Documente Academic

Documente Profesional

Documente Cultură

Icp Brochure Grade 80

Încărcat de

Tee Bun Pin0 evaluări0% au considerat acest document util (0 voturi)

305 vizualizări8 paginiIndustrial Concrete Products Sdn Bhd (ICP) is the largest manufacturer of pretensioned spun concrete piles in Southeast Asia, known as ICP PC piles. ICP piles are circular, range in diameter from 250mm to 1200mm, and can be manufactured up to 46m in length. They are used for foundations of structures like buildings, bridges, and marine projects. ICP piles have advantages like durability, ability to be driven through hard soil, and environmentally friendly installation.

Descriere originală:

Catalogue

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentIndustrial Concrete Products Sdn Bhd (ICP) is the largest manufacturer of pretensioned spun concrete piles in Southeast Asia, known as ICP PC piles. ICP piles are circular, range in diameter from 250mm to 1200mm, and can be manufactured up to 46m in length. They are used for foundations of structures like buildings, bridges, and marine projects. ICP piles have advantages like durability, ability to be driven through hard soil, and environmentally friendly installation.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

305 vizualizări8 paginiIcp Brochure Grade 80

Încărcat de

Tee Bun PinIndustrial Concrete Products Sdn Bhd (ICP) is the largest manufacturer of pretensioned spun concrete piles in Southeast Asia, known as ICP PC piles. ICP piles are circular, range in diameter from 250mm to 1200mm, and can be manufactured up to 46m in length. They are used for foundations of structures like buildings, bridges, and marine projects. ICP piles have advantages like durability, ability to be driven through hard soil, and environmentally friendly installation.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Unit 1-13-01, Menara IJM Land, No.1 Lebuh Tunku Kudin 3, 11700 Gelugor, Penang.

Tel: 604-296 1399 Fax: 604-296 1398

Email: icppg@ijm.com

August 2012

Wisma IJM Annexe, Jalan Yong Shook Lin, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: 603-7955 8888 Fax: 603-7958 1111 E-mail: icpsales@ijm.com Website: www.icpb.com

Senai

INDUSTRIAL CONCRETE PRODUCTS SDN BHD

MS 1SO 9001 : 2008 REG. NO AR0122

SPECIAL FEATURES OF ICP PILES

INDUSTRIAL CONCRETE PRODUCTS SDN BHD

(ICP) is the first commercial manufacturer of

HIGH PERFORMANCE PRETENSIONED SPUN

CONCRETE PILES (ICP PC PILES) in Malaysia.

Presently, ICP is the largest manufacturer in

South East Asia.

The company was incorporated in Malaysia

on 6 April 1977 and commenced business in

September 1977.

In September 1993, ICP started manufacturing

HIGH PERFORMANCE Pretensioned Spun High

Strength Concrete Piles (ICP PHC PILES) which

offer an economical foundation system with

consistent and superior quality compared to

the ordinary concrete piles. With the vast

experience in the manufacturing of

pretensioned spun concrete piles and utilising

the latest concrete technology, ICP is the

market leader in concrete piles.

ICP Piles are circular in cross-section and are

manufactured in sizes ranging from diameter

250mm to 1,200mm with standard lengths

varying from 6m to 46m in single pieces. ICP

Piles can be easily joined to any combination

of length as per design requirement. ICP Piles

are manufactured with steel end plates for

splicing.

ICP Piles have been used extensively as

foundation piles for power stations, highrise

buildings, civil engineering works, bridges,

marine structures, harbours, schools and

government projects, etc.

ICP Piles are exported to Brunei, Singapore,

Sri Lanka, the Middle East, Indonesia,

Philippines, Vietnam, Myanmar, USA, Canada

and Maldives.

As a market leader in the concrete industry,

ICP constantly improves the quality of its

products and services. All ICP factories are MS

ISO 9001 : 2008 certified.

Chenor Bridge,

Maran Pahang

Aden Flour Mill Jetty at Aden,

Yemen

Areas of Application

Bridges

Building Foundations

Civil Engineering Works

Marine Structures

Piled Embankments

Product Attributes

Spinning process results in more

durable concrete with high resistance

to corrosion.

Grade 80 concrete enables the piles to

be driven through hard strata.

Can be manufactured up to dia. 1200mm

and a maximum single length of 46 metres.

Environmentally friendly installation by

hydraulic jacking equipment which are

free of noise, air pollution and vibration.

Kementerian Perusahaan, Perdagangan

dan Komoditi, Putrajaya

1km Container Terminal at

Chittagong Port, Bangladesh

E-gate, Penang

Sg. Buloh Hospital, Selangor

SPECIAL FEATURES OF ICP PILES

INDUSTRIAL CONCRETE PRODUCTS SDN BHD

(ICP) is the first commercial manufacturer of

HIGH PERFORMANCE PRETENSIONED SPUN

CONCRETE PILES (ICP PC PILES) in Malaysia.

Presently, ICP is the largest manufacturer in

South East Asia.

The company was incorporated in Malaysia

on 6 April 1977 and commenced business in

September 1977.

In September 1993, ICP started manufacturing

HIGH PERFORMANCE Pretensioned Spun High

Strength Concrete Piles (ICP PHC PILES) which

offer an economical foundation system with

consistent and superior quality compared to

the ordinary concrete piles. With the vast

experience in the manufacturing of

pretensioned spun concrete piles and utilising

the latest concrete technology, ICP is the

market leader in concrete piles.

ICP Piles are circular in cross-section and are

manufactured in sizes ranging from diameter

250mm to 1,200mm with standard lengths

varying from 6m to 46m in single pieces. ICP

Piles can be easily joined to any combination

of length as per design requirement. ICP Piles

are manufactured with steel end plates for

splicing.

ICP Piles have been used extensively as

foundation piles for power stations, highrise

buildings, civil engineering works, bridges,

marine structures, harbours, schools and

government projects, etc.

ICP Piles are exported to Brunei, Singapore,

Sri Lanka, the Middle East, Indonesia,

Philippines, Vietnam, Myanmar, USA, Canada

and Maldives.

As a market leader in the concrete industry,

ICP constantly improves the quality of its

products and services. All ICP factories are MS

ISO 9001 : 2008 certified.

Chenor Bridge,

Maran Pahang

Aden Flour Mill Jetty at Aden,

Yemen

Areas of Application

Bridges

Building Foundations

Civil Engineering Works

Marine Structures

Piled Embankments

Product Attributes

Spinning process results in more

durable concrete with high resistance

to corrosion.

Grade 80 concrete enables the piles to

be driven through hard strata.

Can be manufactured up to dia. 1200mm

and a maximum single length of 46 metres.

Environmentally friendly installation by

hydraulic jacking equipment which are

free of noise, air pollution and vibration.

Kementerian Perusahaan, Perdagangan

dan Komoditi, Putrajaya

1km Container Terminal at

Chittagong Port, Bangladesh

E-gate, Penang

Sg. Buloh Hospital, Selangor

PROPERTIES OF ICP PILES - STANDARD PRODUCTS

(Subject to change without prior notice)

FORMULA FOR AXIAL LOAD

Based on BS 8004: 1986, the maximum allowable axial stress that may be applied to a pile acting as a short strut

should be one quarter of (specified works cube strength at 28 days less the prestress after losses)

N = fca x A

= 1/4(fcu - fpe) x A

Where, N = maximum allowable axial load

A = cross section area of concrete

fca = permissible compressive strength of concrete

fcu = specified compressive strength of concrete

fpe = effective prestress in concrete

CLASS A (EFFECTIVE PRESTRESS 4.0 N/mm

2

)

CLASS B (EFFECTIVE PRESTRESS 5.0 N/mm

2

)

CLASS C (EFFECTIVE PRESTRESS 7.0 N/mm

2

)

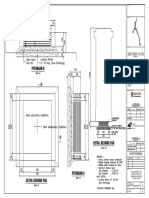

EXTENSION PILE

STARTER PILE

SPIRAL WIRE AT 50 mm

PITCH x 3D

SPIRAL WIRE AT 100 mm PITCH

SPIRAL WIRE

PILE SHOE

FILLET WELD

MS PLATE

PRESTRESSING BAR

PRESTRESSING BAR

SEE DETAIL A

SPIRAL WIRE AT 50 mm

PITCH x 3D

D

1

5

MS JOINTING PLATE

MS BAND

SECTIONAL DETAILS OF ICP PILES

JOINT WELDING DETAILS

Dia Of Pile

D

Throat

Thickness

A W

Root

R

Dia Of Pile Dia. Quantity L

HT Bars

BONDING ICP PILES INTO PILE CAP

As the PC bars are bonded with concrete, ICP Piles may be cut off at any point. The piles need not be

stripped down to expose the bars, and can be bonded to the pile cap as shown in the following sketch.

If the piles are not subjected to tensile loads, the recommended h.t. bars are considered adequate.

DETAIL A

mm mm mm mm

250 8.5 4.0 1.5

300 8.5 4.0 1.5

350 8.5 4.0 1.5

400 10 4.5 1.5

450 10 4.5 1.5

500 12 5.0 1.5

600 12 5.0 1.5

700 12 5.0 1.5

800 14 6.0 2.0

900 14 6.0 2.0

1000 14 6.0 2.0

1200 14 6.0 2.0

HT BARS

PILE CAP

ICP PILE

GRADE 30

CONCRETE PLUG

1.5 mm MS PLATE

TACK-WELDED TO

HT BARS

D

D

mm No. mm mm

250 4 12 500

300 4 12 500

350 5 12 550

400 5 12 700

450 5 15 800

500 6 15 900

600 8 15 1000

700 8 18 1200

800 8 20 1400

900 10 25 1500

1000 12 25 1500

1200 20 25 2000

kNm

9.0mm 10.7mm12.6mm

kNm

kNm kNm

kNm kNm

PROPERTIES OF ICP PILES - STANDARD PRODUCTS

(Subject to change without prior notice)

FORMULA FOR AXIAL LOAD

Based on BS 8004: 1986, the maximum allowable axial stress that may be applied to a pile acting as a short strut

should be one quarter of (specified works cube strength at 28 days less the prestress after losses)

N = fca x A

= 1/4(fcu - fpe) x A

Where, N = maximum allowable axial load

A = cross section area of concrete

fca = permissible compressive strength of concrete

fcu = specified compressive strength of concrete

fpe = effective prestress in concrete

CLASS A (EFFECTIVE PRESTRESS 4.0 N/mm

2

)

CLASS B (EFFECTIVE PRESTRESS 5.0 N/mm

2

)

CLASS C (EFFECTIVE PRESTRESS 7.0 N/mm

2

)

EXTENSION PILE

STARTER PILE

SPIRAL WIRE AT 50 mm

PITCH x 3D

SPIRAL WIRE AT 100 mm PITCH

SPIRAL WIRE

PILE SHOE

FILLET WELD

MS PLATE

PRESTRESSING BAR

PRESTRESSING BAR

SEE DETAIL A

SPIRAL WIRE AT 50 mm

PITCH x 3D

D

1

5

MS JOINTING PLATE

MS BAND

SECTIONAL DETAILS OF ICP PILES

JOINT WELDING DETAILS

Dia Of Pile

D

Throat

Thickness

A W

Root

R

Dia Of Pile Dia. Quantity L

HT Bars

BONDING ICP PILES INTO PILE CAP

As the PC bars are bonded with concrete, ICP Piles may be cut off at any point. The piles need not be

stripped down to expose the bars, and can be bonded to the pile cap as shown in the following sketch.

If the piles are not subjected to tensile loads, the recommended h.t. bars are considered adequate.

DETAIL A

mm mm mm mm

250 8.5 4.0 1.5

300 8.5 4.0 1.5

350 8.5 4.0 1.5

400 10 4.5 1.5

450 10 4.5 1.5

500 12 5.0 1.5

600 12 5.0 1.5

700 12 5.0 1.5

800 14 6.0 2.0

900 14 6.0 2.0

1000 14 6.0 2.0

1200 14 6.0 2.0

HT BARS

PILE CAP

ICP PILE

GRADE 30

CONCRETE PLUG

1.5 mm MS PLATE

TACK-WELDED TO

HT BARS

D

D

mm No. mm mm

250 4 12 500

300 4 12 500

350 5 12 550

400 5 12 700

450 5 15 800

500 6 15 900

600 8 15 1000

700 8 18 1200

800 8 20 1400

900 10 25 1500

1000 12 25 1500

1200 20 25 2000

kNm

9.0mm 10.7mm12.6mm

kNm

kNm kNm

kNm kNm

Cage Making / Mould

Setting

PC bars in coil form are

straightened and cut to correct

lengths. The ends are warm-

headed to form button heads.

The bars are passed through

the cage forming machine where

spiral wires is automatically

spot-welded at the correct

spacings. End plates are fitted

to the cage. The whole cage is

then placed onto the bottom

half mould.

Pile Spinning

The filled mould is then placed

on the centrifugal spinning

machine to be spun automatically

in four stages. Spinning results

in high compaction and

squeezes out excess water. The

resulting decrease in final

water cement ratio increases

the concrete strength in pile.

1

Stressing

The PC bars are stressed against

the mould through a central

shaft and stressing plate.

The stressing being carried out

in a single operation ensures

uniformity of stress in all the PC

bars and hence straightness of

the pile.

3 2

Concrete Feeding

Concrete from the

computerised batching plant is

discharged into a feeding

hopper. Concrete is then fed

into the bottom half mould

through a reversible screw

feeder. The top half mould is

then bolted to the

bottom half.

4 5 6

MANUFACTURING PROCESS OF ICP PILES

Standards

ICP PHC Piles comply with MS 1314:Part 4:2004 and

also generally comply with JIS A 5337:1987. ICP PHC

Piles are modified to suit BS 8004:1986 - Foundations

and BS 8110:1997 - Structural Use of Concrete.

Materials

Aggregates

Coarse aggregates shall be 20mm granite. Fine

aggregates shall be clean river sand or washed

mining sand.

Cement

Ordinary Portland cement to MS 522:1989.

Prestressing Steel

High frequency induction heat treated bars

manufactured to JIS G 3137:1994 or equivalent.

Spiral Wire

Hard drawn wire.

Concrete Strength

Minimum concrete cube strength:

at transfer of prestress 28 days

30 N/mm

2

78.5 N/mm

2

Joint

The joint is designed to have the same performance

as the main body particularly in respect of bending

strength. All ICP PHC Piles will be supplied with steel

extension plates for splicing.

Lifting Points

Two lifting points will be marked on all piles

exceeding 12m. No special lifting bolt or wire rope is

cast into the piles. Lifting is by wrapping wire ropes

round the piles at specified points.

Pile Shoes

All ICP PHC Piles will be supplied either open ended,

with a flat shoe or with an X-pointed shoe.

Curing

After casting, the piles are steam cured. When the

concrete reaches the specified transfer strength, the

piles are demoulded, marked and checked for quality.

The piles can normally be transported and driven

when the cube strength reaches 50 N/mm

2

.

Identification

All ICP PHC Piles have the typical markings as follows:

Logo as Trademark

Companys Initial

Malaysian Standard

Pile Size and Class

Date of Cast (yy/mm/dd)

Serial No & Factory Code

Pile Length and Type

Other markings if used, S for Starter (flat shoe or

X-pointed shoe)

Standard Lengths

ICP PHC Piles are available in lengths of 6m to 46m

subject to certain limitations.

Delivery

Usually two to three weeks from date of confirmed

order. ICP Standard Piles are normally available ex-

stock for test driving.

Technical Data

Technical data of piles are given in the table on

the next page. They refer to our standard products.

Please note that the axial loads represent the

structural capacities of the piles. Whether the driven

piles can safely carry these loads depend on the

soil conditions and the pile slenderness ratio.

Appropriate reduction of axial loads should be

applied for

(a) marine structures,

(b) piles subjected to bending,

(c) high upstand,

(d) piles driven through very poor top stratum,

(e) raking piles, etc.

Definitions

ICP PHC Piles: High Performance Pretensioned Spun

High Strength Concrete Piles

MS : Malaysian Standard

JIS : Japanese Standard

BS : British Standard

GENERAL SPECIFICATION FOR ICP PILES

Delivery

When the cube strength

reaches the required

strength the piles can be

transported and installed.

Curing

Steam curing enables the

piles to be demolded

earlier.

MS 1SO 9001:2008 REG. NO. AR0122

Cage Making / Mould

Setting

PC bars in coil form are

straightened and cut to correct

lengths. The ends are warm-

headed to form button heads.

The bars are passed through

the cage forming machine where

spiral wires is automatically

spot-welded at the correct

spacings. End plates are fitted

to the cage. The whole cage is

then placed onto the bottom

half mould.

Pile Spinning

The filled mould is then placed

on the centrifugal spinning

machine to be spun automatically

in four stages. Spinning results

in high compaction and

squeezes out excess water. The

resulting decrease in final

water cement ratio increases

the concrete strength in pile.

1

Stressing

The PC bars are stressed against

the mould through a central

shaft and stressing plate.

The stressing being carried out

in a single operation ensures

uniformity of stress in all the PC

bars and hence straightness of

the pile.

3 2

Concrete Feeding

Concrete from the

computerised batching plant is

discharged into a feeding

hopper. Concrete is then fed

into the bottom half mould

through a reversible screw

feeder. The top half mould is

then bolted to the

bottom half.

4 5 6

MANUFACTURING PROCESS OF ICP PILES

Standards

ICP PHC Piles comply with MS 1314:Part 4:2004 and

also generally comply with JIS A 5337:1987. ICP PHC

Piles are modified to suit BS 8004:1986 - Foundations

and BS 8110:1997 - Structural Use of Concrete.

Materials

Aggregates

Coarse aggregates shall be 20mm granite. Fine

aggregates shall be clean river sand or washed

mining sand.

Cement

Ordinary Portland cement to MS 522:1989.

Prestressing Steel

High frequency induction heat treated bars

manufactured to JIS G 3137:1994 or equivalent.

Spiral Wire

Hard drawn wire.

Concrete Strength

Minimum concrete cube strength:

at transfer of prestress 28 days

30 N/mm

2

78.5 N/mm

2

Joint

The joint is designed to have the same performance

as the main body particularly in respect of bending

strength. All ICP PHC Piles will be supplied with steel

extension plates for splicing.

Lifting Points

Two lifting points will be marked on all piles

exceeding 12m. No special lifting bolt or wire rope is

cast into the piles. Lifting is by wrapping wire ropes

round the piles at specified points.

Pile Shoes

All ICP PHC Piles will be supplied either open ended,

with a flat shoe or with an X-pointed shoe.

Curing

After casting, the piles are steam cured. When the

concrete reaches the specified transfer strength, the

piles are demoulded, marked and checked for quality.

The piles can normally be transported and driven

when the cube strength reaches 50 N/mm

2

.

Identification

All ICP PHC Piles have the typical markings as follows:

Logo as Trademark

Companys Initial

Malaysian Standard

Pile Size and Class

Date of Cast (yy/mm/dd)

Serial No & Factory Code

Pile Length and Type

Other markings if used, S for Starter (flat shoe or

X-pointed shoe)

Standard Lengths

ICP PHC Piles are available in lengths of 6m to 46m

subject to certain limitations.

Delivery

Usually two to three weeks from date of confirmed

order. ICP Standard Piles are normally available ex-

stock for test driving.

Technical Data

Technical data of piles are given in the table on

the next page. They refer to our standard products.

Please note that the axial loads represent the

structural capacities of the piles. Whether the driven

piles can safely carry these loads depend on the

soil conditions and the pile slenderness ratio.

Appropriate reduction of axial loads should be

applied for

(a) marine structures,

(b) piles subjected to bending,

(c) high upstand,

(d) piles driven through very poor top stratum,

(e) raking piles, etc.

Definitions

ICP PHC Piles: High Performance Pretensioned Spun

High Strength Concrete Piles

MS : Malaysian Standard

JIS : Japanese Standard

BS : British Standard

GENERAL SPECIFICATION FOR ICP PILES

Delivery

When the cube strength

reaches the required

strength the piles can be

transported and installed.

Curing

Steam curing enables the

piles to be demolded

earlier.

MS 1SO 9001:2008 REG. NO. AR0122

Unit 1-13-01, Menara IJM Land, No.1 Lebuh Tunku Kudin 3, 11700 Gelugor, Penang.

Tel: 604-296 1399 Fax: 604-296 1398

Email: icppg@ijm.com

August 2012

Wisma IJM Annexe, Jalan Yong Shook Lin, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: 603-7955 8888 Fax: 603-7958 1111 E-mail: icpsales@ijm.com Website: www.icpb.com

Senai

INDUSTRIAL CONCRETE PRODUCTS SDN BHD

MS 1SO 9001 : 2008 REG. NO AR0122

S-ar putea să vă placă și

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Design of RCC FoundationDocument10 paginiDesign of RCC FoundationUvie M. PtwolanÎncă nu există evaluări

- Fhwa HRT 04 043Document384 paginiFhwa HRT 04 043hana saffanahÎncă nu există evaluări

- VSL Strand Post Tensioning Systems PDFDocument41 paginiVSL Strand Post Tensioning Systems PDFJonathan GallegosÎncă nu există evaluări

- Seismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingDocument8 paginiSeismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingSherif FodaÎncă nu există evaluări

- CE5710 Assignment IDocument1 paginăCE5710 Assignment INani RujaÎncă nu există evaluări

- Non-Shrink GroutDocument7 paginiNon-Shrink GroutIm ChinithÎncă nu există evaluări

- 8 Storey Project Report - FINAL PDFDocument110 pagini8 Storey Project Report - FINAL PDFNeil Norman Simon MAnansalaÎncă nu există evaluări

- En B 373 Project 2012Document9 paginiEn B 373 Project 2012April IngramÎncă nu există evaluări

- İsrail Deprem Yönetmeliği EkiDocument18 paginiİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanÎncă nu există evaluări

- 2000 CALTRANS Bridge Design SpecificationsDocument14 pagini2000 CALTRANS Bridge Design Specificationsrhonald2000Încă nu există evaluări

- (Etic Far East) : TEST Post-Tensioning LTDDocument39 pagini(Etic Far East) : TEST Post-Tensioning LTDKunto Dwi WicaksonoÎncă nu există evaluări

- Booth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)Document219 paginiBooth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)CRISTIAN OMAR TUCTO ARANDAÎncă nu există evaluări

- TeklaS-Midas v20 ManualDocument10 paginiTeklaS-Midas v20 ManualNikola RajićÎncă nu există evaluări

- Sluis Et - Al. (2014) - Modelling of A Pile Row in A 2D Plane Strain FE-AnalysisDocument7 paginiSluis Et - Al. (2014) - Modelling of A Pile Row in A 2D Plane Strain FE-AnalysisViet Anh PhamÎncă nu există evaluări

- Materi Hari 2 Davy Sukamta PDFDocument20 paginiMateri Hari 2 Davy Sukamta PDFLaode AliyaÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument29 paginiDisclosure To Promote The Right To InformationRajanbabuÎncă nu există evaluări

- CIGRE b2-305Document8 paginiCIGRE b2-305Jorge Pinto RochaÎncă nu există evaluări

- A New Design To Prevent Progressive Collapse of Re PDFDocument7 paginiA New Design To Prevent Progressive Collapse of Re PDFKoresh KhalpariÎncă nu există evaluări

- "Polefdn" - Pole Foundation Analysis ProgramDocument28 pagini"Polefdn" - Pole Foundation Analysis ProgramBenedict OgbaghaÎncă nu există evaluări

- Finite Element Analysis of Composite Element For FRP Reinforced Concrete Slab by Using ANSYSDocument9 paginiFinite Element Analysis of Composite Element For FRP Reinforced Concrete Slab by Using ANSYSInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Lampiran 3. WPS of Pile JointDocument3 paginiLampiran 3. WPS of Pile JointDoni TriatmojoÎncă nu există evaluări

- Pratical Nonlinear Alaysis of Unreinforced Concrete Tunnel LiningDocument14 paginiPratical Nonlinear Alaysis of Unreinforced Concrete Tunnel LiningCarmine TranfaÎncă nu există evaluări

- Arindam Dey, RSS, Qip-Stc Gepd 2014Document147 paginiArindam Dey, RSS, Qip-Stc Gepd 2014AnÎncă nu există evaluări

- Geometrical Issues On The Structural Analysis of TDocument20 paginiGeometrical Issues On The Structural Analysis of TPower System OperationÎncă nu există evaluări

- Ashram StructureDocument49 paginiAshram StructureSandip BudhathokiÎncă nu există evaluări

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDocument25 paginiAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyÎncă nu există evaluări

- TTE033-2103-04-01-A0 - Conveyor C-51Document106 paginiTTE033-2103-04-01-A0 - Conveyor C-51Fandy SipataÎncă nu există evaluări

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocument14 paginiComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82Încă nu există evaluări

- Calculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValueDocument3 paginiCalculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValuehuhumaluÎncă nu există evaluări

- Sample L Pile OutputDocument10 paginiSample L Pile OutputManikumar Chebolu100% (1)

- Design Wind SpeedDocument6 paginiDesign Wind SpeedmohamadÎncă nu există evaluări

- 24.detail Bearing Pad 32.8Document1 pagină24.detail Bearing Pad 32.8putrapipanolisÎncă nu există evaluări

- Analysis of Laterally Loaded Piles Using Finite ElementDocument14 paginiAnalysis of Laterally Loaded Piles Using Finite ElementravirainbowÎncă nu există evaluări

- AISI S100-07 Appendix 1 With CommentaryDocument32 paginiAISI S100-07 Appendix 1 With CommentaryPrima AdhiyasaÎncă nu există evaluări

- Flexural Behavior of Circular Hollow Columns With A Single Layer of Reinforcement Under Seismic LoadingDocument92 paginiFlexural Behavior of Circular Hollow Columns With A Single Layer of Reinforcement Under Seismic LoadingArnold TunduliÎncă nu există evaluări

- IEI Rules of Thumb Line Card 03012016Document2 paginiIEI Rules of Thumb Line Card 03012016Anonymous 4ItkiwIÎncă nu există evaluări

- 02 Monorail PDFDocument295 pagini02 Monorail PDFDerry Trey FebriansyahÎncă nu există evaluări

- 21 - Ahmadi - HDNR Seismic Isolators Performance and Historical DevelopmentDocument45 pagini21 - Ahmadi - HDNR Seismic Isolators Performance and Historical DevelopmentHasrina Mohd RamaziÎncă nu există evaluări

- OS6450 AOS 6.6.4.309 R01 Release NotesDocument54 paginiOS6450 AOS 6.6.4.309 R01 Release NotesДмитрий ВасильевÎncă nu există evaluări

- Motions and Forces in Rope SystemDocument13 paginiMotions and Forces in Rope SystemNyi NyiÎncă nu există evaluări

- Tutorials Pad Footing Nta 5 (2012&2013)Document3 paginiTutorials Pad Footing Nta 5 (2012&2013)Host FredyÎncă nu există evaluări

- Flooring Design GuideDocument81 paginiFlooring Design GuideArmin KovacevicÎncă nu există evaluări

- 13 1611Document8 pagini13 1611teguh andriantoÎncă nu există evaluări

- Wind Induced Vibration and Dynamic Response On Concrete ColumnDocument23 paginiWind Induced Vibration and Dynamic Response On Concrete ColumnAndres FernandezÎncă nu există evaluări

- Hilti - Seismic Brochure en W4039Document12 paginiHilti - Seismic Brochure en W4039xpertsteelÎncă nu există evaluări

- 4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Document27 pagini4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Jair llacuachaqui villalvaÎncă nu există evaluări

- Development of Guideline of Performance-Based Design For Steel Strctures in Korea PDFDocument41 paginiDevelopment of Guideline of Performance-Based Design For Steel Strctures in Korea PDFCarlos Enrique Sánchez CáceresÎncă nu există evaluări

- Cyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsDocument12 paginiCyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsJoaquin PalermoÎncă nu există evaluări

- Beams On Elastic Foundation Using Winkler ModelDocument41 paginiBeams On Elastic Foundation Using Winkler Modeladnan-651358Încă nu există evaluări

- Underpass Design ReportDocument23 paginiUnderpass Design ReportMuhammad MinhasÎncă nu există evaluări

- Aci 440 1r 03 FRP Bars PDFDocument42 paginiAci 440 1r 03 FRP Bars PDFAdel Dib Al-jubeh0% (1)

- Aci 318 95Document32 paginiAci 318 95rakollÎncă nu există evaluări

- Loads For Designing FoundationDocument38 paginiLoads For Designing Foundationmuzaffar86ahmedÎncă nu există evaluări

- Standardized Pile Shoes On Steel Pipe PilesDocument1 paginăStandardized Pile Shoes On Steel Pipe PilesnenmilÎncă nu există evaluări

- ICP Spun Pile BrochureDocument7 paginiICP Spun Pile BrochureTee Bun PinÎncă nu există evaluări

- Spun PileDocument7 paginiSpun Pileمحمد فيذول100% (2)

- Multi Color Project BrochureDocument20 paginiMulti Color Project BrochureHai NguyenÎncă nu există evaluări

- Kiswire - NeptuneDocument8 paginiKiswire - NeptunealphadingÎncă nu există evaluări

- BSD-Steel Guide 2011 2Document112 paginiBSD-Steel Guide 2011 2Kiran Kumar K T0% (1)

- Steel Sheet PileDocument8 paginiSteel Sheet PileTee Bun PinÎncă nu există evaluări

- L I P P E D Channels - Avaitabte: Hot Rolled & Galvanized MaterialDocument2 paginiL I P P E D Channels - Avaitabte: Hot Rolled & Galvanized MaterialTee Bun PinÎncă nu există evaluări

- Cold Formed Rectangular Hollow Section - CatalogueDocument3 paginiCold Formed Rectangular Hollow Section - CatalogueTee Bun PinÎncă nu există evaluări

- Zeds & Cees: Users GuideDocument40 paginiZeds & Cees: Users GuideTee Bun PinÎncă nu există evaluări

- BRC CatalogueDocument34 paginiBRC CatalogueTee Bun Pin100% (1)

- Steel Sheet PileDocument8 paginiSteel Sheet PileTee Bun PinÎncă nu există evaluări

- ICP Spun Pile BrochureDocument7 paginiICP Spun Pile BrochureTee Bun PinÎncă nu există evaluări

- BRC CatalogueDocument34 paginiBRC CatalogueTee Bun Pin100% (1)

- Wind Loading On Tall BuildingsDocument14 paginiWind Loading On Tall BuildingsHarish T S GowdaÎncă nu există evaluări

- RC PilesDocument4 paginiRC Pileshasif21Încă nu există evaluări

- Zaber Catalog2012Document86 paginiZaber Catalog2012Tee Bun PinÎncă nu există evaluări

- OKA G45 RC - Square PilesDocument4 paginiOKA G45 RC - Square PilesTee Bun PinÎncă nu există evaluări

- Pile Foundation Design and Construction - What Can Go Wrong PDFDocument6 paginiPile Foundation Design and Construction - What Can Go Wrong PDFpabulumzeng100% (1)

- Basement Wall Rev1Document9 paginiBasement Wall Rev1Tee Bun Pin0% (1)

- Meyerhof Method PDFDocument3 paginiMeyerhof Method PDFTee Bun Pin50% (2)

- SPT N Limit PDFDocument1 paginăSPT N Limit PDFTee Bun PinÎncă nu există evaluări

- Staircase Design - Span 7.8mDocument2 paginiStaircase Design - Span 7.8mTee Bun Pin67% (3)

- AASHTO GeoTechnical Design of PileDocument6 paginiAASHTO GeoTechnical Design of PileTee Bun PinÎncă nu există evaluări

- Meyerhof Method - Pile CapacityDocument2 paginiMeyerhof Method - Pile CapacityTee Bun Pin77% (26)

- ANSYS - Method of AnalysisDocument6 paginiANSYS - Method of AnalysisTee Bun PinÎncă nu există evaluări

- BH 1 UploadDocument8 paginiBH 1 UploadTee Bun PinÎncă nu există evaluări

- Designation ASTM E1368 14Document14 paginiDesignation ASTM E1368 14Haryono MrÎncă nu există evaluări

- Renault Nissan AllianceDocument5 paginiRenault Nissan AllianceColin Farley100% (1)

- Question Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Document2 paginiQuestion Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Madhankumar .JÎncă nu există evaluări

- Residents Air Objections Despite $76 Tax Cut: Salary Increases, Ipads in New Municipal BudgetDocument20 paginiResidents Air Objections Despite $76 Tax Cut: Salary Increases, Ipads in New Municipal BudgetelauwitÎncă nu există evaluări

- QP Nonconforming Product Sample 2014Document2 paginiQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Aviation InsuranceDocument30 paginiAviation Insurancelaxmi sambreÎncă nu există evaluări

- Sap MM TutorialDocument39 paginiSap MM Tutorialiqbal1439988Încă nu există evaluări

- 5620 SAM Part Number ListingDocument109 pagini5620 SAM Part Number ListingSa VahidiÎncă nu există evaluări

- HTA Contener TerminalDocument9 paginiHTA Contener TerminalMaja LutovacÎncă nu există evaluări

- EAT 340 UNIT 1 LESSON 10 - Resource Planning and Scheduling Study NotesDocument12 paginiEAT 340 UNIT 1 LESSON 10 - Resource Planning and Scheduling Study NotesNhật DuyÎncă nu există evaluări

- Shore ApproachDocument5 paginiShore Approachvpandya1981Încă nu există evaluări

- Iso 19232 2 2013Document9 paginiIso 19232 2 2013NDT HITECHÎncă nu există evaluări

- Kartal Urban DesignDocument73 paginiKartal Urban DesignkanipakÎncă nu există evaluări

- Challenger Ethical Case StudyDocument7 paginiChallenger Ethical Case StudySam GitongaÎncă nu există evaluări

- TSB XK 2101505Document2 paginiTSB XK 2101505jdroalkvamÎncă nu există evaluări

- Hydraulic Breaker TOR Series: Break Anything... Except The BankDocument6 paginiHydraulic Breaker TOR Series: Break Anything... Except The BankYeison RamirezÎncă nu există evaluări

- Designing Customer Focus at KONEDocument15 paginiDesigning Customer Focus at KONETushar MalhotraÎncă nu există evaluări

- 45-D01135-En iLEC Technology Benefits of Use PDFDocument4 pagini45-D01135-En iLEC Technology Benefits of Use PDFcaparedeszÎncă nu există evaluări

- Snap728 enDocument8 paginiSnap728 enRajÎncă nu există evaluări

- Ict SystemsDocument12 paginiIct SystemsHaa'Meem Mohiyuddin100% (1)

- Quantity Surveyor PDFDocument9 paginiQuantity Surveyor PDFshanky22Încă nu există evaluări

- Curriculam Vitae-Civil EngineerDocument3 paginiCurriculam Vitae-Civil EngineerSubhankar Chandra KirtaniaÎncă nu există evaluări

- Selecting ERPs PDFDocument17 paginiSelecting ERPs PDFlucky414Încă nu există evaluări

- CV For UK CollegeDocument1 paginăCV For UK CollegeMartha NortonÎncă nu există evaluări

- Toyota Products Failure Case StudyDocument3 paginiToyota Products Failure Case StudyAfiq AfifeÎncă nu există evaluări

- Industrial SpecialtiesDocument103 paginiIndustrial SpecialtiesRahul ThekkiniakathÎncă nu există evaluări

- Bs 2782 3 Methods340aand340b 1978 PDF FreeDocument9 paginiBs 2782 3 Methods340aand340b 1978 PDF FreeE Hammam El MissiryÎncă nu există evaluări

- Simulation Using PromodelDocument711 paginiSimulation Using PromodelMulky TianovalÎncă nu există evaluări

- P3Document39 paginiP3venkatÎncă nu există evaluări

- Momenat I ProbojDocument404 paginiMomenat I ProbojSonja DragovicÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)