarbons, etc.

hydrocarbons, etc.

-

-

Free water

Free water

pigging operation, etc.

pigging operation, etc.

-

-

Regeneration at high temperature

Regeneration at high temperature

-

-

Regeneration at high pressure

Regeneration at high pressure

UOP 4733-07

Regeneration Regeneration

at high temperature at high temperature

& high pressure & high pressure

Discussion

Discussion

Refluxing condition results in:

Refluxing condition results in:

Accelerated

Accelerated

Breakup

Breakup

Increased

Increased

Pressure

Pressure

Drop

Drop

Channeling

Channeling

Premature

Premature

Water

Water

Breakthrough

Breakthrough

UOP 4733-08

Crust Formation on Vessel Walls

Crust Formation on Vessel Walls

UOP 4733-09

Crust Formation Measured on Vessel Walls

UOP 4733-10

Solid caked layer of Solid caked layer of

adsorbent and salt adsorbent and salt

fused together fused together

Effective diameter reduced Effective diameter reduced

to 1500 to 1500- -2000 mm 2000 mm

Original bed diameter Original bed diameter

3100 mm 3100 mm

Approx Approx

1500 1500 - - 2000 2000

3100 3100

Thermocouple

Thermocouple

Crust Broken up

UOP 4733-11

Crust Formation Top of Bed

UOP 4733-12

Discussion

Solutions

Solutions

-

-

Process

Process

Reduce regeneration pressure Reduce regeneration pressure

Temperature ramping Temperature ramping

-

-

Product

Product

Guard Bed (alumina, silica gel, etc.) Guard Bed (alumina, silica gel, etc.)

More robust molecular sieve adsorbent More robust molecular sieve adsorbent

Case Histories

Case Histories

-

-

1. North African Operator (NGL from natural gas)

1. North African Operator (NGL from natural gas)

-

-

2. Central African Processor (NGL from associated gas)

2. Central African Processor (NGL from associated gas)

-

-

3. North American Producer (cryogenic liquids recovery)

3. North American Producer (cryogenic liquids recovery)

UOP 4733-13

Case 1: North African Operator

5

5

-

-

Train natural gas NGL

Train natural gas NGL

recovery plant

recovery plant

420,000 Nm

420,000 Nm

3 3

/hr

/hr

each train

each train

Feed pressure

Feed pressure

1120 psia

1120 psia

Regenerate with product gas

Regenerate with product gas

Regeneration Pressure

Regeneration Pressure

1062 psia

1062 psia

Re

Re

-

-

inject regenerant

inject regenerant

Regeneration is stripping

Regeneration is stripping

limited

limited

Adsorbent Life Doubled with UI

Adsorbent Life Doubled with UI

-

-

94 Adsorbent

94 Adsorbent

Feed Composition Feed Composition

Mole % Mole %

Methane Methane 85.9 85.9

Ethane Ethane 7.88 7.88

Propane Propane 2.77 2.77

i i - -Butane Butane 0.63 0.63

n n- -Butane Butane 0.68 0.68

i i - -Pentane Pentane 0.25 0.25

n n- -Pentane Pentane 0.17 0.17

C C

6 6

+ +

Balance Balance

Nitrogen Nitrogen 0.61 0.61

Carbon Dioxide Carbon Dioxide 0.78 0.78

UOP 4733-14

UOP

TM

MOLECULAR SIEVE ADSORBERS

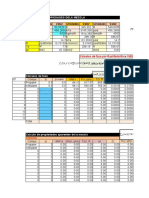

Fig 2 - Pressure drop data review July 1999 - April 2006 Pressure drop evolution

0

5

10

15

20

25

30

35

40

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

Service Life (years)

p

r

e

s

s

u

r

e

d

r

o

p

(

p

s

i

)

First UOP charge loaded in July 1999

Compound bed UI-94

1

/8 +4A-DG

1

/8 +

4A-DG

1

/16

Third UOP charge loaded in November 2004

Compound bed UI-94

1

/8 + 4A-DG

1

/16

Ramped heating

Second UOP charge loaded in July 2001

Compound bed UI-94

1

/8 + 4A-DG

1

/8 + 4A-DG

1

/16

Ramped heating

UOP

TM

MOLECULAR SIEVE ADSORBERS

Fig 2 - Pressure drop data review July 1999 - April 2006 Pressure drop evolution

0

5

10

15

20

25

30

35

40

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

Service Life (years)

p

r

e

s

s

u

r

e

d

r

o

p

(

p

s

i

)

First UOP charge loaded in July 1999

Compound bed UI-94

1

/8 +4A-DG

1

/8 +

4A-DG

1

/16

Third UOP charge loaded in November 2004

Compound bed UI-94

1

/8 + 4A-DG

1

/16

Ramped heating

Second UOP charge loaded in July 2001

Compound bed UI-94

1

/8 + 4A-DG

1

/8 + 4A-DG

1

/16

Ramped heating

Case 2: Central African Processor

Case 2: Central African Processor

Adsorbent Life Doubled with UI

Adsorbent Life Doubled with UI

-

-

94 Adsorbent

94 Adsorbent

UOP 4733-15

Case 3: North American Producer

Revamped a 3

Revamped a 3

-

-

train cryogenic liquids recovery plant

train cryogenic liquids recovery plant

High pressure regeneration (1050 psig)

High pressure regeneration (1050 psig)

Processing 20% more gas than design

Processing 20% more gas than design

Occasional liquid carryover evident

Occasional liquid carryover evident

Initial adsorbent charge lasted ~6 months

Initial adsorbent charge lasted ~6 months

Some plant modifications but still adsorbent life was

Some plant modifications but still adsorbent life was

< 12 months

< 12 months

Changed over to UI

Changed over to UI

-

-

94 in 2002

94 in 2002

Adsorbent charges now exceed 2 years life.

Adsorbent charges now exceed 2 years life.

Customer very satisfied with UI

Customer very satisfied with UI

-

-

94 Adsorbent

94 Adsorbent

UOP 4733-16

Summary

Summary

MOLSIV

MOLSIV

UI

UI

-

-

94 Adsorbent developed for

94 Adsorbent developed for

challenging natural gas dehydration service

challenging natural gas dehydration service

-

-

Tight designs

Tight designs

-

-

Changing process conditions

Changing process conditions

-

-

Resistant to glycol and amine carryover

Resistant to glycol and amine carryover

-

-

Upsets

Upsets

periodic liquid entrainment

periodic liquid entrainment

UOP MOLSIV UI

UOP MOLSIV UI

-

-

94 Adsorbent is

94 Adsorbent is

a robust product that maintains

a robust product that maintains

its integrity under challenging

its integrity under challenging

operational conditions

operational conditions

UOP 4733-17

UOP 4733-18

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Code of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Document51 paginiCode of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Justin ChongÎncă nu există evaluări

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasDocument41 paginiCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoÎncă nu există evaluări

- Hydrogen Flare Stack Diffusion Flames ReportDocument38 paginiHydrogen Flare Stack Diffusion Flames ReportcottomohrÎncă nu există evaluări

- Ozone DepletionDocument2 paginiOzone DepletionHamza AyubÎncă nu există evaluări

- PSA GeneralDocument17 paginiPSA GeneralMohammed AhmedÎncă nu există evaluări

- What Materials Are Compatible With Gases - LindeDocument4 paginiWhat Materials Are Compatible With Gases - LindeDinesh RajÎncă nu există evaluări

- CEN-BTWG197 N0231 Adopted Deliverable D1-3 - Future Gas ProfiDocument100 paginiCEN-BTWG197 N0231 Adopted Deliverable D1-3 - Future Gas ProfiMilos BajicÎncă nu există evaluări

- Alternative Fuels GuidebookDocument1 paginăAlternative Fuels GuidebookSarthak GuptaÎncă nu există evaluări

- Ibpr Gas LPGDocument194 paginiIbpr Gas LPGJohn KalvinÎncă nu există evaluări

- Compressed Gas SafetyDocument28 paginiCompressed Gas SafetyDiaa Gab-AllahÎncă nu există evaluări

- Hydrocarbons-and-Alkanes-worksheet HOMEWORKDocument3 paginiHydrocarbons-and-Alkanes-worksheet HOMEWORKTeena SheikhÎncă nu există evaluări

- Boiler Combustion AnalysisDocument4 paginiBoiler Combustion AnalysisDha'z SuiiciderzÎncă nu există evaluări

- Compressed Gas SafetyDocument90 paginiCompressed Gas Safetym_alodat6144Încă nu există evaluări

- Cryogenic Air Separation Process and FeaturesDocument2 paginiCryogenic Air Separation Process and FeaturesDelta DigitronicsÎncă nu există evaluări

- Gas composition and condensate analysisDocument43 paginiGas composition and condensate analysismakasad26Încă nu există evaluări

- Fuel and Combustion CalculationsDocument6 paginiFuel and Combustion Calculationsvvijaybhan100% (2)

- Freon Hot Shot 2 Conversion GuidelinesDocument2 paginiFreon Hot Shot 2 Conversion Guidelinesmates isÎncă nu există evaluări

- Ejsr 85 1 14Document8 paginiEjsr 85 1 14hmudassir_1Încă nu există evaluări

- Technology Upgradation in Chemical & Petrochemical IndustryDocument139 paginiTechnology Upgradation in Chemical & Petrochemical IndustryMiguel MartinezÎncă nu există evaluări

- Sample ODS Record BookDocument9 paginiSample ODS Record BookcaptanupamÎncă nu există evaluări

- LPG Qatar Petroleum LPG Product SpecificationsDocument1 paginăLPG Qatar Petroleum LPG Product SpecificationsJoeÎncă nu există evaluări

- Characteristics of Molecular Compositions in China's Giant Natural Gas FieldsDocument22 paginiCharacteristics of Molecular Compositions in China's Giant Natural Gas FieldsMonel LenomÎncă nu există evaluări

- Welder ID Card BRE KarahaDocument5 paginiWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Overview KilangDocument6 paginiOverview KilangArShyhy Citcuit ArsyamaliaÎncă nu există evaluări

- TENARIS - Supply Solutions For The HPIOKDocument2 paginiTENARIS - Supply Solutions For The HPIOKEl_GasistaÎncă nu există evaluări

- Stoichiometric Calculations Made EasyeducationDocument13 paginiStoichiometric Calculations Made Easyeducationandrew surajÎncă nu există evaluări

- Senscient ELDS - : MSA Fixed Gas and Flame Detection Category IDocument6 paginiSenscient ELDS - : MSA Fixed Gas and Flame Detection Category ImoisesÎncă nu există evaluări

- ESAB Filler Metals for Welding ASTM SteelsDocument29 paginiESAB Filler Metals for Welding ASTM SteelsMohd Zulfadli Mohamad IzaraeeÎncă nu există evaluări

- Variables Unidades Valor Unidades Valor Unidades Valor: Calculo de Propiedades Dela MezclaDocument33 paginiVariables Unidades Valor Unidades Valor Unidades Valor: Calculo de Propiedades Dela MezclaDiego MartinezÎncă nu există evaluări

- Earth's Atmosphere - SNDocument2 paginiEarth's Atmosphere - SNJoanna Marie Delos SantosÎncă nu există evaluări