Documente Academic

Documente Profesional

Documente Cultură

Acuracy of SSM Processes

Încărcat de

Ah_DiantreTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Acuracy of SSM Processes

Încărcat de

Ah_DiantreDrepturi de autor:

Formate disponibile

Materials & Design. Vol. 17, No. 3, pp.

159-166, 1996

0 1997 Elsevier Science Ltd

Printed in Great Britain. Al l rights reserved

0261-3069/96 $15.00 + 0.00

PII: SO261-3066(96100060-7

Experimental design and analysis of in-plane

processing accuracy for SSM process

Wanlong Wang,, Wei Feng,b Yongnian Yan,b and Jerry Y.H. Fuh,

aDepattment of Mechanical and Production Engineering, National University

of Singapore, IO Kent Ridge Crescent, 119260 Singapore

bDepattment of Mechanical Engineering, Tsinghua University, Beijing 100084,

P.R. China

Received 20 August 1996; accepted 24 August 1996

Processing accuracy is an important area studied in rapid prototyping (RP) research. It is mainly

dependent on the processing parameters, material characteristics and many other factors.

Studies on processing accuracy can be divided into two categories: in-plane processing accuracy

and vertical processing accuracy (that determines the staircase on the surfaces of prototypes).

This work focuses on the in-plane processing accuracy. Similar to laminated object

manufacturing (LOM) process, slicing solid manufacturing (SSM) uses paper and CO2 laser as

material and energy source, respectively. This paper introduces an integrated method that

combines orthogonal experimental design and analysis, and neural network analysis to

determine the optimal processing conditions. The key processing parameters and their degree

of influences on the processing accuracy, and the quantitative relations between input

parameters and output accuracy will be investigated. This method of experimental design and

analysis is not only effective for the SSM process, but also applicable to other RP processes that

use the principle of 3D layered manufacture. 0 1997 Elsevier Science Ltd. All rights reserved

Keywords: rapid prototyping; slicing solid manufacturing (SSM); processing accuracy;

orthogonal experimental design; back propagation network

Introduction

As more and more global competition arises, manufactur-

ing industries are facing new challenges of bringing

concept design to manufacture very quickly. This puts

demands on enterprises not only to produce high quality

products with low cost, but also to be content with a short

lead time into market. Rapid prototyping techniques are

new born manufacturing technologies, that will bring

revolutionary changes in new products development. But

the present status of part accuracy cannot meet the industry

requirements. Many approaches have been taken to

improve the techniques, such as looking for new processes,

enhancing the existing processes and studying the relations

between processing accuracy and processing parameters.

Owing to the nature of layer-by-layer fabrication, the

studies on processing accuracy can be divided into two

categories: in-plane processing accuracy and vertical

processing accuracy (that determines the staircase on the

surface of prototypes). Rapid prototyping (RP) processes

produce the parts layer-by-layer on a certain plane, e.g. on

the X-Y plane. The in-plane accuracy, that contributes to

the overall accuracy is, thereby, an important area studied.

Whether in-plane or vertical accuracy, a good experimental

design and analysis can save time and cost, and also

produce valuable information on improving the process. In

the RP processes, there are many factors affecting their

*Correspondence to W. Wang.

accuracy. For example, in the SLA process, laser spot size

(diameter), laser power, scanning speed, slicing pitch, resin,

recoating, etc. will all affect the final part accuracy.

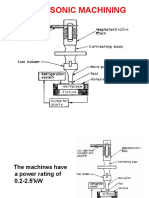

The sliding solid manufacturing (SSM) process (as

shown in Figure I) is developed by the Centre for the Laser

Rapid Prototyping in the Tsinghua University, China. The

process uses paper and COZ laser as materials and energy

source, respectively. In this process, there are many factors

affecting the processing accuracy. In such a case, the design

of the experiments for studying accuracy will be very

important.

Generally speaking, a good design scheme should

possess the following characteristics:

1. requires a lower cost, shorter time and higher reliability;

2. can produce more relevant information;

3. the results of experiment are easily to be interpreted.

In this paper, the method of orthogonal experimental

design will be used to study the relations between the

processing parameters and the resulting part accuracy.

Overview of present status on accuracy research

Although many researches are devoted to the experimental

design and analysis for studying the RP accuracy, Jacobs is

the first one to systematically investigate the processing

accuracy in terms of distortion and warpage in the SLA

process. Bugeda et ~2. have studied distortion in the SLA

Materials & Design Volume 17 Number 3 1996 159

Processing accuracy for SSM process: Wanlong Wang et

(a) Cross-sectionalProfile

elevator

/:/li: 3#,

n

(b) Layered manufacturing

Figure 1 The SSM process

curing process by means of the finite element method.

Wiedemann et CZL.~ studied the factors causing processing

inaccuracy due to part distortion in the SLA process. Lee et

a1.4 investigated the layer position accuracy in powder-

based rapid prototyping, analyzed the main parameters

affecting position accuracy and suggested appropriate

selection of materials and techniques to achieve higher

packing density for accuracy improvement. Lu et al.

examined the depth and width of the laser curing lines for

the stereolithography (SL) process, and relationships

between the result and process parameters: the laser power,

scan pitch and scanning pattern. Chen et aL6 studied the

parameters affecting the Z-height inaccuracy of the SL

process. All the above-mentioned researches are mainly

devoted to the resulting accuracy or experimental studies,

the relations between the processing parameters and

processing accuracy being not much investigated. In our

work, the emphasis is placed on studying the factors that

determine part accuracy through a systematic approach.

Experimental design

Experimental objectives

The objective7 of the processing accuracy experiments is to

systematically study the main factors affecting processing

accuracy in the SSM process, so as to realise the following

three aspects through a good experimental design and

analysis:

1. to identify the relationships between in-plane processing

accuracy and processing parameters;

2.

3.

al.

to study the overall processing accuracy of pro-

totypes;

to study the mechanical properties, glue quality and

carbonisation rate.

According to experimental observation and analysis, the

factors affecting processing accuracy are: laser spot

diameter, laser power and focus distance, laser cutting

speed, paper and its thickness, adhesive material, tempera-

ture, pressure, and rolling speed. For a certain situation, this

can be further simplified. For example, when the equipment

decided upon, the laser spot size and focus distance are also

decided. If the paper and adhesive material are known, the

other five will be the only influencing factors. Those factors

are the laser power, laser cutting speed, temperature,

pressure and rolling speed. Assuming processing accuracy

has a correlation with the above-mentioned five parameters,

the following function exists:

d = f(W, v, T, f, u)

where

(1)

d is the laser cutting width,

W is the laser power,

Y is the laser cutting speed,

T is the temperature,

P is the pressure, and

u is the rolling speed.

Measurement of the laser cutting width

A rectangular profile (Figure 2) is used to measure the laser

cutting width. After cutting, the distances between the inner

and the outer borders will be determined using the

following relation:

d = (u - b)/2

(2)

where a is the outer distance and b is the inner distance.

Orthogonal experimental design

Orthogonal experimental designsV9 method, also known as

the Latin square method, is widely used in the engineering

fields. It is mainly applied in determining the key

influencing factors. It has many standard tables that can

be used to decide experimental conditions and arrange

experimental schemes.

The advantages of the orthogonal tables are that they can

be used to decide the optimal experimental conditions, and

thus reduce the number of iterations required in extensive

experiments. Besides, this method also enables further

Figure 2 Measurement of the laser cutting width

160 Materials & Design Volume 17 Number 3 1996

analysis on each factor and obtaining more useful

information from the experimental results.

Orthogonal table and orthogonal experiment

Orthogonal table is a kind of table which is constructed

according to certain laws based on the combinatorial

theory. It has found wide applications in experimental

design. An experiment that employs orthogonal tables to

arrange experimental schemes and conducts result analysis

is called an orthogonal experiment. It is more appropriate to

apply this to experiments involving multi-factor, multi-

target (i.e. results examined in an experiment), interactions

between multi-factors (i.e. correlation among factors), and

experiments with random errors. Through orthogonal

experiment, the influences of the factors and their

interactions on the experimental results can be analyzed,

the sequence of the key factors can be ranked, and the

optimal process conditions can be determined. In an

orthogonal experiment, each factor considered must be

controllable. The value of each factor is called the level of

that factor.

The symbol of the orthogonal table is L,(b): where L is

orthogonal table; the subscript a is the row number

representing the number of experiments; c is the column

number representing the maximum number of factors

arranged in the experiment; b is the number of the different

values, meaning the number of values for each factor. For

example, in table L&27) (shown in Table I), 8 means that

there are 8 rows, i.e. the number of experiments is 8; 7

means that there are 7 columns, and the maximum number

of experimental factors (including the interactional col-

umns) is 7; 2 means that each factor has only two levels.

This type of orthogonal table is also called a two-level

orthogonal table.

According to the former analysis on the main factors

affecting processing accuracy, there are five key parameters

used in the orthogonal experiment design. Considering the

experimental quantities and conditions, four levels are used

in the orthogonal table. In such a case, table L16(45) (shown

in Table 2) is obtained. This table does not take into

account the interactions among the factors. The head

designs of the orthogonal table, L16(45), are shown in

Table 3.

Interactional columns in orthogonal tables

If factors are not independent in the experiments, the

interactional effect must be considered. Once any two

columns are determined, the interaction between the two

columns can be represented by other columns. This column

is called the interactional column. There is one interactional

column in a two-level orthogonal table, but two in a three-

level one. For example, in the interactional table of table

Table 1 The orthogonal table of Ls(2)

Factors 1 2 3 4 5 6 7

1 1 1 1 1 1 1 1

2 1 1 1 2 2 2 2

3 1 2 2 1 1 2 2

4 1 2 2 2 2 1 1

5 2 1 2 1 2 1 2

6 2 1 2 2 1 2 1

7 2 2 1 1 2 2 1

8 2 2 1 2 1 1 2

able 2 The orthogonal table of &(4)

Factors

l(A) 2(B) 3(C) 4(D) 503

1 1 1 1 1 1

2 1 2 2 2 2

3 1 3 3 3 3

4 1 4 4 4 4

5 2 1 2 3 4

6 2 2 1 4 3

I 2 3 3 1 2

8 2 4 4 2 1

9 3 1 3 4 2

10 3 2 4 3 1

11 3 3 1 2 4

12 3 4 2 1 3

13 4 1 4 2 3

14 4 2 3 1 4

15 4 3 2 4 1

16 4 4 1 3 2

Table 3 The header design for 5 factors, 4 levels not considering

interactions 46(45)

Column number 1 2 3 4 5

Factors A B C D E

Note: A denotes the laser power, B is the cutting speed, C is the

temperahue, D is the pressure, and E is the rolling speed.

Table 4 The interactional table for Z&2)

1 2 3 4 5 6 7 Column number

(1) 3 2 5 4 7 6

(2) 1 6 7 4 5 :

(3) 7 6 5 4 3

(4) 1 2 3 4

(5) 3 2 5

(6) 1 6

(7) 7

&(27) (shown in Table 4), the interactional column of

column 1 and column 2 is column 3, the interactional

column of column 3 and column 5 is column 6, etc.

In this paper, for comparison, another orthogonal table,

L16(215), (shown in Table 5), considering interactions

between two factors, is adopted. Its interactional table

can be obtained (shown in Table 6). The head design of the

orthogonal table, Li6(215), is shown in Table 7. Thus, two

types of orthogonal tables - one considering and the other

not considering the interactions - are used in this work.

The orthogonality of the orthogonal tables

The orthogonal tables possess the following orthogo-

nality:

l In any column, all iterative numbers for each level are

equal. For example, in table Ls(27), each level of any

column repeats itself four times.

l In any two of the columns, the number of pairs

composed at one level embody all possible number

pairs (under that level), and the iterative numbers for

each number matched are equal. For example, in table

Z&34), the number of pairs composed of any two of

the columns embody all possible number pairs under

three levels: (1, 11, (1,2), (1,3), (2, 0, C&2), C&3), (3,

l), (3, 2), (3, 3), and all iterative numbers equal 1.

Processing accuracy for SSM process: Wanlong Wang et al.

Materials & Design Volume 17 Number 3 1996 161

Processing accuracy for SSM process: Wanlong Wang et al.

Table 5 The orthogonal table of L16(215)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

2 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2

3 1 1 1 2 2 2 2 1 1 1 1 2 2 2 2

4 1 1 1 2 2 2 2 2 2 2 2 1 1 1 1

5 1 2 2 1 1 2 2 1 1 2 2 1 1 2 2

6 1 2 2 1 1 2 2 2 2 1 1 2 2 1 1

I 1 2 2 2 2 1 1 1 1 2 2 2 2 1 1

8 1 2 2 2 2 1 1 2 2 1 1 1 1 2 2

9 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2

10 2 1 2 1 2 1 2 2 1 2 1 2 1 2 1

11 2 1 2 2 1 2 1 1 2 1 2 2 1 2 1

12 2 1 2 2 1 2 1 2 1 2 1 1 2 1 2

13 2 2 1 1 2 2 1 1 2 2 1 1 2 2 1

14 2 2 1 1 2 2 1 2 1 1 2 2 1 1 2

15 2 2 1 2 1 1 2 1 2 2 1 2 1 1 2

16 2 2 1 2 1 1 2 2 1 1 2 1 2 2 1

Table 6 The interactional table for L1~(2~)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 (1)

:2,

2 5 4 7 6 9 8 11 10 13 12 15 14

2 :3) 6 I 4 5 10 11 8 9 14 15 12 13

3 7 6 5 4 11 10 9 8 15 14 13 12

4 (4) :5) 2 3 12 13 14 15 8 9 10 11

5 :6) 2 13 12 15 14 9 8 11 10

6

f7)

14 15 12 13 10 11 8 9

I ta: 14 13 12 11 10 9 8

8 :9, 2 3 4 5 6 I

9 :w 2 5 4 I 6

10 fw 6 I 4 5

11

12

712) 6 5 4

:13) 2 3

13

:14)

2

14 1

Table 7 The header design for 5 factors, 2 levels while considering interactions &(215)

Column Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A B AB c AC BC DE D AD BD CE CD BE Al? E

Note: A denotes the laser power, B is the cutting speed, C is the temperature, D is the pressure, and E is the rolling speed. AxC is simplified as AC.

Because of this orthogonality, the orthogonal experiment

can be arranged in equilibrium and uniformity.

Steps and methods of experimental scheme

The steps of arranging an orthogonal experiment are as

follows:

Determine the number of varying factors and levels of

each factor.

Preliminarily analyze the interactions of the factors,

and determine the one that must be considered by

experience.

Determine the approximate number of experiments

according to the experimental conditions, such as

manpower, equipment, time and cost.

Choose appropriate orthogonal tables and arrange

experimental schemes.

The methods of arranging an orthogonal experiment are as

follows:

162 Materials & Design Volume 17 Number 3 1996

In the case of non-consideration of the interactions,

arrange each factor into any column of the orthogonal

table. Then the experimental conditions (level adopted

for each factor) of each experiment (corresponding to

the row of the orthogonal table) are determined by the

levels of each of the factors arranged. For example, in

the in-plane processing accuracy experiment, five

factors and four levels are adopted to arrange the

experiment. The experimental target is the cutting

width of the laser. Table 8 gives this arrangement.

In the case of consideration of the interactions, the

factors cannot be randomly arranged. They must be

arranged using the corresponding table title design.

Note that different factors (including interactions)

cannot be placed in the same column. This is because,

it is difficult to analyze the actions of different factors

in the same column. If this requirement is not met,

then a large table should be adopted. For example, in

the m-plane processing accuracy experiment, five factors

and two levels are adopted to arrange the experiment. The

Processing accuracy for SSM process: Wanlong Wang et al.

Table 8 Factors and four levels while not considering interaction

Laser power Cutting speed Temperature Pressure Rolling speed

25 W 40 mm/s 120C -0.2 40 mm/s

27 w 48 mm/s 130C -0.1 49 mm/s

30 w 60 mm/s 140C 0.1 63 mm/s

32.5 W 80 mm/s 150C 0.2 88 mm/s

Table 9 Factors and two levels while considering interaction

Laser power Cutting speed Temperature Pressure Rolling speed

1 25 w 48 mm/s 120C -0.1 49 mm/s

2 30 w 80 mm/s 140C 0.1 88 mm/s

experimental target, here also, is the cutting width of

the laser. Table 9 gives this arrangement.

Analysis of the orthogonal tables

Calculation of the lever! sum and mean of the level i

For example, using table L16(45), the analysis is shown in

Table 10. In Table 10, the variables are calculated as

follows:MV = the sum of y values of level i in column j;

mu = r Mu (the average value of i levels in j column :

n

n is the experimental number, r is the level number);

(3)

(the divergence square sum of each column);

(4)

(the maximum difference of each column); (5)

Table 10 The calculation of orthogonal table

1 (4 2 @I 3 (C) 4 (D) 5 (E)

Result (y)

1 Al Bl Cl Dl El

Yl

2 Al B2 c2 D2 E2

Y2

3 Al B3 c3 D3 E3

Y3

4 Al B4 c4 D4 E4

Y4

5 A2 Bl c2 D3 E4

Y5

6 A2 B2 Cl D4 E3

Y6

I A2 B3 c4 Dl E2

Y7

8 A2 B4 c3 D2 El

YS

9 A3 Bl c3 D4 E2

Y9

10 A3 B2 c4 D3 El

YlO

11 A3 B3 Cl D2 E4

Yl l

12 A3 B4 c2 Dl E3

Yl2

13 A4 Bl c4 D2 E3

Y13

14 A4 B2 c3 Dl E4

Y14

15 A4 B3 c2 D4 El Yl5

16 A4 B4 Cl D3 E2

Y1b

Mlj MII M12 Ml3 M14 M15

4

M21 M22 M23 M24 M25

M3j M31 M32 M33 M34 M35

M4j M41 M42 M43 M44 M45

mlj ml1 ml2 ml3 ml4 ml5

mzj m21 m22 m23 m24 m25

m3j m31 m32 m33 m34 m35

m4j m41 m42 m43 m44 m45

Ri Rl R2 R1 R4 R5

si s4 s5

cq = mu - 7 = i [rMg - T]

(the effect of leveliin column j);

(6)

Ranking of key factors

According to the maximum difference of each column, the

important ranking of the key factors can be determined.

The bigger the difference is, the more important the factor

will be.

The optimal process conditions

In the case of non-consideration of the interactions, find the

best point for each factor on the experimental target,

combine all corresponding experimental conditions and

form the optimal process conditions. This can also be

achieved by choosing a highest or lowest point on the curve

figured out from the analysis results.

In the case of consideration of the interactions, if the

analysis results show that the interaction of two of the

factors has a big influence on the experimental target,

compare all the experimental results of all possible

combinations of the two factors (if there are several

experimental results, the mean value should be used), and

choose the best one. Finally, consider the other factors

synthetically and determine the optimal process conditions.

Experimental results and analysis

The following are the experimental results and analysis for

a certain kind of paper with one adhesive material.

Five factors, two levels experimental results and analysis

considering interactions

The values of laser cutting width measured in the

experiments are as follows:

y1 = 0.244, y2 = 0.205, y3 = 0.205, y4 = 0.192,

y5 = 0.123, y6 = 0.093, yl = 0.096, y8 = 0.127,

y9 = 0.170, ylo = 0.019, yll = 0.202, y12 = 0.203,

~13 = 0.087, ~14 = 0.085, ~15 = 0.113, y16 = 0.098.

Hence,

7 = eyi/ 16 = 0.152

i=l

where yi is the value measured, and y is the mean value.

Following the orthogonal analysis method, Table 11 can

be obtained. Obviously, the divergence square sum of each

Materials & Design Volume 17 Number 3 1996 163

Table 11 Calculation results of five factors and two levels while

considering interaction

Factors MI

M2

ml m2 Ri

s,

A 1.283 1.153 0.160 0.144 0.130 0.0011

B 1.614 0.822 0.202 0.103 0.792 0.0392

AB 1.227 1.209 0.153 0.151 0.018 0.0000

C 1.175 1.236 0.147 0.155 0.061 0.0002

AC 1.279 1.157 0.160 0.145 0.122 0.0009

BC 1.246 1.190 0.156 0.149 0.056 00002

DE 1.241 1.189 0.156 0.149 0.058 0.0002

D 1.238 1.198 0.155 0.150 0.040 0.0001

AD 1.247 1.189 0.156 0.149 0.058 0.0002

BD 1.222 1.214 0.153 0.152 0.008 0.0000

CE 1.265 1.171 0.158 0.146 0.094 0.0006

CD 1.242 1.194 0.155 0.149 0.048 0.0001

BE 1.279 1.157 0.160 0.145 0.122 0.0009

AE 1.194 1.242 0.149 0.155 0.018 0.0001

E 1.205 1.231 0.151 0.154 0.026 o.oooo

factor is ranked as:

SB > SA > SAxC = SBxE > SCxE

That means that B, A, AxC, BxE, CxE are the key

factors. In other words, the laser cutting speed, laser power,

interactions between laser power and temperature, cutting

speed and rolling speed, temperature, and rolling speed are

the key factors affecting cutting width. Especially, the

divergence square sum of laser cutting speed is 36 times

larger than that of the laser power (see Table 11). Hence,

the cutting speed is the most significant factor.

The optimal experimental conditions can be determined

from Table 11. For B, A, AxC, BxE and CxE, the cutting

widths are narrower in the high level than that in the low

level. But for C and D, the cases are reverse. Taking into

account that the interactions of AxC, B xE and C xE are

larger than that of C and D, the following conditions are the

optimal experimental conditions:

Bz A2 (A x C>, (B x E)2 (C x El,

It could be simplified as:

B2 A2 C2 E2

Because of the little influence of the factor D, a lower

conditions is chosen; the final optimal experimental

conditions are:

A2 B2 C2 Dl E2

The mean value under the optimal experimental conditions

is:

p=y+&p- y + a2 + bz + cz + ez = 0.098

kcj

This means that if the optimal experimental conditions

are used, the laser cutting width will be 0.098 mm. It is

great to get such an accuracy. In such a case, the optimal

experimental conditions are: the laser power 30 W, the

cutting speed 80 mm/s, the temperature 14OC, the thermal

pressure -0.1 mm (compression distance in the z direc-

tion), and the rolling speed 88 mm/s.

Five factors, four levels experimental results and analysis

not considering interactions

The values of laser cutting width measured in the

experiments are as follows:

164 Materials & Design Volume 17 Number 3 1996

Processing accuracy for SSM process: Wanlong Wang et al.

yl = 0.230, y2 = 0.163, y3 = 0.138, y4 = 0.087,

y5 = 0.273, y6 = 0.223, y7 = 0.142, ys = 0.108,

Yg = 0.293, ylo = 0.222, yll = 0.190, y12 = 0.098,

~13 = 0.232, y14 = 0.263, yls = 0.130, y16 = 0.152.

Thus,

3 = gyi / 16 = 0.184

i=l

where yi is the value measured, and F is the mean value.The

values of Mii, mu, R and S are shown in Table 12.

Obviously, the ranking of S can be obtained from the

above table is

s2 > Sl > s3 > s5 > s4

that is, the sequence of the important factors is B, A, C, E,

D. This result is consistent with the case considering the

interaction effect.

From Table 12, the values of cutting width of Ai, Bq. C2,

Dz and El are the smallest under four levels. So, the

optimal processing conditions are A1B4CZDZE1, i.e. the

laser power 25 W, the cutting speed 80 mm/s, the

temperature 13oC, the thermal pressure 0.1 mm (compres-

sion distance in the z direction), and the rolling speed 40

mm/S.

By comparing the two kinds of analysis results, it is

found that the sequences of important factors are the same.

This means that the interaction effects should be taken into

account. The results of considering interaction effects are to

be used in the following calculation. The results of the

orthogonal experimental analysis show that the possibility

of process improvements is quite high.

Principle and analysis of the back-propagation

neural network

Artificial neural network (ANN) is a kind of non-linear

system that is composed of a large number of processing

neurons. It possesses abilities of learning, memory,

calculation and other intelligent processing functions, and

can also simulate the information processing, storing and

indexing abilities of a human brain at different degrees and

levels. It is widely used in information processing, pattern

recognition and function approximation.

At present, there are three kinds of methods in the ANN

studies. The fust is a network composed using physical

models, which includes Hopfield network based on non-

possibility neurons and Boltzmann machine (BM) model

based on possibility neurons. The second is developed from

Table 12 Calculation results of five factors and four levels without

considering interaction

Factors

Ml

M2

M3

M4

ml

A B C D E

m2

m3

0.618 1.208 0.795 0.733 0.690

0.746 0.871 0.664 0.693 0.750

0.803 0.600 0.802 0.785 0.691

0.777 0.445 0.683 0.733 0.813

0.1545 0.2570 0.1988 0.1833 0.1725

0.1865 0.2178 0.1660 0.1733 0.1875

0.2008 0.1508 0.2005 0.1963 0.1728

0.1943 0.1113 0.1708 0.1833 0.2033

0.185 0.588 0.138 0.092 0.123

0.00505 0.05167 0.00396 0.00107 0.00257

Processing accuracy for SSM process: Wanlong Wang et al.

the theory of auto-adaptive signal processing, and is best

known as forward multi-layer neural network and back

propagation algorithm (abbreviated as BP). The third is

composed using self-organisation methods, which includes

auto-adaptive resonance theory (ART) and self-organisa-

tion feature mirror network. From the system integrity point

of view, the first and second are better than the third, but for

simulating human recognition procedure and intelligent

processing, the third one is better than the remaining two.

From the maturity and application point of view, the second

one is better than the remaining two. In this work, the

second method, which is the BP network, is adopted.

Basic algorithm of BP network

The learning algorithm of a BP network is divided into

two stages. In the first stage (forward propagation), the data

is inputted, then the hidden layers process these data and

calculate the actual values of the outputs. If the outputs of

the final layer are not the expected ones, the second stage

(back propagation) calculates the differences (errors)

between the actual outputs and expected outputs for each

layer, then adjust the weight coefficients until the outputs

are satisfactory.

For a general case, assume that the network has L layers,

an N-dimension input vector, and an M-dimension output

vector, given P learning samples (+, yp),p = 1, 2, . . . , P.

The S function is adopted to demonstrate the characteris-

tics of the neurons. While the pth sample is the input, there

is:

ne& =

c

w! of-

I P

Ojp = f(ietjp)

Ep = i C(Yip - jjp)

I

(7)

(8)

(9)

where ~jp denotes the actual output of neuronj, and the total

error is:

E=&kEp

p=l

(10)

Define Sip = 3, then

IP

aEP _

aEp anetjp _ aEp

%----

-.

&etjp d W,:

o!- = 6 d-1

&etjp lp

ip @

(11)

(1) If the neuron j is the output unit, then

Of = jp

(y! _ aEP *P

.-

Jp &. &zetjp

(12)

=

-(rp - jpP) fYne$pL (: 1: 1 M-l (13)

> > . . . 7

(2) If the neuron j is the hidden layer neuron, then

where qp is theapput for the next layer (1+1). If it is

desirable to get &-, it is calculated back from the (1+1)

layer. Generally sp&king,

i

=

(16)

In the above equations, k is used to substitute for j so as to

avoid confusion.

In short, the BP network algorithm is summarised as

follows:

(1) Choose the initial values of weights. These could be

generated by random or by given.

(2) Repeat the following procedures until the results are

convergent.

a. From p = 1 to P

l For every neuron of each layer, calculate ($-and

ne$p,jp,l = 2,3, . . . ,L.

(the forward propagation procedure);

l For every neuron of each layer, calculate 6jp,

1 = L- 1, . . . ,2

(the back propagation procedure).

b. adjust weights by

wji = Wji - Pq

Input Data

Input Layer

Hidden Layer

One or Multi-layer

output Layer

Output Data

Figure 3 Figure 3

Materials & Design Volume 17 Number 3 1996 Materials & Design Volume 17 Number 3 1996 166 165

Processing accuracy for SSM process: Wanlong Wang et al.

Table 13 The weight coefficients of the BP network, Wi,

-0.362 -0.109

-0.589 -0.561

0.261 -0.343

0.166 0.207

0.016 -0.569

-0.203 -0.386

-0.361 0.511

-0.472 -0.286

-0.261 0.110

-0.115 0.556

0.265 -0.354

0.418 -0.452

-0.050 -0.645

0.026 -0.819

0.908 0.685

0.179 -0.643

0.320 0.349

0.449 -0.182

-0.582 0.122

-1.692 -0.670

-0.474 0.473 0.018

0.409 -0.454 -0.073

0.437 0.428 -0.054

-0.242 0.065 -0.423

0.266 0.176 0.079

-0.417 0.295 -0.115

0.115 -0.220 0.860

0.414 -0.438 -0.400

-0.137 0.091 0.651

0.468 -0.273 0.567

-0.039 -0.291 -0.761

0.375 -0.298 -1.260

-0.157 -0.123 -0.359

0.610 -0.126 -0.817

-0.292 -0.045 -0.211

0.135 0.648 0.549

0.090 -0.644 -0.129

0.252 0.398 -0.647

0.582 0.508 0.225

-0.727 -0.911 0.136

0.056

0.062

-0.039

-0.224

-0.429

-0.242

-0.176

0.013

0.316

-0.486

-0.342

0.259

0.073

0.810

-0.05 1

-0.008

-0.043

0.099

-0.069

dE 1

c

paEp

l?Wji = iF p=l aWji

l Synthesis of two analytical methods to determine the

sequence of key parameters affecting the accuracy and

build qualitative and quantitative relationships be-

tween the accuracy and process parameters.

The orthogonal experimental design is an effective

experimental design method, which could provide more

experimental information with limited number of experi-

ments. The analysis gives the ranking of the key factors, the

optimal processing conditions and the mean value. But it

cannot build quantitative relationships between the proces-

sing accuracy and processing parameters.

The advantage of the BP neural network is that it can

build the quantitative relationships within a complex

system. In the SSM process, it can build the quantitative

relationships between the processing accuracy and proces-

sing parameters. The two methods can be complementary

to each other. The integration of these two is, thereby, used

for this study.

This method has been proved useful in the design and

analysis of the in-plane processing accuracy for the SSM

process. It is also applicable to other RP processes for

experimental design and analysis.

where p is the adjusting coefficient in the above equation.

References

The BP network model for analysis of in-plane processing

accuracy

For the in-plane processing accuracy experiment, the input

vector has five elements: laser power, laser cutting speed,

temperature, thermal pressure and rolling speed. The output

vector has just one element, that is the cutting width.

Following the former equations, a program has been written

to solve this problem. As shown in Figure 3, the control

variables and results are: 5 input variables; 1 output

variable; 16 learning samples; the learning step n = 0.3; the

weight adjusting coefficient CY = 0.2; the total error is

0.0001; the maximum individual error is 0.00005; the

maximum repeating number is 3000; three hidden layers;

and the number of each layer are 5, 8 and 4.

The result shows that when the cycle number reaches

223 1, the algorithm is convergent. The weight coefficients

of the BP networks are shown in Table 13. There are a total

of 119 weight coefficients. It is noted that in each hidden

layer, one constant input is added so as to increase the

convergent speed.

Conclusions

A new integrated method for studying processing accuracy

has been presented. This method has the combined

advantages of the orthogonal experiment design and

artificial neural network, and possesses the following

characteristics:

l Minimum number of experiments (i.e. the lowest cost

and shortest time spent) to obtain the necessary

information for the experimental analysis.

l Limited experimental data to determine the optimal

process conditions and provide the theoretical and

experimental bases for process improvement.

1

2

3

4

5

6

7

8

9

10

11

Jacobs, P. E, Rapid Prototyping and Manufactaring: Fundamentals of

Stereolithography. 1st ed., Society of Manufacturing Engineers,

Dearborn, MI, 1992.

Bugeda, G., Cervera, M. et al., Numerical analysis of stereolitho-

graphy processes using the finite element method. Rapid Pmtptyping

Journal, 1995, Vol. 1, Iss. 2, pp 13-23, MCB University Press,

University of Nottingham, Nottingham, UK.

Wiedemamr, B., Dusel, K.-H. and Es&l, .I., Investigation into the

influence of material and process on part distortion. Rapid Pmtptyp-

ing Journal, 1995, Vol. 1, Iss. 3, pp 17-22, MCB University Press,

University of Nottingham, Nottingham, UK.

Lee, S. J. J., Sachs, E. and Cima, M., Layer position accuracy in

powder-based rapid prototyping. Rapid Pmtptyping Journal, 1995,

Vol. 1, Iss. 4, pp 24-37, MCB University Press, University of

Nottingham, Nottingham, UK.

Lu, J., Fuh, J. Y. H., Choo, Y. S., Nee, A. Y. C. and Lee, K. C.,

Material characterization of photo-fabrication process. Materials and

Manufacturing Processes, 1995, Vol. 10, No. 4, pp 653-666.

Chen, C. C. and Sullivan, P. A., Solving the mystery - the problem of

Z-height inaccuracy of the stereolithography parts. Proc. of the 6th

International Conference on Rapid Pmtotyping, eds Chartoff, R. P.

and Lightman, A. J., Dayton, OH, 1995, pp 153-170 .

Wang, W. L., Studies on unified manufacturing theory and slicing

solid manufacturing technology (in Chinese). PhD dissertation,

Department of Mechanical Engineering, Tsinghua University, Beijing,

P. R. China, 1995.

Ma, F. S. and He, L. C., Applied mathematics statistics (in Chinese).

Beijing University of Aeronautics and Astronautics Press, Beijing, P.

R. China, 1986.

Edited by Compilation Team of Mathmatical Handbook. Mathmatical

/u&boo&in Chinese). High Education Press, Beijing, P. R. China,

1979.

Yang, X. J. and Zheng, J. L., Artjcial neural network (in Chinese).

1st ed., High Education Press, Beijing, P. R. China, 1992.

Yan, P. H. and Huang, D. X., Artificial neural network - models,

analysis and application (in Chinese). Anhui Education Press, Anlmi,

P. R. China, 1993.

166 Materials & Design Volume 17 Number 3 1996

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- British Army Vehicles Equipment LKDocument35 paginiBritish Army Vehicles Equipment LKLIVE3ORDIEÎncă nu există evaluări

- Basic Electronics Tutorial PDFDocument21 paginiBasic Electronics Tutorial PDFMr HunterÎncă nu există evaluări

- 8TH Week Electromagnetic WaveDocument4 pagini8TH Week Electromagnetic WaveMira VeranoÎncă nu există evaluări

- User Manual - Raycus - Type IIIDocument22 paginiUser Manual - Raycus - Type IIIEnjoywork SomwangÎncă nu există evaluări

- DSS 2011 Exhibit Guide SONYDocument124 paginiDSS 2011 Exhibit Guide SONYvb_pol@yahooÎncă nu există evaluări

- Laser Wavelength ChartsDocument3 paginiLaser Wavelength Chartsm16 wolÎncă nu există evaluări

- PRF Geog Trimble 5503DR Manual enDocument112 paginiPRF Geog Trimble 5503DR Manual enRăducu Albu100% (1)

- HP 2600n Laser Scanner Mirror CleaningDocument6 paginiHP 2600n Laser Scanner Mirror CleaningJon Edwards100% (1)

- Ultrasonic MachiningDocument21 paginiUltrasonic MachiningMuhd Nur JihadÎncă nu există evaluări

- DVD615 PDFDocument228 paginiDVD615 PDFFreddy FerrerÎncă nu există evaluări

- 2 (16) Lyth United KingdomDocument13 pagini2 (16) Lyth United KingdomAshish KumarÎncă nu există evaluări

- TIPO-Q101-CA Manual Spanish PDFDocument42 paginiTIPO-Q101-CA Manual Spanish PDFAriel0% (1)

- XII Physics Chapter 8 - Electromagnetic Waves Saju HssliveDocument7 paginiXII Physics Chapter 8 - Electromagnetic Waves Saju HssliveVikash SharmaÎncă nu există evaluări

- Links To This File's Tables and Notes LithographyDocument28 paginiLinks To This File's Tables and Notes Lithographynasamohd17Încă nu există evaluări

- Duo Binary Modulation For Optical SystemsDocument10 paginiDuo Binary Modulation For Optical SystemsErasmo VizzaccaroÎncă nu există evaluări

- ICH Q1B - Pruebas de Estabilidad - FotoestabilidadDocument12 paginiICH Q1B - Pruebas de Estabilidad - FotoestabilidadEdgar Levi Plasencia CotrinaÎncă nu există evaluări

- 2017 Ncstar CatalogDocument144 pagini2017 Ncstar CatalogOld_RomadÎncă nu există evaluări

- Non Destructive Testing of Concrete StructuresDocument24 paginiNon Destructive Testing of Concrete StructuresThe Engineers EDGE, CoimbatoreÎncă nu există evaluări

- P C F I: Hotonic Rystal Iber NterfacingDocument11 paginiP C F I: Hotonic Rystal Iber NterfacingNadia F Mohammad Al-RoshdeeÎncă nu există evaluări

- Welding Training InspectionDocument46 paginiWelding Training InspectionAdhanom G.Încă nu există evaluări

- D. B. Macdougall, Formerly of The University of ReadingDocument6 paginiD. B. Macdougall, Formerly of The University of ReadingKarla VioletaÎncă nu există evaluări

- Lab 6 SpectrophotometerDocument11 paginiLab 6 SpectrophotometerChing Wai YongÎncă nu există evaluări

- Build A Simple Marx GeneratorDocument18 paginiBuild A Simple Marx Generatorjoao carlosÎncă nu există evaluări

- Research PapersDocument6 paginiResearch PapersJason BrownÎncă nu există evaluări

- 711 Sokkia Manualset130rDocument182 pagini711 Sokkia Manualset130rjose antonio carazoÎncă nu există evaluări

- Compact Optical Switches and Modulators Based On DDocument13 paginiCompact Optical Switches and Modulators Based On DJorge GuerreroÎncă nu există evaluări

- CUAS Infographic FINAL 012519 PrintDocument1 paginăCUAS Infographic FINAL 012519 PrintTsymetric GreyÎncă nu există evaluări

- © All Rights Reserved by Gateforum Educational Services Pvt. Ltd. No Part of This Booklet May Be Reproduced or Utilized in Any Form Without TheDocument18 pagini© All Rights Reserved by Gateforum Educational Services Pvt. Ltd. No Part of This Booklet May Be Reproduced or Utilized in Any Form Without Theakhtar_140Încă nu există evaluări

- Denon DVD1600Document117 paginiDenon DVD1600zombo8Încă nu există evaluări

- B.E R2016-Curriculum and SyllabusDocument149 paginiB.E R2016-Curriculum and SyllabusAjay Krishna R VÎncă nu există evaluări