Documente Academic

Documente Profesional

Documente Cultură

H400 450HDS

Încărcat de

Rodney RichardsonTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

H400 450HDS

Încărcat de

Rodney RichardsonDrepturi de autor:

Formate disponibile

H400-450HD/S

Series A236

Big Truck Line

H400-

450HD/S

As working environments change, Hyster Companys product line must

change. That is why Hyster is excited to introduce a new series of trucks,

the A236. This new series will replace Hyster Companys A214-FLT.

The models offered in this series are: H400HD, H400HDS, H450HD,

Frame

The FLT frame is a welded construction of channels built from 1 inch

thick top and bottom anges to a inch thick side plate. This provides

an opportunity to apply material to the highest stress area.

Two frame congurations are offered to meet the various applications.

H400-450HDS Wheelbase 138 inches

H400-450HD Wheelbase 148 inches

Bolted on fuel and hydraulic tanks cleaned to ISO 19-17-14 to reduce

risk of contamination on initial machine start up.

Low prole frame channels to allow easy side access for maintenance

and servicing of components located inside frame.

Operators Compartment

All steel structure with both pressed steel panels and formed sections to

give a very strong operator compartment exceeding applicable regula-

tions.

To promote driver comfort and productivity, the operator compartment

features spacious dimensions, adjustable suspension seat, adjustable

tilt steering wheel, integrated seat and adjustable armrest with low

effort controls, and power assist steering and brakes.

Powered side tilting for improved service access is standard.

Multi-function display panel with error code message facility for auto

shift transmission and engine monitoring.

Load sensed steering system. Steering column has both height and

axial adjustment, and includes lever controls as appropriate i.e. trans-

mission shift, turn signal lever and central warning light.

The operator compartment is mounted on 4 rubber isolators to minimize

the transmission of structure borne noise and vibration from the frame

to the operator, thereby reducing noise and driver fatigue.

Wide-angle side view mirrors are provided in the top left and right hand

front corners of the cab.

Handrails are provided to assist the operator in mounting and dismount-

ing the unit.

The controls are provided with a seat-mounted armrest and are indepen-

dently adjustable to the seat and maintain position relative to the seat,

when the seat is adjusted.

Lights are available for full cab-equipped units as well as non-cab units.

Operator Cab:

Curved glass to provide excellent visibility. The front windshield is tem-

pered. Laminated glass is available as an aftermarket option.

A high capacity heater system with 10 outlet air vents provides all round

heating/cooling. A replaceable paper lter element ensures that the

operator receives clean air from outside. Recirculation and fresh air

positions can be manually selected. The 3-speed fan and variable heat

output controls are located on the right hand side console.

Air conditioning system provides 35,100 btu/hour cooling capacity. Two

speed electric condenser fans are used to ensure constant performance

at low engine operating conditions. This condenser is mounted inside

the center counterweight cooling inlet.

Defrosting of the front and rear windows is via ducting integral with the

cab structure, which connect to the front and rear plastic moldings.

Molded, easy clean oor mats, provide an effective barrier to noise, and

a softer feel to the feet of the operator.

The cab oor is at and provides the operator with an unobstructed

space for his feet. Additionally, the oor plate is an integral part of the

cab and seals against noise ingress.

For heavy rain conditions a dual (H-pattern) wiper is standard. A washer

is connected to the wiper. The motor system is mounted below the cab

to give unobscured visibility.

The rear window is curved glass (tempered) and is provided with a

wiper motor/washer in the centre of the screen. The rear window wraps

around the side of the rear corner and provides good visibility.

2

STANDARD FEATURES & OPTIONS

and H450HDS. These trucks are rated at 40,000 & 45,000 pounds, respectively, at a 36-inch load center. Hyster has

answered the challenge by offering two new wheelbases per model without jeopardizing capacities.

If your application requires limited operating space, then the H400-450HDS, 138 wheelbase should be your units of

choice. Those who are not constrained for space will prefer the H400-450HD with a 148 wheelbase.

The top surface of the cab is a large laminated glass panel bonded to

the frame. Additional clamps are tted at the front of the cab to ensure a

positive seal when the truck is being transported at high speed.

An internally mounted roller type sunblind mounted in the roof and at

the rear window is standard.

Mechanical and air suspension seats are available.

Joystick and lever pilot control options are available. All controls are

simple and easy to use and can be comfortably reached.

The electronic module for the transmission is housed in the operator

compartment within the right hand module, fully protected from the

environment.

A training seat is available as an option.

Doors are single piece steel framed with (tempered) glass for maximum

visibility. The outside of the doors mount ush to the outside of the edge

of the A pillar. The steel frame provides stiffness for the glass door and

also attachment points for the door lock mechanism and hinges. The

door handle is mounted at a low level to permit the operator to open the

door from ground level.

Seats:

A full suspension Sears seat is standard, featuring a durable cloth

surface (vinyl with non-cab) and contoured for operator comfort. The

seat has an adjustable backrest angle, an armrest on the right side, and

spring rate adjustability for operator weight. The seat rail has 7 inches

of travel.

A high backrest version seat is optionally available.

An air suspension seat is optional.

All seat options have operator restraints.

All seats are tted with an electrical seat switch wired to the warning

buzzer system. If the operator leaves the seat with the park brake not

applied a continuous sound will occur. The seats are tted with an

electrical seat switch wired to the Operator Presence System:

If the operator leaves the seat, this system will de-activate the trans-

mission and both lift and tilt functions; an alarm will also sound if the

parking brake is not applied.

Engine

The engine offered will be the Cummins QSB6.7 Tier 3, turbocharged

and charge air cooled.

Cummins QSB engines feature advanced electronics, new sculpted

blocks, rear gear trains, and High-Pressure Common-Rail fuel systems.

6-cylinder, 6.7 liters, 195 hp at 1800 rpm

Optionally and required for certain truck models

6-cylinder, 6.7 liters, 230 hp at 1800 rpm

Cummins engine detailed features:

Has Cummins renowned quality and durability built-in.

Product built on the strengths and experience of the B Series engine,

renowned for simplicity, reliability, durability and low life cycle costs In

cylinder combustion approach achieving Tier 3 requirements without

after treatment or EGR.

Signicantly improved exhaust acceleration, black and white smoke

characteristics compared to Tier 2.

Various engine sub-systems have been integrated to provide a less

complex engine with fewer parts.

Lower engine noise and vibration levels contributing to lower truck and

drivers ear noise levels.

Rated load governed speed is 230 hp @ 1800 rpm or 195 hp @ 1800 rpm.

Bosch HPCR with full authority electronic control fuel pump system.

Wastegated Holset HX-35 turbocharger.

4 valve cylinder head.

Rear Gear Train with die-cast aluminum gear housing.

To assist engine starting in cold weather an engine grid heater in the air

intake manifold is automatically activated below 10 F ambient.

500 hour oil and lter change periods.

Standard fuel/torque de-rate through shutdown are enabled for

Coolant temperature

Air intake temperature

Oil pressure

Full ow lubricating oil system

The standard shutdown and de-rate features have the following settings:

Condition Driver Warning

De-rate

(after 5 seconds)

Shutdown

(after 30 seconds)

High Engine Coolant Temp 225 F 238 F 238 F

Low Engine oil Pressure 6 psi 6 psi 6 psi

High Engine Inlet Air Temp 200 F 210 F 210 F

3

H400-450HD/S

TRANSMISSION:

A. POWERSHIFT TRANSMISSION

The truck series uses Dana SOH designed power shift transmissions:

TE-13 (rated for 195 hp)

TE-17 (rated for 230 hp)

The main difference is in the number of clutch plates where the TE-17

has 2 more than the TE-13 depending the clutch group.

These are 3-speed forward and reverse heavy-duty, electronically con-

trolled transmissions, are mounted to the engine ywheel housing, and

include the following features:

Soft shift characteristics for up-down gear shifting and reversals

Inching performance improved by electronic solenoid clutch modula-

tion

Automatic shift standard

Diagnostic software Userlink is SOH-NMHG jointly developed user

interface built on T50 Userlink experience and which is already avail-

able with the TE-10, TE-27, and TE-32 transmissions

Optimal clutch ll by factory calibration procedure

Larger pump drive, suitable for 2 speed hydraulic loads

Improved transmission protection (limited adjustments to param-

eters)

Exceed parameters dened and error codes displayed to driver

Engine de-rate at extreme transmission conditions

Transmission control at extreme transmission conditions

Electric automatic shifting is standard and is controlled by a new elec-

tronic transmission controller located within the cab console. The con-

troller receives its signals from speed sensors on the transmission case.

Shifting moments are depending throttle pedal position in combination

with power train load and provide optimal shifting points with smooth

shifting characteristics.

The APC 200 controller provides an adjustable option to limit maximum

truck speed.

When travelling in reverse and shifting forward, the controller will shift

into rst gear only when the speed is below 3.1 mph and 1400 rpm

engine speed.

The main hydraulic pump drive facility is located on the rear of the

transmission housing (front side in truck).

A torque converter with 2.191:1 (TE-13) / 2.109:1 (TE-17) stall ratio is

used to match engine to transmission to give exceptional tractive and

travel speed performance.

The torque converter has two main functions:

To work as a uid coupling to reduce shock loads in the power train

for a smooth transfer of power from the engine to the transmission.

To multiply torque from the engine to match the traction power

requirements when needed.

The hydraulic system for the transmission is separate from the main

hydraulic system of the truck. The transmission has its own large sump,

an externally mounted spin-on lter, charge pump and control valve. Trans-

mission oil temperature is controlled by an oil cooler to reduce wear on the

clutches and promote long life. In case of overheating, a sender unit in the

oil sump turns on a warning light in the instrument module. There are few

potential leak points in the transmission since it is self-contained.

The transmission control valve controls the pressure and the ow of oil

to the clutch piston cavities and to the torque converter. It also provides

oil ow to cool the clutch discs and lubricate the transmission. A modu-

lating pressure valve is used to cushion directional shifts, reduce shock

loads, and provide smooth clutch engagement. The modulator valve is

sandwiched between the main control valve and the converter housing.

4

STANDARD FEATURES & OPTIONS

The control valve is mounted to the side of the torque controller housing.

Drillings and passages in the control valve permit oil to ow from the

valve body to passages in the transmission housing. This limits hydrau-

lic lines and ttings to reduce the possibility of leakage.

The engine can only be started when the transmission is in neutral or

with the inching pedal depressed.

The transmission contains two directional and 3 range clutch packs that

have friction discs per following table:

TE-13 no. of discs TE-17 no. of discs

Forward pack 9 11

Reverse pack 9 10

1st gear range pack 5 6

2nd gear range pack 5 6

3rd gear range pack 4 5

All transmission inching occurs by disengaging either the forward or

reverse directional clutch packs.

Torque is transmitted through the transmission by engaging one direc-

tional clutch pack, and one range clutch pack.

The transmission shafts contain oil passages that direct oil to the clutch

packs for actuation and cooling. The oil is routed into the shafts through

sealing rings located at the ends of the shafts.

Helical gearing is used throughout the transmission, except for the

auxiliary PTO gears for smooth, quiet operation.

B. STEERING SYSTEM

The steering system is all-hydraulic and is designed to give precise reli-

able control.

The hydrostatic steering system consists of a steering wheel and tilting

column assembly, steering control unit, pump with priority control valve,

steer axle, cylinder and wheel hubs and spindles.

The steering control unit is a Danfoss OSPC500 dynamic load sensed

hand pump that is controlled by the steering wheel. The unit is mounted

on the underside of the cab oor and is connected by a shaft to the

steering wheel.

The tilt angle of the steering wheel is innitely adjustable for both rake

angle and height (within xed end stops), by releasing a single lever

on the steering column assembly. A compact 13.75-diameter steering

wheel with centrally mounted horn button is tted.

The load sensing system has been designed to provide low steering

effort and good performance at all engine speeds.

A hydraulic pump with a displacement of 54cc per rev. will supply

steering ow.

The steer axle is a welded, sandwich construction with a transverse

mounted double acting cylinder, 2 non-adjustable tie rods, 2 spindles,

taper roller bearings and 2 wheel hubs. The axle is pin mounted to the

frame.

The one-piece axle weldment carries the axle loads, and provides the

mounting for the spindles and cylinder. The axle weldment is designed

for high loads and long life.

The steering axle spindles are supported by tapered roller bearings, and

sealed to prevent contaminate entry or loss of grease. Bearing pre-load

is set shimming the lower bearing cap. Increased outer bearing sizes

and spindle design improvements have been introduced to cope with

higher truck capacities.

The steer cylinder is secured to the axle by 8 high tensile bolts. By this

design the cylinder does not exert an external force on the frame. This

design permits large wheel angles and greater maneuverability.

No steering linkage adjustments are required. The only regular mainte-

nance points are the lubricating ttings on the spindle and tie rod pins.

This axle design, with its large sealed bearings, precision-machined

parts, and non-adjustable tie rods, provides a durable and low mainte-

nance system with precise steering control.

C. DRIVE AXLE

PRC-1756W3H axles feature a heavy-duty ductile iron axle housing to

ensure durability and has a load rating increased from 94,600 pounds to

110,000 pounds (+16%). These axles are securely mounted to the truck

frame with 4 bolts per side for the FLT.

Drive axle shafts are splined at both hub and differential ends and have

increased strength by induction hardening. The axle assembly is a full

oating design, which means that the truck weight is carried by the axle

housing, not the axle shafts.

Wet disc wheel speed brakes are standard for all models and provide for

smooth braking and to:

Eliminate occasional brake noise complaints with the shaft speed

PRC-1756.

Eliminate any concerns regarding inching and rock-back.

Effectively increases the torque rating of the wheel end gears by 10%

over shaft speed design.

5

Brakes

Wet Brake System

The wet brake system consists of a hydraulic supply and storage sec-

tion, drive axle wheel speed multi-disc brakes. Hydraulic oil is supplied

to an accumulator system from an engine-driven hydraulic pump. The

oil used to actuate and cool the brakes comes from the main hydraulic

reservoir. Brake cooling oil is cooled by separate oil to air cooler located

in front of the hydraulic bay area. Brake cooling ow is ltered as it

returns to the tank.

The wet brake axles include a dry disc park brake. The park brake

comprises a AxleTech model 1270 (Knott) pinion mounted disc brake

with hydraulically released spring applied disk pads and is common to

all models.

The large 14.7 inches diameter wet disc brakes with each 6 (FLT) plates

ensure braking compliance with ISO and ANSI standards.

Increased hub bearing size to withstand higher load capacity.

The wheel stud replacement/servicing can occur without disassembling

the wheel hub.

Modied wheel hub to house higher capacity bearings and to accommo-

date larger bolt circle diameter for brake driver bolted joint.

Magnets are located in axle housing to eliminate recommended initial oil

change and reduce oil pollution.

A separate wet brake oil cooler is used with oil temperature-warning

sensors on each side to provide the operator with an early indication of

excessive oil temperature 230 F.

6

STANDARD FEATURES & OPTIONS

D. HYDRAULIC SYSTEM

A 3771 psi lift hydraulic system allows the use of small hydraulic lines

and components which increases operating efciency and improves fuel

economy. Tilt and auxiliaries will have 2741 psi relief in all valve variations.

Slim diameter lift cylinders provide good visibility.

Small hydraulic lines and components mean better maintenance acces-

sibility.

In-tank, full ow, return ltration for protection of the hydraulic circuit.

Both steering and main hydraulic system oil are ltered as the oil

returns to the tank.

O Ring Face Seal hydraulic ttings are used throughout. Fittings with

o-ring bosses are used to connect hoses and tubes to individual hydrau-

lic components.

Flexible wire-braid hoses and limited conventional steel hydraulic tubing

are used to simplify the hydraulic plumbing. These hydraulic lines are

carefully routed and clamped. This feature extends service life and

simplies service access.

Main Hydraulic Pump

The main hydraulic pump is a tandem pump that contains a 74cc pump-

ing section for the lift system, a 54cc pumping section for the steering

with excess ow to tilt, auxiliary or lift system and a 23cc pumping

section for the hydraulic cooling circuit.

The Haldex-Barnes G302020 pump features high performance gear

type pumping sections with improved efciency and long life.

It is mounted to the transmission PTO, and is driven by a gear train from

the torque converter hub. This mounting location is centrally located

within the truck but close to the hydraulic bay area and provides for

an efcient hydraulic system. Hydraulic line lengths are minimized

to reduce hydraulic system pressure losses, thereby lowering power

requirements and overall system temperatures.

Main Hydraulic Control Valve

The Husco 6000 series main control valve features include:

Dual lift spools directing main and unused steering/tilt/aux oil ow to

the lift function and increasing lifting speeds at these conditions.

Metering notches in the spool control surfaces allow control of oil ow

during the lift or tilt functions and provide load protection.

Multiple relief valves limit the lift pressure to 3771 psi, while limiting

the pressure for tilt and auxiliary functions to 2741 psi. This provides

high efciency for the tilt section with hydraulic pressure compatible

with the relief setting for the front end equipment.

Simultaneous operation of lift and auxiliary functions are made possible.

Pilot actuated hydraulic control valve sections provide the means of

operator control of hydraulic functions and realize ne tuned metering of

hydraulic functions.

Lift and tilt functions will be proportional controlled

Auxiliary functions will be non-proportional controlled

The valve assemblies are open-center, sectional type design.

Combination Valve

A newly designed HydraForce valve combines pilot pressure, accumula-

tor charging, brake pressure, steering priority and park brake actuation

functions.

Reduces the number of individual valves, ttings and plumbing signi-

cantly. Therefore the potential for leakages is reduced also.

Improves access and serviceability with cartridge valves and solenoids

assembled into one block located on the upper side of the front of the

frame.

Tilt Control Valve

Anti-cavitation tilt control valves are plumbed at the tilt cylinder ports. It

has three functions:

It keeps the mast from moving forward if the tilt function is actuated

when the engine is not running.

During forward tilting, it controls the oil ow from the tilt cylinders

to maintain positive pressure at the piston end of the cylinder, and

improve control of the mast and the load.

When the tilt function is not actuated, it blocks the ow of hydraulic oil

to all tilt cylinder ports, and prevents uid transfer from one tilt cylinder

to the other. This hydraulic locking resists masts torsion loading.

Hydraulic Tank

An 84 gallon (58 gallons usable volume) hydraulic tank is mounted on

the outside of the right-hand frame channel by 4 bolts. This location

permits the tank to radiate heat away from the truck and operator.

The oil level is easily checked with a glass type level indicator with oat-

ing ball. This is conveniently mounted to the side wall of the tank.

Provisions (2 NPT anges) are made at the bottom of the tank to allow

for a customer/dealer installed hydraulic pre-heater.

Hydraulic Filter

A replaceable hydraulic lter is located within the hydraulic tank, and

maybe serviced by simply unscrewing the hydraulic lter head. The lter

may be replaced without opening the hood.

The lter contains a 10-micron paper element that protects the hydraulic

system from contaminants, promotes reliable performance and helps to

extend life for all the system components.

The hydraulic lter assembly has a by-pass relief valve to provide oil

ow in the event of lter clogging.

Oil added to the hydraulic system must pass through the lter.

Hydraulic Tank Breather

The hydraulic tank air breather includes a lter and is located outside

of the operator compartment to prevent undesirable fumes. The high

quality lter protects the hydraulic system from airborne contaminants.

This breather also incorporates a stand pipe to prevent lter element dirt

dropping into hydraulic tank while replacing the lter element.

Steering Control Unit

The steering control unit is a hydraulic oil-metering valve that is con-

trolled by the steering wheel.

The unit is mounted inside the steering pod, and is connected by a shaft

to the steering wheel. This open-center, rotary actuated hand pump

determines the amount of oil that ows to the steering cylinder. When

the steering wheel is stationary, oil ows freely through the control unit

and not to the steering cylinder.

If the engine stops running, the steering control becomes a manually

operated hand pump, so the truck can be steered to a controlled stop

with increased steering wheel effort.

A manifold assembly is mounted to the steering control unit, which

contains the relief valve set at 2400 psi. A check valve is provided to

prevent steering kick back.

7

8

Tilt Cylinders

Two double-acting tilt cylinders are mounted in a shielded location above

the fenders. The tilt cylinder mounting is widely spaced for mast support

and good visibility.

The cylinders are fastened to the mast and frame anchors by hardened

steel pins, and pivot through replaceable spherical bushings. Lube t-

tings are provided at each tilt pin to reduce wear.

Chromed rods and single-lip urethane seals are self lubricating to offer

outstanding cylinder life and low maintenance. Wiper rings are used to

help prevent contaminants from entering the cylinders.

Hydraulic (brake) oil cooler

A separate cooler unit is mounted in front of the truck near the hydraulic

valve bay area. Three (3) electric driven fans are switched on at an oil

temperature of 158 F.

The 1138 btu/min cooler unit with low return line restriction is plumbed

into the brake system.

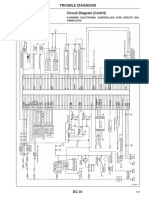

E. ELECTRICAL SYSTEM 24 VOLT

Emphasis has been to improve truck reliability with a major upgrade

in the connector technology and the routing of the harness. Signicant

improvements in the level and quality of information are available to

the operator by a new state of the art instrumentation cluster that has

been introduced.

Deutsch sealed wiring connectors are employed throughout the truck. The

harnesses are pre-wired for ease of option tment in both factory and eld.

A single color wire with number codes for each wire has been introduced.

A multi-function display panel provides the operator with all information

on the machine status.

Switches are mounted on the right hand armrest and console. Provision

is made available for 12 switches on the armrest and 7 others are avail-

able on the console.

A 12V converter has been made standard and comes with a 12V

power socket and radio mounting bracket. The operator compartment

headliner is wired with two 12V connections for Radio and CB or other

electrical equipment and is powered by the 12V converter option.

The fuse and relay panels are located in the right hand side console.

They are grouped together and are easy to access. Depending on the

machine specication there is provision for 40 fuses and 8 relays.

Particular attention has been paid to the location, routing and clamp-

ing of the wire harness to ensure that it is not exposed to heat and oil

contamination.

The standard (Delco 24SI) alternator has an output of 70-amp and has

an internal regulator.

The truck is wired and prepared for light options:

Cab and front fenders are pre-drilled to make it easy to install.

The tail light assembly is standard and is a cluster of brake/tail, turn

and reversing lights positioned into the rear fenders/ counterweight.

Both Halogen and H(igh) I(ntensity) D(ischarge) lights are available

as options

The electrical system is designed to meet UL 558 requirements.

Two batteries each 12V 900A cold cranking amps are employed. These

are mounted in the battery box located at the left-hand running board.

The box is integrated into the fuel tank side wall.

Warning LEDs are mounted in the steering column directly in line with

the operators line of sight to provide a warning of any malfunction

indicated by the display in the right-hand console. This arrangement

provides excellent forward visibility whilst alerting the operator of any

need to check the comprehensive indicator display. Further information

on the fault is available on this multi-functional indicator display panel

located to the operators right.

The starter motor is a 24-volt heavy duty with integral over-running

clutch mechanism and solenoid. The clutch functions to protect the

starter armature from over-speeding. A starter lockout mechanism is

contained in the key switch to prevent engagement of the starter when

the engine is running.

A lockout switch prevents engagement of the starter unless the trans-

mission is in neutral, by placing the direction control in neutral on the

lever-shifted trucks, or by applying the park brake on Monotrol trucks.

You can start if you apply the brake/inching pedal.

The air horn is located below the cab and can be actuated in a number

of ways depending on the machine specication. These are:

Pressing the horn button in the center of the steering wheel;

Pressing the button on the joy-stick;

Pressing the switch on the right hand side arm rest.

All electrical connections to the operator compartment are via high qual-

ity quick release plug and socket connectors.

Audible and visual warnings are provided as shown in the following

chart on page 9.

Truck is equipped with a standard audible backup alarm.

STANDARD FEATURES & OPTIONS

9

20,000

25,000

30,000

35,000

40,000

45,000

50,000

0 12 24 36 48 60 72

R

A

T

E

D

L

O

A

D

(

l

b

s

)

LOAD CENTER (in)

RATED LOAD vs. LOAD CENTER

STANDARD CARRIAGE

U. S. CUSTOMARY

H450HD

H450HDS

H400HD

H400HDS

TRUCK CONFIGURATION:

Vista 2-Stage 212/173 mast.

Standard pin type sideshift fork positioner

carriage.

RATED CAPACITIES

VISTA CAB DASH DISPLAY

Dash display

warning light

Dash display dial

Master steer pod

warning light

Intermittent

audible warning

Engine shut down

Park brake X X

Fasten seat belt X

Engine low oil pressure 0.4 bar / 6 psi X X X X

Engine coolant high temperature 107 C / 225 F X X X X

Engine air inlet high temperature 93 C / 200 F X

Engine coolant low level 50% X

Water separator fuel system X

Engine air lter high restriction X

Battery charge (alternator) (Vbatt < 22.5V)

Fuel low level 10% X X

Hydraulic brake system low pressure 90 bar / 1300 psi X

Hydraulic brake high oil temperature 110 C / 230 F X

Transmission low oil pressure (T.C.-out) 9 bar / 130 psi X X X

Transmission high oil temperature 125 C /257 F X X X

Transmission high oil temp (sump) <= 50% throttle

Transmission error - code X X (LCD) X

Engine hour meter X (LCD)

Engine shut down warning X X X

Engine error - code X X (LCD)

Operator not present with park brake off 10 sec

|1P

|NS|UL 1UPN|NG PAU|US

10

SPECIFICATIONS

1B

20

21

22

42

23

1S

1S

14

14

19

11

DIMENSIONS

CERTIFICATION: These Hyster

lift trucks meet design specications of Part II ANSI B56.1-1969, as required by OSHA Section 1910.178(a)(2) and also comply with Part III ANSI B56.1-revision in effect at time of

manufacture. Certication of compliance with the applicable ANSI standards appears on the lift truck.

NOTE: Performance specications / ratings are for truck equipped as described under Standard Equipment in this Technical Guide. Performance specications are affected by the condition of the vehicle and how it is

equipped, as well as by the nature and condition of the operating area. Specications are subject to change and the proposed application should be discussed with your authorized Hyster Dealer.

G

E

N

E

R

A

L

1

2

3a

3b

5

6

7

8

D

I

M

E

N

S

I

O

N

S

10

11

13a

13b

14

15

16

17

18

19

20

21

22

23

24

25

26

27

P

E

R

F

O

R

M

A

N

C

E

28

29

30

31

32

33

34

35

W

T

.

36

37

38

39

W

H

E

E

L

S

40

41

42

43

44

Manufacturer Name HYSTER HYSTER HYSTER HYSTER

Model H400HDS H400HD H450HDS H450HD

Load capacity (36 load center) lb 40,500 40,500 45,000 45,000

Load capacity (48 load center) lb 35,200 35,200 39,600 39,600

Power: battery, diesel, LPG, electric mains Diesel Diesel Diesel Diesel

Operation: manual, pedestrian, stand, sit, seat Sit Sit Sit Sit

TIres: L=pneumatic, V=solid, SE=pneumatic-shaped solid L/SE L/SE L/SE L/SE

Number of wheels, front/rear (X = driven) 4X/2 4X/2 4X/2 4X/2

Lift height (TOF) in 212.6 212.6 212.6 212.6

Free lift (TOF) in N/A N/A N/A N/A

Fork dimensions, thickness/width/length in 4 x 8 x 96 4 x 8 x 96 4 x 10 x 96 5 x 10 x 96

Fork carriage width in 105 105 114 114

Mast tilt, a = forward /b = back degrees 10/12 10/12 10/12 10/12

Length to face of forks in 216 226 216 226

Center Drive Tire to Face of Forks in 39.8 39.8 42 42

Overall width in 116 116 116 116

Height of mast, lowered in 174.2 174.2 179.5 179.5

Height of mast, extended in 278.5 277.2 283.9 283.9

Cab height (deduct 2 inch for non-cab option) in 133 132 133 133

Seat height in 86 84 86 86

Towing coupling height in 34 34 34 34

Overall length (with 96 inch forks) in 312 322 312 322

Outer turning radius in 197 207 197 207

Inner turning radius (To C.L. of truck) in 77 80 77 80

Aisle width for 90 deg stack with pallets 48 x 48 wide (a=0 mm) in 344 350 344 350

Stability (Comply with ANSI B56.1) YES YES YES YES

Travel speed with/without load mph 16.7 / 19.2 16.1 / 17.4 17.3 / 18.0 17.3 / 18.0

Lifting speed with/without load ft/min 64.9 / 74.8 64.9 / 74.8 64.9 / 74.8 64.9 / 74.8

Lowering speed with/without load ft/min 66.9 / 76.7 66.9 / 76.7 66.9 / 76.7 66.9 / 76.7

Drawbar pull with/without load @ 1.m/h lbs-f 24953 / 20457 21805 / 22255 24953 / 20232 24953 / 20232

Drawbar pull with/without load, Max. lbs-f 25627 / 25852 28325 / 28774 24953 / 25852 24953 / 25852

Gradeability with/without load @ 1 m/h % 24 / 35 24 / 42 22 / 34 22 / 33

Gradeability with/without load, Max. % 29 / 37 32 / 35 28 / 36 28 / 36

Acceleration time with/without load (0-50 ft distance) sec 5.9 / 6.5 5.9 / 6.5 5.6 / 6.4 5.6 / 6.4

Unladen weight including front end lb 60,289 58,679 66,204 64,034

Axle loading with load, front/rear (36in LC) lb 92,983 / 7,870 90,059/8,262 100,513 / 9,700 97,303/8,464

Axle loading with load, front/rear (48in LC) lb 87,628 / 7,934 85,535/8,170 96,959 / 8,933 92,200/8,250

Axle loading without load, front/rear (36in and 48in LC) lb 28,752 / 31,536 27,415/30,406 30,961 / 35,249 28,526/32,240

Tire size, front (minimum) 14.00 X 24 - 20 14.00 X 24 - 20 14.00 X 24 - 20 14.00 X 24 - 20

Tire size, rear (minimum) 14.00 X 24 - 20 14.00 X 24 - 20 14.00 X 24 - 20 14.00 X 24 - 20

Wheelbase in 138 148 138 148

Tread width, front (cl outer tires ) in 100 100 100 100

Track width, rear in 83 83 83 83

Hyster and are registered trademarks of Hyster Company. ComforCab II, Yardmaster and

are trademarks of Hyster Company. Hyster products are subject to change without notice.

Cummins, Dana, Spicer, AxleTech International, Sears, Danfoss, Barnes, Husco, HydraForce, and Delco are registered

trademarks of their respective companies. 2007 Hyster Company. All rights reserved.

Hyster Company

P.O. Box 7006

Greenville, North Carolina

27835-7006

Part No. H400HD-450HD/S

BTG 2/2007 Litho in U.S.A.

Its not just about the lift trucks.

Any company worth its weight knows success has just as much to do with

the support before and after the sale as the sale itself. We pride ourselves on

being more than just a lift truck manufacturer. Through our Dealer Network,

were also eet managers, parts suppliers, capital procurement specialists and

trainers. Youll nd that when it comes to service, we do it all.

Hyster Fleet Services

As much as wed like for your entire eet to be Hyster, we know thats not

always the case. But just because you also operate other brands doesnt mean

we cant manage your lift truck maintenance and replacement plan. We can

analyze your current eet or provide summary of your eet history and a

cost-effective proposal for replacement and scheduled maintenance of all your

vehicles. Once this initial review is complete, well continue to monitor your

eet to ensure its performing optimally.

UNISOURCE Parts Program

In addition to providing eet management for a variety of brands, we can

also serve as your source of parts for all your lift trucks. With the Hyster

UNISOURCE parts and service program, we offer approximately 2 million

part number crosses for most brands of materials handling and other in-plant

mobile equipment. UNISOURCE also has remanufactured parts that provide

the same quality and guarantee but at a lower price. And we can deliver parts

to you in less than 24 hours, any day of the week. Hows that for convenience?

Rental Products

At Hyster Company, were always looking for ways to help you keep your

productivity up. Through the Hyster Dealer Network, you can access rental

equipment for the times when leasing or buying isnt a practical option. Your

local Hyster Dealer has access to over 14,000 units that are available for short-

or long-term rental. Whether you need one truck to substitute for a vehicle

thats being serviced or several lift trucks to accommodate seasonal changes

in your business, well help you maintain output in a cost-effective manner.

Hyster Capital

We know that nancing new additions to your eet can sometimes be

challenging. Thats why your Hyster Dealer has a long list of ways for you to

fund your purchase. We are skilled in arranging solutions for special nancing

requirements, taking the difculties out of buying the equipment you need.

Whether you purchase or lease a new or used lift truck, Hyster Capital offers

better service and competitive rates, ensuring you receive the value you deserve.

Special Products

Engineering Department (SPED)

In a perfect world, every application could be handled with a standard lift truck.

However, in the real world, different materials require different handling. Thats

why Hyster Companys Special Products Engineering Department works with

you to customize* your lift trucks. From strobe lights to specially made forks,

SPED can provide you with the tools you require to get the job done right.

* May be subject to an additional charge. Contact your local authorized Hyster Dealer for more

information.

Automated Warehouse Solutions

As societys technological capabilities advance, we strive to nd practical

applications. One of our most recent innovations in that pursuit is our

development of automated warehouse solutions. We can help you determine

if your operation would benet from this type of system, which improves

inventory accuracy, warehouse productivity and safety records, as it reduces

maintenance and overtime.

Operator and Service Training

Hyster Company recognizes that proper training is a key element of a protable

company. Thats why your local authorized Hyster Dealer offers a training

program for your lift truck operators as well as those who maintain your vehicles.

Proper education in running and servicing lift trucks cuts down on the number

of repairs and risk of injuries due to accidents while increasing productivity. All of

our trainers are professionals with experience in materials handling.

I

S

O

9

0

0

1: 2000 A

1

2

4

3

5

R

E

G

I

S

T

ERED

F

I

R

M

H

Y

S

T

ER COM

P

A

N

Y

U

L

Visit us online at www.hysteramericas.com

or call us at 1-800-HYSTER-1.

S-ar putea să vă placă și

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDe la EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallEvaluare: 4 din 5 stele4/5 (8)

- Axor WebDocument14 paginiAxor Webkremoso100% (1)

- GP15N GP35N IC Pneumatic Trucks Electronic Sales ManualDocument139 paginiGP15N GP35N IC Pneumatic Trucks Electronic Sales ManualRodney Richardson83% (6)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 2.5 din 5 stele2.5/5 (2)

- JCB Drivetrain System 9803-9240 Service ManualDocument108 paginiJCB Drivetrain System 9803-9240 Service ManualMarcin Marszałek100% (1)

- PC1250-8 PC1250SP-8Document20 paginiPC1250-8 PC1250SP-8Banu Agus Hartoyo100% (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Încă nu există evaluări

- CAT D9 SpecsDocument28 paginiCAT D9 SpecsKocic Balicevac100% (1)

- 80ZV 80C4 5001 93309 00134 - UsaDocument604 pagini80ZV 80C4 5001 93309 00134 - UsaДенис Сухарев100% (3)

- Catalogo 962GII PDFDocument28 paginiCatalogo 962GII PDFlkrlozZ100% (1)

- 973CDocument24 pagini973CVictor M. Mejia Diaz100% (1)

- FTR 900 Singular Cab y Crew Cab Australia PDFDocument4 paginiFTR 900 Singular Cab y Crew Cab Australia PDFdionymackÎncă nu există evaluări

- Bulldozer d9t CatDocument20 paginiBulldozer d9t CatJuan David JaramilloÎncă nu există evaluări

- Yale 13500Document6 paginiYale 13500VitorMelloÎncă nu există evaluări

- Wheel ExcavatorDocument32 paginiWheel Excavatorpricopdaniel100% (1)

- 928G 6XR ElectricoDocument4 pagini928G 6XR ElectricoRodney Richardson100% (3)

- Construction and Manufacture of AutomobilesDe la EverandConstruction and Manufacture of AutomobilesEvaluare: 5 din 5 stele5/5 (1)

- 953CDocument24 pagini953CVictor M. Mejia Diaz0% (1)

- Ficha Tecnica d6tDocument28 paginiFicha Tecnica d6tWilmer Stiven MartinezÎncă nu există evaluări

- 140 H GlobalDocument20 pagini140 H GlobalJoan CzÎncă nu există evaluări

- Truck FC4J ServiceDocument646 paginiTruck FC4J ServiceAndres JuarezÎncă nu există evaluări

- D5N PDFDocument24 paginiD5N PDFPedro Calderon Vasquez75% (4)

- Cat D11RDocument24 paginiCat D11Rluphynt_4100% (2)

- Epiroc RD20 BrochureDocument8 paginiEpiroc RD20 BrochureY.EbadiÎncă nu există evaluări

- Technical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 TonnesDocument16 paginiTechnical Information KALMAR DCF280-500, DIESEL.: Heavy Lift Trucks 28 - 50 Tonnescostinha fabio50% (2)

- Cat 16m Grader BrochureDocument24 paginiCat 16m Grader BrochureSauro GordiniÎncă nu există evaluări

- Caterpillar M320D Wheel - ExcavatorDocument24 paginiCaterpillar M320D Wheel - ExcavatorЮлия Дам100% (5)

- Volvo Crawler Excavators: More Care. Built inDocument12 paginiVolvo Crawler Excavators: More Care. Built inAnonymous 0PuvmpoÎncă nu există evaluări

- Mack EpcDocument1 paginăMack Epcjansjoh100% (1)

- Tractores de Ruedas Cat Specalog 824h Wheel DozerDocument20 paginiTractores de Ruedas Cat Specalog 824h Wheel DozerAnthony Lalo MartinezÎncă nu există evaluări

- Fuente Segura Cat 2013Document676 paginiFuente Segura Cat 2013aleruho100% (7)

- WA470-5 KatalogDocument7 paginiWA470-5 KatalogPhilip Chandra100% (2)

- ECMDocument6 paginiECMRodney Richardson100% (7)

- Volvo ECR58Plus ECR88PlusDocument12 paginiVolvo ECR58Plus ECR88PlusShailesh KhodkeÎncă nu există evaluări

- Tiguan Haldex Gen4Document32 paginiTiguan Haldex Gen4kscoggs100% (1)

- PM 565 BDocument21 paginiPM 565 BFlorin Gabor100% (1)

- CAT CG Excavadoras Ruedas M315DDocument36 paginiCAT CG Excavadoras Ruedas M315DEriksen Mallma MoránÎncă nu există evaluări

- 963CDocument24 pagini963CVictor M. Mejia Diaz100% (1)

- RH6.5 ProspektDocument14 paginiRH6.5 ProspektEslam FaroukÎncă nu există evaluări

- Yale 3000Document2 paginiYale 3000VitorMelloÎncă nu există evaluări

- Truck Systems Design Handbook PT 41 P 62519365Document5 paginiTruck Systems Design Handbook PT 41 P 62519365Shaswat SinghÎncă nu există evaluări

- 928GDocument24 pagini928GChe Jose100% (4)

- Motoniveladora Cat 140M Motor C9 PDFDocument28 paginiMotoniveladora Cat 140M Motor C9 PDFdanilo100% (3)

- BFL Case StudyDocument20 paginiBFL Case StudyRajesh K Pillania88% (8)

- IS .6521.1.1972 Tower CraneDocument45 paginiIS .6521.1.1972 Tower CraneHs ChopraÎncă nu există evaluări

- TB45 Software User GuideDocument21 paginiTB45 Software User GuideRodney RichardsonÎncă nu există evaluări

- Power Transfer Electric Shift Circuit TAYLOR FORKLIFTDocument2 paginiPower Transfer Electric Shift Circuit TAYLOR FORKLIFTRodney RichardsonÎncă nu există evaluări

- Caterpillar Wheel Loader CAT IT28gDocument28 paginiCaterpillar Wheel Loader CAT IT28glpolob9061Încă nu există evaluări

- User Manual PDFDocument124 paginiUser Manual PDFmukeshÎncă nu există evaluări

- 12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFDocument16 pagini12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFadamajaks1985100% (2)

- Fendt700 800InfoGuideDocument56 paginiFendt700 800InfoGuideKole964Încă nu există evaluări

- ATEGO - SpecificationsDocument18 paginiATEGO - SpecificationsKovács Áron100% (3)

- BW216DH 3 BW225D 3 Service TrainingDocument217 paginiBW216DH 3 BW225D 3 Service TrainingTimon2005Încă nu există evaluări

- Giga Cxz415 Giga Cxy415 Ark0578Document4 paginiGiga Cxz415 Giga Cxy415 Ark0578Yogi YoiÎncă nu există evaluări

- Camiones Hitachi 2Document7 paginiCamiones Hitachi 2Lineker Diaz100% (1)

- Hitachi Monorail Technology Presentation: September 3, 2013Document29 paginiHitachi Monorail Technology Presentation: September 3, 2013Luis Mogrovejo100% (1)

- Series: Counterbalanced Electric, Cushion TireDocument20 paginiSeries: Counterbalanced Electric, Cushion Tireleorodrigues2012100% (1)

- H400-450HDS BTGDocument12 paginiH400-450HDS BTGMd. Hasanuzzaman ShowketÎncă nu există evaluări

- Cs 583 eDocument16 paginiCs 583 easadiqbalansariÎncă nu există evaluări

- Komatsu HD325 6Document8 paginiKomatsu HD325 6Munawar Sher MuhammadÎncă nu există evaluări

- Blue Bird All American Rear Engine School BusDocument2 paginiBlue Bird All American Rear Engine School BusMacAllister MachineryÎncă nu există evaluări

- 2008 - Cargador 980GDocument28 pagini2008 - Cargador 980GAlejo_alar2014100% (1)

- HD325 6Document8 paginiHD325 6Tara Ayu CendaniÎncă nu există evaluări

- 420E/420E IT: Backhoe LoadersDocument28 pagini420E/420E IT: Backhoe LoadersCèsar Velasquez MestanzaÎncă nu există evaluări

- Retroexcavadoras Cat 420e-420e It (Acert 4.4)Document28 paginiRetroexcavadoras Cat 420e-420e It (Acert 4.4)Raul ChuraÎncă nu există evaluări

- 216 BrochureDocument12 pagini216 Brochureleotiger123Încă nu există evaluări

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 paginiSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezÎncă nu există evaluări

- Cargador Frontal WA500-6 (English) KomatsuDocument12 paginiCargador Frontal WA500-6 (English) KomatsuRoman Roa Machuca100% (1)

- Dca0078 Actros 3244Document6 paginiDca0078 Actros 3244eng_ebrahim_20000% (1)

- Wa200-5 Aess643-00Document12 paginiWa200-5 Aess643-00alsief1951100% (4)

- Cat 657g PDFDocument20 paginiCat 657g PDFMario E. Garcia Rodriguez100% (1)

- Hydraulic Excavator: Engine WeightsDocument24 paginiHydraulic Excavator: Engine WeightsRoberto HernandezÎncă nu există evaluări

- ECR28 ECR38 BrochureDocument12 paginiECR28 ECR38 Brochuredalibor_bogdanÎncă nu există evaluări

- Otor Rader: 149 KW 200 HP 14870 KG 32,780 LB 3.71 M 12 FTDocument7 paginiOtor Rader: 149 KW 200 HP 14870 KG 32,780 LB 3.71 M 12 FTAdi SekarepeÎncă nu există evaluări

- Off-Highway TruckDocument28 paginiOff-Highway TruckrodizianoÎncă nu există evaluări

- With New Hi-Line Versions: Traditionally InnovativeDocument16 paginiWith New Hi-Line Versions: Traditionally InnovativemiminiweweÎncă nu există evaluări

- K-Engine Electronic Controlled Ecm Circuit Diagram (Gasoline)Document1 paginăK-Engine Electronic Controlled Ecm Circuit Diagram (Gasoline)Rodney RichardsonÎncă nu există evaluări

- K-Engine Electronic Controlled Ecm Circuit Diagram (Combined Gasoline and LPG)Document1 paginăK-Engine Electronic Controlled Ecm Circuit Diagram (Combined Gasoline and LPG)Rodney Richardson100% (1)

- K-Engine Electronic Controlled Ecm Circuit Diagram (Gasoline)Document1 paginăK-Engine Electronic Controlled Ecm Circuit Diagram (Gasoline)Rodney RichardsonÎncă nu există evaluări

- General Precautions For Service OperationsDocument1 paginăGeneral Precautions For Service OperationsRodney RichardsonÎncă nu există evaluări

- Diagnostic Test Mode 1 - Bulb CheckDocument1 paginăDiagnostic Test Mode 1 - Bulb CheckRodney RichardsonÎncă nu există evaluări

- Service and Replacement Parts Manual: WarningDocument136 paginiService and Replacement Parts Manual: WarningRodney RichardsonÎncă nu există evaluări

- 2013 Shop SuppliesDocument1 pagină2013 Shop SuppliesRodney RichardsonÎncă nu există evaluări

- Motec CamerasDocument32 paginiMotec CamerasRodney RichardsonÎncă nu există evaluări

- SX125 CompleteDocument109 paginiSX125 CompleteMuhamad KarisÎncă nu există evaluări

- Automotive Transmission - 2Document9 paginiAutomotive Transmission - 2Pradeep SudhanÎncă nu există evaluări

- MRDocument32 paginiMRZicon77Încă nu există evaluări

- Maintenance InstructionDocument96 paginiMaintenance InstructionIonut Valentin VladÎncă nu există evaluări

- Drive Train FINAL EXAM 47 of 70Document15 paginiDrive Train FINAL EXAM 47 of 70Sunny SÎncă nu există evaluări

- Brosur Loader CaterpillarDocument4 paginiBrosur Loader CaterpillarWildan KurniaÎncă nu există evaluări

- New Release - July 3, 2014Document17 paginiNew Release - July 3, 2014KacyOlesonÎncă nu există evaluări

- T815 SpecDocument1 paginăT815 SpecSohil SolaniÎncă nu există evaluări

- Tiguan Haldex All Wheel DriveDocument30 paginiTiguan Haldex All Wheel DriveAntónio FernandesÎncă nu există evaluări

- UK and Ireland/UK/Stralis Euro VI/Hi-Road (At) - Hi Street (AD) /Rigid/6x2/Stralis Euro VI AD at 260S31YPDocument2 paginiUK and Ireland/UK/Stralis Euro VI/Hi-Road (At) - Hi Street (AD) /Rigid/6x2/Stralis Euro VI AD at 260S31YPCristian ChiruÎncă nu există evaluări

- MT6300D AcDocument4 paginiMT6300D AcАлиса Пестрова100% (1)

- Determination of Floor Load Requirements PDFDocument7 paginiDetermination of Floor Load Requirements PDFNeil WilsnachÎncă nu există evaluări

- 42SWP22 Lawn SweeperDocument12 pagini42SWP22 Lawn SweeperPurpleRyderÎncă nu există evaluări

- Question Bank Automobile EngineeringDocument5 paginiQuestion Bank Automobile EngineeringAjay Kumar AgarwalÎncă nu există evaluări

- Front Suspension - Basic Suspension, ServicingDocument20 paginiFront Suspension - Basic Suspension, ServicingEttore ScolaÎncă nu există evaluări

- Machine Design Complete PDFDocument215 paginiMachine Design Complete PDFJobert Arsenal CaroÎncă nu există evaluări