Documente Academic

Documente Profesional

Documente Cultură

48-60cr Imo Tier II - Marine

Încărcat de

jonny8dTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

48-60cr Imo Tier II - Marine

Încărcat de

jonny8dDrepturi de autor:

Formate disponibile

48/60CR

Project Guide Marine

Four-stroke diesel engines

compliant with IMO Tier II

MAN Diesel & Turbo

86224 Augsburg, Germany

Phone +49 821 322-0

Fax +49 821 322-3382

marineengines-de@mandieselturbo.com

www.mandieselturbo.com

C

o

p

y

r

i

g

h

t

M

A

N

D

i

e

s

e

l

&

T

u

r

b

o

S

u

b

j

e

c

t

t

o

m

o

d

i

f

i

c

a

t

i

o

n

i

n

t

h

e

i

n

t

e

r

e

s

t

o

f

t

e

c

h

n

i

c

a

l

p

r

o

g

r

e

s

s

.

D

2

3

6

6

4

7

2

E

N

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

G

M

C

-

A

U

G

-

0

2

1

1

0

.

5

falzen falzen

4

8

/

6

0

C

R

P

r

o

j

e

c

t

G

u

i

d

e

M

a

r

i

n

e

F

o

u

r

-

s

t

r

o

k

e

d

i

e

s

e

l

e

n

g

i

n

e

s

c

o

m

p

l

i

a

n

t

w

i

t

h

I

M

O

T

i

e

r

I

I

falzen falzen

PJG_48_60CR_25mm_Ruecken.indd U4 03.02.2011 14:15:20

T

i

t

e

l

s

e

i

t

e

M

a

r

i

n

e

4

8

-

6

0

M

D

c

r

.

f

m

48/60CR

Project Guide Marine

Four-stroke diesel engines

compliant with IMO Tier II

Status Version Checked Date Checked Date

05.2011 2.13 Franz 2011-05-10 Utjesinovic 2011-05-10

T

i

t

e

l

s

e

i

t

e

M

a

r

i

n

e

4

8

-

6

0

M

D

c

r

.

f

m

All data provided in this document is non-binding. This data serves informational purposes only and is

especially not guaranteed in any way.

Depending on the subsequent specific individual projects, the relevant data may be subject to changes

and will be assessed and determined individually for each project. This will depend on the particular

characteristics of each individual project, especially specific site and operational conditions.

If this document is delivered in another language than English and doubts arise concerning the transla-

tion, the English text shall prevail.

For latest updates on Project Guides, visit our website www.mandieselturbo.com:

"Products Marine Engines & Systems Medium speed Project Guides".

In addition, please always contact MAN Diesel & Turbo at early project stage to ensure that the latest

information is transferred and the latest status of project tools is used.

MAN Diesel & Turbo

86224 Augsburg, Germany

Phone +49 821 322-0

Fax +49 821 322-3382

marineengines-de@mandieselturbo.com

www.mandieselturbo.com

MAN Diesel & Turbo

Reproduction permitted provided source is given.

48/60CR Page 1 - 1

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

Table of contents

1 lntroduction........................................................................ 1 - 1

1.1 Four stroke diesel engine programme for marine................................................ 1 - 3

1.2 Engine description 48/60CR lMO Tier ll .............................................................. 1 - 5

1.3 Overview 48/60CR............................................................................................... 1 - 9

1.4 Typical marine plants and engine arrangements ............................................... 1 - 13

2 Engine and operation ......................................................... 2 - 1

2.1 Engine design ...................................................................................................... 2 - 3

2.1.1 Engine cross section ........................................................................................... 2 - 3

2.1.2 Engine designations - Design parameters .......................................................... 2 - 5

2.1.3 Engine main dimensions, weights and views ...................................................... 2 - 7

2.1.4 Engine inclination................................................................................................. 2 - 9

2.1.5 Engine equipment for various applications ....................................................... 2 - 11

2.1.6 Engine equipment for various applications - General description.................... 2 - 13

2.2 Ratings (outputj and speeds.............................................................................. 2 - 17

2.2.1 Standard engine ratings .................................................................................... 2 - 17

2.2.2 Engine ratings (outputj for different applications............................................... 2 - 19

2.2.3 Engine speeds and related main data .............................................................. 2 - 23

2.2.4 Speed adjusting range....................................................................................... 2 - 25

2.3 Engine operation under arctic conditions .......................................................... 2 - 27

2.4 Low load operation ............................................................................................ 2 - 31

2.5 Propeller operation, suction dredger (pump drivej ............................................ 2 - 33

2.5.1 Operating range for controllable-pitch propeller ............................................... 2 - 33

2.5.2 General requirements for propeller pitch control .............................................. 2 - 35

2.5.3 Operating range for dredge pumps................................................................... 2 - 39

2.5.4 Acceleration times ............................................................................................. 2 - 41

2.6 Diesel-electric operation.................................................................................... 2 - 45

2.6.1 Operating range for diesel-electric operation.................................................... 2 - 45

2.6.2 Starting conditions and load application for diesel-electric plants ................... 2 - 47

2.6.3 Load application - Preheated engine................................................................ 2 - 51

2.6.4 Load application - Cold engine (only emergency casej .................................... 2 - 54

2.6.5 Available outputs and permissible frequency deviations .................................. 2 - 59

2.6.6 Load reduction................................................................................................... 2 - 61

Page 1 - 2 48/60CR

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

2.6.7 Diesel-electric operation of vessels - Failure of one engine ............................. 2 - 63

2.6.8 Alternator - Reverse power protection.............................................................. 2 - 65

2.6.9 Earthing of diesel engines and bearing insulation on alternators...................... 2 - 67

2.7 Fuel oil; lube oil; starting air/control air consumption........................................ 2 - 69

2.7.1 Fuel oil consumption for emission standard lMO Tier ll .................................... 2 - 69

2.7.2 Lube oil consumption........................................................................................ 2 - 71

2.7.3 Starting air/control air consumption.................................................................. 2 - 72

2.7.4 Calculation of fuel consumption at site ............................................................. 2 - 73

2.7.5 Aging.................................................................................................................. 2 - 75

2.8 Planning data for emission standard: lMO Tier ll............................................... 2 - 77

2.8.1 Nominal values for cooler specification - L48/60CR......................................... 2 - 78

2.8.2 Temperature basis, nominal air and exhaust gas data - L48/60CR.................. 2 - 80

2.8.3 Nominal values for cooler specification - v48/60CR ........................................ 2 - 81

2.8.4 Temperature basis, nominal air and exhaust gas data - v48/60CR ................. 2 - 83

2.8.5 Load specific values at tropical conditions - 48/60CR..................................... 2 - 84

2.8.6 Load specific values at lSO-conditions - 48/60CR........................................... 2 - 85

2.8.7 Filling volumes and flow resistances ................................................................ 2 - 86

2.8.8 Operating/service temperatures and pressures ................................................ 2 - 87

2.8.9 venting amount of crankcase and turbocharger ............................................... 2 - 91

2.9 Exhaust gas emission ........................................................................................ 2 - 93

2.9.1 Maximum allowed emission value NO

x

lMO Tier ll ........................................... 2 - 93

2.9.2 Exhaust gas components of medium speed four-stroke diesel engines .......... 2 - 95

2.10 Noise.................................................................................................................. 2 - 97

2.10.1 Engine noise ...................................................................................................... 2 - 97

2.10.2 lntake noise ....................................................................................................... 2 - 99

2.10.3 Exhaust gas noise............................................................................................ 2 - 101

2.11 vibration........................................................................................................... 2 - 103

2.11.1 Torsional vibrations ......................................................................................... 2 - 103

2.12 Requirements for power drive connection (staticj ........................................... 2 - 107

2.13 Requirements for power drive connection (dynamicj ...................................... 2 - 109

2.13.1 Moments of inertia - Engine, damper, flywheel............................................... 2 - 109

2.13.2 Balancing of masses - Firing order ................................................................. 2 - 111

2.13.3 Static torque fluctuation .................................................................................. 2 - 115

2.14 Power transmission.......................................................................................... 2 - 119

2.14.1 Flywheel arrangement ..................................................................................... 2 - 119

2.15 Arrangement of attached pumps..................................................................... 2 - 123

48/60CR Page 1 - 3

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

2.16 Foundation....................................................................................................... 2 - 125

2.16.1 General requirements for engine foundation................................................... 2 - 125

2.16.2 Rigid seating.................................................................................................... 2 - 127

2.16.3 Chocking with synthetic resin.......................................................................... 2 - 135

2.16.4 Resilient seating.............................................................................................. 2 - 141

2.16.5 Recommended configuration of foundation.................................................... 2 - 143

2.16.6 Engine alignment ............................................................................................. 2 - 153

3 Engine automation ............................................................. 3 - 1

3.1 SaCoS

one

system overview ................................................................................. 3 - 3

3.2 Power supply and distribution ............................................................................. 3 - 9

3.3 Operation ........................................................................................................... 3 - 11

3.4 Functionality....................................................................................................... 3 - 13

3.5 lnterfaces ........................................................................................................... 3 - 17

3.6 Technical data.................................................................................................... 3 - 19

3.7 lnstallation requirements.................................................................................... 3 - 21

3.8 Engine-located measuring and control devices................................................. 3 - 23

4 Specification for engine supplies ....................................... 4 - 1

4.1 Explanatory notes for operating supplies ............................................................ 4 - 3

4.1.1 lntake air .............................................................................................................. 4 - 3

4.1.2 Fuel ...................................................................................................................... 4 - 3

4.1.3 Engine cooling water ........................................................................................... 4 - 4

4.1.4 Lubricating oil ...................................................................................................... 4 - 4

4.2 Specification for lubricating oil (SAE 40j for operation with marine gas oil,

diesel oil (MGO/MDOj and bio-fuels .................................................................... 4 - 5

4.3 Specification for lubricating oil (SAE 40j for operation on heavy fuel oil (HFOj.. 4 - 11

4.4 Specification for gas oil/diesel oil (MGOj ........................................................... 4 - 17

4.5 Specification for bio-fuel .................................................................................... 4 - 19

4.6 Specification for marine diesel oil (MDOj ........................................................... 4 - 21

4.7 Specification for heavy fuel oil (HFOj ................................................................. 4 - 23

4.8 viscosity-temperature diagram (vT diagramj..................................................... 4 - 35

Page 1 - 4 48/60CR

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

4.9 Specification for engine cooling water............................................................... 4 - 37

4.10 Cooling water inspecting ................................................................................... 4 - 45

4.11 Cooling water system cleaning.......................................................................... 4 - 47

4.12 Specification for intake air (combustion airj....................................................... 4 - 49

5 Engine supply systems....................................................... 5 - 1

5.1 Basic principles for pipe selection....................................................................... 5 - 3

5.1.1 Engine pipe connections and dimensions........................................................... 5 - 3

5.1.2 lnstallation of flexible pipe connections for resiliently mounted engines ............ 5 - 5

5.1.3 Condensate amount .......................................................................................... 5 - 11

5.2 Lube oil system.................................................................................................. 5 - 15

5.2.1 Lube oil system diagram ................................................................................... 5 - 15

5.2.2 Lube oil system description............................................................................... 5 - 19

5.2.3 Prelubrication/postlubrication ........................................................................... 5 - 29

5.2.4 Lube oil outlets .................................................................................................. 5 - 31

5.2.5 Lube oil service tank.......................................................................................... 5 - 35

5.2.6 Pressure control valve ....................................................................................... 5 - 39

5.2.7 Lube oil automatic filter ..................................................................................... 5 - 41

5.2.8 Lube oil double filter .......................................................................................... 5 - 42

5.2.9 Crankcase vent and tank vent ........................................................................... 5 - 43

5.3 Water systems ................................................................................................... 5 - 45

5.3.1 Cooling water system diagram.......................................................................... 5 - 45

5.3.2 Cooling water system description..................................................................... 5 - 51

5.3.3 Advanced HT cooling water system for increased fresh water

generation.......................................................................................................... 5 - 57

5.3.4 Cooling water collecting and supply system..................................................... 5 - 61

5.3.5 Miscellaneous items .......................................................................................... 5 - 63

5.3.6 Cleaning of charge air cooler (built-in conditionj by a ultrasonic device........... 5 - 65

5.3.7 Turbine washing device, HFO-operation........................................................... 5 - 67

5.3.8 Nozzle cooling system and diagram.................................................................. 5 - 69

5.3.9 Nozzle cooling water module ............................................................................ 5 - 73

5.3.10 Preheating module............................................................................................. 5 - 77

5.4 Fuel oil system................................................................................................... 5 - 79

5.4.1 Marine diesel oil (MDOj treatment system......................................................... 5 - 79

5.4.2 Marine diesel oil (MDOj supply system for diesel engines ................................ 5 - 81

5.4.3 Heavy fuel oil (HFOj treatment system.............................................................. 5 - 85

5.4.4 Heavy fuel oil (HFOj supply system................................................................... 5 - 89

5.4.5 Fuel supply at black out conditions................................................................. 5 - 103

48/60CR Page 1 - 5

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

5.5 Compressed air system................................................................................... 5 - 105

5.5.1 Starting air system........................................................................................... 5 - 105

5.5.2 Starting air vessels, compressors ................................................................... 5 - 111

5.5.3 Jet Assist ......................................................................................................... 5 - 115

5.6 Engine room ventilation and combustion air ................................................... 5 - 117

5.7 Exhaust gas system......................................................................................... 5 - 119

5.7.1 General information ......................................................................................... 5 - 119

5.7.2 Components and assemblies.......................................................................... 5 - 121

6 Engine room planning ........................................................ 6 - 1

6.1 lnstallation and arrangement ............................................................................... 6 - 3

6.1.1 General details..................................................................................................... 6 - 3

6.1.2 lnstallation drawings............................................................................................ 6 - 5

6.1.3 Removal dimensions of piston and cylinder liner .............................................. 6 - 13

6.1.4 3D Engine viewer-

A support programme to configure the engine room........................................ 6 - 17

6.1.5 Comparison of engine arrangements ................................................................ 6 - 23

6.1.6 Lifting appliance ................................................................................................ 6 - 25

6.1.7 Major spare parts............................................................................................... 6 - 29

6.1.8 Arrangement of diesel-electric propulsion plants............................................. 6 - 33

6.2 Exhaust gas ducting .......................................................................................... 6 - 37

6.2.1 Example: Ducting arrangement ......................................................................... 6 - 37

6.2.2 Position of the outlet casing of the turbocharger .............................................. 6 - 39

7 Propulsion packages.......................................................... 7 - 1

7.1 General................................................................................................................. 7 - 3

7.2 Dimensions .......................................................................................................... 7 - 5

7.3 Propeller layout data............................................................................................ 7 - 9

7.4 Propeller clearance ............................................................................................ 7 - 11

Page 1 - 6 48/60CR

M

a

r

i

n

e

_

4

8

-

6

0

C

R

_

e

x

t

e

r

n

a

l

_

T

i

e

r

-

l

l

l

v

Z

.

f

m

8 Diesel-electric propulsion plants........................................ 8 - 1

8.1 Diesel-electric propulsion plants.......................................................................... 8 - 3

8.1.1 Advantages of diesel-electric propulsion ............................................................ 8 - 3

8.1.2 Efficiencies in diesel-electric plants..................................................................... 8 - 4

8.1.3 Components of a diesel-electric propulsion plant............................................... 8 - 5

8.1.4 Diesel-electric plant design ................................................................................. 8 - 7

8.1.5 Engine selection .................................................................................................. 8 - 8

8.1.6 E-plant, switchboard and alternator design ........................................................ 8 - 9

8.1.7 Over-torque capability....................................................................................... 8 - 12

8.1.8 Protection of the electric plant .......................................................................... 8 - 13

8.1.9 Drive control ...................................................................................................... 8 - 14

8.1.10 Power management........................................................................................... 8 - 15

8.1.11 Example configurations of diesel-electric propulsion plants............................. 8 - 19

9 Annex ................................................................................. 9 - 1

9.1 Safety instructions and necessary safety measures............................................ 9 - 3

9.1.1 General ................................................................................................................ 9 - 3

9.1.2 Safety equipment/measures provided by plant-side .......................................... 9 - 4

9.2 Programme for Factory Acceptance Test (FATj .................................................. 9 - 7

9.3 Engine running-in................................................................................................. 9 - 9

9.4 Definitions .......................................................................................................... 9 - 13

9.5 Symbols ............................................................................................................. 9 - 19

9.6 Preservation, packaging, storage ...................................................................... 9 - 23

9.6.1 General information ........................................................................................... 9 - 23

9.6.2 Storage location and duration ........................................................................... 9 - 24

9.6.3 Follow-up preservation when preservation period is exceeded........................ 9 - 25

9.6.4 Removal of corrosion protection ....................................................................... 9 - 25

9.7 Engine colour ..................................................................................................... 9 - 27

9.8 Form................................................................................................................... 9 - 31

9.8.1 Diesel-electric plant layout data ........................................................................ 9 - 31

9.8.2 Propeller layout data.......................................................................................... 9 - 37

lndex......................................................................................... l

Page 1 - 1

K

a

p

i

t

e

l

t

i

t

e

l

1

M

2

.

f

m

1 lntroduction

Page 1 - 2

K

a

p

i

t

e

l

t

i

t

e

l

1

M

2

.

f

m

lntroduction

1.1 Four stroke diesel engine programme for marine

C-BB Page 1 - 3

0

1

0

1

-

0

0

0

0

M

A

l

l

2

.

f

m

1.1 Four stroke diesel engine programme for marine

Application complies with lMO Tier ll

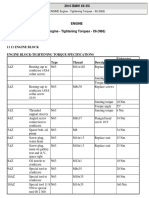

Figure 1-1 MAN Diesel & Turbo engine programme

MAN Medium Speed Propulsion Engines

400-428 L58/64

500-514 L51/60DF V51/60DF

500-514 L48/60CR V48/60CR

500-514 L48/60B V48/60B

720-750 L32/44CR V32/44CR

720-750 L32/40 V32/40

1000-

1032

V28/33D*

1000-

1032

V28/33D STC*

800

L27/38

L27/38 (MGO)

1000 L21/31

0 5,000 10,000 15,000 20,000 25,000

r/min

kW

Engine type

* The engine complies with EPA Tier 2.

lntroduction

1.1 Four stroke diesel engine programme for marine

Page 1 - 4 C-BB

0

1

0

1

-

0

0

0

0

M

A

l

l

2

.

f

m

lntroduction

1.2 Engine description 48/60CR lMO Tier ll

A-BB 48/60CR Page 1 - 5

0

1

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

1.2 Engine description 48/60CR lMO Tier ll

General

With the 48/60CR (Common Railj, MAN Diesel &

Turbo is embarking on a new era in modern die-

sel engine design. Based on the more than

600-fold well proven 48/60 engine, the 48/60CR

was developed for use as a propulsion engine in

cruise liners, tankers or container ships. By the

use of electronic injection, variable valve Timing,

improved turbocharger and by improved com-

bustion, increasingly stringent emission stand-

ards can be fulfilled and improved part load

performance (smoke, SFOCj can be obtained

without compromising on the engines high avail-

ability and specific power output. The 48/60CR

thereby sets the new standard in this engine

class and is therefore a true prime mover" in

every respect.

Fuels

The common rail injection system of the

48/60CR was designed for operation with heavy

fuel oil (HFOj in accordance with specification

DlN lSO 8217 (viscosities up to 700 cSt at 50 Cj

and fuel temperatures up to 150 C. The fuel oil

system is designed to allow the engine to be

started and stopped with HFO. Of course, the

engine can operate marine diesel oil (MDOj and

marine gas oil too. ln accordance with

DlN lSO 8217, minimal viscosity is limited to

2 cSt at 40 C. Special attention was directed

during development on the reliable functionality

of all components during operation with all ap-

proved fuel qualities.

lnjection

The principal advantage of common rail injec-

tion is the flexibility gained by separating pres-

sure generation and injection control.

MAN Diesel & Turbo has kept its common rail

technology as simple as possible. For example,

there is no separate servo circuit to activate the

injection valves. Conventional pressure control-

led injectors are used and solenoid valves are in-

tegrated into the rail units away from the heat of

the cylinder heads, resulting in greater system

reliability and easy maintenance.

The common rail system is released for ships

with single propulsion systems.

Modular division of the rail units and their as-

signment to individual cylinder units reduces

material costs and assembly effort and allows

for short lengths of high-pressure injection

pipes.

Features and advantages

As a matter of principle, MAN Diesel & Turbo has

kept the basic concept of its Common Rail Tech-

nology as simple as possible and has integrated

technically proven components into the design.

For example, in keeping with this philosophy, the

design does not use a separate servo circuit for

activating the injection valve. Less maintenance

is one of the benefits as well as extremely quick

and accurate reaction times of the injection sys-

tem. The electronically controlled injection

valves are on the rail outside the cylinder head,

resulting in greater system reliability and easy

maintainability. Also, integrated into the com-

mon rail technology are well-proven compo-

nents with long service experience, such as

conventional injection nozzles.

With the 48/60CR it has been possible to com-

bine conflicting development specifications like

"high power density" and "low emissions" with

"low wear" in a revolutionary way. The engine

represents the newest technology in the area of

medium speed operated industrial sized diesel

engines. Engine technology that is ready for the

future.

lntroduction

1.2 Engine description 48/60CR lMO Tier ll

Page 1 - 6 48/60CR A-BB

0

1

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Electronics

The 48/60CR is equipped with the well proven

Safety and Control System (SaCoS

one

j. As an

in-house development it is best adapted to MAN

Diesel & Turbo engines. SaCoS

one

combines all

functions of a modern engine management sys-

tem within one complete system. SaCoS

one

of-

fers:

lntegrated self-diagnosis functions

Maximum reliability and availability

Simple use and diagnosis

Quick exchange of modules (plug inj

Trouble-free and time-saving commissioning

Safety concept

Safety in design and operation is one of the

most important considerations, especially for

marine engines. To ensure that all possible fail-

ures are covered by the common rail safety con-

cept, MAN Diesel & Turbo has completed an

extensive failure mode and effects analysis

(FMEAj process.

lnjectors are only pressurized during injection

No danger of uncontrolled injection, even if a

control valve or injection valve leaks.

High-pressure components are double-

walled

No danger of fuel escaping in case of leaking

or broken pipes.

Flow-limiting valves for each cylinder

No danger of excessive injection quantity,

even in case of leaking or broken compo-

nents.

Two to four high-pressure pumps

Should one pump fail, emergency

operation is possible.

Pressure-limiting valve with additional pres-

sure-controlfunction/safety valve

Emergency operation possible, even in case

of any failure in rail pressure control.

Emergency stop valve/flushing valve

The valve, actuated by compressed air, stops

the engine in case of emergency.

Redundant rail-pressure sensors and TDC

speed pick-ups

No interruption of engine operation neces-

sary due to pick-up or sensor error.

NO

x

Reduction Measures 48/60CR

Rl - Retarded lnjection

Retarded injection timing delays combustion

heat release and thus lowers combustion cham-

ber temperature peaks.

New Piston for lncreased Compression Ratio

The use of a new piston provides a higher com-

pression ratio and gives a faster reduction in

temperature after the ignition of the fuel, thus re-

ducing NOx formation. The increase in com-

pression ratio also compensates the reduction

in firing temperature due to retarded injection

and hence the associated increase in SFOC.

vvT variable valve Timing

variable valve Timing enables variations in the

opening and closing of the inlet and exhaust

valves. lt can be used to compensate the in-

crease in SFOC associated with lower NOx

emissions.

vvT is an enabling technology of variable Miller

valve timing. A strong Miller effect under high

load operation results in an improvement in the

NOx-SFOC trade-off.

At low load the Miller valve timings are reduced

to attain higher combustion temperatures and

thus lower soot emissions.

Miller valve Timing

To reduce the temperature peaks which promote

the formation of NOx, early closure of the inlet

valve causes the charge air to expand and cool

before start of compression. The resulting re-

duction in combustion temperature reduces

NOx emissions.

lntroduction

1.2 Engine description 48/60CR lMO Tier ll

A-BB 48/60CR Page 1 - 7

0

1

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

High Pressure Ratio Turbocharger

The use of MAN Diesel & Turbo turbochargers

equipped with the latest high efficiency com-

pressor wheels can alleviate the NOx-SFOC

trade off. The higher pressure ratio increases the

efficiency of the engine and thus compensates

the increase in SFOC normally associated with

lower NOx emissions.

The higher pressure ratio also increases the

scope for Miller valve timing.

Common rail injection

Engines equipped with this common rail tech-

nology, and thus an optimised combustion proc-

ess, are also sure to meet more stringent

emission regulations (lMO, World Bankj that

may be imposed in

future. The design ensures that smoke emis-

sions from the funnel stay below the visibility

limit.

lntroduction

1.2 Engine description 48/60CR lMO Tier ll

Page 1 - 8 48/60CR A-BB

0

1

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

lntroduction

1.3 Overview 48/60CR

A-BB 48/60CR Page 1 - 9

0

1

0

3

-

0

0

0

0

M

D

c

r

l

l

.

f

m

1.3 Overview 48/60CR

Figure 1-2 Overview L48/60CR

Legend

Connection point generally

3

HT pump

1

Fuel inlet

4

HT water outlet

2

LT pump

5

Exhaust heat shield

lntroduction

1.3 Overview 48/60CR

Page 1 - 10 48/60CR A-BB

0

1

0

3

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Figure 1-3 Overview L48/60CR

Legend

Connection point generally

2

Air filter

1

Turbocharger exhaust outlet

3

Air cooler

lntroduction

1.3 Overview 48/60CR

A-BB 48/60CR Page 1 - 11

0

1

0

3

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Figure 1-4 Overview v48/60CR

Legend

Connection point generally

2

HT pump

1

Exhaust heat shield

lntroduction

1.3 Overview 48/60CR

Page 1 - 12 48/60CR A-BB

0

1

0

3

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Figure 1-5 Overview v48/60CR

Legend

Connection point generally

4

Air cooler

1

HT water outlet

5

Air filter

2

LT water outlet

6

Tappet cover

3

Turbocharger exhaust outlet

Introduction

1.4 Typical marine plants and engine arrangements

E-BB 48/60B, 48/60CR Page 1 - 13

0

1

0

4

-

0

0

0

0

M

D

A

2

.

f

m

1.4 Typical marine plants and engine arrangements

Figure 1-6 Engine room arrangement: multi purpose and container ships

Figure 1-7 Special carrier: propelled by 2 x 9L48/60, total output 18,900 kW

Introduction

1.4 Typical marine plants and engine arrangements

Page 1 - 14 48/60B, 48/60CR E-BB

0

1

0

4

-

0

0

0

0

M

D

A

2

.

f

m

Figure 1-8 Ferries: propellered by 4 x 8L48/60, total output 38,400 kW

Figure 1-9 Cruising vessel: Diesel-electric propulsion plant with 4 x 14V48/60, total output 58.8 MW

Introduction

1.4 Typical marine plants and engine arrangements

E-BB 48/60B, 48/60CR Page 1 - 15

0

1

0

4

-

0

0

0

0

M

D

A

2

.

f

m

Figure 1-10 Dredge: propelled by 2 x 7L48/60, total output 11.6 MW

Introduction

1.4 Typical marine plants and engine arrangements

Page 1 - 16 48/60B, 48/60CR E-BB

0

1

0

4

-

0

0

0

0

M

D

A

2

.

f

m

Page 2 - 1

K

a

p

i

t

e

l

t

i

t

e

l

2

M

2

.

f

m

2 Engine and operation

Page 2 - 2

K

a

p

i

t

e

l

t

i

t

e

l

2

M

2

.

f

m

Engine and operation

2.1.1 Engine cross section

A-BB 48/60CR Page 2 - 3

0

2

0

1

-

0

0

0

0

M

D

c

r

l

l

.

f

m

2.1 Engine design

2.1.1 Engine cross section

Figure 2-1 Cross section - Engine L48/60CR; view on counter coupling side

Engine and operation

2.1.1 Engine cross section

Page 2 - 4 48/60CR A-BB

0

2

0

1

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Figure 2-2 Cross section - Engine v48/60CR

Engine and operation

2.1.2 Engine designations - Design parameters

A-BB 48/60CR Page 2 - 5

0

2

0

1

-

0

2

0

0

M

D

c

r

l

l

.

f

m

2.1.2 Engine designations - Design parameters

Engine 48/60CR

Example to declare engine designations

18v48/60CR

Piston stroke [cm|

Cylinder bore [cm|

v=vee engine, L= in-line engine

Cylinder number

Design index

Parameter Abbreviations Unit

Number of cylinders 6, 7, 8, 9,

12, 14, 16, 18

-

ln-line engine L

vee engine v

Cylinder bore 48

cm

Piston stroke 60

Table 2-1 Designations engine - 48/60CR

Parameter value Unit

Cylinder bore 480

mm

Piston stroke 600

Swept volume of each cylinder 108.6 dm

3

Compression ratio 1200 kW/cyl. marine plants 16.0 -

Distance between cylinder centres L = 820

mm

Distance between cylinder centres v = 1,000

vee engine, vee angle 50

Crankshaft diameter at journal, in-line engine L = 415

mm Crankshaft diameter at journal, vee engine v = 480

Crankshaft diameter at crank pin 415

Table 2-2 Design parameters engine - 48/60CR

Engine and operation

2.1.2 Engine designations - Design parameters

Page 2 - 6 48/60CR A-BB

0

2

0

1

-

0

2

0

0

M

D

c

r

l

l

.

f

m

Engine and operation

2.1.3 Engine main dimensions, weights and views

A-BB 48/60CR Page 2 - 7

0

2

0

1

-

0

3

0

0

M

D

c

r

l

l

.

f

m

2.1.3 Engine main dimensions, weights and views

Engine L48/60CR

Figure 2-3 Main dimensions - Engine L48/60CR

Minimum centreline distance for twin engine installation: 3,200 mm L-engine

Flywheel data, see "Section 2.13.1: Moments of

inertia - Engine, damper, flywheel, page 2-109"

Legend

Engine Length L Length L1 Width W Weight without fly-

wheel

mm tons

6L48/60CR 8,615 7,455

3,195

106

7L48/60CR 9,435 8,275 119

8L48/60CR 10,460 9,095

3,325

135

9L48/60CR 11,425 9,915 148

The dimensions and weights are given for guidance only.

Engine and operation

2.1.3 Engine main dimensions, weights and views

Page 2 - 8 48/60CR A-BB

0

2

0

1

-

0

3

0

0

M

D

c

r

l

l

.

f

m

Engine v48/60CR

Figure 2-4 Main dimensions - Engine v48/60CR

Minimum centreline distance for twin engine installation: 4,800 mm v-engine

Flywheel data, see "Section 2.13.1: Moments of

inertia - Engine, damper, flywheel, page 2-109".

Legend

Engine Length L Length L1 Weight without flywheel

mm tons

12v48/60CR 10,760 9,088 189

14v48/60CR 11,760 10,088 213

16v48/60CR 13,100 11,088 240

18v48/60CR 14,100 12,088 265

The dimensions and weights are given for guidance only.

Engine and operation

2.1.4 Engine inclination

E-BB Page 2 - 9

0

2

0

1

-

0

4

0

0

M

A

2

.

f

m

2.1.4 Engine inclination

Figure 2-5 Angle of inclination

Note!

For higher requirements contact MAN Diesel & Turbo. Arrange engines always lengthwise of the

ship!

Legend

o

Athwartships

|

Fore and aft

Max. permissible angle of inclination [|

1j

1j

Athwartships and fore and aft inclinations may occur simultaneously.

Application Athwartships o Fore and aft |

Heel to each

side (staticj

Rolling to each

side (dynamicj

Trim (staticj

2j

2j

Depending on length L of the ship.

Pitching

(dynamicj

L < 100 m L > 100 m

Main engines 15 22.5 5 500/L 7.5

Table 2-3 lnclinations

E

D

D

E

Engine and operation

2.1.4 Engine inclination

Page 2 - 10 E-BB

0

2

0

1

-

0

4

0

0

M

A

2

.

f

m

Engine and operation

2.1.5 Engine equipment for various applications

D-BD 48/60CR Page 2 - 11

0

2

0

4

-

0

0

0

0

M

D

c

r

I

I

.

f

m

2.1.5 Engine equipment for various applications

Device/measure Ship Stationary

engines

Propeller

Diesel-

mechanic

Diesel-

electric

Charge air blow-off for firing pressure limitation Order-related, if intake air temp. 5C

Charge air blow-off for firing pressure limitation and

exhaust gas temperature control

Order-related, for plants with catalyst converter

Charge air by-pass X - (X

1)

)

1)

Required for engine 48/60CR Generator operation, enviro version.

-

Two-stage charge air cooler X X X

Charge air preheating by HT-LT switching O (X

2)

)

2)

Required if after first start the still cold engine should run at partial load without increased smoke emission.

O (X

2)

) O (X

2)

)

Charge air preheating by LT shut-off X X X

CHATCO (charge air temperature control) X X X

VIT (Variable Injection timing) Not applicable for common rail engines

VVT (Variable Valve Timing) X X X

Jet Assist (accelerating the turbocharger) O (X

3)

)

3)

Required if special demands exist regarding fast acceleration and fast load application without increased soot emission.

X X

Slow turn O X O (X

4)

)

4)

Required for plants with power management system demanding automatic engine start.

Oil mist detector O O O

Splash oil monitoring X X X

Main bearing temperature monitoring X X X

Attached HT cooling water pump O O O

Attached LT cooling water pump O O O

Attached lubrication oil pump O O O

X = required, O = optional

Table 2-4 Engine equipment

Engine and operation

2.1.5 Engine equipment for various applications

Page 2 - 12 48/60CR D-BB

0

2

0

4

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Engine and operation

2.1.6 Engine equipment for various applications - General description

D-BB Page 2 - 13

0

8

0

4

-

0

0

0

0

A

A

2

.

f

m

2.1.6 Engine equipment for various applications - General description

Charge air blow-off for firing pressure limitation

lf engines are operated at full load at low intake

temperature, the high air density leads to the

danger of excessive charge air pressure and,

consequently, much too high ignition pressure.

ln order to avoid such conditions, part of the

charge air is withdrawn upstream or down-

stream of the charge air cooler and blown off

into the engine room. This is achieved by means

of an electro-pneumatically controlled flap or a

spring-loaded valve.

Charge air blow-off device for firing pressure

limitation and exhaust gas temperature control

after turbine

For plants with an SCR catalyst, downstream of

the turbine, a minimum exhaust gas temperature

upstream of the SCR catalyst is necessary in or-

der to ensure its proper performance.

This minimum exhaust gas temperature de-

pends on the type and design of the SCR cata-

lyst and is fixed by its manufacturer. ln case the

temperature downstream of the turbine falls be-

low the set minimum exhaust gas temperature,

a flap provided on the engine is opened gradu-

ally in order to blow off the charge air until the

exhaust gas temperature downstream of the en-

gine (and thus upstream of the SCR catalystj has

reached the required level.

Charge air by-pass

The charge air pipe is connected to the exhaust

pipe via a reduced diameter pipe and a by-pass

flap. The flap is closed in normal operation.

Mainly in propeller operation between 25 and

60 % engine load (above cross-over pointj the

charge air by-pass is opened, so that the turbo-

charger is operated at a higher air flow with high-

er efficiency. The resultant increased charge air

pressure with improved scavenging pressure

gradient leads to lower component tempera-

tures.

Two-stage charge air cooler

The two stage charge air cooler consists of two

stages which differ in the temperature level of

the connected water circuits. The charge air is

first cooled by the HT circuit (high temperature

stage of the charge air cooler, enginej and then

further cooled down by the LT circuit (low tem-

perature stage of the charge air cooler, lube oil

coolerj.

Charge air preheating by HT-LT switching

Charge air preheating by HT-LT switching is

used in the load range from 0 % up to 20 % to

achieve high charge air temperatures during part

load operation. lt contributes to improved com-

bustion and, consequently, reduced exhaust

gas discolouration. Unlike the charge air pre-

heating by means of the CHATCO control valve,

there is no time delay in this case. The charge air

is preheated immediately after the switching

process by HT cooling water, which is routed

through both stages of the two-stage charge air

cooler.

Charge air preheating by LT shut off (integrated

in CHATCOj

Charge air preheating by LT shut off (by means

of the CHATCO control valvej is as well used in

the load range from 0 % up to 20 % to reduce

exhaust gas discolouration. Higher charge air

temperatures are achieved by shut off the LT

stage of the two stage charge air cooler. De-

pending on engine type there is a delay in time

of about 15 to 25 minutes, till the positive effect

can be noticed, because previously remaining

LT water in the LT stage needs to be heated up

by the charge air.

Engine and operation

2.1.6 Engine equipment for various applications - General description

Page 2 - 14 D-BB

0

8

0

4

-

0

0

0

0

A

A

2

.

f

m

CHATCO (Charge Air Temperature Controlj

The charge air temperature control CHATCO

serves to prevent accumulation of condensed

water in the charge air pipe. ln this connection,

the charge air temperature is, depending on the

intake air temperature, controlled in such a way

that, assuming a constant relative air humidity of

80 %, the temperature in the charge air pipe

does not fall below the condensation tempera-

ture.

lntegrated in the functionality of CHATCO is

Charge air preheating by LT shut off.

Waste gate (blowing off the exhaust gasj

By blowing off the exhaust gas upstream of the

turbine and returning it to the exhaust pipe

downstream of the turbine, a charge air pressure

reduction and/or a drop in turbine speed at full

load is achieved. This measure is necessary if

the turbocharger has been designed for opti-

mised part load operation.

Jet Assist (acceleration of the turbochargerj

This equipment is used where special demands

exist regarding fast acceleration and/or load ap-

plication. ln such cases, compressed air from

the starting air vessels is reduced to a pressure

of approx. 4 bar before being passed into the

compressor casing of the turbocharger to be ad-

mitted to the compressor wheel via inclined

bored passages. ln this way, additional air is

supplied to the compressor which in turn is ac-

celerated, thereby increasing the charge air

pressure. Operation of the accelerating system

is initiated by a control, and limited to a fixed

load range.

vlT (variable lnjection Timingj

For some engine types with conventional injec-

tion a vlT is available allowing a shifting of injec-

tion start. A shifting in the direction of advanced

injection" is supposed to increase the ignition

pressure and thus reduces fuel consumption.

Shifting in the direction of retarded injection"

helps to reduce NO

x

emissions.

vvT (variable valve Timingj

variable valve Timing enables variations in the

opening and closing of the inlet valves. At low

load operation it is used to attain higher com-

bustion temperatures and thus lower soot emis-

sions. At higher loads it is used to attain low

combustion temperatures and thus lower NO

x

emissions (Miller valve timingj.

Slow turn

Engines, which are equipped with slow turn",

are automatically turned prior to engine start,

with the turning process being monitored by the

engine control. lf the engine does not reach the

expected number of crankshaft revolutions (2.5

revolutionsj within a specified period of time, or

in case the slow-turn time is shorter than the

programmed minimum slow-turn time, an error

message is issued. This error message serves

as an indication that there is liquid (oil, water, fu-

elj in the combustion chamber. lf the slow-turn

manoeuvre is completed successfully, the en-

gine is started automatically.

Oil mist detector

Bearing damage, piston seizure and blow-by in

combustion chamber leads to increased oil mist

formation. As a part of the safety system the oil

mist detector monitors the oil mist concentration

in crankcase to indicate these failures at an early

stage.

Splash oil monitoring system

The splash-oil monitoring system is a constitu-

ent part of the safety system. Sensors are used

to monitor the temperature of each individual

drive unit (or pair of drive at v enginesj indirectly

via splash oil.

Main bearing temperature monitoring

As an important part of the safety system the

temperatures of the crankshaft main bearings

are measured just underneath the bearing shells

in the bearing caps. This is carried out using oil-

tight resistance temperature sensors.

Engine and operation

2.1.6 Engine equipment for various applications - General description

D-BB Page 2 - 15

0

8

0

4

-

0

0

0

0

A

A

2

.

f

m

vTA (variable Turbine Areaj

vTA-turbochargers allow precise, stepless and

continuous control of charge air pressure and

air-flow according to the respective engine oper-

ating conditions.

Engine and operation

2.1.6 Engine equipment for various applications - General description

Page 2 - 16 D-BB

0

8

0

4

-

0

0

0

0

A

A

2

.

f

m

Engine and operation

2.2.1 Standard engine ratings

E-BB 48/60CR Page 2 - 17

0

2

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

2.2 Ratings (outputj and speeds

2.2.1 Standard engine ratings

Engine 48/60CR, GenSet and controllable-pitch propeller (CPPj

1200 kW/cyl., 500/514 rpm

Engine type

No. of cylinders

Engine rating P

lSO, Standard

1j2j

1j

P

lSO, Standard

as specified in DlN lSO 3046-1, see "Paragraph: Definition of engine rating, page 2-18".

2j

Engine fuel: Distillate according to lSO 8217 DMA/DMB/DMZ-grade fuel or RM-grade fuel, fullfilling the stated quality

requirements.

500rpm Available turn-

ing direction

514rpm Available turn-

ing direction

kW CW

3j

CCW

4j

3j

CW clockwise.

4j

CCW counter clockwise.

kW CW

3j

CCW

4j

6L48/60CR 6 7,200 Yes/Yes 7,200 Yes/Yes

7L48/60CR 7 8,400 Yes/Yes 8,400 Yes/Yes

8L48/60CR 8 9,600 Yes/Yes 9,600 Yes/Yes

9L48/60CR 9 10,800 Yes/Yes 10,800 Yes/Yes

12v48/60CR 12 14,400 Yes/Yes 14,400 Yes/Yes

14v48/60CR 14 16,800 Yes/Yes 16,800 Yes/Yes

16v48/60CR 16 19,200 Yes/Yes 19,200 Yes/Yes

18v48/60CR 18 21,600 Yes/Yes 21,600 Yes/Yes

Table 2-5 Engine ratings 48/60CR ll, GenSet and CPP

Engine and operation

2.2.1 Standard engine ratings

Page 2 - 18 48/60CR E-BB

0

2

0

2

-

0

0

0

0

M

D

c

r

l

l

.

f

m

Engine 48/60CR, Suction dredger/pumps (mechanical drivej

1080 kW/cyl., 500/514 rpm

Definition of engine rating

General definition of diesel engine rating

(according to lSO 15550: 2002; lSO 3046-1:

2002j

Engine type

No. of cylinders

Engine rating P

lSO, Standard

1j2j

1j

P

lSO, Standard

as specified in DlN lSO 3046-1, see "Paragraph: Definition of engine rating, page 2-18".

2j

Engine fuel: Distillate according to lSO 8217 DMA/DMB/DMZ-grade fuel or RM-grade fuel, fullfilling the stated quality

requirements.

500rpm Available turn-

ing direction

514rpm Available turn-

ing direction

kW CW

3j

CCW

4j

3j

CW clockwise.

4j

CCW counter clockwise.

kW CW

3j

CCW

4j

6L48/60CR 6 6,480 Yes/Yes 6,480 Yes/Yes

7L48/60CR 7 7,560 Yes/Yes 7,560 Yes/Yes

8L48/60CR 8 8,640 Yes/Yes 8,640 Yes/Yes

9L48/60CR 9 9,720 Yes/Yes 9,720 Yes/Yes

12v48/60CR 12 12,960 Yes/Yes 12,960 Yes/Yes

14v48/60CR 14 15,120 Yes/Yes 15,120 Yes/Yes

16v48/60CR 16 17,280 Yes/Yes 17,280 Yes/Yes

18v48/60CR 18 19,440 Yes/Yes 19,440 Yes/Yes

Table 2-6 Engine ratings 48/60CR ll, GenSet and CPP

Reference Conditions:

lSO 3046-1: 2002; lSO 15550: 2002

Air temperature T

r

K/C 298/25

Air pressure p

r

kPa 100

Relative humidity ur % 30

Cooling water temperature

upstream charge air cooler t

cr

K/C 298/25

Net calorific value LCv kj/kg 42,700

Table 2-7 Standard reference conditions

Engine and operation

2.2.2 Engine ratings (outputj for different applications

D-BB 48/60CR Page 2 - 19

0

2

0

2

-

0

2

0

a

M

D

c

r

l

l

.

f

m

2.2.2 Engine ratings (outputj for different applications

P

Application, lSO

: Available rating (outputj under lSO-conditions dependent on application

P

A

p

p

l

i

c

a

t

i

o

n

A

v

a

i

l

a

b

l

e

o

u

t

p

u

t

i

n

p

e

r

c

e

n

t

a

g

e

o

f

l

S

O

-

s

t

a

n

d

a

r

d

-

o

u

t

p

u

t

F

u

e

l

s

t

o

p

p

o

w

e

r

(

b

l

o

c

k

i

n

g

j

M

a

x

.

a

l

l

o

w

e

d

s

p

e

e

d

r

e

d

u

c

t

i

o

n

a

t

m

a

x

i

m

u

m

t

o

r

q

u

e

1

j

1j

Maximum torque given by available output and nominal speed.

T

r

o

p

i

c

c

o

n

d

i

t

i

o

n

s

(

t

r

/

t

c

r

/

p

r

=

1

0

0

k

P

a

j

2

j

2j

t

r

= Air temperature at compressor inlet of turbocharger.

t

cr

= Cooling water temperature before charge air cooler.

p

r

= Barometric pressure.

N

o

t

e

s

O

p

t

i

o

n

a

l

p

o

w

e

r

t

a

k

e

-

o

f

f

i

n

p

e

r

c

e

n

t

a

g

e

o

f

l

S

O

-

s

t

a

n

d

a

r

d

-

o

u

t

p

u

t

Kind of application % % % C - -

Marine main engines (with mechanical or diesel-electric drivej

Main drive alternator 100 110 - 45/38

3j

3j

According to DlN lSO 8528-1 load > 100 % of the rated engine output is permissible only for a short time to provide

additional engine power for governing purpose only (e. g. transient load conditions and suddenly applied loadj.

This additional power shall not be used for the supply of electrical consumers.

Yes/up to 100 %

Main drive with controllable pitch propeller 100 100 - 45/38 - Yes/up to 100 %

Suction dredger/pumps (mechanical drivej

Main drive with speed reduction at maxi-

mum torque

90 90 20 45/38

4j

5j

4j

According to DlN lSO 3046-1 MAN Diesel & Turbo has specified a maximum continuous rating for marine engines

listed in the column P

Application

.

5j

Special turbocharger matching required.

Yes/up to 100 %

Table 2-8 Available outputs/related reference conditions 48/60CR

Engine and operation

2.2.2 Engine ratings (outputj for different applications

Page 2 - 20 48/60CR D-BB

0

2

0

2

-

0

2

0

a

M

D

c

r

l

l

.

f

m

Engine and operation

2.2.2 Engine ratings (outputj for different applications

D-BB Page 2 - 21

0

2

0

2

-

0

2

0

b

M

A

2

.

f

m

P

Operating

: Available rating (outputj under local conditions and dependent on application

Dependent on local conditions or special application demands a further load reduction of

P

Application, lSO

might be needed.

1. No de-rating necessary, provided the conditions listed in the respective column

(see "Table 2-9: De-rating - Limits of ambient conditions"j are met:

2. De-rating due to ambient conditions and negative intake pressure before compressor or exhaust

gas back pressure after turbocharger.

No de-rating up to

stated reference

conditions (Tropicj,

see 1.

De-rating needed according to formula,

see 2.

De-rating

needed

accord. to spe-

cial calculation,

see 3.

Air temperature before

turbocharger T

x

s 318 K (45 Cj 318 K (45 Cj < T

x

s 333 K (60 Cj > 333 K (60 Cj

Ambient pressure > 100 kPa (1 barj 100 kPa (1 barj > p

ambient

> 90 kPa < 90 kPa

Cooling water temper-

ature inlet charge air

cooler (LT stagej

s 311 K (38 Cj 311 K (38 Cj < T

cx

s 316 K (43 Cj > 316 K (43 Cj

lntake pressure before

compressor

> -20 mbar

1j

1j

Below/above atmospheric pressure.

-20 mbar > p

air before compressor

> -40 mbar

1j

< -40 mbar

1j

Exhaust gas back

pressure after turbo-

charger

s 30 mbar

1j

30 mbar < p

exhaust after turbine

s 60 mbar

1j

> 60 mbar

1j

Table 2-9 De-rating - Limits of ambient conditions

a

318

T

x

U O + +

----------------------------

\ .

| |

=

311

T

cx

----------

\ .

| |

1 2 ,

1 09 0 09 , , with a 1 s

P

Operati ng

P

Application, lSO

a =

a Correction factor for ambient conditions

T

x

Air temperature before turbocharger [K| being considered (T

x

= 273 + t

x

j

U lncreased negative intake pressure before compressor leads to an de-rating, calculated as increased air tempera-

ture before turbocharger

U 20mbar p

Air before compressor

[mbar] ( ) 0 25K/mbar , =

O lncreased exhaust gas back pressure after turbocharger leads to a de-rating, calculated as increased air temper-

ature before turbocharger:

Engine and operation

2.2.2 Engine ratings (outputj for different applications

Page 2 - 22 D-BB

0

2

0

2

-

0

2

0

b

M

A

2

.

f

m

3. De-rating due to special conditions or demands.

Please contact MAN Diesel & Turbo, if:

limits of ambient conditions mentioned in

"Table 2-9: De-rating - Limits of ambient

conditions" are exceeded. A special calcula-

tion is necessary.

higher requirements for the emission level ex-

ist. For the allowed requirements see "Sec-

tion: Exhaust gas emission."

special requirements of the plant for heat re-

covery exist

special requirements on media temperatures

of the engine exist

any requirements of MAN Diesel & Turbo

mentioned in the Project Guide can not be

kept.

Note!

Operating pressure data without further specifi-

cation are given below/above atmospheric pres-

sure.

T

cx

Cooling water temperature inlet charge air cooler (LT stagej [K| being considered

(T

cx

= 273 + t

cx

j

T Temperature in Kelvin [K|

t Temperature in degree Celsius [C|

O p

Exhaust after turbi ne

[mbar] 30mbar ( ) 0 25 , K/mbar = with 0 0 >

Engine and operation

2.2.3 Engine speeds and related main data

D-BB 48/60CR Page 2 - 23

0

2

0

2

-

0

3

0

0

M

D

c

r

l

l

.

f

m

2.2.3 Engine speeds and related main data

Unit 50 Hz 60 Hz

Cylinder rating kW/cyl. 1200 1200

Rated speed rpm 500 514

Mean piston speed m/s 10.0 10.3

Mean effective pressure bar 26.5 25.8

Number of pole pairs - 6 7

Lowest engine operating speed:

in case of rigid foundation

in case of resilient foundation speed

depends on layout of mounting

rpm

approx. 130

-

approx. 130

-

Highest engine operating speed rpm 525

1j

1j

This concession may possibly be restricted, see "Figure 2-18: Permissible frequency deviations and corresponding

max. output.

525

Speed adjusting range

rpm

see "Section 2.2.4: Speed adjusting range,

page 2-25"

Note!

Power take-off on engine free end up to 100 % of rated output.

Table 2-10 Engine speeds and related main data

Engine and operation

2.2.3 Engine speeds and related main data

Page 2 - 24 48/60CR D-BB

0

2

0

2

-

0

3

0

0

M

D

c

r

l

l

.

f

m

Engine and operation

2.2.4 Speed adjusting range

L-BA 48/60CR Page 2 - 25

0

2

0

2

-

0

4

0

0

M

D

c

r

l

l

.

f

m

2.2.4 Speed adjusting range

The following specification represents the

standard settings. For special applications, de-

viating settings may be necessary.

Drive Speed droop

Maximum

speed at full

load

Maximum

speed at idle

running

Minimum

speed

E

l

e

c

t

r

o

n

i

c

g

o

v

e

r

n

o

r

s

1 main engine with control-

lable-pitch propeller and with-

out PTO

0 % 100 % (+0,5%j 100 % (+0,5%j 60 %

1 main engine with control-

lable-pitch propeller and with

PTO

0 % 100 % (+0,5%j 100 % (+0,5%j 60 %

Parallel operation of 2 engines

driving 1 shaft with/without

PTO:

Load sharing via speed droop

or

5 % 100 % (+0,5%j 105 % (+0,5%j 60 %

Master/Slave operation 0 % 100 % (+0,5%j 100 % (+0,5%j 60 %

GenSets/Diesel-electric

plants:

with load sharing via speed

droop

or

5 % 100 % (+0,5%j 105 % (+0,5%j 60 %

lsochronous operation 0 % 100 % (+0,5%j 100 % (+0,5%j 60 %

Table 2-11 Electronic governors

Engine and operation

2.2.4 Speed adjusting range

Page 2 - 26 48/60CR L-BA

0

2

0

2

-

0

4

0

0

M

D

c

r

l

l

.

f

m

Engine and operation

2.3 Engine operation under arctic conditions

D-BB Page 2 - 27

0

2

0

5

-

0

0

0

0

A

A

2

.

f

m

2.3 Engine operation under arctic conditions

Arctic condition is defined as:

Air intake temperatures of the engine below

+5 C

lf engines operate under arctic conditions (inter-

mittently or permanentlyj, the engine equipment

and plant installation have to meet special de-

sign features and requirements. They depend on

the possible minimum air intake temperature of

the engine and the specification of the fuel used.

Minimum air intake temperature of the engine,

t

x

:

Category A

+5 C > t

x

> 15 C

Category B

-15 C > t

x

> 35 C

Category C

t

x

< 35 C

Special engine design requirements

Charge air blow-off according to categories

A, B or C

lf arctic fuel (with very low lubricating proper-

tiesj is used, the following actions are re-

quired:

- The maximum allowable fuel temperatures

have to be kept.

- Fuel injection pump

Only in case of conventional fuel injection

system, dependent on engine type instal-

lation and activation of sealing oil system

may be necessary, because low viscosity

of the fuel can cause an increased leakage

and the lube oil will possibly being con-

taminated.

- Fuel injection valve

Nozzle cooling has to be switched off to

avoid corrosion caused by temperatures

below the dew point.

- lnlet valve lubrication

Has to be activated to avoid an increased

wear of the inlet valves.

Engine equipment

SaCoS/SaCoS

one

SaCoS/SaCoS

one

equipment is suitable to be

stored at minimum temperatures of -15 C.

ln case these conditions cannot be met, pro-

tective measures against climatic influences

have to be taken for the following electronic

components:

- EDS Databox APC620

- TFT-touchscreen display

- Emergency switch module BD5937

These components have to be stored at plac-

es, where the temperature is above -15 C.

A minimum operating temperature of > 0 C

has to be ensured. The use of an optional

electric heating is recommended.

Alternators

Alternator operation is possible according to

suppliers specification.

Plant installation

lntake air conditioning

Air intake of the engine and power house/en-

gine room ventilation have to be two different

systems to ensure that the power house/en-

gine room temperature is not too low caused

by the ambient air temperature.

Engine and operation

2.3 Engine operation under arctic conditions

Page 2 - 28 D-BB

0

2

0

5

-

0

0

0

0

A

A

2

.

f

m

lt is necessary to ensure that the charge air

cooler cannot freeze when the engine is out

of operation (and the cold air is at the air inlet

sidej.

Gas engines

- An air intake temperature > +5 C has to

be ensured by preheating.

- ln addition, the maximum ambient tem-

perature has to be considered since the

engine control can only compensate a lim-

ited temperature range (approx. 20 Kj.

Example:

Maximum ambient temperature .. +35 C

Temperature compensation

by engine......................................... 20 K

> An air intake temperature of > +15 C

(35 C - 20 K = 15 Cj has to be en-

sured by preheating.

Dual fuel engines

- Category A, B

No additional actions are necessary. The

charge air before the cylinder is preheated