Documente Academic

Documente Profesional

Documente Cultură

BCD5-190-42-RPT-4-101-00-Rev. D.

Încărcat de

aerfans0 evaluări0% au considerat acest document util (0 voturi)

138 vizualizări48 paginiPetroChina International Jabung Ltd. Betara Complex Development Job No. : BCD - 471 - CA PROCESS HYSYS SIMULATION REPORT FEED for WB-SB Non Associated Gas Early Facilities WB-GRF Document BCD5-1900-42-RPT-4-007101-00 Revision D CONTRACTOR DOCUMENT REVIEW FOR CONFORMANCE WITH SPECIFICATIONS AND DESIGN DRAWINGS Review Code A Accepted as it is or

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPetroChina International Jabung Ltd. Betara Complex Development Job No. : BCD - 471 - CA PROCESS HYSYS SIMULATION REPORT FEED for WB-SB Non Associated Gas Early Facilities WB-GRF Document BCD5-1900-42-RPT-4-007101-00 Revision D CONTRACTOR DOCUMENT REVIEW FOR CONFORMANCE WITH SPECIFICATIONS AND DESIGN DRAWINGS Review Code A Accepted as it is or

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

138 vizualizări48 paginiBCD5-190-42-RPT-4-101-00-Rev. D.

Încărcat de

aerfansPetroChina International Jabung Ltd. Betara Complex Development Job No. : BCD - 471 - CA PROCESS HYSYS SIMULATION REPORT FEED for WB-SB Non Associated Gas Early Facilities WB-GRF Document BCD5-1900-42-RPT-4-007101-00 Revision D CONTRACTOR DOCUMENT REVIEW FOR CONFORMANCE WITH SPECIFICATIONS AND DESIGN DRAWINGS Review Code A Accepted as it is or

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 48

PetroChina International Jabung Ltd.

Betara Complex Development

Job No. : BCD 471 CA

PROCESS

HYSYS SIMULATION REPORT

FEED for WB-SB Non Associated Gas Early Facilities WB-GRF

Document

BCD5-1900-42-RPT-4-007101-00

Revision D

CONTRACTOR DOCUMENT REVIEW

FOR CONFORMANCE WITH SPECIFICATIONS AND DESIGN DRAWINGS

Review Code

A Accepted as it is or with minor comments

B Accepted as noted - Resubmittal required

C Not Accepted

D Information Only

THIS REVIEW DOES NOT RELIEVE THE CONTRACTOR/VENDOR

OF ANY CONTRACTUAL OBLIGATION, INCLUDING THE

RESPONSIBILITY FOR ENGINEERING AND DETAIL DESIGN.

PetroChina International Jabung Ltd.

Date By

D Re-Issued For Approval 15-Aug-13 AEN DJ JH -

C Issued For Approval 4-June-13 AEN DJ JH -

B Issued For Review 7-May-13 AEN DJ JH -

A For Discipline Coordination 2-May-13 AEN DJ JH -

Rev. Description Date

Prepared

By

Checked

By

Reviewed

By

Approved

By

TABULATION OF REVISED PAGES

PAGE

REVISIONS

PAGE

REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 52

2 53

3 54

4 55

5 X X 56

6 57

7 X 58

8 X 59

9 X 60

10 61

11 62

12 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT APPENDIX

42 1 X X

43 2

44 3

45 4

46 5

47 6

48

7

49 8

3

Procedure Project Progress Reporting

PetroChina International Jabung Ltd.

Betara Complex Development

Job No. : BCD 335 CA

STUDY REPORT

WB GAS RECOVERY SIMULATION REPORT

Document

BCD4-190-42-REPT-4-007-00

Revision AB0

0 Approved for Construction 26-Nov-09 HMP SPD ECR/RPS RSD

C For Acceptance 14-Oct-09 HMP SPD ECR/RPS RSD

B For Acceptance 30-Jul-09 HMP SPD ECR/RPS RSD

A For Discipline Coordination 2723-Jul-09 HMP SPD ECR/RPS RSD

Rev. Description Date

Prepared

By

Checked

By

Approved

By

Approved

By

50 9

51 10

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 4

26

TABULATION OF REVISED PAGES

PAGE

REVISIONS

PAGE

REVISIONS

A B C D 0 A B C D 0

1 52

2 53

3 54

4 55

5 56

6 57

7 58

8 59

9 60

10 61

11 62

12 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT APPENDIX

42 1 A

43 2 B

44 3 C

45 4 D

46 5 E

47 6 F

48

7 G

49 8 H

50 9 I

51 10 J

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 5

26

TABULATION OF REVISED PAGES

PAGE

REVISIONS

PAGE

REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 X X X 52

2 X X X 53

3 X X X 54

4 X X X 55

5 X X X 56

6 X X X X 57

7 X X X X 58

8 X X X X 59

9 X X X X 60

10 X X 61

11 X X 62

12 X 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT APPENDIX

42 1 X X X X

43 2 X X X X

44 3 X X X

45 4 X X X

46 5 X X

47 6

48

7

49 8

50 9

51 10

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 6

26

Sign Date

Prepared by AEN

Checked by DJ

Approval by JH

Doc/DWG No.: BCD5-190-42-RPT-4-101-00 Rev. No: D

No. Para./Section Items Explanation/Reason

1 Sec 1 Update Introduction Implemented

2 Sec 4

Process Description &

Fig. 4.1

Implemented

3 Sec 5

Pressure drop control

valve and metering

Implemented :

Attachment -2 : Hydraulic calculation

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 7

26

Table of Contents

Section Title Page

1.0 INTRODUCTION ................................................................................................ 8

2.0 OBJECTIVE ....................................................................................................... 8

3.0 REFERENCE DOCUMENT ............................................................................... 8

4.0 PROCESS DESCRIPTION ................................................................................ 8

5.0 SIMULATION BASIS AND ASSUMPTION .................................................... 11

5.1 Operating Pressure ........................................................................................ 11

5.2 Production Rates............................................................................................ 12

5.3 Simulation Cases ........................................................................................... 12

5.4 Feed Stream Composition ............................................................................ 12

5.5 Simulation Assumption ................................................................................. 13

6.0 RESULTS ......................................................................................................... 14

6.1 Product Composition ..................................................................................... 14

6.2 Equipment Design Data ................................................................................. 17

6.3 Hydrate Formation Prediction ...................................................................... 18

7.0 ATTACHMENT ................................................................................................ 18

Attachment 3 Stream Data (Case 1)

Attachment 4 Stream Data (Case 2)

Attachment 5 H&MB Fuel Gas Conditioning Package

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 8

26

1.0 INTRODUCTION

The existing WB GRF Facility is designed for handling and processing the wellfluids

from oil wells. The incoming wellfluids is separated into a single phase where the

separated gas, called as associated gas, is delivered directly to BGP/CPS via 12/10

trunk-lines.

PetroChina International Jabung Ltd, called as PCI, now intends to upgrade the

existing WB Facility to handle wellfluids from non associated gas wells. The gas and

liquid from non associated gas wells will be separated and measured before

combined and delivered to BGP/CPS through existing 12/10 trunk-line. It is

expected that trunk-line pressure of 850 psig will be at WB Facility.

Initially when the reservoir pressure is high, It is possible that the gas and liquid will

flow to BGP/CPS on its own pressure. In future, when the wells pressure declinesrop,

gas compression and liquid pumps shall be installed to meet keep the pipeline back

pressure.

2.0 OBJECTIVE

This Process Simulation Report is intended to present the data sources, simulation

methodology & basis, and summary of the process simulation for the development of

WB Facility in regard additional equipment for gas well treatment.

3.0 REFERENCE DOCUMENT

Following documents were used as reference for this simulation:

Project Design Criteria (BCD4-000-42-CRT-4-012-00).

1. Process Design Basis (BCD5-190-42-DBM-4-101-00).

2. Scope of Work for BCD4-471-WOR-017 ( BCD3-195-40-SOW-4-001-

00)Companys

4.0 PROCESS DESCRIPTION

By having new gas wells in the area of WB Facility, it is understood that the existing

facility should be modified in order to measure the volumetric rates of each fluid, and to

drive whenever the well pressure decline.

The wellfluids from gas wells are directed to (3-phase) Production Separator via

trunklines and manifold. The mixed gas, liquid and water are separated into a single

D

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

WB SB Non Associated Gas Simulation

Doc: Document1 Page 9

26

phase. During high pressure case, the outlet gas and liquid are measured

independently, then combined & routed to BGP/CPS via 12/10 Trunk-lines, water

shall be routed to separate produced water handling system and connection for it shall

be kept. The Production Separator is operated higher than expected export pressure of

850 psig.

During low pressure case, it is scheduled to operate the Production Separator at 150

psig as the Lowest Pressure Operating could be implemented. Since the export

pressure of 850 is kept constant then additional equipment, such as compressor and

pump, are required to drive the separated gas and liquid respectively. Again, the

pressurized gas and liquid are combined and routed to BGP/CPS via 12/10 trunk-

lines.

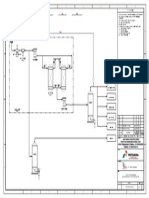

Systematically, a simple process schematic is provided below.

Formatted: Body Text, Justified, Indent: Left:

0.39", Space Before: 0 pt, After: 0 pt

PetroChina International Jabung Ltd. Report

WB-SB Non Associated Gas Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 10 7/4/2014

Field Code Changed

Field Code Changed

Notes :

: High Presssure Operating Case

Figure 4.1 Process Schematic

Wellfluids from WB- SB

Gas WellsNon

Associated

Measured

Wellfluids to

BGP/CPS via

12/10

Trunk-

linesWB- SB

Non

Associated

195-V-200

Production Separator

Gas

Meter

Turbine

Meter

195-E-200A/B/C

195-K-200A/B/C

195-V-201 A/B/C

195-V-202A/B/C

195-V-203A/B/C

195-K-200 A/B/C

195-E-201A/B/C

3 x 50%

WB- SB Gas Compression

PackagesNon Associated

2 x 100%

WB- SB Pump

PackagesNon

Associated

195-P-200 A/B

PCV

LCV

To Produced Water System

D

Formatted: Justified

Formatted: Font: Arial, Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

Formatted: Font: Bold

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 11

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

5.0 SIMULATION BASIS AND ASSUMPTION

5.1 Operating Pressure

Based on the given production profile of gas wells, it is intended to deliver naturally

the well fluids from WB Facility to BGP/CPS via 12/10 trunk-lines by keeping the

export pressure of 850 psig. This could be implemented during initial operation where

the reservoir pressure is still high. This mode operation is called as High Pressure

Operating case. The operating pressure at Production Separator is set at 875 psig

with pressure drop of valves and metering as follow;

a. Pressure Control Valve

The pressure drop across PCV should be defined to keep the export pressure at

850 psig. From hydraulic calculation (see attachment 2) the pressure drop of PCV

is 18 psi

b. Liquid Control Valve

To keep the export pressure at 850 psig, the LCV pressure drop should also be

defined. From hydraulic calculation (see attachment 2) the pressure drop of LCV

is 14 psi

c. Gas Metering

From calculation (see attachment 2) pressure drop across gas metering package

during high pressure operating case is 1.93 psi

d. Liquid Metering

The pressure drop at Turbine Meter is 6 psi (taken from vendor data)

The decline reservoir pressure is called as Low Pressure Operating case, it is

intended to operate the Production Separator at 150 psig. Since the export pressure

is kept at 850 psig, additional compression and pumping systems are added where

gas and liquid phase are comingled and delivered to BGP/CPS via 12/10 trunk-

lines. Due to higher gas flow rate during low pressure operating case, the pressure

drop across gas metering package is changed to 2.96 psi (see attachment 2). The

same pressure drop on control valves are implemented since control valve will do the

throttling fuction.

The simulation uses HYSYS V7.2 with Peng-Robinson Equation of State.

D

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 12

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

5.2 Production Rates

The estimated production rates for High and Low Pressure Operating Cases are

taken from Companys process simulation results. The followings are feed rates to

Production Separator at High and Low Operating Pressure cases ;

Table 5-1 Feed Rates

Description

Gas

(MMscfd)

Condensate

(Std BPD)

Water

(Std BPD)

(Note 1)

Remarks

High Pressure

Operating case

10.80 635.6 3800

The total molar

flow is equal to

39.62 MMscfd

Low Pressure

Operating case

31.35 1401.74 3800

The total molar

flow is equal to

61.33 MMscfd

Note 1. Maximum water flow rate is used (see attachment 3)

5.3 Simulation Cases

Simulation cases for WB-SB Non Associated Gas Development Facilities Production

Separator and Gas Metering System are as follows:

Case 1: High Pressure Operating case where the Production Separator is

operated at 875 psig.

Case 2: Low Pressure Operating case where the Production Separator is

operated at 150 psig.

5.4 Feed Stream Composition

The wellfluids compositions for High and Low Pressure Operating cases are taken

from Companys process simulation results as the inlet of Production Separator.

Refer to Table 5-2 for details.

Formatted: Caption, Left

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 13

27302601-JulNovMay-09 13

Field Code Changed

...

Field Code Changed

...

Table 5-2 Feed Stream Composition

Components

High Pressure

Operating Case

Low Pressure

Operating Case

(Mole Fraction) (Mole Fraction)

CO

2

0.0017 0.0056

Nitrogen 0.0062 0.0084

Methane 0.1991 0.3598

Ethane 0.0305 0.0558

Propane 0.0305 0.0568

i-Butane 0.0057 0.0110

n-Butane 0.0078 0.0149

i-Pentane 0.0028 0.0051

n-Pentane 0.0024 0.0040

Hexane 0.0025 0.0035

Heptane 0.0024 0.0043

Octane 0.0020 0.0034

Nonane 0.0007 0.0012

Decane 0.0004 0.0006

n-C11 0.0001 0.0002

n-C12 0.0001 0.0001

n-C13 0.0001 0.0000

H

2

O 0.7052 0.4653

5.5 Simulation Assumption

Some assumption are taken to generate the simulation :

1. Pressure drop in Separator is assumed 5 psi

2. The future Compressor Package are assumed as follow;

a. The Air Cooler pressure drop is 10 psi

b. The temperature outlet of Air Cooler is 110

0

F

c. The Compressor polytropic efficiency is 70%.

1.3. Ambient temperature is assumed 73 95

0

F

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 14

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

1.06.0 RESULTS

6.1 Product Composition

Based on the simulation results, the product specificationproduct compositions for

export to BGP/CPS are as follow ;

Table 6-1 Product Composition for High Pressure Operating Case

Components

Gas Phase Liquid Phase

Combined Gas +

Liquid Phase

(Mole Fraction) (Mole Fraction) (Mole Fraction)

CO

2

0.0056 0.0028 0.0054

Nitrogen 0.0221 0.0030 0.0208

Methane 0.7085 0.2029 0.6730

Ethane 0.1044 0.0874 0.1032

Propane 0.0974 0.1799 0.1032

i-Butane 0.0166 0.0541 0.0192

n-Butane 0.0219 0.0885 0.0265

i-Pentane 0.0067 0.0475 0.0095

n-Pentane 0.0053 0.0446 0.0080

Hexane 0.0040 0.0687 0.0085

Heptane 0.0024 0.0834 0.0081

Octane 0.0000 0.0000 0.0000

Nonane 0.0012 0.0799 0.0067

Decane 0.0003 0.0323 0.0025

n-C11 0.0001 0.0162 0.0012

Formatted: Indent: Left: 0.5", Space After:

0 pt

Formatted: Indent: Left: 0.59", Space After:

0 pt

Formatted: Caption, Space Before: 0 pt

Formatted: Space After: 0 pt, Line spacing:

single

Comment [e1]:

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Space After: 0 pt

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 15

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

n-C12 0.0000 0.0042 0.0003

n-C13 0.0000 0.0028 0.0002

H

2

O 0.0036 0.0020 0.0035

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 16

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

Table 6-2 Product Composition for Low Pressure Operating Case

Components

Gas Phase Liquid Phase

Combined Gas

+ Liquid Phase

(Mole Fraction) (Mole Fraction) (Mole Fraction)

CO

2

0.0108 0.0017 0.0104

Nitrogen 0.0165 0.0003 0.0157

Methane 0.7014 0.0432 0.6718

Ethane 0.1074 0.0372 0.1042

Propane 0.1049 0.1311 0.1061

i-Butane 0.0186 0.0589 0.0205

n-Butane 0.0240 0.1074 0.0278

i-Pentane 0.0065 0.0732 0.0095

n-Pentane 0.0045 0.0684 0.0074

Hexane 0.0021 0.1006 0.0065

Heptane 0.0010 0.1559 0.0080

Octane 0.0003 0.1360 0.0064

Nonane 0.0000 0.0503 0.0023

Decane 0.0000 0.0243 0.0011

n-C11 0.0000 0.0067 0.0003

n-C12 0.0000 0.0044 0.0002

n-C13 0.0000 0.0000 0.0000

H

2

O 0.0018 0.0004 0.0018

Comment [e2]:

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 17

27302601-JulNovMay-09 13

Field Code Changed

...

6.2 Equipment Design Data

Table 6-3 shows the summary of equipment data from HYSYS simulation.

Table 6-3 Equipment Design Data

1.1.1.1.1.1 Equipm

ent

Case 1 Case 2

High Operating

Pressure

Low Operating

Pressure

Production Separator (195-V-200)

- Liquid Flow Rate,

Actual BPD

635.58 1381.85

- Gas Flow Rate,

MMSCFD

10.77 31.38

- Water Flow Rate,

BPD

3800 3800

- Operating Pressure,

psig

870 150

- Operating

Temperature,F

145 66.02

Pump (195-P-200 A/B)

- Flow Rate, Actual

BPD

- 1381.85

- Suction Pressure, psig - 145

- Discharge Pressure,

psig

- 870

- Power, hp

- 33.6

Compressor 195-K- 200 A/B/C (1

st

Stage)

- Gas Flow Rate,

MMSCFD

- 15.69

- Suction Pressure, psig - 126.9

- Discharge Pressure,

psig

- 340

- Pressure Ratio - 2. 60

- Power, hp - 1030

Compressor 195-K- 201 A/B/C (2

nd

Stage)

- Gas Flow Rate,

MMSCFD

- 15.69

- Suction Pressure, psig - 325

- Discharge Pressure,

psig

- 868

- Pressure Ratio 2. 60

D

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted Table

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

Formatted

...

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 18

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

6.3 Hydrate

Formation

Prediction

This HYSYS simulation is also used to determine the hydrate formation in gas lines.

Table 6-4 shows the summary of hydrate simulation results.

Table 6-4 Hydrate Formation

No. Line From To Remarks

1 195202 195-V-200 195-PV-200 Will Not Form

2 195203 195-PV-200 195-V-201 Will Not Form

3 195203A2/B2 195-V-201

195-K-200(1

st

Stage)

Will Not Form

4 195203A3/B3

195-K-200 (1

st

Stage)

195-E-200 (1

st

Stage)

Will Not Form

5 195203A4/B4 195-E-200 195-V-202 Will Not Form

6 195203A5/B5 195-V-202

195-K-200(2

nd

Stage)

Will Not Form

7 195203A6/B6

195-K-200(2

nd

Stage)

195-E-201 (2

nd

Stage)

Will Not Form

8 195203A7/B7 195-E-201 195-V-203 Will Not Form

9 195204 195-V-203 Gas Metering Will Not Form

10 195205 Gas Metering

BGP/CPS

Trunk-lines

Will Not Form

2.07.0 ATTACHMENT

Attachment 1 : HYSYS Simulation

Attachment 2 : Hydraulic Calculation

Attachment 3 : WB-SB Water Production Forecast

- Power, hp - 1069

Air Cooler 195-E-200 A/B/C (1

st

Stage)

- Duty, MMBTU/hr - -3.60

Air Cooler 195-E-201 A/B/C (2

nd

Stage)

- Duty, MMBTU/hr - -3.45

Formatted: Font: Arial, No underline, Font

color: Black

Formatted: Indent: Left: 0", Space After: 0

pt, Position: Horizontal: Center, Relative to:

Page

Formatted: Indent: Left: 0", Space After: 0

pt, Add space between paragraphs of the same

style, Position: Horizontal: Center, Relative to:

Page

Formatted Table

Formatted: Space After: 0 pt, Position:

Horizontal: Center, Relative to: Page

Formatted: Body Text 2, Indent: Left: 0.5"

Formatted: Caption, Indent: Left: 0.39",

Space Before: 0 pt

Formatted: Indent: Left: 0.38", No bullets

or numbering, Tab stops: Not at 0.89"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 19

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

Formatted: Indent: Left: 0.38", No bullets

or numbering, Tab stops: Not at 0.89"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 20

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

1.0INTRODUCTION

1.0PROCESS SIMULATION HAS BEEN PERFORMED FOR THE WEST BETARA (WB)

FLARE ASSOCIATED GAS RECOVERY FACILITIES USING HYSYS 200V7.06.5.

THE WB FLARE ASSOCIATED GAS RECOVERY FACILITIES WILL CONTAIN

PROCESS FACILITIES AND PIPELINES FOR USE ASTO PRODUCE AND

TRANSPORT LIFT GAS TO WB WELLS AND ASSOCIATED GAS TO FOR

TRANSMISSION THE EXISTING BGP/CPS VIA NEW GAS GATHERING

FACILITIES.

1.0THE ASSOCIATED GAS AT WB IS PRODUCED FROM THE PRODUCTION

SEPARATOR, WHERE OIL AND GAS SEPARATION OCCURS. GAS FROM THE

PRODUCTION SEPARATOR WILL BE ROUTED TO THE ASSOCIATED AND LIFT

GAS COMPRESSORS AND CONDENSATE WILL BE SENT TO THE EXISTING

GAS BOOT.

1.0VAPOR FROM THE EXISTING GAS BOOT WILL BE RECOVERED AND

INTRODUCED TO VAPOR RECOVERY UNIT (VRU) COMPRESSOR TO BOOST UP

THE PRESSURE AND THEN SENT TO THE ASSOCIATED GAS AND LIFT GAS

COMPRESSORS.

1.0A PART OF ASSOCIATED GAS FROM WB PRODUCTION SEPARATOR WILL ALSO

BE INTRODUCED TO WB LIFT GAS COMPRESSOR FOR REINJECTION TO THE

WELLS AS LIFT GAS.

1.0ASSOCIATED GAS COMPRESSOR COMPRESSES THE GAS FROM 100 PSIG UP

TO THE REQUIRED PRESSURE FOR FINAL TERMINATION IN BGP/CPS.

1.0OBJECTIVE

1.0THE OBJECTIVES OF THIS SIMULATION OF THE FLARE GAS RECOVERY

FACILITIES ARE ARE AS FOLLOWS:

1.0TO IDENTIFY PRESSURE AND TEMPERATURE PROFILE ALONG THE FACILITIES.

1.0TO DETERMINE MAXIMUM OPERATING PRESSURE AS INPUT TO DETERMINE

PIPELINE DESIGN PRESSURE.

1.0TO ESTIMATE REQUIRED COMPRESSOR POWER.

1.0TO GENERATE HEAT AND MATERIAL BALANCE FOR PROCESS DESIGN.

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 21

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

1.0TO ESTABLISH GAS/LIQUID FLOW RATES FOR LINE SIZING CALCULATION.

1.0TO GENERATE THERMODYNAMIC PROPERTIES FOR USE IN VARIOUS

EQUIPMENT/INSTRUMENT SIZING.

1.0TO PROVIDE BASE CASE FOR OTHER SIMULATIONS/STUDIES.

1.0REFERENCE DOCUMENT

1.0FOLLOWING DOCUMENTS ARE WERE USED AS REFERENCE FOR THIS

SIMULATION:

1.0PROJECT DESIGN CRITERIA (BCD4-000-42-CRT-4-012-00).

1.0PROCESS DESIGN BASIS (BCD4-000-42-DBM-4-001-00).

1.0DATA SHEET FOR SWB ASSOCIATED GAS COMPRESSOR PACKAGE (BCD4-

185195-4243-DS-4-K-100-00).

1.0DATA SHEET FOR SWB VRU COMPRESSOR PACKAGE (BCD4-185195-4243-DS-4-

K-101-00).

1.0DATA SHEET FOR SWB LIFT GAS COMPRESSOR PACKAGE (BCD4-185195-4243-

DS-4-K-102-00).

1.0SWB/WB PIPELINE HYDRAULIC SIMULATION REPORT (BCD4-190-42-REPT-4-004-

00).

PFD OF WB GAS RECOVERY FACILITY.

P&ID OF WB GAS RECOVERY FACILITY.

PRELIMINARY DATA FROM EAST ASIA ENERGY (VENDOR OF AG AND LG

COMPRESSORS).

PRELIMINARY DATA FROM MEMBRANE TECHNOLOGY AND RESEARCH INC.

(VENDOR OF FUEL GAS CONDITIONING PACKAGE).

4.0BASIS AND ASSUMPTION

Formatted: Bullets and Numbering

Formatted: Heading 1, None, Space After: 0

pt, Line spacing: single, No bullets or

numbering, Don't keep with next, Tab stops:

Not at 0.89"

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 22

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

4.0THE FOLLOWING BASIS AND ASSUMPTIONS HAVE BEEN MADE BY USING

INFORMATION SUPPLIED BY COMPANYPCI.

4.0BASIS

4.0BASIS FOR THIS SIMULATION ARE AS FOLLOWDESCRIBED AS FOLLOWING:

4.0FEED GAS COMPOSITION AND CONDITIONS BASED ON STREAM AT THE INLET

PRODUCTION SEPARATOR.

4.0COMPRESSOR SUCTION / DISCHARGE PRESSURE BASED ON SWB/WB PIPELINE

HYDRAULIC SIMULATION REPORT [6]COMPRESSOR PACKAGE DATASHEET.

4.0THE SIMULATION USES HYSYS 200V6.57.0 WITH PENG-ROBINSON EQUATION OF

STATE.

4.0SIMULATION CASES

4.0TWO CASES ARE WERE CARRIED OUT IN THIS SIMULATION:

4.0CASE 1: WITHOUT INJECTION OF 1,000 BBL/DAY FREE WATER AT THE INLET

PRODUCTION SEPARATOR.

4.0CASE 2: WITH INJECTION OF 1,000 BBL/DAY FREE WATER AT THE INLET

PRODUCTION SEPARATOR.

4.0PROCESS FLOW SCHEME

4.0THE SIMULATION FLOW FOR THE FLARE GAS RECOVERY FACILITIES IS WAS

BASED ON THE FLOW SCHEMATIC, WHICH HAS BEEN EXTRACTED FROM THE

PFD AS THE FOLLOWING:

4.01X100% RECIPROCATING COMPRESSOR WITH TWO (2) STAGES WILL BE

INSTALLED FOR WBAS WB ASSOCIATED GAS COMPRESSOR.

4.01X100% WB LIFT GAS COMPRESSOR WITH THREE (3) STAGES WILL

COMPRESSES THE LIFT GAS. THE LIFT GAS WILL RETURN TO WB WELLS

AND SEND TO WB TRUNKLINE.

4.0TWO (2) STAGES VRU COMPRESSOR TO BE INSTALLED TO COMPRESS THE

BOOT (194-T-100) FROM 0.31 PSIG TO 105 PSIG. RECOVERED GAS FROM VRU

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 23

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

WILL BE SENT TO 1

ST

STAGE ASSOCIATED GAS AND LIFT GAS COMPRESSOR

(194195-V-100).

42.0 THE BOOSTED GAS AND THE ASSOCIATED GAS FROM THE PRODUCTION

SEPARATOR IS MIXED AND INTRODUCED TO THE ASSOCIATED GAS

COMPRESSOR. THE ASSOCIATED GAS COMPRESSOR COMPRESSES THE

MIXED GAS AND SENDS IT TO CPS VIA WB TRUNKLINE.

4.4FEED STREAM COMPOSITION

4.4COMPOSITION OF THE FLUID ENTERING WB PRODUCTION SEPARATOR IS

TAKEN FROM PROCESS DESIGN BASIS (BCD4-000-42-DBM-4-001-00). TABLE 4-

1 BELOW SHOWS THE FLUID COMPOSITION ENTERING THE PRODUCTION

SEPARATOR. THE FLUID COMPOSITION IS BASED ON THE SATURATED GAS

WITH WATER.

4.4

46.0

47.0

48.0

49.0 TABLE 4-1

50.0 FEED STREAM COMPOSITION

51.0

52.0 FLUID COMPOSITION TO PRODUCTION

SEPARATOR

Formatted: Heading 1, None, Space After: 0

pt, Line spacing: single, No bullets or

numbering, Don't keep with next

Formatted: Bullets and Numbering

Formatted: Heading 1, Left, None, Space

After: 0 pt, Line spacing: single, No bullets

or numbering, Don't keep with next

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 24

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

53.0 COMPONENT 54.0 MOLE %

55.0 CO2 56.0 2.12632.2020

57.0 H2S 58.0 0.00000.0000

59.0 NITROGEN 60.0 0.88850.9201

61.0 METHANE 62.0 36.934738.2497

63.0 ETHANE 64.0 6.96507.2130

65.0 PROPANE 66.0 8.16298.4535

67.0 I-BUTANE 68.0 1.77911.8425

69.0 N-BUTANE 70.0 2.20392.2824

71.0 I-PENTANE 72.0 0.84770.8779

73.0 N-PENTANE 74.0 0.66220.6858

75.0 N-HEXANE 76.0 0.67870.7029

77.0 N-HEPTANE 78.0 0.71170.7370

79.0 N-OCTANE 80.0 0.78060.8083

81.0 N-NONANE 82.0 0.50430.5222

83.0 N-DECANE 84.0 0.40020.4145

85.0 N-C11 86.0 0.31380.3250

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 25

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

87.0 N-C12 88.0 0.23200.2402

89.0 N-C13 90.0 0.24170.2503

91.0 N-C14 92.0 0.21460.2222

93.0 N-C15 94.0 0.26350.2729

95.0 N-C16 96.0 0.15270.1582

97.0 N-C17 98.0 0.12050.1248

99.0 N-C18 100.0 0.14890.1542

101.0 N-C19 102.0 0.08440.0874

103.0 N-C20 104.0 0.79710.8255

105.0 H2O 106.0 33.785031.4275

107.0 TOTAL 108.0 100

109.0 SOURCE: PROCESS DESIGN BASIS (BCD4-000-42-DBM-4-001-00)

110.0 COMPRESSOR TYPE AND EFFICIENCY

111.0 ALL COMPRESSORS ARE ASSUMED TO BE RECIPROCATING TYPE AND

SIMULATED WITH THE ASSUMED EXPECTED EFFICIENCY OF 90%.

112.0 PRODUCTION SEPARATOR OPERATING PRESSURE

113.0 SWB PRODUCTION SEPARATOR OPERATING PRESSURE = 100 PSIG.

114.0 LIFT GAS FLOW AND PRESSURE

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 26

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

TOTAL LIFT GAS REQUIRED FOR WB (17 WELLS) IS 10.2 MMSCFD. IT IS

ASSUMED ASSUMED 50% OF THE WELLS WILL REQUIRED GAS LIFT AT THE

SAME TIME SO THAT THE LIFT GAS REQUIREMENT WOULD BE 5.1 MMSCFD.

THE LIFT GAS COMPRESSORS ARE DESIGNED TO ACCOMMODATE 7 MMSCFD

OF GAS LIFT GAS COMPRESSORSAND THE DISCHARGE PRESSURE IS TAKEN

AS 1260 PSIG CONSIDERING INJECTION PRESSURE 1200 PSI AT CASING

HEAD.

FUEL GAS CONDITIONING PROCESS

THE FUEL GAS CONDITIONING PROCESS WAS SIMULATED BY USING THE

PRELIMINARY DATA FROM VENDOR OF FUEL GAS CONDITIONING PACKAGE.

A MEMBRANE SYSTEM IS CONSIDERED TO BE USED IN THIS PROCESS. A

COMPONENT SPLITTER WAS ASSUMED TO BE USED AS A MEMBRANE IN

THIS SIMULATION. THE COMPONENT SPLIT FRACTION OF PERMEATE GAS

AND CONDITIONED GAS WAS TAKEN FROM H&MB GIVEN BY THE VENDOR OF

FUEL GAS CONDITIONING PACKAGE. ATTACHMENT 5 SHOWS THE H&MB FOR

THE FUEL GAS CONDITIONING PACKAGE.

115.0

116.0 RESULT AND DISCUSSION

117.0 IMPACT OF INJECTING FREE WATER AT INLET OF PRODUCTION SEPARATOR

118.0 FREE WATER OF 1,000 BBL/DAY IS INJECTED AT THE INLET OF THE

PRODUCTION SEPARATOR TO OBSERVE THE IMPACT ON THE ASSOCIATED

GAS COMPRESSOR SUCTION COMPOSITION. THE SIMULATION HAS SHOWN

THAT THERE IS NO SIGNIFICANT EFFECT OF INJECTING FREE WATER

BECAUSE THE ASSOCIATED GAS IS ALREADY ON NEARLY AT WATER

SATURATED CONDITION AND MOST OF THE WATER HAS BEEN KNOCKED

OUT AT THE PRODUCTION SEPARATOR. TABLE 5-1 BELOW SHOWS THE

COMPARISON OF INLET ASSOCIATED GAS COMPRESSOR COMPOSITION ON

BOTH CASES.

119.0

Formatted: Bullets and Numbering

Formatted: Heading 1, None, Space Before:

0 pt, Line spacing: single, No bullets or

numbering, Don't keep with next, Border: Left:

(No border)

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 27

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

120.0 TABLE 5-1

121.0 INLET COMPRESSOR COMPOSITION

122.0

123.0 COMPOSITION OF INLET ASSOCIATED GAS

COMPRESSOR

124.0 125.0 CASE 1 126.0 CASE 2

127.0 COMPONENT 128.0 MOLE % 129.0 MOLE %

130.0 CO

2

131.0 3.6183.512 132.0 3.6133.507

133.0 H

2

S 134.0 0.0000.000 135.0 0.0000.000

136.0 NITROGEN 137.0 1.3181.462 138.0 1.3181.462

139.0 METHANE 140.0 59.70260.841 141.0 59.69560.842

142.0 ETHANE 143.0 11.82811.525 144.0 11.82511.525

145.0 PROPANE 146.0 14.00613.390 147.0 14.00113.390

148.0 I-BUTANE 149.0 2.9312.761 150.0 2.9312.761

151.0 N-BUTANE 152.0 3.4883.285 153.0 3.4903.285

154.0 I-PENTANE 155.0 1.0651.017 156.0 1.0671.017

157.0 N-PENTANE 158.0 0.7470.720 159.0 0.7500.720

160.0 N-HEXANE 161.0 0.3760.392 162.0 0.3780.392

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 28

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

123.0 COMPOSITION OF INLET ASSOCIATED GAS

COMPRESSOR

124.0 125.0 CASE 1 126.0 CASE 2

127.0 COMPONENT 128.0 MOLE % 129.0 MOLE %

163.0 N-HEPTANE 164.0 0.1470.170 165.0 0.1490.170

166.0 N-OCTANE 167.0 0.0550.069 168.0 0.0560.069

169.0 N-NONANE 170.0 0.0130.017 171.0 0.0130.017

172.0 N-DECANE 173.0 0.0040.005 174.0 0.0040.005

175.0 N-C11 176.0 0.0010.001 177.0 0.0010.001

178.0 N-C12 179.0 0.0000.000 180.0 0.0000.000

181.0 N-C13 182.0 0.0000.000 183.0 0.0000.000

184.0 N-C14 185.0 0.0000.000 186.0 0.0000.000

187.0 N-C15 188.0 0.0000.000 189.0 0.0000.000

190.0 N-C16 191.0 0.0000.000 192.0 0.0000.000

193.0 N-C17 194.0 0.0000.000 195.0 0.0000.000

196.0 N-C18 197.0 0.0000.000 198.0 0.0000.000

199.0 N-C19 200.0 0.0000.000 201.0 0.0000.000

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 29

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

123.0 COMPOSITION OF INLET ASSOCIATED GAS

COMPRESSOR

124.0 125.0 CASE 1 126.0 CASE 2

127.0 COMPONENT 128.0 MOLE % 129.0 MOLE %

202.0 N-C20 203.0 0.0000.000 204.0 0.0000.000

205.0 H2O 206.0 0.7010.833 207.0 0.7100.838

208.0 TOTAL 209.0 100 210.0 100

211.0

212.0 COMPRESSORS DATA

213.0

214.0 TABLE 5-2 SHOWS THE SUMMARY OF COMPRESSOR DATA RESULTING FROM

HYSYS SIMULATION BY ASSUMING COMPRESSOR EFFICIENCY OF AT 90%.

ALL OF THE DATA STILL NEEDARE SUBJECT TO BE CONFIRMEDATION BY

FROM COMPRESSOR VENDORMANUFACTURER.

215.0 TABLE 5-2

216.0 COMPRESSORS DATA

217.0

218.0 TAG

NO.

219.0 TAG

NAME

220.0 TYPE 221.0 GAS FLOW (MMSCFD) 222.0 PRESSURE (PSIG) 223.0 COMP

RATIO

224.0 POWER (HP)

225.0 SUCTION 226.0 DISCHARGE

227.0 CASE 1 228.0 CASE 2 229.0 230.0 231.0 CASE 1 232.0 CASE 2

Formatted Table

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 30

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

233.0 195-

K-

100

234.0 WB

ASSOC

IATED

GAS

COMP

RESSO

R

235.0 (1

ST

STAGE

)

236.0 RECIP.

237.0 9.309.79 238.0 9.309.79 239.0 85.0087.3 240.0 263.10277.4 241.0 2.792.86 242.0 522.80578.9 243.0 523.10579

244.0 WB

ASSOC

IATED

GAS

COMP

RESSO

R

245.0 (2

ND

STAGE

)

246.0 RECIP.

9.839 84

247.0 (NOTE 1)

248.0 9.839 84

(NOTE 1)

249.0 253.10264.4 250.0 860.00824.5 251.0 3.273.01 252.0 614.70570.1 253.0 614.70570

254.0 195-

K-

101

255.0 WB

VRU

COMP

RESSO

R (1

ST

STAGE

)

256.0 RECIP.VANE

257.0 0.250.2554 258.0 0.250.2554 259.0 1.000.3 260.0 33.3027.67 261.0 3.062.82 262.0 14.9814.27 263.0 14.9614.27

264.0 WB

VRU

COMP

RESSO

R (2

ND

265.0 RECIPVANE

266.0 0.25

0.2791

(NOTE 1)

267.0 0.250.2791

(NOTE 1)

268.0 31.3014.67 269.0 105.00105 270.0 2.604.08 271.0 13.0420.63 272.0 13.0120.63

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 31

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

STAGE

)

273.0 195-

K-

102

274.0 WB

LIFT

GAS

COMP

RESSO

R (1

ST

STAGE

)

275.0 RECIP.

276.0 7.005.1 277.0 7.005.1 278.0 85.0077.3 279.0 213.10227.5 280.0 2.282.63 281.0 315.40276.5 282.0 315.60276.5

283.0 WB

LIFT

GAS

COMP

RESSO

R (2

ND

STAGE

)

284.0 RECIP.

4.9837.17

285.0 (NOTE 12)

286.0 4.9837.17

(NOTE 12)

287.0 203.10214.5 288.0 586.60850 289.0 2.763.77 290.0 395.10366.1 291.0 395.10366.1

292.0 WB

LIFT

GAS

COMP

RESSO

R (3

RD

STAGE

)

293.0 RECIP.

4.7386.98

294.0 (NOTE 32)

295.0 4.7386.98

(NOTE 32)

296.0 576.60837 297.0 1260.001260 298.0 2.161.50 299.0 259.6083.61 300.0 259.5083.6

301.0

302.0 NOTE:

303.0 INCLUDING RECYCLE FLOW FROM DISCHARGE KO DRUM / SCRUBBER.

304.0 GAS FLOW DECREASE BECAUSE OF 0.31 MMSCFD FUEL GAS SUPPLY.

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: No underline, Font color: Auto

Formatted: Font: 10 pt

Formatted: No underline, Font color: Auto

Formatted: Font: 10 pt

Formatted: No underline, Font color: Auto

Formatted: Font: 10 pt

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 32

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

305.0 DECREASING GAS FLOW DUE TO CONDENSATION AT 195-E-1044 (LIFT GAS

COMPRESSOR AFTER INTER COOLER-2

ND

2

ND

STAGE).

306.0

5.3FLARE ASSOCIATED GAS RECOVERY RATE

THE ASSOCIATED GAS RECOVERY RATE FROM WB ASSOCIATED GAS

RECOVERY FACILITIES IS SHOWN IN TABLE 5-3 BELOW.

TABLE 5-3

WB ASSOCIATED GAS RECOVERY RATE

FLOWRATE

GAS

CONDENSAT

E

WATE

R

(MMSCFD

) (BPD) (BPD)

CAS

E 1 7.363 97.730 0.164

CAS

E 2 7.359 97.780 0.164

THIS ASSOCIATED GAS WAS TAKEN FROM OUTLET OF THE ASSOCIATED

GAS COMPRESSOR KO DRUM EXCLUDING THE 3.497 MMSFCFD FUEL GAS

Formatted: No underline, Font color: Auto

Formatted: No underline, Font color: Auto

Formatted: Font: 10 pt

Formatted: Bullets and Numbering

Formatted: Heading 1

Formatted: Heading 1, No bullets or

numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 33

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

SUPPLY FOR PRODUCING 0.6 MMSCFD OF CONDITIONED FUEL GAS. THE

REMAINING GAS FROM OUTLET OF THE LIFT GAS COMPRESSOR KO DRUM

WHICH WAS NOT INJECTED TO WELL HAS ALREADY INCLUDED IN THIS

ASSOCIATED GAS RATE.

THE PRESSURE DROP OF LIFT GAS ACROSS 195-PCV-115 FROM 1260 PSIG TO

850 PSIG WILL CAUSE A LIQUID CONDENSATION IN THE GAS STREAM.

THEREFORE, LIQUID PRESENT IN THE GAS STREAM TO WB TRUNKLINE.

308.0 AS PER SIMULATION RESULT, THE FLARE GAS RECOVERY RATE FROM WB

ASSOCIATED GAS FACILITIES IS AS FOLLOWS:

309.0 GAS CASE 1 = 9.335 MMSCFD (CASE 1 AND CASE 2)

310.0 CONDENSATECASE 2 = 9.334 MMSCFD 0 BPD (CASE 1 AND CASE

2)

311.0 WATER = 0 BPD (CASE 1 AND CASE 2)

312.0

313.0

314.0

315.0

316.0

317.0 THE ASSOCIATED GAS COMPOSITION TO WB TRUNKLINE IS SHOWN IN

TABLE 5-3 4 BELOW.

318.0

319.0 TABLE 5-34

WB ASSOCIATED GAS COMPOSITION

Formatted: Heading 1, None, Space After: 0

pt, Line spacing: single, No bullets or

numbering, Don't keep with next

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 34

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

GAS COMPOSITION TO WB TRUNKLINE

CASE 1 CASE 2

COMPONENT MOLE % MOLE %

CO

2

3.6723.561 3.6683.556

H

2

S 0.0000.000 0.0000.000

NITROGEN 1.3451.485 1.3451.485

METHANE 60.79461.776 60.79861.779

ETHANE 11.94411.656 11.94311.657

PROPANE 13.89913.413 13.89713.414

I-BUTANE 2.8402.718 2.8402.718

N-BUTANE 3.3363.198 3.3373.199

I-PENTANE 0.9590.937 0.9600.937

N-PENTANE 0.6530.645 0.6540.646

N-HEXANE 0.2570.278 0.2570.278

N-HEPTANE 0.0600.069 0.0600.069

N-OCTANE 0.0100.010 0.0100.010

N-NONANE 0.0010.001 0.0010.001

Formatted: Bullets and Numbering

Formatted Table

Formatted Table

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 35

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

GAS COMPOSITION TO WB TRUNKLINE

CASE 1 CASE 2

COMPONENT MOLE % MOLE %

N-DECANE 0.0000.000 0.0000.000

N-C11 0.0000.000 0.0000.000

N-C12 0.0000.000 0.0000.000

N-C13 0.0000.000 0.0000.000

N-C14 0.0000.000 0.0000.000

N-C15 0.0000.000 0.0000.000

N-C16 0.0000.000 0.0000.000

N-C17 0.0000.000 0.0000.000

N-C18 0.0000.000 0.0000.000

N-C19 0.0000.000 0.0000.000

N-C20 0.0000.000 0.0000.000

H2O 0.2300.251 0.2300.251

TOTAL 100 100

320.0

Formatted Table

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 36

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

HYDRATE FORMATION PREDICTION

THIS HYSYS SIMULATION WAS ALSO USED TO DETERMINE THE HYDRATE

FORMATION OF THE COMPRESSOR SUCTION PRESSURE CONTROL RECYCLE

LINES ON AG, LG AND VRU COMPRESSORS PACKAGE. TABLE 5-5 BELOW

SHOWS THE SUMMARY OF HYDRATE FORMATION PREDICTION.

TABLE 5-5

SUMMARY OF HYDRATE FORMATION PREDICTION

NO. LINE FROM TO

UPSTREAM DOWNSTREAM

HYDRATE

FORMATION AT

DOWNSTREAM P &

T

REMARKS

P

(PSIG)

T

(

O

F)

P

(PSI

G)

T

(

O

F)

T

(

O

F)

P

(PSI

G)

1

AG

RECY

CLE

195-

V-102

195-

V-

100 850.0 120.0 85.0 43.4 38.0 136.5

WILL NOT

FORM

2

LG

RECY

CLE

195-

V-108

195-

V-

105 1250.0 120.0 85.0 19.6 37.8 -

WILL

FORM

3

VRU

RECY

CLE

195-

V-109

195-

V-

103 95.0 120.0 1.0 105.3 -4.0 -

WILL NOT

FORM

FROM TABLE 5-5 ABOVE, IT CAN BE CONCLUDED THAT HYDRATE

FORMATION WILL POSSIBILITY OCCURS ON LG RECYCLE DUE TO DRAMATIC

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 37

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

DECREASE ON THE PRESSURE FROM UPSTREAM TO DOWNSTREAM WHICH

WILL ALSO CAUSE THE CHANGE OF THE TEMPERATURE.

TO OVERCOME THE HYDRATE FORMATION ISSUE, CONTRACTOR PROPOSES

TO MODIFY THE TAPPING POINT OF THE LG COMPRESSOR SUCTION

PRESSURE CONTROL RECYCLE LINES USING HOT RECYCLE LINE. THE

TAPPING POINT WILL BE MODIFIED FROM DISCHARGE KO DRUM (AFTER

FINAL STAGE COOLER) TO DISCHARGE FINAL STAGE COMPRESSOR

(BEFORE FINAL STAGE COOLER).

TABLE 5-6 BELOW SHOWS THE SUMMARY OF HYDRATE FORMATION

PREDICTION AFTER MODIFYING THE COMPRESSOR SUCTION PRESSURE

CONTROL RECYCLE TAPPING POINT.

TABLE 5-6

SUMMARY OF HYDRATE FORMATION PREDICTION USING HOT RECYCLE

NO. LINE FROM TO

UPSTREAM DOWNSTREAM

HYDRATE

FORMATION AT

DOWNSTREAM P &

T

REMARKS

P

(PSIG)

T

(

O

F)

P

(PSI

G)

T

(

O

F)

T

(

O

F)

P

(PSI

G)

1

AG

RECY

CLE

195-

V-108

195-

V-

100 850.0 120.0 85.0 43.4 38.0 136.5

WILL NOT

FORM

2

LG

RECY

CLE

195-

K-102

(3

RD

STAG

E)

185-

V-

105 1260.0 217.3 85.0 141.7 37.8 -

WILL NOT

FORM

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Indent: Left: -0", Line spacing:

1.5 lines

Formatted: No underline, Font color: Auto,

Superscript

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 38

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

3

VRU

RECY

CLE

185-

V-109

185-

V-

103 95.0 120.0 1.0 105.3 -4.0 -

WILL NOT

FORM

FROM TABLE 5-6 ABOVE, IT WAS PREDICTED THAT HYDRATE FORMATION

WILL NOT OCCURS ON LG COMPRESSOR SUCTION PRESSURE RECYCLE

LINES AFTER MODIFYING THE TAPPING POINT. COMPRESSOR PACKAGE

VENDOR SHALL BE REQUIRED TO STUDY THIS HYDRATE FORMATION IN

MORE DETAIL.

COOLER DUTY REQUIREMENT AT 100% RECYCLE

SIMULATION FOR 100% RECYCLE WAS PERFORMED TO CHECK THE COOLER

DUTY REQUIREMENT IN ORDER TO MEET THE ALLOWABLE LIMIT OF

DISCHARGE TEMPERATURE WHICH WAS SET AT 120

O

F.

TABLE 5-7 BELOW SHOWS THE COMPARISON OF COOLER DUTY

REQUIREMENT AT 0% AND 100% RECYCLES. THE SIMULATION WAS

PERFORMED BASED ON CASE 2 DESIGN CONDITION AFTER MODIFYING THE

TAPPING POINT OF THE AG AND LG COMPRESSORS SUCTION PRESSURE

CONTROL RECYCLE USING HOT RECYCLE LINE.

TABLE 5-7

COMPARISON OF COOLER DUTY REQUIREMENT AT 0% AND 100% RECYCLE

TAG

NO.

TAG NAME DUTY (BTU/HR) DEVIATION

OF DUTY

TEMPERATURE (

O

F) REMARKS

INLET

OUTLET

0% 100% 0% 100%

AG COMP. INTER COOLER

- -

163%

206.

330.7 120

HOT

Formatted: Bullets and Numbering

Formatted: Bullets and Numbering

Formatted: Heading 1, Left, None, Space

After: 0 pt, Line spacing: single, No bullets

or numbering, Don't keep with next

Formatted Table

Formatted: Bullets and Numbering

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 39

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

TAG

NO.

TAG NAME DUTY (BTU/HR) DEVIATION

OF DUTY

TEMPERATURE (

O

F) REMARKS

INLET

OUTLET

0% 100% 0% 100%

195-

E-

100

1.2

1E

+0

6

3.17E+0

6

5 RECYCLE

195-

E-

101 AG COMP. AFTER COOLER

-

2.5

2E

+0

6

0.00E+0

0 -100%

242.

9 - -

195-

E-

106 VRU COMP. INTER COOLER

-

2.2

5E

+0

4

-

3.44E+0

4 53%

160.

8 184.0 120

COLD

RECYCLE

195-

E-

107

VRU COMP. AFTER

COOLER

-

5.8

8E

+0

4

-

3.87E+0

4 -34%

188.

2 190.6 120

195-

E-

103

LG COMP. INTER COOLER

(1

ST

STAGE)

-

6.5

5E

+0

5

-

1.20E+0

6 83%

184.

7 235.7 120

HOT

RECYCLE

195-

E-

104

LG COMP. INTER COOLER

(2

ND

STAGE)

-

1.4

2E

+0

6

-

1.34E+0

6 -5%

226.

7 222.3 120

LG COMP. AFTER COOLER

(3

RD

STAGE)

-

1.3

0.00E+0

0 -100%

217.

3 - -

Formatted Table

Formatted: Bullets and Numbering

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: No underline, Font color: Auto,

Superscript

Formatted: Left, Indent: Left: -0"

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

Formatted: Indent: Left: -0"

Formatted: Bullets and Numbering

Formatted: Left, Indent: Left: -0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 40

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

TAG

NO.

TAG NAME DUTY (BTU/HR) DEVIATION

OF DUTY

TEMPERATURE (

O

F) REMARKS

INLET

OUTLET

0% 100% 0% 100%

195-

E-

105

8E

+0

6

321.0

Gas Composition to WB Trunkline

Case 1 Case 2

Component Mole % Mole %

CO

2

3.561 3.556

H

2

S 0.000 0.000

Nitrogen 1.485 1.485

Methane 61.772 61.774

Ethane 11.656 11.656

Propane 13.414 13.415

i-Butane 2.719 2.719

n-Butane 3.199 3.200

i-Pentane 0.937 0.938

n-Pentane 0.646 0.646

n-Hexane 0.278 0.278

n-Heptane 0.069 0.069

n-Octane 0.010 0.010

n-Nonane 0.001 0.001

n-Decane 0.000 0.000

n-C11 0.000 0.000

n-C12 0.000 0.000

n-C13 0.000 0.000

n-C14 0.000 0.000

n-C15 0.000 0.000

n-C16 0.000 0.000

n-C17 0.000 0.000

n-C18 0.000 0.000

n-C19 0.000 0.000

n-C20 0.000 0.000

H2O 0.252 0.252

Total 100 100

ATTACHMENT -1

Formatted Table

Formatted: Bullets and Numbering

Formatted: Heading 1, Left, None, Space

After: 0 pt, Line spacing: single, No bullets

or numbering, Don't keep with next

Formatted: No Spacing, Centered, Line

spacing: single

Formatted: No Spacing

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 41

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

HYSYS SIMULATION

Formatted: Indent: Left: 0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 42

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

ATTACHMENT -2

HYDRAULIC CALCULATION Formatted: No Spacing

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 43

27302601-JulNovMay-09 13

Field Code Changed

Field Code Changed

ATTACHMENT -3

WB-SB Production Forecast

6.0ATTACHMENTS

Attachment 1 : HYSYS Simulation Process Flow Diagram (Case 1)

Attachment 2 : HYSYS Simulation Process Flow Diagram (Case 2)

Attachment 2 3 : Stream Data (Case 1)

Attachment 4 : Stream Data (Case 2)

Attachment 5 : H&MB Fuel Gas Conditioning Package

Formatted: No Spacing

Formatted: Indent: Left: -0.39"

Formatted: Bullets and Numbering

Formatted: Indent: Left: -0.25", Tab stops:

Not at 0.89"

Formatted: Indent: Left: -0.25", Tab stops:

Not at 0.89"

Formatted: Bullets and Numbering

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 44

7/4/2014 273026

Field Code Changed

Field Code Changed

ATTACHMENT 1

HYSYS SIMULATION PROCESS FLOW DIAGRAM (CASE 1)

Formatted: Indent: Left: 0"

Formatted: Indent: Left: 0"

Formatted: Justified

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 45

7/4/2014 273026

Field Code Changed

Field Code Changed

ATTACHMENT 2

HYSYS SIMULATION PROCESS FLOW DIAGRAM (CASE 2)

Formatted: Justified

Formatted: Justified

Formatted: Indent: Left: 0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 46

7/4/2014 273026

Field Code Changed

Field Code Changed

ATTACHMENT 32

STREAM DATA (CASE 1)

Formatted: Indent: Left: 0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 47

7/4/2014 273026

Field Code Changed

Field Code Changed

ATTACHMENT 4

STREAM DATA (CASE 2)

Formatted: Indent: Left: 0"

PetroChina International Jabung Ltd. Study Report

WB-SB Non Associated Gas Recovery

Simulation

Doc: BCD4-190-42-REP-4-007-00 BCD4-190-42-REP-4-007-00-BDocument1 Page 48

7/4/2014 273026

Field Code Changed

Field Code Changed

ATTACHMENT 5

H&MB FUEL GAS CODITIONING PACKAGE

Formatted: Indent: Left: 0"

Formatted: Centered, Indent: Left: 0", Space

Before: 0 pt

Formatted: Indent: Left: 0", Space Before:

0 pt

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Flow Assurance Study for Senipah-Balikpapan Gas PipelineDocument43 paginiFlow Assurance Study for Senipah-Balikpapan Gas PipelineaerfansÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- TNU-MT-50-001-A4 R0 Material Take OffDocument37 paginiTNU-MT-50-001-A4 R0 Material Take OffaerfansÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- How To InstallDocument2 paginiHow To InstallJaswin BÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19Document9 paginiDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19aerfansÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Update 21-11-2019 - Update (31-01-2020) - 14042020Document20 paginiUpdate 21-11-2019 - Update (31-01-2020) - 14042020aerfansÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- KGR DWG 010 003 A3.Sheet 4 of 4.rev.0 ModelDocument1 paginăKGR DWG 010 003 A3.Sheet 4 of 4.rev.0 ModelaerfansÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19Document9 paginiDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19aerfansÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- TNU-DWG-60-010-A3 - 1 Instrument Control Room LayoutDocument3 paginiTNU-DWG-60-010-A3 - 1 Instrument Control Room LayoutaerfansÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFDocument9 paginiDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFaerfansÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- CP-3513NO-EF-003 - 0G P&ID North - Automatic Well Test System SHT 4 of 4Document1 paginăCP-3513NO-EF-003 - 0G P&ID North - Automatic Well Test System SHT 4 of 4aerfansÎncă nu există evaluări

- KGR DWG 010 002 A3.Sheet 1 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 1 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- KGR DWG 010 002 A3.Sheet 2 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 2 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- KGR DWG 010 002 A3.Sheet 3 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 3 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- KGR DWG 010 001 A3.rev.2 ModelDocument1 paginăKGR DWG 010 001 A3.rev.2 ModelaerfansÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- KGR DWG 010 002 A3.Sheet 2 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 2 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- KGR DWG 010 002 A3.Sheet 1 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 1 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- KGR DWG 010 002 A3.Sheet 3 of 3.rev.2 ModelDocument1 paginăKGR DWG 010 002 A3.Sheet 3 of 3.rev.2 ModelaerfansÎncă nu există evaluări

- KGR DWG 010 001 A3.rev.2 ModelDocument1 paginăKGR DWG 010 001 A3.rev.2 ModelaerfansÎncă nu există evaluări

- KGR DWG 010 001 A3.rev.2 ModelDocument1 paginăKGR DWG 010 001 A3.rev.2 ModelaerfansÎncă nu există evaluări

- JYP DWG 010 004 A3.revDocument1 paginăJYP DWG 010 004 A3.revaerfansÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Epn-Fp - bbm-p-CA-003 Fire Water Demand Rev 0.Document12 paginiEpn-Fp - bbm-p-CA-003 Fire Water Demand Rev 0.aerfans100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Minor Project On Natural Gas.Document29 paginiMinor Project On Natural Gas.NikhilÎncă nu există evaluări

- FDP 1Document73 paginiFDP 1AdolfWaydaDollesinÎncă nu există evaluări

- Power Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsDocument30 paginiPower Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsSakthi MuruganÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Urea Plant SopDocument52 paginiUrea Plant SopAnjal DuttaÎncă nu există evaluări

- Sizing of Air ReceiverDocument6 paginiSizing of Air Receiverraghu_mn100% (1)

- Attach 2-6-1 Process Description and Features of Toyo's H2 PlantDocument15 paginiAttach 2-6-1 Process Description and Features of Toyo's H2 PlantLisbeth Roos RoosÎncă nu există evaluări

- BS&W Models 4528EZ & 4728 Monitors FMCDocument14 paginiBS&W Models 4528EZ & 4728 Monitors FMCFernando MendezÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Boge DrainsDocument2 paginiBoge Drainsأبو أنس البرعصي100% (1)

- Regulators 92BT PDFDocument16 paginiRegulators 92BT PDFAlberto CastellanosÎncă nu există evaluări

- Condensate Line SizingDocument2 paginiCondensate Line Sizingemmanuilmoulos6339100% (1)

- Neft 2Document32 paginiNeft 2Roozbeh PÎncă nu există evaluări

- Line Sizing GuidelinesDocument30 paginiLine Sizing GuidelinesSanjay Parmar100% (1)

- HITRA For PiggingDocument6 paginiHITRA For PiggingAhmedÎncă nu există evaluări

- Preprint - Methods of Stabilization of Gas Condensates PDFDocument10 paginiPreprint - Methods of Stabilization of Gas Condensates PDFمصطفى العباديÎncă nu există evaluări

- G21/GSR21 Service LiteratureDocument99 paginiG21/GSR21 Service Literatureschrieberdieses100% (1)

- Process of LNG Plant PDFDocument26 paginiProcess of LNG Plant PDFodeinatus100% (3)

- PT-104 Pumping Trap Installation and MaintenanceDocument12 paginiPT-104 Pumping Trap Installation and MaintenancevkumaranÎncă nu există evaluări

- Avelair Compressed Air SystemsDocument6 paginiAvelair Compressed Air SystemsTiago PaivaÎncă nu există evaluări

- Designing a firewater network for a gas plantDocument11 paginiDesigning a firewater network for a gas plantHedi Ben MohamedÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Reservoir Fliud Phase BehavoirDocument50 paginiReservoir Fliud Phase BehavoirBrian OmbogoÎncă nu există evaluări

- FW Line List Area 59Document7 paginiFW Line List Area 59darwayne_316346Încă nu există evaluări

- Linde Small Scale LNG Distribution OverviewDocument17 paginiLinde Small Scale LNG Distribution OverviewPawan Chaturvedi100% (1)

- Oil and Gas GlossaryDocument8 paginiOil and Gas Glossaryina23ajÎncă nu există evaluări

- FOIP'd Energy Ministry Emails Pertaining To IEEP ChangesDocument9 paginiFOIP'd Energy Ministry Emails Pertaining To IEEP ChangesAlberta Liberal OppositionÎncă nu există evaluări

- STAXEL O2-AIR-ENERGY SUPPLY MODULE SERVICE MANUALDocument41 paginiSTAXEL O2-AIR-ENERGY SUPPLY MODULE SERVICE MANUALandreu39Încă nu există evaluări

- Effectively Control Column PressureDocument11 paginiEffectively Control Column PressureRashesh Shah0% (1)

- Study On LNG, CNG, NGL, LPG: Ratnesh PandeyDocument32 paginiStudy On LNG, CNG, NGL, LPG: Ratnesh PandeyRatnesh PandeyÎncă nu există evaluări

- 172784-00-PR-LS-00001 - 5-Service Index ListDocument6 pagini172784-00-PR-LS-00001 - 5-Service Index ListStevanNikolicÎncă nu există evaluări

- Jenbacher: 1. Avoidance of Condensate in Fuel Gases For GE Jenbacher Gas EnginesDocument2 paginiJenbacher: 1. Avoidance of Condensate in Fuel Gases For GE Jenbacher Gas EnginesArîfÎncă nu există evaluări

- Pre Lecture Note Module 1 7th Sem 1600932959Document18 paginiPre Lecture Note Module 1 7th Sem 1600932959Arunodhaya NÎncă nu există evaluări