Documente Academic

Documente Profesional

Documente Cultură

Technical Resource Manual

Încărcat de

ShahinDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Resource Manual

Încărcat de

ShahinDrepturi de autor:

Formate disponibile

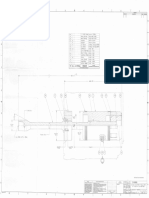

RIG/PLANT

ADDITIONAL CODE

SDRL CODE

TOTAL PGS

REMARKS

MAIN TAG NUMBER

DISCIPLINE

CLIENT PO NUMBER

CLIENT DOCUMENT NUMBER

Client Document Number

REFERENCE

REFERENCE DESCRIPTION

This document contains proprietary and confidential information

which belongs to National-Oilwell Varco, L.P., its affiliates or

subsidiaries (all collectively referred to hereinafter as "NOV"). It is

loaned for limited purposes only and remains the property of NOV.

Reproduction, in whole or in part, or use of this design or

distribution of this information to others is not permitted without the

express written consent of NOV. This document is to be returned to

NOV upon request and in any event upon completion of the use for

which it was loaned. This document and the information contained

and represented herein is the copyrighted property of NOV.

National Oilwell Varco

National-Oilwell Varco, L.P.

10303 Sheldon Rd

Houston, Texas 77049

USA

Phone 281-456-0751

Toll Free 1-800-486-0751

Fax 281-456-7549

DOCUMENT NUMBER

D931000030-MAN-001

REV

03

Quality Tubing

Technical Resource Manual

www.nov.com

Document number

Revision 03

Page 2

REVISION HISTORY

03 28.05.2008 Reissued CH CH JM

02 14.01.2008 Issued for Implementation CH CH JM

01 11.12.2007 Issued for Implementation CH CH JM

Rev Date (dd.mm.yyyy) Reason for issue Prepared Checked Approved

CHANGE DESCRIPTION

Revision Change Description

01 First issue

02 Revised information in the document

03 Fixed errors in the table of contents numbering

www.nov.com

Document number

Revision 03

Page 3

www.nov.com

TABLE OF CONTENTS

1 COILED TUBING WELDING TECHNOLOGY .................................................................. 5

1.1 Introduction ............................................................................................................. 5

1.2 Qualified Welding Procedure .................................................................................. 6

1.3 Qualified and Competent Welder ............................................................................ 7

1.4 Tubing Condition at Time of Welding and Welding Preparation ............................. 8

1.5 Welding Environment .............................................................................................. 9

1.6 Weld Finishing and Inspection ................................................................................ 9

1.7 Welding Technology: Appendix A ......................................................................... 10

2 COLLAPSE PRESSURE ................................................................................................ 14

2.1 Disclaimer ............................................................................................................. 14

2.2 Collapse Pressure for New Coiled Tubing ............................................................ 14

2.3 The Effect of Ovality on New Coiled Tubing ......................................................... 14

2.4 The Effect of Load and Torque ............................................................................. 15

2.5 Calculate the Allowable External Pressure ........................................................... 16

2.6 Some Variables that may Effect Collapse ............................................................. 18

2.7 Comparison with Values in API RP 5C7 ............................................................... 18

2.8 Comparison with Other Collapse Pressure Values ............................................... 19

2.9 Calculation Example ............................................................................................. 19

2.10 Collapse Data (70,000 to 90,000 PSI) .................................................................. 22

2.11 Collapse Data (100,000 to 120,000 PSI) .............................................................. 25

3 FRICTION PRESSURE DROP ....................................................................................... 28

3.1 Disclaimer ............................................................................................................. 28

3.2 Hydrostatic Head .................................................................................................. 28

3.3 Reynolds Number ................................................................................................. 29

3.4 Friction Factor ....................................................................................................... 30

3.5 Determining Pressure Drop .................................................................................. 31

4 WORKING WITH TRUE-TAPER

STRINGS .................................................................. 33

4.1 Manufacture of True-Taper

Strips ....................................................................... 33

4.2 Determining the Wall Thickness of True-Taper

Sections of Coiled Tubing Strings34

Document number

Revision 03

Page 4

www.nov.com

4.3 Wall Tolerances for True-Taper

Strings .............................................................. 34

4.4 True-Taper

Weight & Volume Capacity .............................................................. 34

4.5 Lengths of True-Taper Sections (from Nominal 40,000 lb coils) ........................... 35

4.6 Conclusion ............................................................................................................ 36

Document number

Revision 03

Page 5

www.nov.com

1 COILED TUBING WELDING TECHNOLOGY

1.1 Introduction

Coiled tubing is a unique product because it is designed to retain pressure during and after

undergoing fatigue cycling. It often becomes necessary to place butt welds into sections of

coiled tubing which also must be capable of withstanding fatigue cycling while providing

continued pressure containment.

In order to assure that the weld will provide the desired result in the field, a systematic

approach to making good welds repeatedly must be adhered to. This systematic approach

must consider each individual phase to the system.

Qualified Welding Procedure

Qualified and Competent Welder

Tubing Condition at Time of Welding and Welding Preparation

Welding Environment Conditions

Welding Techniques

Weld Finishing and Inspection

This Technical bulletin will review the considerations for each individual phase of a well-

planned coiled tubing welding system. Because every location and situation is different, not

all of the comments included here will necessarily be applicable all the time or at every

location.

Document number

Revision 03

Page 6

www.nov.com

1.2 Qualified Welding Procedure

A welding procedure is a written document containing welding specifications (WPS), which

provide the work instructions to the welder on how to make a weld. To assure the

procedure is capable of making a sound weld, it is tested to verify that welds made will

adhere to specific mechanical property and inspection quality requirements. Separate

WPSs are required for each distinct grade of coiled tubing and they may be limited in

application by code requirements. Procedures are unique to the specific company or

location performing the welding. The practices used and consumables employed are

dependent on many factors, so "one size fits all" welding procedures are impractical, if not

impossible. Therefore it is difficult to determine if a procedure is correct just by reading it.

Typical procedures reported in the literature or WPSs for specific grades from various

material suppliers may provide guides when preparing procedures.

The decisions leading to selection of welding variables which have produced acceptable

results in WPSs are reviewed in the Welding Technology section of this document.

New or revised welding procedures are tested, both mechanically and non destructively, to

prove they can result in a sound weld. The results of these tests are recorded on a

document supporting the procedure, called the Procedure Qualification Record (PQR).

Coiled tubing undergoes physical distortion in the plastic regime while retaining pressure

during normal operations. Most industry design and welding specifications or standards do

not encounter this level of deformation in welded joints. Consequently, the level of

qualification and inspection of each weld made in coiled tubing must be, of necessity, in

excess of most accepted national standards organizations, like ASME and API

requirements and acceptance criteria. Liquid penetrant, radiography and/or ultrasonic

inspection are imposed on the as welded joint to identify any potential problems before

mechanical testing is started. Non-destructive acceptance criteria are established at the

limit of detection for the method being employed due to the limited critical flaw size for

plastically deforming coiled tubing. Transverse tensile testing requires failure in the parent

material in addition to the strength requirement to assure a weak point will not be

introduced to the tubing. To assure the procedure does not create detrimental phases to

achieve the strength requirement, the weld is sectioned, metalographically inspected, and

the hardness in the weld's heat affected zone and base metal are verified.

Document number

Revision 03

Page 7

www.nov.com

1.3 Qualified and Competent Welder

Welders must demonstrate competency by passing a performance qualification test before

they can perform production welds. This test verifies they are capable of following the

written WPS procedure and producing the same results obtained while testing the WPS.

Before taking the qualification test, welders are trained in the specific skills required to weld

coiled tubing. Experience has shown many welders qualified in other welding disciplines,

including pipe fitters, may not make good coiled tubing welders. A welder qualification

record defined by a specification like ASME Section IX is used to document the welding

and testing. Welders qualifying to weld coiled tubing are tested more stringently than code

requirements. Both non-destructive examination and mechanical testing are employed. The

weld, the heat affected zone and hardness of the base metal are verified.

Once qualified, a welder must maintain proficiency. Because of the unique skills and

techniques required to weld coiled tubing, continuous practice of these specialized skills is

generally necessary to assure acceptable performance. Most coiled tubing welders

maintain proficiency by regularly making welds on coiled tubing and logging their activity.

When activity is slow, proficiency may be maintained by making practice welds on tubing

ends, scrap tubing or samples procured from the manufacturer. When a welder does not

make welds for an extended period, or there is reason to question his proficiency, he

should be re-qualified. Welders making welds routinely inspected by radiography need not

re-qualify on periodic timetables. All these welds are non-destructively tested to

requirements in excess of code qualification requirements. This combined with monitoring

field performance can assure welder proficiency is maintained.

Document number

Revision 03

Page 8

www.nov.com

1.4 Tubing Condition at Time of Welding and Welding Preparation

Coiled tubing is new on the day it is made. From that point on it undergoes physical,

dimensional and mechanical property changes each time it is spooled. Coiled tubing strings

undergo strain softening due to repeated application of stress in the plastic region during

coiling operations. Used tubing exhibits strength properties lower than those of new tubing.

Studies have shown that welding procedures developed for new tubing can also supply

adequate mechanical properties on used tubing.

Welds in used tubing lead to additional challenges. Tubing can become deformed, typically

oval in cross section, as a result of spooling. This presents alignment problems during fit

up. If mismatch is allowed it could generate potential stress risers while in service. Used

tubing can contain residues of produced well fluids, injected fluids, inclusive of acids or

water trapped in surface oxides or pits. Tubing which contained wireline or other galvanized

coated material may be zinc coated. Any of these could contaminate the weld if not

properly removed before welding. Used tubing can be magnetized, requiring demagnetizing

or magnetic countermeasures to be employed to prevent magnetic arc deflection during

welding. Trained and proficient welders recognize these potential problems and take

preventive action to preclude their becoming a cause for a weld imperfection.

Preparation for welding is vital to good finished welds and coiled tubing performance. The

tubing must be aligned so the weld will pass through injectors and over guide arches

without imparting unnecessary stress to the tubing. The internal and external surfaces must

be clean to prevent contamination of the weld. The tubing seam weld internal flash must be

removed to prevent it acting as a localized heat sink during welding and prevent

entrainment of the gas or oxides in the weld. Both the internal cleaning and flash removal

must be done without leaving circumferential grinding marks that could result in stress

risers. External chill blocks must be applied to the tube before welding to remove heat from

the base metal. If the excess heat were not removed properly the heat-affected zone could

experience excessive grain growth and loss of mechanical properties.

Document number

Revision 03

Page 9

www.nov.com

1.5 Welding Environment

Welds can be made at the factory or at service centers in nearly ideal environments. Welds

made at service companys district yards, at field camps, outside operations and on site

operations, can present far less than ideal welding environments. Welds made in non-ideal

environments may necessitate having a safety factor or mechanical property derating

applied to the tubing. This derating should be considered independently from fatigue

derating (if any) and only to the section as defined by coiled tubing management program

containing the butt weld. The magnitude of any derating is the responsibility of the coiled

tubing user. An example might be to treat QT-800 and QT-1000 butt weld mechanical

properties as equivalent to QT-700 properties. The butt welds made in less than ideal

environments, should be removed at the earliest opportunity and replaced by a butt weld

made in a near ideal environment. The replacement weld should be capable of carrying all

intended loads of the parent tubing.

1.6 Weld Finishing and Inspection

After welding, the weld crown required to prevent weld bead cracking must be removed to

allow the tubing to pass through the injector blocks. Removal is done carefully with tools,

which do not leave circumferential scars to a diameter several thousandths of an inch

above the tubing wall. This is adequate to pass through the injectors while not risking

material loss in the surrounding tubing wall.

After cooling to ambient temperature, the weld is dimensionally inspected to assure it

meets all tubing requirements for diameter and ovality. The weld is liquid penetrant

inspected, with special attention to the weld centerline and fusion lines where defects

detectable by this method are likely to occur. The weld, heat affected zone and base metal

are hardness checked to assure no hard or excessively soft areas are present. In shops

using multiple filler metal grades this can provide a check that the correct one was used.

Radiography is then used to volumetrically inspect the weld and surrounding area. The

acceptance criteria are established at the limit of detection for the smallest visible hole or

wire listed in the ASME code for the thickness being radiographed. Welds passing the

inspection acceptance criteria are released for use, and their location in the coiled tubing

string documented in the string management records, allowing monitoring of the weld

during coiled tubing operations.

CTES, L. C., Slimhole and Coiled Tubing Standards Phase 1 Weld Technology, Gas Research Institute

Drilling and Completion Group Final Report GRI-95.0500.1

Van Arnam, W. D. & Smith, D. Good Tubing Welds, Properly Managed, Do Not Break, SPE Paper 60694

Document number

Revision 03

Page 10

www.nov.com

1.7 Welding Technology: Appendix A

Review of Welding Parameters for Coiled Tubing

There are a number of manual GTAW welding procedures, documented in the literature, as

being successful in welding coiled tubing. The following is a discussion of the individual

welding variables considered important to preparation of a welding procedure.

Welding Joint

Several joint designs have been used on coiled tubing. They include double "V" grooves,

with and without a land, "J" and "U" bevels and occasionally the square butt joint.

"V" grooves employ bevel angles to allow introduction of filler metals and distribute welding

stresses developed due to thermal contraction of the weld bead. Included angles in the

bevel can vary from 30 to as much as 90, dependent on local needs. Studies on piping

components have shown that 37 2 per side or 75 included angles distribute these

stresses and minimize distortion in tubing welds effectively. "V" grooves may have

featheredges of 1/16" to 1/8" root faces or lands on the root of the bevel. Featheredges are

easier to prepare by hand grinding, which may be the only option in some locations.

Consistent lands are best prepared by weld bevelling tools, but can be made by

experienced hand grinding operators.

"J" and "U" bevels must be prepared by weld bevelling machines. They are used to reduce

the amount of filler metal required in a weld groove. In coiled tubing welding of thicker and

higher strength materials the dilution of too much filler metal can have an adverse influence

on the mechanical properties of the welded joint.

Square bevels have been used for relatively thin wall coiled tubing and are normally welded

autogenously (without filler metal additions). These joints are no longer recommended for

welding coiled tubing. These close fit joints have no root spacing and the base metal

provides the metal for the weldment. Weld penetration to fuse the inner root must be

carefully controlled and may be limited by the maximum welding amperage. Without filler

metal the bead can be concave, which can in turn, lead to weld cracking.

Weld joint preparation requires removal of internal flash, if present, from the weld area. If

left in place the flash could crate an artificial heat sink or source for weld contamination,

effecting welding characteristics and quality. Joint preparation must leave the weld joint

within tubing tolerances while not creating any local stress risers, such as visible to the

naked eye, circumferential grinding marks, which could affect finished fatigue and

mechanical properties.

Document number

Revision 03

Page 11

www.nov.com

Base Metals

Coiled tubing grades are predominately made from high strength low alloy strip, like coiling

operations. This can significantly increase the tendency for coiled tubing to ASTM A606

Gr4 (Mod.). The tubing manufacture process forms the tubing, seam anneals, stress

relieves and spools this material, making each grade of coiled tubing a unique base

material. This generally leads to the requirement that each separate grade of coiled tubing

requires separate procedure and qualification.

Much welding is performed on tubing that has been used. Provisions must be made to

handle residual bending, ovality, diameter and wall thickness differences in fitting up the

tubing for welding. Contingency plans for handling contaminated, corroded or magnetized

tubing should be in place as well.

Filler Metals

There are no known filler metals with chemistry and welded mechanical property results

matching coiled tubing grades. Filler metals must be selected from the available

commercial grades primarily designed for welding carbon and low alloy steels. Generally,

AWS A5.18 ER70S-2 or ER70S-6 filler metals are used for grades up to and including QT-

900. Though listed as having comparable mechanical properties to coiled tubing grades,

many ER80X-X and ER90X-X grades contain chromium or other elements not

recommended. These filler metals are hardenable during air-cooling from welding

temperatures and require preheat and or post weld heat treatment to control hardness and

cracking. These thermal treatments are capable of severely reducing the strength of the

surrounding coiled tubing base metal. AWS A5.28 ER120-S-1 is normally used for joining

QT-1000.

In most cases the filler metal is "under matched to the base metal. That means it either

contains fewer alloying elements, which will not develop the same welded strength as the

material being welded. To compensate for the under match, dilution of the base metal

chemistry and reproduction of the grain size are important to the finished weldment

properties. Precautions must be taken to assure the filler metal does not create a deposit of

under matched filler metal large enough to create a weak zone in an other wise uniform,

strong coiled tubing string.

Filler metal sizes or GTAW rods are normally 1/32" to 3/32", based on the thickness of the

bead and welder control required. 1/16" diameter filler metal is most often used.

Document number

Revision 03

Page 12

www.nov.com

Positions

Most procedures are developed in the ASME Section IX defined 5G position with the tubing

horizontal. This requires the weld bead to start at the bottom of the weld joint and progress

upward. Welds made in the factory, service center base camps and even field locations are

made in this position. Occasionally there are requirements for welds to be made in the 2G

position with the pipe vertical. In ASME Section IX qualifications, both welding procedures

and welders qualified to weld tubing in the horizontal (5G) position qualify to weld with the

tubing in the vertical (2G) position, but not vice versa. Field experience has indicated the

same is true for coiled tubing qualifications.

Normally, coiled tubing can be set up in either the horizontal or vertical position and the

ASME qualifications allow the set up to be as much as 15 degrees off true horizontal or

vertical using the same procedure. In the unlikely event the tubing must be welded with the

tubing between 15 to 75 degrees of true horizontal or vertical; ASME Section IX requires

separate qualifications be performed with the tubing oriented at 45 degrees from the

horizontal or vertical (6G position). If performed, the qualification in 45 degree

(6G) position, then qualifies the procedure or welder for the horizontal 5G and vertical 2G

positions also.

Preheat

Coiled tubing is made from high strength, low alloy steels designed to be welded without

preheat to prevent thermal cracking. Experience has shown preheating existing coiled

tubing grades can reduce the mechanical properties of the heat-affected zone. In fact, the

use of chill blocks to remove heat and preserve properties is well established in welding all

grades of coiled tubing. To assure mechanical properties in thicker walls, requiring multi-

pass welds, it may be necessary to provide auxiliary cooling to the chill blocks between

passes. There have been no reported incidences of weld cracking due to lack of preheat.

Heat may be applied to drive off absorbed surface moisture from sources including over

night condensation or contaminates carried by used tubing. When this is done, it is

advisable to cool the joint to approach ambient temperature before making the weld.

Historically carbon equivalent equations have been used to predict the need for preheat in

carbon and low alloy weldments. The chemistries of the higher strength grades of coiled

tubing suggest preheat should be employed. The carbon equivalent equations were

developed to include much thicker welds and highly restrained weld joints. Todays coiled

tubing wall thickness and weld fixturing allow more latitude. Coiled tubing grades, primarily

due to their high strength, low alloy and fine grain structure appear more tolerant to welding

without preheat than their low alloy counterparts with comparable carbon equivalents.

Document number

Revision 03

Page 13

www.nov.com

Post Weld Heat Treatment

Existing procedures do not utilize post weld heat treatment. Welding procedures developed

have shown the mechanical properties and base material hardness requirements can be

met without thermal treatment after welding.

Gas

The shielding gas will usually be welding grade Argon or 75% Helium, 25% Argon. It is

important that the gas be welding grade or better to assure it is not contaminated with

elements such as oxygen. Since the shielding gas protects the tungsten electrode and weld

puddle from high temperature oxidation, the purity is important.

The selection of welding gas may first be dictated by availability, particularly in remote

locations. Argon tends to have a cooler welding arc with less penetrating power than

helium. Mixed gases of argon and helium will tend to have hotter arcs and more penetrating

power as the concentration of helium increases. A second benefit is helium, being lighter

than air, tends to rise from the torch flow, while argon, being heavier than air, tends to fall.

Mixed gases entering the inside diameter of the tubing are believed to provide better overall

protection of the root when backing gases are not used.

Gas flow rates are important to provide continuous shielding of the weld pool. The minimum

flow rate must protect the weld pool, while overcoming disruptive influences of arc heating

or cross drafts. If the flow rate is too high, the gas flow can become turbulent and inspire air

with its oxygen to the weld pool. To allow higher flow rates, gas lenses are used in the torch

nozzle to keep flow laminar at higher flow rates. Flow rates should be measured with a flow

meter calibrated for the molecular weight of the shielding gas. The difference in molecular

weight between helium and argon means the flow rates required to provide equivalent

protection for helium are normally higher than for argon.

An important step in assuring the effectiveness of shielding gas is the protection of the

welding area form strong cross drafts. When welding in exposed areas, it is often

necessary to employ barriers to wind flow. Area or cooling fans should be turned off during

the time actual welding is performed. The welding shielding cannot compromise the safety

of the welder and the quality of his breathable air.

Electrical Characteristics

The GTAW process uses direct current, straight polarity in the welding arc. This makes the

tungsten electrode negative in the circuit.

The tungsten electrode is normally 3/32" diameter 2% Throated Tungsten. The electrode is

ground to a point with a controlled included angle, typically 60 degrees. The tip is then

truncated, with a small flat place on the end of the point to prevent the tip melting off into

the weld puddle.

Document number

Revision 03

Page 14

2 COLLAPSE PRESSURE

2.1 Disclaimer

The following section of this document is based on theoretical studies and

experimental data and is only presented by Quality Tubing as a possible benefit to

the customer. Quality Tubing NOV is not responsible for incidents that may occur

when the following information is used. The collapsed pressure should be

determined on a job-by-job basis. For more data, software programs, such as

Cerberus can be used.

2.2 Collapse Pressure for New Coiled Tubing

The collapse pressure (Pc) for new, as-manufactured, perfectly round coiled tubing, in the

absence of axial stress, is calculated using the appropriate formula which is given in API

Bulletin 5C3. A new version of this is under consideration at API and ISO.

These formulas have been developed for tubular collapse in the Yield Strength, Plastic or

Transition collapse regimes. For QTs downhole coiled tubing grades QT-700

, QT-800

,

QT-900

TM

, and QT-1000

, the collapse pressure can be located in the tables at the back of

this section in the columns that correspond to the L=0 and P

c

located under each Yield

Strength division. These values are based on the minimum allowable wall thickness, t

min

,

which is equal to t - .005in.

The values located in the tables were determined from experimental data that was

collected on round oilfield tubing and casing, of the same specified minimum yield strength,

and represent a 95% confidence level of the material surviving the pressure without

collapse. Where no API grade was available, the necessary constants (see API 5C3) were

interpolated between the two adjacent grades.

2.3 The Effect of Ovality on New Coiled Tubing

For all coiled tubing that is in service, the condition of the tube cannot always be

considered to be perfectly round. Coiled Tubing should always be considered to be

somewhat ovaled. For QT-1000

, the minimum ovality should be considered to be 1%,

and for all lower grades, it should be 2% (NOTE: This is a minimum value that is caused

from the spooling process, actual ovality could be greater). The Ovality of the coiled tubing

can drastically reduce the Collapse Pressure of the tubing. The Ovality of the tubing, for

the purpose of these calculations can be determined by the following equation:

D

D D ) (

* 100

min max

= (Eq. 1)

Where,

www.nov.com

Document number

Revision 03

Page 15

= Ovality of a Single Cross-Sectional Area of Tubing

D

max

= The Maximum Measured Diameter of the Cross-Sectional Area of Tubing

D

min

= The Minimum Measured Diameter of the Cross-Sectional Area of Tubing

D = The Specified Diameter of the Tubing

To find the Collapse Pressure of coiled tubing that is not perfectly round, the following

equations that were developed by Timonshenko should be considered.

f g g Pco =

2

(Eq. 2)

) * * 3 2 ( *

4 1 ) / (

min

min max

min

t

D

D

D D P

t D

SMYS

g

c

+ +

=

(Eq. 3)

1 ) / (

* * 2

min

=

t D

P SMYS

f

c

(Eq. 4)

Where,

P

c

= The Collapse Pressure for Perfectly

Round Tubing at Zero Load

P

co

= The Collapse Pressure for the Oval

Tubing at Zero Load

SMYS = Specified Minimum Yield Strength of

Tubing

t

min

= Minimum Wall Thickness of Tubing

These equations will give a theoretical collapse pressure for tubing with no load. There are

multiple variables that are not taken into account in these equations that may affect the

actual collapse pressure of the tubing. This should be considered when using the

calculated values in an actual scenario.

2.4 The Effect of Load and Torque

When a tensile load or a torque acts on coil tubing, the Collapse Pressure will decrease.

Because of this decrease, a Safety Factor should be calculated by the customer to help

assist in examining the risk of tubing collapse. The Safety Factor (greater than or equal to

1) should be based on the Utilization of the coiled tubing (from zero to 100%). The

Utilization of the tubing is based on the age and usage of the string and should be

determined by the customer based on field experience, derating programs for theoretical

fatigue life consumed and/or other methods. Quality Tubing NOV cannot provide the

Utilization number, but will assist with calculations upon request.

www.nov.com

Document number

Revision 03

Page 16

To calculate the theoretical Collapse Pressure with a load or torque on the tubing and a

Safety Factor incorporated, the following equations can be used.

3

4

3

4

3

4

. .

1

y co

L

L

P

P

F S

(Eq. 5)

3

4

3

4

3

4

. .

1

y co

P

P

F S

(Eq. 6)

Where,

S.F. = Safety Factor Chosen by the Customer

P = External Operating Pressure

L = Operating Tensile Load

L

y

= Pipe Body Yield Load

= Operating Torque

y

= Torsional Yield Strength

As seen by Eq. 5 and Eq. 6, the Load Factor and Torque Factor are equal.

y y

L

L

=

Because of this relationship, torque will be ignored for the rest of this section. The reader

should keep in mind that whenever the Load Factor of a string is shown, it can be replaced

by its Torque Factor.

The above equations can be rearranged to calculate different variables. Using minimal

allowable safety factors (which are determined by the user), these equations can be solved

for allowable external pressure, allowable tensile load, required collapse capacity, or

required load capacity.

2.5 Calculate the Allowable External Pressure

In calculating the allowable external pressure for a string of tubing, we will use the Collapse

Pressure Correction Factor, K. This factor is a substitution that will simplify Eq. 5 and Eq. 6

when the user is determining the allowable external pressure. The substitution is shown

below:

co

P K P * = (Eq. 7)

www.nov.com

Document number

Revision 03

Page 17

and rearrange to make,

co

P

P

K = (Eq. 8)

Therefore,

( )

3

4

3

4

3

4

. .

1

+ =

y

L

L

K

F S

(Eq. 9)

This Equation can then be rearranged as follows:

4

3

3

4

3

4

. .

1

=

y

L

L

F S

K (Eq. 10)

The correction factor, K, takes into account the Safety Factor and the Load Factor which is

shown in Eq. 10. The Safety Factor must be selected by the customer, and the Load

Factor is set by the tubing dimensions and the actual load on the tube (depth in hole,

attached tools, etc.). Because these values are set by the circumstances of the situation,

selecting the correction factor, K, can be done on the chart below:

<

20%

20-

30%

30-

40%

40-

50%

50-

60%

60-

70%

70-

80%

80-

100%

1.25 1.30 1.40 1.50 1.60 1.70 1.80 2.00

0.00 0.80 0.77 0.71 0.67 0.63 0.59 0.56 0.50

0.05 0.79 0.75 0.70 0.65 0.61 0.57 0.54 0.48

0.10 0.76 0.73 0.67 0.63 0.58 0.55 0.51 0.46

0.15 0.73 0.70 0.65 0.60 0.55 0.52 0.48 0.42

0.20 0.70 0.67 0.61 0.56 0.52 0.48 0.45 0.38

0.25 0.67 0.64 0.58 0.53 0.48 0.44 0.40 0.34

0.30 0.63 0.60 0.54 0.49 0.44 0.40 0.36 0.29

0.35 0.59 0.56 0.50 0.44 0.39 0.35 0.31 0.24

0.40 0.55 0.51 0.45 0.39 0.34 0.30 0.26 0.18

0.45 0.50 0.46 0.40 0.34 0.29 0.24 0.19 0.11

0.50 0.45 0.41 0.34 0.28 0.23 0.17 0.12 0.00

0.55 0.40 0.36 0.29 0.12 0.16 0.09 0.02

0.60 0.34 0.30 0.22 0.15 0.07

0.65 0.28 0.23 0.14 0.05

0.70 0.21 0.16 0.05

0.75 0.12 0.06

Safety Factor (S.F)

Coiled Tubing Utilization (U)

L/Ly

Table 1

www.nov.com

Document number

Revision 03

Page 18

www.nov.com

To use this table, select the desired Safety Factor or Utilization range (i.e. U = 35% is the

same column as S.F. =1.40), and then select the correct Load Factor, L/L

y

, that represents

the downhole load (the operating tensile load) verses the Pipe Body Yield Load (based on

the dimensions of the string) that is acting on the string. After the two factors are found,

trace them to the point that the respective row and column intersect on the table. This will

be the corresponding correction factor that should be used when finding the Allowable

External Operating Pressure, P. Since the Collapse Pressure, P

co

, is set by the tubing

dimensions, multiplying it by K will give a new pressure that accounts for the Safety Factor

and the Downhole Load acting on the string. With this new value of P, the user can adjust

the internal pressure of the string to compensate for the external pressure so the string will

not be at risk of collapsing.

2.6 Some Variables that may Effect Collapse

1. Active Load at Surface:

a. Tubing and Associated Downhole Tools

b. Buoyancy Effect

c. Pump Friction Force

d. Friction Force between the Tubing and the Well Wall

e. Accuracy of Weight Indicator

f. Deviation of Well

g. Axial Load Added from Tubing being Stuck Downhole

2. Pressure

a. Internal Tube Pressure

b. External Tube Pressure

3. Tubing Specifications

a. Grade of Tubing

b. Wall Thickness

c. Ovality of Tubing

4. Tubing Utilization

a. Safety Factor

b. Tubing Fatigue Life

2.7 Comparison with Values in API RP 5C7

The values calculated for QTs downhole workstring product are based on a minimum wall

of t

min

= t - .005 in. for the entire range of wall thicknesses, since this is the QT wall

thickness tolerance for all sizes. For wall thicknesses above 0.109 in., the collapse

pressures shown in QTs tables exceed those of API Recommended Practice RP5C7

because in the latter document, the collapse pressures are based on a minimum wall

thickness of t 0.008 in.

Document number

Revision 03

Page 19

2.8 Comparison with Other Collapse Pressure Values

The values given here are conservative since the original perfectly round tubing values

are conservative (because of the manner in which the data submitted for the API study

were evaluated). Individual tests on tubing samples obviously represent the performance

of that sample, while the values given here represent those for which there is a 95%

confidence level that a measured value will exceed the tabulated value.

Note

If the collapse pressure is required for a wall thickness not given in the tables below, please

call Quality Tubing NOV. This may occur with in-service coiled tubing, where the wall has

been eroded away during tubing operations.

2.9 Calculation Example

Tubing Specifications:

SMYS = 70,000 PSI

Outside Diameter = 1.25 inches

Wall Thickness = 0.087 inches

User Measured Specifications:

Max. Outside Diameter = 1.27 inches

Min. Outside Diameter = 1.23 inches

Safety Factor = 1.30

Operating Tensile Load = 7,800 PSI

Step 1

Find the Collapse Pressure, P

c

, for perfectly round tubing with the given dimensions and

no load in the attached tables. To do this, locate the row that contains specified outside

diameter, 1.25 in., and wall thickness, 0.087 in. Follow this row to the major column under

the Specified Minimum Yield Strength, SMYS, and then go to its sub-column for zero

ovality and zero tensile load. The value located where the row and column intersect should

be the value for P

c

. In this case, it is 7970 PSI.

Step 2

Determine the ovality of the tubing using Eq. 2. If the ovality cannot be determined a

default value of 2% should be used:

D

D D ) (

* 100

min max

=

% 2 . 3

25 . 1

) 23 . 1 27 . 1 (

* 100 =

=

Therefore, the ovality of the tubing is 3.2%.

www.nov.com

Document number

Revision 03

Page 20

Step 3

Find the Collapse Pressure, P

co

, for tubing that is ovaled, but has no load acting upon it

using Equations 2 through 4.

First the minimum wall thickness must be calculated using QTs specs as follows:

in in in in t t 082 . 0 005 . 0 087 . 0 005 .

min

= = =

Next calculate g using Eq. 6-3:

) * * 3 2 ( *

4 1 ) / (

min

min max

min

t

D

D

D D P

t D

SMYS

g

c

+ +

=

24 . 815 , 11

)

082 . 0

25 . 1

*

25 . 1

23 . 1 27 . 1

* 3 2 ( *

4

7970

1 ) 082 . 0 / 25 . 1 (

000 , 70

=

+ +

=

g

g

Then calculate f using Eq. 4:

1 ) / (

* * 2

min

=

t D

P SMYS

f

c

274 , 335 , 78

1 ) 082 . 0 / 25 . 1 (

7970 * 000 , 70 * 2

=

= f

Finally calculate P

co

using Eq. 2:

f g g Pco =

2

3988

274 , 335 , 78 24 . 815 , 11 24 . 815 , 11

2

=

=

co

co

P

P

Rounding this to the nearest 10

th

gives P

co

= 3990 PSI. This will be the new collapse

pressure for the tubing which includes a percentage of ovality.

Step 4

Incorporate the user determined Safety Factor and Operating Tensile Load that are

relevant to the string. The Operating Tensile Load should include axial loads acting upon

the string caused by the weight of the downhole portion of the string, the weight of any

tools attached to the string, etc.

www.nov.com

Document number

Revision 03

Page 21

First calculate the Pipe Body Yield Load using the following equation:

250 , 22

000 , 70 * 087 . 0 * ) 087 . 0 25 . 1 ( *

* * ) ( *

=

=

=

y

y

y

L

L

SMYS t t D L

L

y

is then used to divide the Operating Tensile Load to determine the Load Factor as

follows:

35 . 0

250 , 22

800 , 7

= = =

y

L

L

LoadFactor

Using the chosen Safety Factor and the calculated Load Factor, Table 1 can be used to

locate the corresponding correction factor, K. On the table, locate the column that

corresponds to the selected Safety Factor of 1.30 (this is also the column that corresponds

to the tubing utilization, U, of 20 to 30%). Also locate the row that corresponds to the

calculated Load Factor of 0.35. Trace the respective row and column until they intersect.

In this case, the value at this intersection is 0.56. This should be used as the Collapse

Pressure Correction Factor.

Step 5

Incorporate the Collapse Pressure Correction Factor into the Allowable External Pressure

by using Eq. 7 as follows:

PSI P K P

co

2230 3960 * 56 . 0 * = = =

The previous calculations estimate that, in order to keep the tubing from collapsing, the

external pressure acting on the tubing must remain below 2230 PSI. This means that the

differential pressure, the well pressure minus the annulus pressure, must remain below

2230 PSI.

www.nov.com

Document number

Revision 03

Page 22

www.nov.com

2.10 Collapse Data (70,000 to 90,000 PSI)

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

70,000 psi 80,000 psi 90,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2

D

(in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

0.750

0.750

0.750

0.750

0.750

0.087

0.095

0.102

0.109

0.118

0.082

0.090

0.097

0.104

0.113

9.146

8.333

7.732

7.212

6.637

13630

14780

15760

16720

17920

9260

10380

11360

12340

13600

6340

7100

7770

8450

9310

7080

8050

8910

9780

10920

4850

5510

6100

6690

7470

15580

16900

18020

19110

20470

10580

11860

12990

14110

15540

7240

8120

8890

9660

10640

8090

9200

10180

11180

12480

5540

6300

6970

7650

8540

17530

19010

20270

21500

23030

11910

13350

14610

15870

17480

8150

9140

10000

10860

11960

9100

10350

11460

12580

14040

6230

7080

7840

8610

9610

1.000

1.000

1.000

1.000

1.000

1.000

0.087

0.095

0.102

0.109

0.118

0.125

0.082

0.090

0.097

0.104

0.113

0.120

12.195

11.111

10.309

9.615

8.850

8.333

10540

11470

12260

13050

14030

14780

6440

7260

7980

8710

9640

10380

4410

4970

5460

5960

6600

7100

4710

5390

5990

6610

7410

8050

3220

3690

4100

4520

5070

5510

12040

13100

14010

14910

16040

16900

7360

8290

9120

9950

11020

11860

5040

5670

6240

6810

7540

8120

5380

6150

6840

7550

8470

9200

3680

4210

4680

5170

5800

6300

13550

14740

15770

16770

18040

19010

8280

9330

10260

11190

12400

13350

5670

6390

7020

7660

8490

9140

6060

>6920

7700

8490

9530

10350

4150

4740

5270

5810

6520

7080

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

0.087

0.095

0.102

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.082

0.090

0.097

0.104

0.113

0.120

0.129

0.140

0.151

0.170

15.244

13.889

12.887

12.019

11.062

10.417

9.690

8.929

8.278

7.353

7970

9330

10020

10680

11510

12150

12960

13920

14870

16450

4670

5440

6000

6560

7300

7870

8620

9540

10460

12060

3200

3720

4110

4490

5000

5390

5900

6530

7160

8250

3320

3900

4350

4810

5420

5900

6530

7320

8120

9530

2270

2670

2980

3290

3710

4040

4470

5010

5560

6520

8830

10400

11450

12200

13160

13890

14810

15910

16990

18800

5270

6150

6860

7500

8340

9000

9850

10900

11960

13790

3610

4210

4700

5130

5710

6160

6740

7460

8190

9440

3760

4420

4970

5500

6190

6750

7470

8370

9280

10900

2570

3030

3400

3760

4240

4620

5110

5730

6350

7460

9620

11410

12880

13730

14800

15620

16660

17900

19120

21150

5840

6840

7710

8440

9380

10120

11080

12270

13450

15510

4000

4680

5280

5780

6420

6930

7580

8400

9210

10620

4180

4930

5590

6190

6970

7590

8400

9410

10440

12260

2860

3370

3830

4240

4770

5190

5750

6440

7150

8390

Document number

Revision 03

Page 23

www.nov.com

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

70,000 psi 80,000 psi 90,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2

D

(in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

0.095

0.102

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.090

0.097

0.104

0.113

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.667

15.464

14.423

13.274

12.500

11.628

10.714

9.934

8.824

8.197

7.576

6780

7770

8760

9750

10300

11000

11850

12670

14070

15000

16040

4010

4560

5110

5770

6240

6850

7600

8360

9680

10590

11640

2740

3120

3500

3950

4270

4690

5200

5720

6630

7250

7970

2840

3240

3650

4170

4550

5050

5670

6310

7440

8230

9160

1940

2220

2500

2850

3110

3460

3880

4320

5090

5630

6270

7450

8600

9740

11150

11780

12580

13540

14490

16080

17140

18330

4510

5140

5780

6600

7130

7830

8690

9550

11060

12100

13300

3090

3520

3960

4520

4880

5360

5950

6540

7570

8280

9100

3200

3660

4140

4760

5200

5770

6480

7210

8500

9410

10470

2190

2500

2830

3260

3560

3950

4440

4930

5820

6440

7170

8060

9360

10670

12340

13250

14150

15230

16300

18090

19280

20620

4980

5700

6420

7370

8020

8810

9770

10750

12450

13620

14970

3410

3900

4390

5040

5490

6030

6690

7360

8520

9320

10250

3550

4070

4610

5330

5850

6490

7290

8110

9570

10580

11780

2430

2790

3160

3650

4000

4440

4990

5550

6550

7240

8060

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.104

0.113

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.827

15.487

14.583

13.566

12.500

11.589

10.294

9.563

8.838

6660

7750

8600

9700

10300

11040

12280

13110

14050

3950

4550

5020

5650

6240

6880

7990

8760

9660

2700

3110

3440

3870

4270

4710

5470

6000

6610

2790

3230

3580

4050

4550

5070

6000

6660

7420

1910

2210

2450

2770

3110

3470

4110

4560

5080

7310

8570

9560

10820

11780

12610

14030

14980

16050

4430

5120

5670

6390

7130

7860

9130

10020

11040

3030

3500

3880

4370

4880

5380

6250

6860

7560

3140

3650

4060

4600

5200

5790

6860

7610

8480

2150

2500

2780

3150

3560

3960

4700

5210

5800

7900

9330

10450

11890

13250

14190

15790

16850

18060

4890

5680

6300

7110

8020

8840

10280

11270

12420

3350

3890

4310

4870

5490

6050

7040

7710

8500

3490

4060

4520

5130

5850

6520

7720

8560

9540

2390

2780

3090

3510

4000

4460

5280

5860

6530

2.000

2.000

2.000

2.000

2.000

2.000

2.000

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.667

15.504

14.286

13.245

11.765

10.929

10.101

6780

7740

8910

9770

10890

11640

12490

4010

4540

5200

5790

6750

7410

8190

2740

3110

3560

3960

4620

5070

5610

2840

3220

3710

4180

4960

5510

6160

1940

2200

2540

2860

3390

3770

4220

7450

8560

9910

11260

12440

13300

14270

4510

5120

5870

6640

7710

8470

9350

3090

3500

4020

4540

5280

5800

6400

3200

3650

4210

4790

5670

6300

7040

2190

2500

2880

3280

3880

4310

4820

8060

9310

10850

12390

14000

14960

16060

4980

5670

6530

7400

8670

9530

10520

3410

3880

4470

5060

5930

6520

7200

3550

4060

4690

5350

6380

7090

7930

2430

2780

3210

3660

4370

4850

5430

Document number

Revision 03

Page 24

www.nov.com

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

70,000 psi 80,000 psi 90,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2

D

(in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

2.375

2.375

2.375

2.375

2.375

2.375

2.375

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.120

0.129

0.140

0.151

0.170

0.183

0.198

19.792

18.411

16.964

15.728

13.971

12.978

11.995

4770

5570

6560

7540

9240

9960

10700

2930

3360

3890

4430

5380

5950

6580

2010

2300

2660

3030

3680

4070

4500

2060

2370

2750

3140

3860

4310

4830

1410

1620

1880

2150

2640

2950

3310

5120

6050

7190

8330

10290

11380

12230

3250

3750

4370

4990

6090

6790

7520

2220

2570

2990

3420

4170

4650

5150

2300

2660

3100

3550

4370

4920

5520

1570

1820

2120

2430

2990

3370

3780

5410

6470

7760

9060

11290

12820

13760

3530

4110

4820

5530

6780

7650

8460

2420

2810

3300

3780

4640

5240

5790

2530

2930

3430

3950

4880

5540

6200

1730

2010

2350

2700

3340

3790

4240

2.625

2.625

2.625

2.625

0.156

0.175

0.188

0.203

0.151

0.170

0.183

0.198

17.384

15.441

14.344

13.258

6250

7790

9080

9760

3730

4570

5220

5780

2550

3130

3570

3960

2630

3250

3720

4170

1800

2220

2550

2850

6840

8620

10380

11160

4180

5150

5960

6610

2860

3520

4080

4520

2960

3670

4250

4770

2030

2510

2910

3260

7360

9390

10770

12550

4600

5710

6480

7430

3150

3910

4440

5090

3280

4090

4660

5370

2240

2800

3190

3680

2.875

2.875

2.875

2.875

0.156

0.175

0.188

0.203

0.151

0.170

0.183

0.198

19.040

16.912

15.710

14.520

5190

6600

7560

8670

3160

3920

4440

5060

2160

2680

3040

3460

2220

2760

3150

3610

1520

1890

2160

2470

5610

7240

8350

9630

3510

4390

5000

5710

2400

3000

3420

3910

2490

3120

3560

4090

1700

2140

2440

2800

5970

7810

9080

10540

3840

4840

5540

6350

2630

3310

3790

4350

2740

3450

3960

4560

1880

2360

2710

3120

3.500

3.500

3.500

0.175

0.188

0.203

0.170

0.183

0.198

20.588

19.126

17.677

4350

5140

6050

2710

3130

3620

1850

2140

2480

1910

2200

2550

1310

1510

1750

4640

5550

6610

2990

3480

4050

2050

2380

2770

2120

2470

2870

1450

1690

1960

4860

5900

7100

3230

3800

4450

2210

2600

3050

2320

2720

3180

1590

1860

2180

Note:

Although collapse pressures are given for all sizes, the sizes may not be available in

certain grades.

Document number

Revision 03

Page 25

www.nov.com

2.11 Collapse Data (100,000 to 120,000 PSI)

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

100,000 psi 120,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0

L=L

y

/

2

L=0

L=L

y

/

2

L=0 L=0

L=L

y

/

2

L=0

L=L

y

/

2

D (in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

1.000

1.000

1.000

1.000

1.000

0.095

0.102

0.109

0.118

0.125

0.090

0.097

0.104

0.113

0.120

11.111

10.309

9.615

8.850

8.333

16380

17520

18640

20050

21120

10370

11400

12440

13780

14830

7100

7800

8510

9430

10150

7690

8560

9430

10590

11500

5260

5860

6450

7250

7870

19660

21020

22360

24060

25340

12440

13680

14920

16530

17790

8510

9360

10210

11310

12180

9700

10820

11970

13480

14680

6640

7410

8190

9230

10050

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

0.102

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.097

0.104

0.113

0.120

0.129

0.140

0.151

0.170

12.887

12.019

11.062

10.417

9.690

8.929

8.278

7.353

14160

15260

16450

17360

18510

19890

21240

23500

8530

9380

10430

11250

12320

13630

14950

17230

5840

6420

7140

7700

8430

9330

10230

11790

6190

6870

7740

8430

9330

10460

11600

13620

4240

4700

5300

5770

6390

7160

7940

9320

16380

18310

19730

20830

22210

23870

25490

28200

10080

11250

12510

13500

14780

16350

17940

20680

6900

7700

8560

9240

10120

11190

12280

14150

7690

8640

9760

10660

11830

13310

14820

17500

5260

5910

6680

7300

8100

9110

10140

11980

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

1.500

0.095

0.102

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.090

0.097

0.104

0.113

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.667

15.464

14.423

13.274

12.500

11.628

10.714

9.934

8.824

8.197

7.576

8630

10090

11560

13440

14720

15720

16920

18110

20100

21420

22920

5430

6240

7060

8120

8910

9780

10860

11940

13830

15130

16630

3720

4270

4830

5560

6100

6690

7430

8170

9470

10360

11380

3890

4480

5080

5880

6490

7210

8100

9010

10630

11760

13080

2660

3070

3480

4020

4440

4930

5540

6170

7280

8050

8950

9590

11390

13190

15510

17310

18860

20310

21730

24120

25710

27500

6270

7270

8270

9580

10600

11740

13030

14330

16590

18150

19960

4290

4980

5660

6560

7250

8040

8920

9810

11350

12420

13660

4760

5510

6280

7290

8110

9080

10230

11420

13530

15030

16780

3260

3770

4300

4990

5550

6210

7000

7820

9260

10290

11480

Document number

Revision 03

Page 26

www.nov.com

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

100,000 psi 120,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0 L=L

y

/2 L=0 L=L

y

/2 L=0 L=0 L=L

y

/2 L=0 L=L

y

/2

D (in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

0.109

0.118

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.104

0.113

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.827

15.487

14.583

13.566

12.500

11.589

10.294

9.563

8.838

8450

10060

11320

12940

14910

15770

17540

18730

20070

5330

6220

6920

7830

8960

9820

11420

12520

13800

3650

4260

4740

5360

6130

6720

7820

8570

9440

3820

4470

4980

5660

6520

7240

8570

9510

10610

2610

3060

3410

3870

4460

4960

5870

6510

7260

9370

11350

12900

14880

17310

18920

21050

22470

24080

6140

7250

8110

9220

10600

11790

13700

15020

16560

4200

4960

5550

6310

7250

8070

9380

10280

11330

4670

5490

6150

7020

8110

9120

10840

12060

13500

3200

3760

4210

4800

5550

6240

7420

8250

9240

2.000

2.000

2.000

2.000

2.000

2.000

2.000

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.120

0.129

0.140

0.151

0.170

0.183

0.198

16.667

15.504

14.286

13.245

11.765

10.929

10.101

8630

10040

11770

13500

15560

16630

17840

5430

6210

7180

8150

9640

10590

11690

3720

4250

4910

5580

6600

7250

8000

3890

4460

5170

5900

7090

7880

8800

2660

3050

3540

4040

4850

5390

6020

9590

11320

13450

15570

18670

19950

21410

6270

7230

8420

9610

11570

12700

14030

4290

4950

5760

6580

7920

8690

9600

4760

5480

6390

7320

8920

9940

11140

3260

3750

4370

5010

6100

6800

7620

2.375

2.375

2.375

2.375

2.375

2.375

0.134

0.145

0.156

0.175

0.188

0.203

0.129

0.140

0.151

0.170

0.183

0.198

18.411

16.964

15.728

13.971

12.978

11.995

6840

8290

9750

12260

13980

15280

4450

5250

6050

7450

8430

9400

3050

3590

4140

5100

5770

6430

3200

3760

4340

5380

6120

6890

2190

2570

2970

3680

4190

4720

7390

9180

10970

14060

16170

18340

5040

6040

7040

8760

9960

11280

3450

4130

4820

6000

6820

7720

3860

4590

5330

6650

7590

8670

2640

3140

3650

4550

5190

5930

2.625

2.625

2.625

2.625

2.625

2.625

0.134

0.145

0.156

0.175

0.188

0.203

0.129

0.140

0.151

0.170

0.183

0.198

20.349

18.750

17.384

15.441

14.344

13.258

5210

6530

7850

10120

11680

13950

3550

4280

5000

6260

7120

8260

2430

2930

3420

4280

4870

5650

2570

3080

3590

4490

5130

5960

1760

2110

2460

3070

3510

4080

5390

7010

8630

11430

13340

16740

3890

4820

5730

7290

8360

9910

2660

3300

3920

4990

5720

6780

3050

3710

4370

5530

6340

7470

2090

2540

2990

3780

4340

5110

Document number

Revision 03

Page 27

www.nov.com

S

p

e

c

i

f

i

e

d

O

u

t

s

i

d

e

D

i

a

m

e

t

e

r

S

p

e

c

i

f

i

e

d

W

a

l

l

T

h

i

c

k

n

e

s

s

M

i

n

i

m

u

m

W

a

l

l

T

h

i

c

k

n

e

s

s

R

a

t

i

o

Specified Minimum Yield Strength

100,000 psi 120,000 psi

Ovality (D

max

-D

min

)/D

0 0.02 0.05 0 0.02 0.05

Tensile Load

L=0 L=0

L=L

y

/

2

L=0

L=L

y

/

2

L=0 L=0

L=L

y

/

2

L=0

L=L

y

/

2

D (in)

t

(in)

t

min

(in)

D/t

min

P

c

P

co

P

co

P

co

P

co

P

c

P

co

P

co

P

co

P

co

2.875

2.875

2.875

2.875

2.875

2.875

2.875

0.125

0.134

0.145

0.156

0.175

0.188

0.203

0.120

0.129

0.140

0.151

0.170

0.183

0.198

23.958

22.287

20.536

19.040

16.912

15.710

14.520

3520

4160

5070

6270

8350

9770

11410

2500

2910

3470

4140

5280

6060

6980

1710

1990