Documente Academic

Documente Profesional

Documente Cultură

Piles - 5

Încărcat de

bsitlerDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Piles - 5

Încărcat de

bsitlerDrepturi de autor:

Formate disponibile

1

Lecture 5

Negative skin friction on pile

C F LEUNG

Center for Soft Ground Engineering

Department of Civil Engineering

National University of Singapore

Bed Rock

End Bearing

Stiff Soil

Loading from the

superstructure

Soft

consolidating

soil

Pile subject to negative skin friction

Negative

friction

Positive

friction

Pile

6.1 Introduction

2

Above neutral plane, soil

settles more than the pile

inducing negative skin

friction

At neutral plane, soil and

pile settlement equals and

there is no load transfer

Below neutral plane, pile

settles more than the soil,

thus positive skin friction

as in normal case

6.2 Causes of soil settlement

Settlement of soil under new fill

Soft soil still undergoing consolidation

Drawdown of groundwater level

Dissipation of excess pore water pressure

created during pile driving in soft soils

3

Consolidation status of soil from

oedometer test

BS1377: 1990 (Part 5)

Typical sample dimension:

75 mm diameter and 19 mm high

The sample is loaded for 24 hours under

each loading pressure (see next slide for

figure) and the consolidation settlement of

the soil sample is measured regularly.

Oedometer

4

Oedometer apparatus

Parameters for the determination

of soil settlement

Compression

index C

c

Preconsolidation

pressure

c

Swelling

index C

s

Settlement of each clay layer

= H = H

o

e/(1 + e

o

)

5

Typical e-log p curve from Singapore

site investigation reports

Soil samples from Singapore site

investigations are often heavily disturbed

6

(1) If preconsolidation

pressure

c

< effective

overburden pressure

v

, soil

is under consolidated and

will settle.

(2) If

c

=

v

, soil is

normally consolidated and

primary consolidation

settlement has completed.

(3) If

c

>

v

, soil is

overconsolidated.

** Negative skin friction

must be considered for (1).

Negative skin friction needs

not be considered if there is

no new fill for (2) & (3).

v

6.3 Examples of negative skin friction problems

(1) Timber or RC piles

The magnitude of

negative skin

friction is larger

than the relatively

small load

bearing capacity of

timber or RC pile

7

Large differential settlement due to downdrag on embankment piles

(2) Piles supporting embankment

Embankment

Vertical piles

Small size

pile caps

Small size

pile caps

Geosynthetics

Geosynthetic reinforced

earth platform

Firm soil or bedrock

s

0

s0

Firm soil or bedrock

Embankment

Inclined piles Inclined piles

Vertical piles

Large size

pile caps

Large size

pile caps

s

0

s

(a) Conventional pile supported embankments

(b) Geosynthetic reinforced and pile supported embankments

Small size

pile caps

Geosynthetic reinforced

earth platform

s

0

s

Embankment

Inclined piles Inclined piles

Vertical piles

Large size

pile caps

Large size

pile caps

s

0

s

Embankment

Inclined piles

Large size Large size

s

0

s

(b) Geosynthetic reinforced and pile supported embankments

Settling

soil may

also induce

severe

bending on

inclined

piles

8

6.4 Mechanism of Negative skin friction

Mechanism of negative skin friction is not

entirely clear

Many different methods and approaches for the

design of pile against negative skin friction

Engineers often have differing views on whether

negative skin friction should be considered in the

design

Present state of the art

Examination of mechanism

To examine the mechanism of negative

skin friction using centrifuge modelling

technique

To investigate the performance of pile

subject to simultaneous negative skin

friction and vertical load

9

NUS

Geotechnical

Centrifuge

NUS

Geotechnical

Centrifuge

Effective radius 1.82 m; Maximum 200g; Maximum payload 40g-t

Centrifuge Modelling

By subjecting a

reduced-scale model

to an acceleration

field N times Earths

gravity (Ng), the

prototype stress

levels can be

reproduced.

N is the scale factor

between model and

prototype.

Centrifuge in-flight

Centrifuge in-flight

Acceleration

field

Ng =

2

R

10

Advantage of centrifuge modeling

for negative skin friction study

Consolidation time of clay can be speeded

up by N

2

times

A 24-hr soil consolidation in the centrifuge

at 100g is equivalent to

24 x 100 x 100 hrs

=240,000 hrs

=over 27 years in prototype scale

NUS Centrifuge Control Room

1--Centrifuge operation control 2--Signal amplifiers 3--Data acquisition system

4--Hydraulic servo-valve controller 5--Hydraulic control panel 6--CCTV 7--Image

processing system

1

2

3

4

5

6

7

11

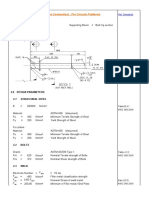

(1) Vertical actuator

(2) Long LVDT

(3) Sand hopper

(4) Loading frame

(5) Supporting frame

(6) Soil container

(7) Load cell

(8) Horizontal actuator

(9) Guiding flaps

(10) Model pile

(11) Clay sample

(12) Sand layer

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(3)

(2) (1)

4

0

5

1

0

8

0

1

2

0

7

5

4

8

0

Schematic experimental

setup (unit in mm)

Clay sample

Vertical actuator

Sand hopper

Supporting frame

Soil container

Horizontal actuator

Sand surcharge

Onboard hydraulic

control system

Side-view camera

Dense sand

12

Stain gauges Pile cap

Copper wire

Terminals

Semi-conductor strain gauges were installed along the model

pile shaft. The gauges have large gauge factor and provides much

better sensitivity in strain measurement.

The sand hopper (top view) capable of

applying sand surcharge in-flight

13

Top view: sand allowed to fall onto clay to simulate surcharge

placement during centrifuge flight

Side view

14

T-bar Penetrometer tests were carried

out at 100g and 1g on the soil to

measure the soil strength profile

25mm

5mm

Laboratory vane shear tests were conducted

on the soil at 1g to calibrate the T-bar tests

15

0 10 20 30 40

Undrained shear strength (kPa)

20

16

12

8

4

0

S

o

i

l

d

e

p

t

h

(

m

)

Vane shear_1

Vane shear_2

Vane shear_3

Vane shear_4

Vane shear_5

Vane shear_6

regress line

projected strength

(100g)

T-bar test (1g) T-bar test (100g)

After self-weight

consolidation

After sand

surcharge

before surcharge

Soil strength profile

Note soil

strength

reduces

significantly

from 100g field

to 1g field

0

400

800

1200

1600

2000

0 20 40 60 80 100 120 140 160 180 200

S

o

i

l

s

u

r

f

a

c

e

s

e

t

t

le

m

e

n

t

(

m

m

)

0

20

40

60

80

100

P

i

l

e

h

e

a

d

s

e

t

t

le

m

e

n

t

(

m

m

)

Soil surface

settlement

Pile head settlement

0

20

40

60

80

100

0 20 40 60 80 100 120 140 160 180 200

Time (month)

E

x

c

e

s

s

p

o

r

e

p

r

e

s

s

u

r

e

(

k

P

a

)

P1

P2

P1 P2

P2

P1

Locationof transducers

-20

0

20

40

60

80

0 20 40 60 80 100 120 140 160 180 200

Time (month)

P

r

e

s

s

u

r

e

(

k

P

a

)

surcharge

self-weight

consolidation

surcharge loading

(a)

(b)

(c)

Development of

(a) surcharge loading

(b) soil and pile head

settlement and

(c) excess pore water

pressure with time

(1) Negative skin

friction only

Self-weight consolidation

stage simulates the condition

of piles installed in under-

consolidating soil

16

Pile settlement

Pile settlement is a major concern as it

increases with increasing soil settlement until full

pile slip (when soil strength is fully mobilized and

pile does not settle any further even with

increasing soil settlement);

see Fig. (b) of last slide

Thus engineers must examine soil and pile

settlements under working condition

0

500

1000

1500

2000

0 20 40 60 80 100 120 140 160 180 200

Time (month)

D

o

w

n

d

r

a

g

f

o

r

c

e

(

k

N

)

Level-03

Self-weight consolidation Surcharge loading

Level-04

Level-01

Level-05

Level-06

Level-07

Level-09

Level-08

Development of downdrag forces versus time

(readings obtained from highly sensitive semi-

conductor strain gauges along pile shaft)

Pile top

Pile base

Level 1 to 9 pile top to base

17

0

400

800

1200

1600

2000

2400

0 1000 2000 3000 4000 5000 6000

Prototype ti me (days)

P

i

l

e

a

x

i

a

l

f

o

r

c

e

(

k

N

)

0

20

40

60

80

100

P

i

l

e

h

e

a

d

s

e

t

t

l

e

m

e

n

t

(

m

m

)

Maximum downdrag

force on the pile

Pile head settlement

test NSF1

test NSF2

test NSF1

test NSF2

Development of downdrag force follows that of pile head settlement

-4

0

4

8

12

16

20

24

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Pile axial force (kN)

D

e

p

t

h

b

e

l

o

w

o

r

i

g

i

n

a

l

g

r

o

u

d

s

u

r

f

a

c

e

(

m

)

3th month

12th month

30th month

Commencement of surcharge

84th month

86th month

120th month

End of test

Sand

Neutral plane

End of self-

weight

Pile axial force transfer profiles (Test N1 on friction

pile socketed in sand; negative skin friction only)

(b) Surcharge

(a)

Neutral

plane is at

about 90%

of clay

depth

18

0

4

8

12

16

20

24

-30 -20 -10 0 10 20 30

Uni t shaft resi stance (kPa)

D

e

p

t

h

(

m

)

90 days

180 days

1 year

2 years

3 years

end of stage

Time after spinning

Sand

Unit shaft friction distribution during self-weight consolidation

0

4

8

12

16

20

24

-40 -20 0 20 40 60

Uni t shaft resi stance (kPa)

D

e

p

t

h

(

m

)

end of previous stage

5 days

30 days

90 days

1 year

2 years

4 years

end of test

Time after surcharge

Sand

Unit shaft friction distribution after surcharge loading

The results show that the soil strength has been fully

mobilized. That is pile adhesion factor = 1

19

-4

0

4

8

12

16

20

24

0 400 800 1200 1600 2000 2400

Pi l e axi al force (kN)

D

e

p

t

h

(

m

)

Test N1

Test N2

Test N1

Test N2

End of self-weight

consolidation

End of consolidation

after surcharge

bottom of clay layer

Test NSF1

Test NSF2

Test N1: friction pile (results shown earlier) neutral plane at 90% of clay depth

Test N2: end-bearing pile (pile resting on hard rock) neutral plane at 100% of

clay depth

Neutral

plane

Mobilization of soil strength

Pile adhesion factor = 1 (as established

earlier)

factor from 0.2 to 0.3 (see next figure)

Conventional design values are hence

acceptable.

20

0

4

8

12

16

20

24

0 0.1 0.2 0.3 0.4 0.5

C

l

a

y

d

e

p

t

h

(

m

)

Test N1

Test N2

Test A1

Test A2

Test A3

Test A4

Test ID

Measured values from centrifuge tests

Pile experiences negative skin Pile experiences negative skin

friction is also likely to carry vertical friction is also likely to carry vertical

load simultaneously or afterwards load simultaneously or afterwards

The next series of tests investigates The next series of tests investigates

behaviour of pile subject to negative behaviour of pile subject to negative

skin friction under different working skin friction under different working

vertical loads vertical loads

(2) Pile subject to simultaneous negative

skin friction and vertical load

21

Onboard hydraulic servo-valve closed-loop control

system for the application of vertical load on pile

0

1000

2000

3000

4000

5000

6000

7000

0 1000 2000 3000 4000 5000 6000

Prototype ti me (days)

P

i

l

e

a

x

i

a

l

f

o

r

c

e

(

k

N

)

Level-01

Level-02

Level-03

Level-04

Level-05

Level-06

Level-07

Level-08

Level-09

Self-weight

consolidation

Axial loading

stage

consolidation under

surcharge loading

-20

0

20

40

60

80

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

k

P

a

)

surcharge

In this example, a vertical load of 4750kN was applied in-between

the self-weight consolidation stage and surcharge loading stage.

22

-8

-4

0

4

8

12

16

20

24

0 1000 2000 3000 4000 5000 6000 7000

Pile axial force (kN)

D

e

p

t

h

b

e

l

o

w

o

r

i

g

i

n

a

l

g

r

o

u

n

d

s

u

r

f

a

c

e

(

m

)

End of axial

loading

1 week

1 month

6 month

End of test

Sand

End of self-weight

consolidation

Moving trend of

the neutral plane

Pile axial load transfer profiles under vertical load and sand surcharge.

At stage 1 under self-weight consolidation, pile subject to negative skin friction

as before. The lock-in negative skin friction is about 800 kN.

I ncreasing vertical load

after surcharge

Fig. 5.25 Typical result of load settlement response

(Test No. 6)

0

1000

2000

3000

4000

5000

6000

0 30 60 90 120 150

Settl ement at pi l e top (mm)

L

o

a

d

(

k

N

)

Pile top

Pile Tip

Maintained axial load

Load=4750KN

Additional settlement due to

surcharge

Additional settlement after

Maintaining axial load

S

a

S

At stage 2 under vertical load, a vertical load of about 2400

kN would cause the pile to settle more than the soil and is

enough to eliminate the lock-in NSF in pile.

Note that there is no further soil settlement at this stage!

23

-200

0

200

400

600

800

0 500 1000 1500 2000 2500 3000 3500

Ti me start from pi l e axi al l oadi ng (days)

R

e

l

a

t

i

v

e

s

e

t

t

l

e

m

e

n

t

,

S

r

(

m

m

)

Level-09

Level-08

Level-07

Level-06

Level-05

Level-04

Level-03

Level-02

Level-01

Axial loading stage

level-09

level-08

level-07

level-06

level-05

level-04

level-01

level-03

level-02

At stage 3 surcharge loading, soil settlement along the upper

part of the pile exceeds the pile settlement inducing NSF again.

The neutral point lies in-between strain gauge level 4 and 5.

Important findings

If there is no more soil settlement under working

condition, it may not be necessary to consider

negative skin friction if the applied vertical load is

large enough to overcome the lock-in negative

skin friction.

Negative skin friction must be considered if there

is concurrent soil settlement under working

condition.

24

-8

-4

0

4

8

12

16

20

24

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

P

z

/P

D

e

p

t

h

(

m

)

Test A1 (P=4750 kN)

Test A2 (P=3350 kN)

Test A3 (P=8000 kN)

Sand

Test ID

Pile axial force distribution

after surcharge loading

Two more tests were conducted with applied

load of 3350 kN and 8000 kN respectively

-4

0

4

8

12

16

20

24

0 400 800 1200 1600 2000

Force P

add

(kN)

D

e

p

t

h

(

m

)

3350 kN

4750 kN

8000 kN

Sand

Axi al l oad P

Thus it is established that the load transfer due to applied load

and the development of negative skin friction along the pile shaft

are independent of each other and can be analysed separately.

Development of negative skin friction for the 3 tests is fairly consistent.

25

-8

-4

0

4

8

12

16

20

24

1000 2000 3000 4000 5000 6000 7000

Pi l e axi al force (kN)

D

e

p

t

h

(

m

)

before surcharge

1 week

6 months

end of test

>before surcharge

>1 week

>6 months

>end of test

Sand

Sand surcharge

Time after surcharge

Test A1

Test A4

Claylayer

Shift of neutral

plane in test A1

Shift of neutral

plane in test A4

The finding of 2 independent process can be further

confirmed from the above

Important finding

As the process of negative skin friction and axial

load transfer along pile shaft are independent,

Allowable load (geotechnical capacity) =

(Base resistance +positive skin friction below

neutral plane)/factor of safety

minus negative skin friction

plus load transfer from ground to neutral plane

26

Load

D

e

p

t

h

b

e

l

o

w

g

r

o

u

n

d

s

u

r

f

a

c

e

Load

D

e

p

t

h

b

e

l

o

w

g

r

o

u

n

d

s

u

r

f

a

c

e

D

e

p

t

h

b

e

l

o

w

g

r

o

u

n

d

s

u

r

f

a

c

e

Load

P P

Studies on pile group in process

Piles are often arranged in group

It is believed that the pile-soil-pile cap

interaction effect can reduce the

magnitude of negative skin friction (but by

how much?)

Further tests are currently in progress to

investigate pile group subject to negative

skin friction and vertical load

27

-4

0

4

8

12

16

20

24

0 300 600 900 1200 1500 1800

Pile axial force (kN)

D

e

p

t

h

b

e

l

o

w

o

r

i

g

i

n

a

l

g

r

o

u

n

d

s

u

r

f

a

c

e

(

m

)

Series8

single pile

2 pile group

4 pile group

Series5

Single pile

2 pile group

4 pile group

Sand

Self-weight consolidation

At the end of test

Preliminary pile

group results

Single pile has the

highest negative skin

friction. However,

the difference in

magnitude of

negative skin friction

between single pile

and small pile groups

(pile number < 5) is

not significant.

Summary of findings

Pile settlement must be checked if there is

soil settlement under working condition

Position of neutral plane for friction pile

can be lower than that proposed by

existing theories

Determination of magnitude of negative

skin friction by existing theories is okay

28

Summary of findings (cont.)

If there is no soil settlement under working

condition, it may not be necessary to consider

negative skin friction if the applied load is large

enough to eliminate the lock-in negative skin

friction

The load transfer due to applied load from the

surface to neutral plane can be employed to

arrive at a less conservative design for negative

skin friction

Summary of findings (cont.)

Friction piles

Negative skin friction less severe than that on

end-bearing piles

Pile settlement is a major concern

End-bearing piles

Negative skin friction more severe

Pile settlement is smaller than that of friction

piles

29

6.5 Design method for single pile

(1) Pile head settlement (very important and can

be critical)

Soil settlement has completed

Not a major concern as the large pile settlement

occurs before construction of superstructure

On-going soil settlement

Pile settlement is a major concern as settling soil will

drag the pile down

Difficult to evaluate (case by case)

(a) Settlement of end-bearing piles

Pile head settlement is approximately the sum of

(i) Elastic compression of pile due to applied load

(ii) Elastic compression of pile due to negative skin

friction

(iii) Pile tip deformation [treated as rigid footing on

hard stratum]

=(Applied Load +negative skin friction)

x(1 -

b

2

)/d

b

E

b

30

(b) Settlement of friction piles

Depends on the magnitude of downward

soil movement before full pile slip

Finite element analysis is required to

estimate the pile head settlement (this

requires the magnitudes of subsurface

movements; normally not available in

practice)

(2) Pile material stress (structural capacity)

Important and can also be critical especially for

lightly loaded piles in soft soils

Net allowable load =allowable load minus

negative skin friction

Notes:

(a) Negative skin friction is taken as a load

(b) HK GEO recommends that transient live loads need

not be included for above case. Hence the net allowable

load must be at least >dead loads. (Poser question:

Why?)

31

(3) Geotechnical capacity

Allowable load =

(Base resistance +positive skin friction below

neutral plane)/factor of safety

minus negative skin friction

Take factor of safety as 1.5 for this extreme scenario

(also in view of the findings in Section 6.4).

Position of neutral plane:

(a) at base of soft soil layer for end-bearing pile; or (b) at

about 0.9 depth of settling soil for friction pile

Determination of negative skin

friction

Same approach as positive friction case

e.g. unit skin friction

f

s

= c

u

where is pile adhesion factor (taken as 1

for conservative design)

and c

u

is soil undrained shear strength

The method can also be used.

32

IMPORTANT

Both the structural and geotechnical pile

capacity must also pass the usual design

(without negative skin friction

consideration) checks covered in Lecture

2!

6.6 Case study and example

Different loadings and soil conditions

warrant different pile types and sizes Refer

to attached Excel file for details.

Poser question 1 Does tunnel

excavation induce negative skin friction on

adjacent existing piles? If yes, what would be

the anticipated subsurface settlement profile and

its effects on the piles?

33

+ 5 m CD

0 m CD

- 25 m CD

Sand fill

Soft clay of variable thickness

Stiff clay

Poser question 2 Jurong Island deep sea reclamation: 30 m

sand fill followed by thick underconsolidating soft clay. Discuss

problems of negative skin friction on piles in this case and

recommend remedial measures.

6.7 Reduction of negative skin friction

Provide dummy casing or sleeve around

pile to prevent direct contact with settling

soil

Predrill oversized hole through soft soil

prior to pile installation (hole filled with

bentonite slurry)

Use of slender pile section in soft soil

layers

34

Electro-osmosis

Current applied between pile (cathode) and

an anode causes migration of pore pressure

towards pile

Reduce effective stress and hence negative

skin friction

Very good effect on silty soils

Bitumen coating (see next slide)

If magnitude of negative skin friction is too large, the pile

may be coated with bitumen (above neutral plane) to reduce

the negative skin friction (up to 90% reduction reported).

Bitumen coated on prestressed spun pile

35

6.8 Pile group

Group interaction effects are beneficial as

negative skin friction on individual piles will be

reduced (up to 30% reported).

Distribution of negative friction among piles is

not the same (centre piles has the least negative

skin friction due to the most severe group

interaction).

Little benefits for small pile group (number of pile

<5) in very soft soils due to full pile slip.

Settling

soil

Pile cap

Pile

group

Pile

More efforts are required to drag the entire pile group

including the pile cap. The pile-pile cap-soil interaction

helps to reduce negative skin friction on a pile group.

Pile cap

Settling

soil

Pile

group

Pile

The magnitude of free field soil movement for pile group

is reduced especially for inner piles.

36

(1) Bowles and HK GEO recommend that

the negative skin friction of a pile group

may be taken as the lesser of

Sum of negative skin friction around pile

group perimeter plus effective weight of

settling soil enclosed by the perimeter (i.e.

sum of 1 +2 +3 +4 in next slide), or

Sum of negative skin friction on individual

piles

Different approaches:

Fill

Settling soil

Neutral plane

(1) Effective weight of

fill within pile group

perimeter

(2) Negative skin

friction of fill

around pile group

perimeter

(3) Effective weight of

settling soil within

pile group perimeter

(4) Negative skin

friction of settling

soil around pile

group perimeter

Pile settles more than the

soil beneath neutral plane

Ground level

37

Negative skin friction on pile group

(2) Terzaghi and Peck -- Sum of negative skin

friction for settling soil around pile group

perimeter plus effective weight of fill enclosed by

the perimeter (i.e. sum of 1 +4 from previous

slide)

(3) NAFAC DM7, Tomlinson and Canadian

Geotechnical J ournal -- Sum of effective weight

of fill and settling soil enclosed by the pile group

perimeter (i.e. sum of 1 +3 from previous slide)

Comments

Approach (1) is the most conservative,

perhaps too conservative.

Suggest to adopt approach (2) and (3)

and take the higher of the 2 values of

negative skin friction on pile group.

Need further research to study

mechanism of negative skin friction on

pile group!

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- CE 579 Lecture 3 Stability-Energy MethodDocument30 paginiCE 579 Lecture 3 Stability-Energy MethodbsitlerÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Chapter 2. - Second-Order Differential EquationsDocument7 paginiChapter 2. - Second-Order Differential EquationsbsitlerÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- CE 579 Lecture 4 Stability-Energy Method LRG DeflectionsDocument11 paginiCE 579 Lecture 4 Stability-Energy Method LRG DeflectionsbsitlerÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- CE 579 Lecture 4 Stability-Energy Method SM DeflDocument5 paginiCE 579 Lecture 4 Stability-Energy Method SM DeflbsitlerÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- CE 579 Lecture 6 Stability - Differential Equations-TorsionDocument16 paginiCE 579 Lecture 6 Stability - Differential Equations-TorsionbsitlerÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- CE 579 Lecture 7 Stability-Differential EquationsDocument18 paginiCE 579 Lecture 7 Stability-Differential EquationsbsitlerÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- CE 579 Lecture 1 Stability-Stability Vs BucklingDocument16 paginiCE 579 Lecture 1 Stability-Stability Vs BucklingbsitlerÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Composite Beam DesignDocument8 paginiComposite Beam DesignbsitlerÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- FE - 11 Plane StrainDocument13 paginiFE - 11 Plane StrainbsitlerÎncă nu există evaluări

- CE 579 Lecture8 Stability - Differential EquationsDocument16 paginiCE 579 Lecture8 Stability - Differential EquationsbsitlerÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Prof. Salah CE591compcol - F13Document30 paginiProf. Salah CE591compcol - F13magdyamdb100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- CE 579 Lecture 6 Stability-Differential EquationsDocument8 paginiCE 579 Lecture 6 Stability-Differential EquationsbsitlerÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- CE 579 Lecture 2 Stability-DesignDocument17 paginiCE 579 Lecture 2 Stability-DesignbsitlerÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Eccentric ShearDocument20 paginiEccentric ShearbsitlerÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Column Beam DetailsDocument9 paginiColumn Beam DetailsbsitlerÎncă nu există evaluări

- Steel Design Beam Column ConnectionDocument34 paginiSteel Design Beam Column ConnectionbsitlerÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Gusset Plate ExampleDocument8 paginiGusset Plate Examplebsitler100% (1)

- Composite Beam ShoringDocument2 paginiComposite Beam ShoringbsitlerÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Composite Beam ExampleDocument4 paginiComposite Beam ExamplebsitlerÎncă nu există evaluări

- FE - 9 2D InterpolationDocument16 paginiFE - 9 2D InterpolationbsitlerÎncă nu există evaluări

- Composite Beam ColDocument6 paginiComposite Beam ColbsitlerÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- DeflectionDocument3 paginiDeflectionbsitlerÎncă nu există evaluări

- FE - 10 Plane StressDocument22 paginiFE - 10 Plane StressbsitlerÎncă nu există evaluări

- FE - 3 FE ConceptDocument13 paginiFE - 3 FE ConceptbsitlerÎncă nu există evaluări

- FE - Lecture Notes IndexDocument3 paginiFE - Lecture Notes IndexbsitlerÎncă nu există evaluări

- FE - 6 FE ProgrammingDocument8 paginiFE - 6 FE ProgrammingbsitlerÎncă nu există evaluări

- FE - 8 Beam ElementDocument12 paginiFE - 8 Beam ElementbsitlerÎncă nu există evaluări

- FE - 5 Global Stiffness MatrixDocument13 paginiFE - 5 Global Stiffness MatrixbsitlerÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- FE - 4 Numerical IntegrationDocument10 paginiFE - 4 Numerical IntegrationbsitlerÎncă nu există evaluări

- EC4 Composite DesignDocument51 paginiEC4 Composite DesignbsitlerÎncă nu există evaluări

- Simplified - Field - Balancing - One Correction Plane or TwoDocument11 paginiSimplified - Field - Balancing - One Correction Plane or TwoPeak NeoÎncă nu există evaluări

- CH 1 Sustainable Energy CengageDocument40 paginiCH 1 Sustainable Energy CengageDr Mohammad AlzoubyÎncă nu există evaluări

- Numerical Modeling of Fire Resistance Test As A Tool To Design Lightweight Marine Fire Doors: A Preliminary StudyDocument11 paginiNumerical Modeling of Fire Resistance Test As A Tool To Design Lightweight Marine Fire Doors: A Preliminary StudybilalÎncă nu există evaluări

- Evolution of Atomic ModelsDocument52 paginiEvolution of Atomic ModelsJayson OlipasÎncă nu există evaluări

- WRCEDocument1 paginăWRCERichmark MacuhaÎncă nu există evaluări

- Method For Preliminary Sizing of Large Propeller Driven AircraftsDocument52 paginiMethod For Preliminary Sizing of Large Propeller Driven AircraftsHARISH PÎncă nu există evaluări

- Stewart Swerdlow - Blue Blood True BloodDocument125 paginiStewart Swerdlow - Blue Blood True BloodZoltán NagyÎncă nu există evaluări

- Design of Solid Slabs: Prepared By: Ir. Dr. Zainorizuan Mohd Jaini Edited By: Koh Heng BoonDocument25 paginiDesign of Solid Slabs: Prepared By: Ir. Dr. Zainorizuan Mohd Jaini Edited By: Koh Heng BoonZahirah SaffriÎncă nu există evaluări

- Differences Between Solids and FluidsDocument4 paginiDifferences Between Solids and FluidsgknindrasenanÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Problem Set 1Document2 paginiProblem Set 1Julienne InaanuranÎncă nu există evaluări

- CFD Approach As Design Optimization For Gas TurbinDocument12 paginiCFD Approach As Design Optimization For Gas TurbinFurqanÎncă nu există evaluări

- Basic Principles: Conservation of EnergyDocument7 paginiBasic Principles: Conservation of Energyzehra001Încă nu există evaluări

- SPH3U Vectors Online Activity: Download As A PDFDocument10 paginiSPH3U Vectors Online Activity: Download As A PDFJanaarthÎncă nu există evaluări

- Quizbowl - ElimDocument4 paginiQuizbowl - ElimChrysler DuasoÎncă nu există evaluări

- 1-1 Points Lines and PlanesDocument27 pagini1-1 Points Lines and PlanesJoseph Bryan VictoriaÎncă nu există evaluări

- Engineering Mechanics Statics and Dynamics 3Rd Edition Michael Plesha Full ChapterDocument67 paginiEngineering Mechanics Statics and Dynamics 3Rd Edition Michael Plesha Full Chaptermichael.lynch155100% (5)

- The Principle of Space Frame ConstructionDocument4 paginiThe Principle of Space Frame ConstructionIhsan MuhtadiÎncă nu există evaluări

- Programme For SEFET 2023 FinalDocument22 paginiProgramme For SEFET 2023 FinalDinesh KumarÎncă nu există evaluări

- Bloodstain Pattern Analysis: Fourth EditionDocument53 paginiBloodstain Pattern Analysis: Fourth Editionccondeiu1Încă nu există evaluări

- 7.1.eddy Current Testing-Part-1Document15 pagini7.1.eddy Current Testing-Part-1Mohanad AlmalahÎncă nu există evaluări

- 1988zhang - JAP - An NMR Study of Tetragonal Nd2Fe1 4B and Nd2Fe14 xCoxBDocument4 pagini1988zhang - JAP - An NMR Study of Tetragonal Nd2Fe1 4B and Nd2Fe14 xCoxBPatrícia CanazartÎncă nu există evaluări

- Dielectric StrengthDocument3 paginiDielectric Strengthdraganscribd12Încă nu există evaluări

- Cleat Connection For PlatformsDocument29 paginiCleat Connection For PlatformsRajveer SinghÎncă nu există evaluări

- PDF Concrete Designdocx DDDocument19 paginiPDF Concrete Designdocx DDAlexes DomingoÎncă nu există evaluări

- BCHT 10 Nov 21Document34 paginiBCHT 10 Nov 21Abir RahmanÎncă nu există evaluări

- Keynote Speaker - Prof. S. Talukdar - Vehicle Induced Dynamic Response of A Bridge and Moving Load EstimationDocument6 paginiKeynote Speaker - Prof. S. Talukdar - Vehicle Induced Dynamic Response of A Bridge and Moving Load Estimationdigvijay singhÎncă nu există evaluări

- Vortex Panel Method For Calculating Airfoil CharaceristicsDocument7 paginiVortex Panel Method For Calculating Airfoil CharaceristicsNickunj PatelÎncă nu există evaluări

- Lec 4 LevellingDocument27 paginiLec 4 LevellingelakiaÎncă nu există evaluări

- Lecture 3 Fanno Flow: April 2019Document19 paginiLecture 3 Fanno Flow: April 2019Meriam KooliÎncă nu există evaluări

- Ed 10-4 07-EN Maincatalog WebDocument108 paginiEd 10-4 07-EN Maincatalog Websleven21Încă nu există evaluări