Documente Academic

Documente Profesional

Documente Cultură

Drive and Control Systems For Loaders

Încărcat de

Mecanica Automotriz OrgumotorsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drive and Control Systems For Loaders

Încărcat de

Mecanica Automotriz OrgumotorsDrepturi de autor:

Formate disponibile

Drive a nd Cont rol Syst e ms for Loa de rs

2

Drive a nd cont rol syst e ms for loa de rs

Comfort

Efficie ncy

Environme nt

prot e ct ion

Ope ra t iona l

sa fe t y

Opt imum e rgonomic

Funct iona l ope ra t ion

Low me cha nica l force s

Opt imum powe r ut ilisa t ion

Opt imum ma chine ut ilisa t ion

High a va ila bilit y

Re duce d fue l consumpt ion

Re duce d e xha ust e missions

Re duce d noise e missions

St a nda rdise d compone nt s

Modula r de sign

Re duct ion of me cha nica l compone nt s

Adva nt a ge s of hydrost a t ic drive syst e ms

Ve ry high de ma nds a re pla ce d on t he drive

t e chnology of mobile loa ding ma chine s wit h

re ga rd t o e fficie ncy a nd drive r comfort .

The Ma nne sma nn Re xrot h Group of compa nie s,

wit h it s busine ss se ct ors of Brue ningha us Hydroma t ik

a nd Re xrot h Hydra ulics, supply comple t e drive a nd cont rol syst e ms

t ha t fully me e t t he se re quire me nt s.

For loa de rs in t he powe r ra nge of up t o 6 0 kW pure ly hydrost a t ic

drive s a re t he norm.

For t he highe r powe r ra nge (> 6 0 kW) a s we ll a s t he hydrost a t ic

drive s wit h a subse que nt powe r shift ge a rbox, mult iple mot or

drive s wit h a summa t ion ge a rbox a re a lso ut ilise d.

Wit h mult iple mot or drives t wo hydra ulic mot ors opera t e in pa ra llel

a nd a re conne ct e d t o t he drive sha ft via a me cha nica l summa t ion

ge a rbox.

For t he powe r ra nge a bove 1 2 5 kW mult i-mot or conce pt s wit h

swit cha ble summa t ion ge a rboxe s provide t he ide a l solut ion.

The ma na ge me nt of t he e nt ire drive t ra in is cont rolle d via a micro-

cont rolle r.

As wit h t he t ra ve l drive s t he e fficie ncy, high pe rforma nce a nd

ope ra t or comfort of t he se rvice hydra ulics is of e qua l import a nce.

As we ll a s t he conve nt iona l ope n ce nt e r cont rols a nd loa d se nsing

syst e ms wit h fixe d or va ria ble displa ce me nt pumps t he LUDV

cont rol, which ha s be e n de ve lope d a nd pa t e nt e d by Re xrot h

Hydra ulics, is be ing incre a singly a pplie d.

3

4

K

1

K

2

K

3

K

4

30

25

20

15

10

5

30 60 90 120 150 180 210 250

6

5

4

3

2

1

0,5

An ove rvie w of t ra ve l drive syst e ms

Corre la t ion of drive syst e ms t o powe r ra nge

Hydrost a t ic

t ra nsmission

U

n

l

a

d

e

n

w

e

i

g

h

t

o

f

u

n

i

t

(

t

)

B

u

c

k

e

t

v

o

l

u

m

e

(

m

3

)

Drive power (kW)

wit h

summa t ion

ge a rbox

k 2 mot ors

wit h

powe r shift

ge a rbox

wit h

summa t ion

ge a rbox

k 2 mot ors

k 1 coupling

wit h

summa t ion

ge a rbox

k 2 mot ors

k 3 couplings

wit h me cha -

nica l dirce t

t hrough

drive

5

Hydrost a t ic

k Hydra ulic conve rsion, st e ple ss

k Shift (hydra ulic mot or) shock-fre e

k No int e rrupt ion of t ra ct ive e ffort

A4 VG + A6 VM

Drive Powe r ra nge < 6 0 kW

Hydrost a t ic + powe r shift ge a rbox

k Hydra ulic conve rsion,

st e ple ss + me cha nica l swit ching st a ge s

k Shift (ge a rbox) virt ua lly shock-fre e

k Brie f int e rrupt ion of t he t ra ct ive e ffort

A4 VG + A6 VM + powe r shift ge a rbox

Hydrost a t ic + summa t ion ge a rbox

k Hydra ulic conve rsion, st e ple ss

k Shift (hydra ulic mot or) shock-fre e

k No int e rrupt ion of t ra ct ive e ffort

A4VG + 2 x A6VM + summa t ion ge a rbox

(wit hout /wit h ge a r shift coupling)

Powe r ra nge > 5 0 kW

Powe r ra nge > 6 0 kW

Powe r ra nge 5 0 1 0 0 kW

Hydrost a t ic + me cha nica l

k Hydra ulic conve rsion,

st e ple ss + me cha nica l dire ct t hrough drive

k Shift virt ua lly shock-fre e

k Brie f int e rrupt ion of t he t ra ct ive e ffort

A4 VG + A6 VM + summa t ion ge a rbox

(wit h ge a r shift clut ch)

6

1 2

Va ria ble displa ce me nt pump A4VG...DA

Da t a she e t RE 9 2 0 0 3

Va ria ble displa ce me nt pump A10VG...DA

Da t a she e t RE 9 2 7 5 0

Drive dire ct ion va lve

DA cont rol va lve for

RPM re la t e d spe e d de finit ion

Loa d limit a t ion cont rol

Int e gra t e d inching funct ion,

inching va lve ca n be

opt iona lly cont rolle d by t he

bra ke pre ssure

Pre ssure cut -off

Va ria ble displa ce me nt mot or

A6VM...HA1R

Da t a she e t RE 9 1 6 0 4

Loa d de pe nde nt cont rol (HA1 )

V

g ma x

circuit :

Mot or ca n be he ld in t he V

g ma x

posit ion via a swit ching sole noid

Va lve for direct ion of t ra vel signa l

se nsing

Hydrost a t ic t ra nsmission

Mechanical

injection pump

Accelerator

pedal

Inching

pedal

Brakes

Direction

of travel

Override

A4VG..DA

A6VM..HA1R

T

r

a

c

t

i

v

e

e

f

f

o

r

t

Vehicle velocity

Motor

Pump

7

MC

+

Softwa re

LSG

BB-3

RS 232

K

1

K

2

STM

T

r

a

c

t

i

v

e

e

f

f

o

r

t

Vehicle speed

1. Gear

2. Gear

A

c

t

u

a

l

R

P

M

P

o

s

i

t

i

o

n

c

o

m

m

a

n

d

v

a

l

u

e

P

o

s

i

t

i

o

n

a

c

t

u

a

l

v

a

l

u

e

R

P

M

G

e

a

r

2

G

e

a

r

1

Hydrost a t ic t ra nsmission wit h a powe r shift ge a rbox

Va ria ble displa ce me nt mot or

A6VM...DA2

Da t a she e t RE 9 1 6 0 4

RPM de pe nde nt spe e d se le ct ion

V

g ma x

circuit :

Mot or ca n be he ld in t he V

g ma x

posit ion via a swit ching sole noid

Va lve for direct ion of t ra vel signa l

se nsing

Powe r shift ge a rbox wit h a n A6VM

Da t a she e t RE 9 1 6 0 4

Direction of

travel

Accelerator

pedal

Gear

selection

Change

manual/

automatic

BB-3 Software

Bodem

Inching

A6VM..DA A4VG..DA

Mechanical

injection pump

Electrical

actuator

Diagnostics

Parameter setting

Process monitoring

8

1 2

STM

K

2

K

1

K

3

MC

+

Softwa re BB-3

RS 232

Summation gearbox with/without coupling

Summation gearbox with 3 gear shift clutches

RPM

Hydrost a t ic t ra nsmission wit h summa t ion ge a rbox

Mechanical

injection pump

A4VG..DA

A6VM..HA1U

A6VM..HA1R

Accelerator

pedal

Inching

pedal

Brakes

Direction

of travel

Override

Direction of

travel

Accelerator

pedal

Gear

selection

Inching

pedal

BB-3 Software

Bodem

A6VM

2

A4VG

A6VM

1

Vehicle speed

T

r

a

c

t

i

v

e

e

f

f

o

r

t

A6VM

1

x i

1

A6VM

2

x i

3

A6VM

1

/De -couple d

A6VM

2

x i

3

A6VM

1

x i

2

A6VM

2

/De -couple d

P

o

s

i

t

i

o

n

c

o

m

m

a

n

d

v

a

l

u

e

P

o

s

i

t

i

o

n

a

c

t

u

a

l

v

a

l

u

e

Mechanical

injection pump

Electrical

actuator

Diagnostics

Parameter setting

Process monitoring

Vehicle speed

T

r

a

c

t

i

v

e

e

f

f

o

r

t

9

P

n

L

STM

K

2

K

1

MC

+

Softwa re

BB-3

RS 232

T

r

a

c

t

i

v

e

e

f

f

o

r

t

Vehicle speed

Switching point

Hydrostatic

Hydromechanical drive - force transmission

Mechanical

Hydromechanical drive

R

P

M

Hydrost a t ic t ra nsmission wit h a me cha nica l dire ct

t hrough drive

Hydrome cha nica l drive

k Combine s t he a dva nt a ge s of t he

hydrost a t ic drive wit h t ha t of t he

me cha nica l drive

Hydrost a t ic drive (working ra nge )

k Ma ximum t ra ct ive e ffort a t low die se l

spe e ds

k High st a rt -up e fficie ncy

k Je rk-fre e cha nge of t ra ve l dire ct ion

k Loa d limit ing cont rol a lso wit h powe r

consume d by a uxilia ry a ct ua t ors

k Re quire me nt de pe nde nt powe r

dist ribut ion be t we e n t he t ra ve l drive a nd

se rvice hydra ulics

Me cha nica l drive (cha nging t he

ope ra t ing loca t ion)

k Low e fficie ncy losse s

k Re duce d noise e missions

BKM

BKM

BB-3 Software

Bodem

A6VM

A4VG

Hydros ta tic

drive

Me cha nica l

dire ct drive

Direction of

travel

Accelerator

pedal

Gear

selection

Inching

pedal

P

o

s

i

t

i

o

n

c

o

m

m

a

n

d

v

a

l

u

e

P

o

s

i

t

i

o

n

a

c

t

u

a

l

v

a

l

u

e

Mechanical

injection pump

Electrical

actuator

Diagnostics

Parameter setting

Process monitoring

10

n

1

n

2

n

1

= n

2

n

1

< n

2

n

1

= n

2

B

K

M

A10VG

MCR

G2

G3

MCR 4TH6 4TH6

3 SM12

O

p

t

i

o

n

B

u

c

k

e

t

B

o

o

m

Steering via speed differences at the wheels on each side

Control of the implement hydraulics and the hydrostatic transmission via a joy-stick

Whe e l drive via MCR ra dia l pist on mot or

Hydrost a t ic t ra nsmission for compa ct loa de rs

2 circuit drive wit h a compa ct t a nde m pump

spe cia l de sign for compa ct loa de rs

Tandem pump A10VG + A10VG

11

12

STM

MC

+

Softwa re

FGR BB-3

RS 232

Accelerator

pedal

Inching

pedal

Travel direction:

forwards/neutral/

reverse

Tractive effort

limitation

Constant

Speed Drive

Cont rol block M7

Loa d se nsing a nd LUDV

Ant i-ca vit a t ion - pre -cha rge va lve

Ele ct rica l floa t posit ion

Se pa ra t e t a nk line wit h re ge ne ra t ion

Da t a she e t RE 6 4 2 9 1

Va ria ble displa ce me nt pump A4VG

For close d circuit t ra ve l drive s wit h e le ct ro-

proport iona l cont rol. The pump for t he

imple me nt hydra ulics is fit t e d t o t he t hrough

drive (1 0 0 % t hrough drive t orque ).

Da t a she e t RE 9 2 0 0 3

Va ria ble displa ce me nt pump

A10VO/A11VO

For ope n circuit imple me nt hydra ulics

cont rolle d via a microcont rolle r

Da t a she e t s RE 9 2 7 0 1 (A1 0 VO)

a nd RE 9 2 5 0 0 (A1 1 VO)

Va ria ble displa ce me nt mot or A6VM

For close d circuit t ra nsmission wit h e le ct ro-

proport iona l cont rol

Da t a she e t RE 9 1 6 0 4

Implement hydraulics

R

P

M

Ele ct ronic cont rol

Electronics for travel controls

Electronic control for implement hydraulics

A4VG A10VO/A11VO A6VM

BB-3 Software

Bodem

Control

block M7

Micro-

controller

Die s e l

motor

A4VG A10VO/A11VO

P

o

s

i

t

i

o

n

c

o

m

m

a

n

d

v

a

l

u

e

P

o

s

i

t

i

o

n

a

c

t

u

a

l

v

a

l

u

e

Mechanical

injection pump

Electrical

actuator

Diagnostics

Parameter setting

Process monitoring

13

BB-3

BODEM

Microcont rolle r MC7 + Soft wa re FGR

Enca psula t e d microcont rolle r for mobile

a pplica t ions

Soft wa re wit h loa d limit ing cont rol for hydro-

st a t ic t ra nsmission wit h a ut omot ive spe e d

cont rol

Da t a she e t s RE 9 5 0 5 0 , RE 9 5 0 5 7

Ele ct ronic a mplifie r ca rds MHVA, MHVT

Da t a she e t s, RE 2 9 8 7 5 , RE 2 9 8 8 0 ,

RE 2 9 8 8 2 , RE 2 9 8 8 3

Ele ct ronic t ra ve l cont rols

k Dire ct ion of t ra ve l pre -se le ct ion

k Pre -se t spe e d

k Acce le ra t ion/de ce le ra t ion pre -se le ct ion

k Drive cha ra ct e rist ics

Working mode : fla t cha ra ct e rist ic curve

Tra ve l mode : st e e p cha ra ct e rist ic curve

k Loa d limit ing cont rol

k Inching/bra king funct ion

k Ove r-spe e d sa fe t y for t he e ngine

k Hydra ulic mot or a djust me nt de vice

Ele ct ronic DA cont rol

V

g ma x

circuit

Addit iona l funct ions

k Tra ct ive e ffort limit a t ion

k Spe e d limit a t ion

Cra wl ge a r

Const a nt spe e d drive (CSD)

k Fue l e conomizing driving

k Int e gra t ion of t he se rvice hydra ulics

Ne t work via a CAN-bus

Accelerator

pedal

Inching

pedal

Service

hydraulics

Steering Travel

direction

Tractive

effort

CSD Diesel

motor

Variable

displacement

pump

Variable

displacement

motor

MC + FGR

Tra ve l c ont rols

MC

Se rvic e

hydra ulic s

Display

Process monitoring

(actual values)

CAN-Bus

PC +Software Bodem

Control panel BB-3

Diagnostics

Parameter setting

Process

monitoring

Ele ct ronic imple me nt hydra ulics

k Opt imum le ve lling ca pa bilit y e ve n due t o

t he Z-kine ma t ics

k Loa d limit a t ion, i. e. prot e ct ion a ga inst

ove r-loa ding t he bucke t

k Weight ing fa cilit y for t he bucket cont ent s

k Die se l mot or loa d limit a t ion

k Ma t ching t he working spe e d t o t he

ope ra t or

k St e e ring cont rol via a joy-st ick wit h a

sa fe t y swit ch

k Ne t working t he die se l mot or a nd t ra ve l

hydra ulics via a CAN-bus is possible

(se e be low)

14

80 KW

60 KW

100 KW

30 60 90 120 150 180 210 250

30

25

20

15

10

5

6

5

4

3

2

1

0,5

Fixe d displa ce me nt pumps Va ria ble displa ce me nt pumps

Fixe d displa ce me nt

pump G2/G3

For furt he r informa t ion se e da t a

she e t s RE 1 0 0 3 0 a nd RE 1 0 0 3 9

Va ria ble displa ce me nt

pump A10VO/3

For furt he r informa t ion se e

da t a she e t RE 9 2 7 0 1

Imple me nt hydra ulics for whe e l loa de rs

B

o

o

m

B

u

c

k

e

t

S

t

e

e

r

i

n

g

B

o

o

m

B

u

c

k

e

t

S

t

e

e

r

i

n

g

U

n

l

a

d

e

n

w

e

i

g

h

t

o

f

u

n

i

t

(

t

)

B

u

c

k

e

t

v

o

l

u

m

e

(

m

3

)

Drive power (kW)

15

Fixe d or va ria ble displa ce me nt pumps

for t he implement hydra ulics ca n be mount ed

ont o t he t hrough drive of (1 0 0 % t hrough

drive t orque) t he va ria ble displa cement t ra vel

drive pump. A split t e r box is not re quire d.

Cont rol block M7

Loa d se nsing a nd LUDV

Ele ct rica l floa t posit ion

Se pa ra t e t a nk line wit h re ge ne ra t ion

Da t a she e t RE 6 4 2 9 1

Cont rol block M1 a nd MO

Ope n ce nt e r cont rol

Ele ct rica l floa t posit ion

Re ge ne ra t ion va lve

Da t a she e t s RE 6 4 2 6 3 a nd RE 6 4 2 6 6

Pilot cont rol unit s 4THF6, 5THF6, 4TH6,

2TH6

Ele ct rica l or me cha nica l de t e nt

Floa t posit ion funct ion

Da t a she e t s RE 6 4 5 2 2 , 6 4 5 5 3 , 6 4 5 5 5

St e e ring unit s LAGUV a nd LSPSD

Amplifica tion a nd conversion for emergency

ope ra t ion

Priorit y va lve

Da t a she e t RE 1 4 3 6 5

Ca rt ridge va lve s a nd comple t e cont rol

blocks Da t a she e t RE 0 0 1 8 2

Drive with variable displacement pump

Drive with fixed displacement pump

Control

block

Die s e l

motor

Priority

valve

Die s e l

motor

Priority

valve

Control

block

16

Slew

Support

Boom

Dipper

Bucket

H

o

i

s

t

B

u

c

k

e

t

A

d

d

i

t

i

o

n

a

l

e

q

u

i

p

m

e

n

t

Fixe d displa ce me nt pumps G2/G3

For furt he r informa t ion se e da t a she e t s

RE 1 0 0 3 0 a nd RE 1 0 0 3 9

Va ria ble displa ce me nt pumps A10VO/3

For furt he r informa t ion se e da t a she e t

RE 9 2 7 0 1

Fixe d or va ria ble displa ce me nt pumps

for t he implement hydra ulics ca n be mount ed

ont o t he t hrough drive of (1 0 0 % t hrough

drive t orque) t he va ria ble displa cement t ra vel

drive pump

A split t e r box is not re quire d

Cont rol block M1 a nd MO

Ope n ce nt e r cont rol

Ele ct rica l floa t posit ion

Re ge ne ra t ion va lve

For furt he r informa t ion se e da t a she e t s

RE 6 4 2 6 3 a nd RE 6 4 2 6 6

Cont rol block M7

Loa d se nsing a nd LUDV

Ele ct rica l floa t posit ion

Se pa ra t e t a nk line wit h re ge ne ra t ion

For furt he r informa t ion se e da t a she e t

RE 6 4 2 9 1

Pilot cont rol unit s 4THF6, 5THF6, 4TH6,

2TH6

Ele ct rica l or me cha nica l de t e nt

Floa t posit ion funct ion

For furt he r informa t ion se e da t a she e t s

RE 6 4 5 2 2 , RE 6 4 5 5 3 , RE 6 4 5 5 5

St e e ring unit s LAGUV a nd LSPSD

Amplifica tion a nd conversion for emergency

ope ra t ion

Priorit y va lve

For furt he r informa t ion se e da t a she e t

RE 1 4 3 6 5

Ca rt ridge va lve s a nd comple t e cont rol

blocks

For furt he r informa t ion se e da t a she e t

RE 0 0 1 8 2

B

o

o

m

/

t

i

l

t

T

e

l

e

s

c

o

p

e

L

e

v

e

l

c

o

m

p

e

n

s

a

t

i

o

n

A

d

d

i

t

i

o

n

a

l

e

q

u

i

p

m

e

n

t

S

u

p

p

o

r

t

Imple me nt hydra ulics for ba ckhoe loa de rs

Service hydra ulics for t elescopic loa ders

Drive with variable displacement pump

Drive with variable displacement pump

Die s e l

motor

Loader control block

with priority valve

C

o

n

t

r

o

l

b

l

o

c

k

e

x

c

a

v

a

t

o

r

Loader control block

with priority valve

Die s e l

motor

17

D

ie

s

e

l

Diesel

Diesel

Hydra ulic re mot e ly powe re d bra ke

Brake light

switch

Accumulator pressure

warning switch

Brake pedal

Accumulator

pressure warning

Accumulator

loading valve

Additional (optional)

actuators

Brake pedal

Spring loaded

accumulator

2 circuit brake

valve

Parking brake

valve

Additional (optional)

actuators

2 circuit brake

valve

Brake light

switch

Parking brake

valve

Accumulator

loading valve

Spring loaded

accumulator

Compa ct de sign

k Piping re duce d t o a minimum

k Pa rking bra ke e le ct rica lly a ct ua t e d

k Possibilit y of dire ct ly mount ing t he

a ccumula t or

k Se nsit ive me t e ring

Compact brake block

LT13, Data sheet

RE 66220

Accumulator loading

valve LT06, Data sheet

RE 66191

Compact brake block

LT17, (for mounting in

the drivers cab)

Data sheet RE 66222

1 circuit remotely

powered brake valve

LT05, Data sheet

RE 66144

Inching brake valve

LT31, Data sheet

RE 66226

Modula r de sign

k Compone nt s ha ve a low spa ce

re quire me nt

k Compone nt s ca n be loca t e d whe re ve r

re quire d

k Se nsit ive me t e ring

k Quickly re a dy for ope ra t ion

18

EF

P

1

2

3

4

6

5

Service hydraulics

Priority valve

High pressure (not metered)

High pressure (metered)

Low pressure

Suction pressure

Entrapped oil

Ambient pressure

St e e ring syst e ms

k Ope n ce nt re st e e ring wit h non re a ct ion

k Close d ce nt re st e e ring wit h non re a ct ion

(loa d se nsing dyna mic)

Non rea ct ion mea ns t ha t t he occurring wheel

force s do not a ct on t he st e e ring whe e l via

t he st e e ring hydra ulics

LAG and LAS

Steering with chamber isolation - servo operation

RSM valve

Logic valve

LFA-D2 valve

4/2-way directional

valve

DBD valve

(design tested)

Accumulator

The Rexrot h st a bilisa t ion syst em RSM is built

int o t he lift cylinde rs of t he whe e le d loa de rs

a nd da mpe ns out t he pit ching oscilla t ions

which occur whilst t he ve hicle is moving.

The inst a lla t ion of t he RSM syst e m in whe e l

loa de rs re sult in t he following furt he r

a dva nt a ge s:

k Short e r bra king dist a nce s

k St a ble st e e ring cha ra ct e rist ics

k Highe r t ra nsport spe e ds

k Highe r t ra nsfe r ra t e s

k Gre a t e r comfort for drive r

k Lowe r re pa ir cost s or idle t ime s

St e e ring

St a bilisa t ion module RSM

For furt he r informa t ion se e da t a she e t

RE 6 4 6 1 5

RSM Syst e m

19

B

A

B

A

B

A

Filt e r ra t ing

To gua ra nt ee t he funct iona l sa fet y of t he a xia l

pist on unit s t he following cle a nline ss

cla sse s a re t he minimum re quire me nt s

ne ce ssa ry of t he pre ssure fluids

k 9 t o NAS 1 6 3 8

k 6 t o SAE

k 1 8 /1 5 t o ISO/DIS 4 4 0 6

For ve ry high pre ssure fluid t e mpe ra t ure s

(9 0 C up t o a ma ximum of 1 1 5 C) t he

following clea nliness cla sses a re the minimum

re quire me nt

k 8 t o NAS 1 6 3 8

k 5 t o SAE

k 1 7 /1 4 t o ISO/DIS 4 4 0 6

The fine r t he filt ra t ion t he be t t e r t he fluid

clea nliness cla ss obt a ined a nd t he higher t he

se rvice life of t he a xia l pist on unit s.

Use filt e r wit hout bypa ss.

Re comme nda t ion: use clogging indica t ors.

Furt her informa t ion rega rding filt ra t ion of t he

pre ssure fluids ca n be found in t he pump

da t a she e t s.

St a nda rd: suct ion filt ra t ion

(A4 VG / A1 0 VG)

Va ria nt : pre ssure filt ra t ion

(A4 VG / A1 0 VG)

Opt imum cold st a rt condit ions for pre ssure filt ra t ion is

a chie ve d via t he int e gra t e d filt e r short circuit va lve

Va ria nt : suct ion/re t urn filt ra t ion

Adva nt a ge s k Low spa ce re quire me nt s

k Improve d suct ion cha ra ct e rist ics

Return oil from the

implement hydraulics

Filt ra t ion

Crit e ria for t he funct iona l sa fe t y of a xia l pist on unit s

Drive a nd Cont rol

St a bilisa t ion module RSM

For da mpe ning t he pit ching

movements which occur during

ope ra t ion

For furt he r informa t ion se e

da t a she e t RE 6 4 6 1 5

Compone nt s

Va ria ble displa ce me nt pump

A4 VG

Close d circuit

Nomina l pre ssure 4 0 0 ba r

Pe a k pre ssure 4 5 0 ba r

For furt he r informa t ion se e

da t a she e t RE 9 2 0 0 3

Va ria ble displa ce me nt pump

A1 0 VO

Ope n circuit

Nomina l pre ssure 2 8 0 ba r

Pe a k pre ssure 3 5 0 ba r

For furt he r informa t ion se e

da t a she e t RE 9 2 7 0 1

Va ria ble displa ce me nt mot or

A6 VM

Ope n a nd close d circuit

Nomina l pre ssure 4 0 0 ba r

Pe a k pre ssure 4 5 0 ba r

For furt he r informa t ion se e

da t a she e t RE 9 1 6 0 4

Va ria ble displa ce me nt pump

A1 1 VO

Ope n circuit

Nomina l pre ssure 3 5 0 ba r

Pe a k pre ssure 4 0 0 ba r

For furt he r informa t ion se e

da t a she e t RE 9 2 5 0 0

Cont rol blocks

SM 1 2 /1 8 RE 6 4 1 2 2 /1 2 4

SP 1 2 /1 8 RE 6 4 1 4 5 /1 4 8

SX 1 8 RE 6 4 1 2 7

M1 -1 6 /2 2 /3 2 RE 6 4 2 6 3

M7 -2 2 RE 6 4 2 8 7

Pilot cont rol unit s

4 /5 THF6 RE 6 4 5 5 3

4 TH6 RE 6 4 5 5 5

2 -2 TH6 RE 6 4 5 5 2

Brue ningha us Hydroma t ik GmbH

Glocke ra ust ra e 2

D 8 9 2 7 5 Elchinge n, Ge rma ny

Te l + 4 9 (0 ) 7 3 0 8 8 2 0

Fa x + 4 9 (0 ) 7 3 0 8 7 2 7 4

Ma nne sma nn Re xrot h AG

Re xrot h Hydra ulics

Ja hnst ra e 3 -5

D 9 7 8 1 6 Lohr a m Ma in, Ge rma ny

Te l + 4 9 (0 ) 9 3 5 2 1 8 0

Fa x + 4 9 (0 ) 9 3 5 2 1 8 1 0 4 0

Cont rol block M7

Loa d se nsing a nd LUDV

For furt he r informa t ion se e

da t a she e t RE 6 4 2 9 1

Ra dia l pist on mot or MCR

Close d circuit

Nomina l pre ssure 4 0 0 ba r

Pe a k pre ssure 4 5 0 ba r

For furt he r informa t ion se e

da t a she e t s RE 1 5 2 0 5

t o 1 5 2 1 0

R

E

9

8

0

5

6

/

0

4

.

9

8

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- 145 KV Sf6 Circuit Breaker H'Mu NDocument15 pagini145 KV Sf6 Circuit Breaker H'Mu NQuang NguyenÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Iso 4029Document9 paginiIso 4029ellisforheroesÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Lombardini K 6C3780 1 CECOELDocument44 paginiLombardini K 6C3780 1 CECOELEber.CVÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- TUCSON (JM) 2008 G 2.7 DOHC Clutch SystemDocument20 paginiTUCSON (JM) 2008 G 2.7 DOHC Clutch Systemrobin machadoÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

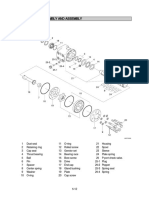

- 5-3 Group 3 Disassembly and AssemblyDocument25 pagini5-3 Group 3 Disassembly and Assemblystefan corjucÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Ottawa T1 4x2 Parts Manual-143-150Document8 paginiOttawa T1 4x2 Parts Manual-143-150suresh100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Single Slider Crank ChainDocument9 paginiSingle Slider Crank ChainSunny RajÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Jazz GK5 Starting System Circuit Diagram Separate Type MICU Without KeylessDocument2 paginiJazz GK5 Starting System Circuit Diagram Separate Type MICU Without KeylessTomyÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Arctic Cat 2012 DVX 300 300 Utility Service ManualDocument10 paginiArctic Cat 2012 DVX 300 300 Utility Service Manualrobt100% (46)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- M78Document94 paginiM78Alex Maceira Graterol80% (5)

- Especificaciones Motores de ArranqueDocument19 paginiEspecificaciones Motores de ArranqueVictor LuqueÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Catalogo de Pecas CMP18Document105 paginiCatalogo de Pecas CMP18Waitylla Dias0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- ITP For Lighting & Small PowerDocument5 paginiITP For Lighting & Small PowerGanga Daran100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Yamaha Roadstar 1700 04 SupplementDocument83 paginiYamaha Roadstar 1700 04 Supplementmasonmark100% (3)

- Conduit Fill Calculations NECDocument16 paginiConduit Fill Calculations NECMohammed HijaziÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hunter TC3250iDocument33 paginiHunter TC3250iИван ВепревÎncă nu există evaluări

- Fabco PTO 180 PTO 180 23 Parts ManualDocument27 paginiFabco PTO 180 PTO 180 23 Parts Manualeliseo cardosoÎncă nu există evaluări

- NEC CHAPTER 3 QUIZ With AnswersDocument20 paginiNEC CHAPTER 3 QUIZ With AnswersAbdul RaheemÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Massey Ferguson MF 1100 TRACTOR Service Parts Catalogue ManualDocument15 paginiMassey Ferguson MF 1100 TRACTOR Service Parts Catalogue Manualqlb898316Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Chassis: LZFF25T4XDD255721 - VP: JUHMB5AA000010 - Model: GENLYON TIPPER - Class: 52 - Group: 08 - Subgroup: 04 - Plate: 136699Document3 paginiChassis: LZFF25T4XDD255721 - VP: JUHMB5AA000010 - Model: GENLYON TIPPER - Class: 52 - Group: 08 - Subgroup: 04 - Plate: 136699Khin Choaye0% (1)

- Ae Mod1 5@azdocuments - inDocument188 paginiAe Mod1 5@azdocuments - inBhargav AngadiÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- 60F RCP 03BR0Document14 pagini60F RCP 03BR0bayu.agungnugroho96Încă nu există evaluări

- Catálogo de Peças: 1470 CombinesDocument840 paginiCatálogo de Peças: 1470 CombinesMarcelo Schons100% (1)

- Threaded Mechanical FastenersDocument32 paginiThreaded Mechanical FastenersfahkingmoronÎncă nu există evaluări

- Evinrude Carburetor Group Parts For 1966 18hp 18602 Outboard MotorDocument8 paginiEvinrude Carburetor Group Parts For 1966 18hp 18602 Outboard MotorWouter GrootÎncă nu există evaluări

- Sops ListDocument64 paginiSops ListPaul Galvez100% (1)

- Volvo F9Q EngineDocument42 paginiVolvo F9Q EngineAoife Fitzgerald100% (2)

- 200 XC-W USA 2007: Spare Parts Manual: EngineDocument24 pagini200 XC-W USA 2007: Spare Parts Manual: EnginecharlesÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- ZT20J ZT68J Parts Manual Metric - Imperial 0730.2020Document183 paginiZT20J ZT68J Parts Manual Metric - Imperial 0730.2020Luis AlbertoAlmeidaSilvaÎncă nu există evaluări

- 994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsDocument58 pagini994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsEvan AT YoelÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)