Documente Academic

Documente Profesional

Documente Cultură

Kddy Welding Technoh2065

Încărcat de

vuong0 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări11 paginifso

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentfso

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări11 paginiKddy Welding Technoh2065

Încărcat de

vuongfso

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

The Back Purging and Welding Requirements

for

Fabrication of HASTELLOY

alloy Pipe Systems

BACKGROUND

Peri odi cal l y, f abri cat ors are requi red t o i nst al l pi pi ng syst ems where access t o t he

i nsi de of t he pi pe i s not possi bl e. I n such si t uat i ons, ei t her open-but t pi pe wel di ng

t echni ques or wel di ng t echni ques usi ng a consumabl e i nsert are empl oyed. Because

consumabl e i nsert s are not readi l y avai l abl e f or t he HASTELLOY al l oy product s, open-

but t wel di ng usi ng t he gas t ungst en arc wel di ng (GTAW) process i s normal l y empl oyed

i n maki ng such root -pass wel ds.

When t hese one-si ded wel di ng t echni ques are used, i t i s necessary t o prot ect t he root

si de of t he wel d j oi nt f rom oxi dat i on duri ng wel di ng wi t h an i nert shi el di ng gas (usual l y

wel di ng grade argon). The shi el di ng t echni que, whi ch prot ect s t he i nsi de of t he pi pe,

i s cal l ed "back purgi ng".

H-2065A

Lack of pr oper shi el di ng pr oduces a condi t i on whi ch i s of t en r ef er r ed t o as " sugar "

of t he r oot pass. An exampl e of such a r oot - pass wel d, made on an 8" di amet er

HASTELLOY C- 22

al l oy pi pe, i s shown i n Fi gur e 1. An unaccept abl e r oot pass i s

char act er i zed by a bl ack, cr ust y appear ance of t he wel d met al on t he i nsi de ( r oot )

of t he pi pe and an i r r egul ar r oot cr oss- sect i on.

Fi gure 1: Exampl e of root wel d made wi t h poor back purgi ng t echni que.

HIGH PERFORMANCE ALLOYS

Technical Information

When t hi s condi t i on occur s, t he mol t en wel d met al does not f l ow out and " wet " t he

base mat er i al . Thi s condi t i on makes wel di ng di f f i cul t and t he passi ng of a r adi o-

gr aphi c exami nat i on near l y i mpossi bl e. Common wel di ng def ect s whi ch f or m as a

r esul t of t hi s condi t i on i ncl ude i ncompl et e penet r at i on, l ack- of - f usi on, r oot - pass

cr acki ng and r oot - pass suck back. I t has been r epor t ed, by sever al Haynes I nt er -

nat i onal cust omer s, t hat t he ni ckel - base ( HASTELLOY) al l oys ar e mor e di f f i cul t t o

wel d, usi ng t hi s one- si ded t echni que, t han ar e t he st ai nl ess or car bon st eel s.

Labor at or y wor k was conduct ed t o det er mi ne back pur gi ng and wel di ng t echni ques

whi ch wi l l pr oduce accept abl e open- but t r oot - pass wel ds i n al l oys such as

HASTELLOY C- 22

al l oy pi pe. The f ol l owi ng sect i ons document t he r esul t s of t hat

l abor at or y wor k.

BACK- PURGI NG TECHNI QUES

Two common met hods ar e used t o back pur ge a pi pe r oot - pass wel d zone. Pur gi ng

t he ent i r e vol ume of a l ong pi pe r un i s of t en suggest ed. Tabl es have been pub-

l i shed concer ni ng pur ge t i mes f or var i ous pi pe di amet er s and l engt hs of pi pe r un.

( 1)

Local pur gi ng of t he i mmedi at e vol ume ar ound t he wel d zone i s an al t er nat i ve

met hod of back pur gi ng and i s gener al l y t he pr ef er r ed t echni que. Var i ous met hods

of f or mi ng t he cl osur e dams ar e r epor t ed i n t he l i t er at ur e. They i ncl ude wat er

sol ubl e dams, i nf l at abl e bl adder dams, col l apsi bl e di sc dams and t her mal l y di spos-

abl e dams.

( 1, 2, 3)

Ther e ar e many compani es whi ch manuf act ur e equi pment and

pr oduct s t o accompl i sh such a l ocal pur ge. A par t i al l i st of suppl i er s of back-

pur gi ng equi pment i s pr esent ed at t he end of t hi s r epor t .

Back pur gi ng i s accompl i shed i n t wo st eps. Fi r st , t he dams must be i nst al l ed and

t he wel d zone vol ume pur ged wi t h ar gon t o accept abl e l evel s. Secondl y, pur gi ng

must cont i nue and accompany t he act ual wel di ng oper at i ons.

I n t he wor k r epor t ed i n t hi s document , *onl y wat er - sol ubl e dams wer e used. As a

way t o ensur e t hat t he pur ge gas ent er ed t he encl osed wel d zone wi t h a mi ni mum

of gas- f l ow t ur bul ence, t hus al l owi ng t he shor t est pur ge t i me,

( 5)

a di f f usi ng devi ce

was manuf act ur ed and secur ed at t he bot t om of one of t he pur ge dams. The l ocal

wel d zone was pur ged at about 40 cubi c f eet per hour ( CFH) of gas- f l ow r at e.

Such f l ow r at es al l owed pur gi ng of an 8" di amet er pi pe sect i on t o about 5000- ppm

oxygen cont ent i n l ess t han 5 mi nut es. Regar dl ess of t he l engt h of t i me of pur gi ng

af t er t he i ni t i al 5 mi nut es, i t was not possi bl e t o consi st ent l y obt ai n oxygen con-

t ent s bel ow t he 5000- ppm oxygen l evel . The 5000- ppm oxygen l evel was, however ,

det er mi ned t o be accept abl e f or wel di ng t he ni ckel - base al l oys.

The wel di ng l i t er at ur e

( 1, 3, 4)

r ecommends t hat t he back pur ge f l ow r at es be l ow

( " bar el y det ect abl e at t he gas exi t por t " ) and makes no r ef er ence t o t he wel di ng

t or ch f l ow r at es at al l . I n t hi s wor k, i t was det er mi ned t hat t he sel ect i on of shi el d-

i ng gas f l ow r at es f or bot h t he back pur ge and t he wel di ng t or ch ar e cr i t i cal i n t he

maki ng of sound r oot - pass wel ds.

Speci f i cal l y, i t was det er mi ned t hat a r at i o of appr oxi mat el y 4 t o 1, bet ween t he

back pur ge f l ow r at e and t he wel di ng t or ch f l ow r at e, i s necessar y t o make a sound

r oot - pass wel d. The f l ow r at es whi ch ar e now r ecommended f or wel di ng

*Pat ent pendi ng

2

HASTELLOY al l oy pi pe ar e 40 CFH f or t he back pur ge and 10 CFH f or t he wel di ng

t or ch. Fi gur e 2 i s i ncl uded t o show t he cr i t i cal i t y of t hose r el at i ve f l ow r at es on

act ual r oot - pass wel ds.

I t shoul d be not ed t hat t he wel d zone vol ume was pur ged t o t he 5000- ppm oxygen

l evel pr i or t o t he st ar t of wel di ng. The " accept abl e" r oot - pass wel d was made f i r st .

Then t he f l ow r at es wer e r ever sed and t he " unaccept abl e" r oot - pass wel d was

made. Thi s i s an i ndi cat i on t hat t he pur i t y of t he back pur ge gas was accept abl e

at t he st ar t of t he " unaccept abl e" wel d and t hat t he di f f er ence i n wel d qual i t y i s a

r esul t of t he f l ow r at es onl y.

The sel ect i on of t he f l ow r at e ( 10 CFH) f or t he t or ch shi el di ng gas i s somewhat l ow

based upon st andar d r ecommendat i ons f or wel di ng t he HASTELLOY ni ckel - base

al l oys.

( 6)

Thi s l ow wel di ng t or ch f l ow r at e does not , however , af f ect t he t or ch si de

shi el di ng as i ndi cat ed by br i ght , shi ny beads whi ch ar e pr esent usi ng ei t her shi el d-

i ng t echni que.

3

Unacceptabl e root wel d

Fl ow rates: Back purge - 10 CFH, wel di ng torch 30 CFH

Acceptabl e root wel d

Fl ow rates: Back purge - 40 CFH, wel di ng torch 10 CFH

Fi gure 2: Act ual root pass wel di ng resul t s.

WELDI NG TECHNI QUES

The pur gi ng and wel di ng of a pi pi ng j oi nt gener al l y i nvol ves si x oper at i ons.

Those oper at i ons i ncl ude:

1. Pr epar at i on of pi pe ends.

2. I nst al l at i on of pur ge dams.

3. Fi t - up of pi pe sect i ons.

4. Pur ge pi pe wel d zone .

5. Tack wel d pi pe sect i ons.

6. Cl osur e wel di ng.

1. Pr epar at i on of t he pi pe ends i s consi der ed a ver y i mpor t ant st ep i n t hi s wel d-

i ng oper at i on. A di agr am of a t ypi cal wel d pr epar at i on det ai l i s shown i n

Fi gur e 3. I t i s r ecommended t hat a wel d angl e of about 35 degr ees be

machi ned ont o t he pi pe ends.

Fur t her , i t i s r ecommended t hat bot h t he I D and OD be cl eaned t o br i ght ,

shi ny met al f or a di st ance of about 1" f r om t he wel d pr epar at i on edge and

t hat a l and be machi ned or gr ound per t he di mensi ons shown i n Fi gur e 3.

Af t er al l machi ni ng and gr i ndi ng oper at i ons ar e compl et ed, t hor ough cl eani ng

and degr easi ng of t he ent i r e ar ea i s r equi r ed.

I t shoul d be r ecogni zed t hat t he pi pe wi l l have some oval i t y whi ch can make

f or a mi smat ch i n t he I D dur i ng f i t - up and wel di ng ( see Fi gur e 3) , i t may be

necessar y t o count er - bor e t he I D of t he pi pe sect i ons i n or der t o obt ai n an

accept abl e mat ch ar ound t he i nsi de di amet er of t he pi pe.

2. Any of t he pur gi ng syst ems di scussed above, except t her mal l y di sposabl e

dams, ar e consi der ed accept abl e f or HASTELLOY al l oy pi pe syst ems. As a way

t o i nsur e t hat t he pur ge gas ent er s t he encl osed wel d zone wi t h a mi ni mum of

gas f l ow t ur bul ence, a gas di f f usi ng devi ce i s r ecommended. Fi gur e 4 shows

one possi bl e desi gn, f or use wi t h l ar ge di amet er pi pes, whi ch can be f abr i -

cat ed i n t he f i el d. Modi f i cat i ons t o such a gener al desi gn wi l l cer t ai nl y be

r equi r ed t o meet ot her speci f i c j ob r equi r ement s. The pur ge dams must be

i nst al l ed deep enough i n t he pi pe sect i on so t hat t he heat of wel di ng wi l l not

cause damage t o t he dams.

3. Fi t - up of t he pi pe sect i ons r equi r es car e so as t o est abl i sh pr oper r oot - gap

t ol er ance bet ween t he t wo pi pe sect i ons. I t i s gener al l y r ecommended t hat

t he r oot gap be at l east 1/ 32" l ar ger t han t he di amet er of wel di ng f i l l er wi r e

t o be used. Thi s wi l l al l ow f or mani pul at i on of t he f i l l er wi r e even when some

shr i nkage occur s dur i ng t ack wel di ng and cl osur e wel di ng.

4. Pur gi ng of t he wel d zone i s done at about 40 CFH. The wel d j oi nt shoul d be

seal ed ar ound t he ci r cumf er ence of t he pi pe except f or a smal l openi ng at

t he t op posi t i on of t he pi pe. The i nt ent i on i s t o have t he shi el di ng gas ent er

at t he bot t om of t he wel d zone and exi t at t he t op. I f pi pe wel di ng i s bei ng

per f or med i n t he ver t i cal ( 2G) posi t i on, t he gas shoul d ent er at t he bot t om

pur ge dam and exi t t hr ough a smal l hol e i n t he t op pur ge dam. Nor mal l y,

f l ow r at es and t i mes ar e sel ect ed so t hat a mi ni mum of 5 t o 6 shi el di ng gas

vol ume changes t ake pl ace pr i or t o wel di ng.

( 1)

4

5. Tack wel di ng i s necessar y t o ensur e t hat t he t wo pi pe sect i ons do not move

dur i ng subsequent cl osur e wel di ng. The t ack wel ds must be l ar ge enough and

pl aced of t en enough ar ound t he j oi nt ci r cumf er ence so t hat t he r oot gap r e-

mai ns open and wi der t han t he wel di ng f i l l er wi r e di amet er . Gener al l y, t he

wel d j oi nt i s kept seal ed except i n t he ar ea wer e wel di ng i s bei ng conduct ed.

I t i s r ecommended t hat t he t ack wel ds be gr ound t o a f eat her edge. Thi s wi l l

hel p ensur e t hat t he cl osur e wel ds wi l l t i e i nt o t he t ack wel ds and not l eave

smal l def ect s whi ch mi ght be det ect ed dur i ng r adi ogr aphi c exami nat i on.

The shi el di ng gas f l ow r at es used dur i ng t ack wel di ng, and dur i ng subsequent

cl osur e wel di ng, shoul d be about 40 CFH f or t he back pur ge and about 10

CFH f or t he wel di ng t or ch. Ot her wel di ng par amet er s ar e document ed i n

Tabl e 1.

Tor ch posi t i on and f i l l er wi r e posi t i on ar e cr i t i cal t o t he success of r oot - pass

wel di ng. A di agr am showi ng t he posi t i ons of t he GTAW t or ch body and wel d-

i ng f i l l er wi r e r el at i ve t o t he pi pe ar e shown i n Fi gur e 5.

( 1)

Tor ch and f i l l er wi r e mani pul at i on consi st of t or ch movement f r om si dewal l t o

si dewal l whi ch f or ms a " keyhol e" . Two dr ops of f i l l er mat er i al ar e mel t ed i nt o

each si dewal l wi t h each back and f or t h mot i on of t he wel di ng t or ch. The

f i l l er met al i s gener al l y posi t i oned i n t he r oot - gap openi ng. I f t he r oot gap

" cl oses- up" , not al l owi ng t he f i l l er wi r e t o be pl aced i n t he r oot - gap openi ng,

t he amount of wel d r ei nf or cement at t he r oot wi l l be l i mi t ed.

6. The cl osur e wel di ng i s per f or med much l i ke t he t ack wel di ng. Agai n, t he j oi nt

i s kept seal ed except i n t he ar ea wer e wel di ng i s bei ng per f or med. Dur i ng

t he l ast por t i on of t he cl osur e wel d, t he gas pur ge f l ow r at e may have t o be

l ower ed so t hat t he dams wi l l not be damaged due t o pur ge gas pr essur e

i ncr ease. I t i s gener al l y r ecommended t hat back pur ge gas be mai nt ai ned

f or t he f i r st t wo f i l l pass wel ds. Thi s wi l l hel p ensur e t hat t he r oot pass i s not

heavi l y oxi di zed dur i ng t hese subsequent wel d passes.

The sel ect i on of wel di ng pr ocess f or t he f i l l passes i s l ef t up t o t he di scr et i on

of t he f i el d wel di ng engi neer .

5

REFERENCES

1. " Recommended Pr act i ces f or Root Pass Wel di ng of Pi pe Wi t hout Backi ng" ,

ANSI / AWS D10. 11- 87, publ i shed by t he Amer i can Wel di ng Soci et y, Mi ami , FL

33135.

2. " Pur gi ng Pr act i ce f or Nucl ear Pi pe Wel di ng" , Er i c Hol by, Wel di ng Engi neer ,

Januar y, 1973.

3. " Power - pl ant pi pe must be l eak- f r ee" , Er i c R. Hol by, Wel di ng Desi gn &

Fabr i cat i on, Mar ch 1986.

4. " Recommended Pr act i ces f or Wel di ng Aust eni t i c Chr omi um- Ni ckel St ai nl ess

St eel Pi pi ng and Tubi ng" , AWS D10. 4- 79, publ i shed by t he Amer i can Wel di ng

Soci et y, Mi ami , FL 33135.

5. ASM Handbook Vol ume 6, Wel di ng and Br azi ng, 9t h Edi t i on, page 199,

publ i shed by ASM I nt er nat i onal , Met al s Par k, OH 44073

6. Fabr i cat i on of HASTELLOY Cor r osi on- Resi st ant Al l oys, H- 2010C, page 11,

publ i shed by Haynes I nt er nat i onal , I nc. , Kokomo, I N 46902

PARTI AL LI ST OF SUPPLI ERS

1. Di ssol vo Pr oduct s, Gi l br et h I nt er nat i onal Cor por at i on, 3300 St at e Road,

PO Box 779, Bensal em, PA 19020

2. Emer son Hal l enbeck Cone Pur ge Uni t Company, 2934 Shor el and Avenue,

Tol edo, OH 43611

3. Sl oan Pur ge Pr oduct s, I nc. , 3112 Ant oni no Avenue, Baker sf i el d, CA 93308

4. Saf et y Mai n St opper Co. , I nc. , PO Box 170287, Ti mes Pl aza St at i on, Br ookl yn,

NY 11217

HASTELLOY i s a r egi st er ed t r ademar k of Haynes I nt er nat i onal , I nc

6

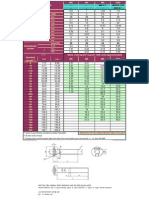

TABLE 1

SUGGESTED WELDI NG PARAMETERS

f or

Root - Pass Open- But t

Gas Tungst en Arc Wel di ng ( GTAW) of Pi pe

Joi nt desi gn: 70 degr ee i ncl uded angl e per Fi gur e 3

Base mat er i al : Var i ous HASTELLOY al l oys

Base mat er i al t hi ckness: up t o 1/ 2"

Fi l l er mat er i al : Var i ous HASTELLOY al l oy f i l l er mat er i al s

Fi l l er mat er i al di amet er : 3/ 32" ( 1/ 8" di amet er can be used wi t h

modi f i cat i on t o t he r oot gap di mensi on)

Pr eheat t emper at ur e: Room t emper at ur e

I nt er pass t emper at ur e: 200F maxi mum

Shi el di ng gas: 100% wel di ng gr ade ar gon

Fl ow r at e 10 CFH

Backi ng gas: 100% wel di ng gr ade ar gon

Fl ow r at e 40 CFH

El ect r i cal char act er i st i cs: DCSP ( el ect r ode - )

Amper age: 50 - 125 amps

Vol t age: 11 - 12 vol t s

Tr avel speed: 2 - 4 i nch per mi nut e

Wel di ng t echni que: Tor ch and f i l l er wi r e posi t i oni ng per Fi gur e 5

Feat her gr i nd al l st ar t s and st ops ( bot h t ack wel ds and

cl osur e wel ds)

Cl eani ng: St ai nl ess st eel wi r e br ush

7

Fi gure 3: Suggest ed Wel d Angl e Preparat i on and Fi t -up.

8

Fi gure 4: Exampl e of Di f f user Devi ce Capabl e of Bei ng

Manuf act ured i n t he Fi el d.

9

Fi gure 5: Suggest ed Wel di ng Torch and Fi l l er Wi re Pl acement .

10

www.haynesintl.com

For Referral to Authorized Distributors in your area

Fax: 1-765-456-6079

Printed in U.S.A.

B-2, B-3

, C-4, C-22

, C-276, C-2000

, D-205

, G-3, G-30

, G-50

, and N

Corrosion-Wear Resistant Alloy

ULTIMET

25, R-41, 75, HR-120

, HR-160

, 188, 214

, 230

, 230-W

, 242

, 263, 556

, 617, 625, 65SQ

, 718,

X-750, MULTIMET

, and Waspaloy

Wear-Resistant Alloy

Ti-3Al-2.5V

HASTELLOY Family of Heat-Resistant Alloys

HASTELLOY

Family of Corrosion-Resistant Alloys

S, W, and X

HAYNES

Family of Heat-Resistant Alloys

6B

HAYNES

Titanium Alloy Tubular

For More Information Contact:

Midwest Service Center

1020 W. Park Avenue

P.O. Box 9013

Kokomo, Indiana 46904-9013

Tel: 765-456-6012

800-354-0806

Fax: 765-456-6905

Southern Service Center

The Northwood Industrial Park

12241 FM 529

Houston, Texas 77041

Tel: 713-937-7597

800-231-4548

Fax: 713-937-4596

Tubular Products

3786 Second Street

Arcadia, Louisiana 71001-9701

Tel: 318-263-9571

800-648-8823

Fax: 318-263-8088

Italy

Haynes International,

S.R.L.

Viale Brianza, 8

20127 Milano

Italy

Tel: 39-2-2614-1331

Fax: 39-2-282-8273

Switzerland

Nickel Contor AG

Hohlstrasse 534

CH-8048 Zurich

Switzerland

Tel: 41-1-434-7080

Fax: 41-1-431-8787

Singapore

Haynes Pacific PTE LTD

15 McCallum Street

#05-03 Natwest Centre

Singapore 069045

Tel: 65-6-222-3213

Fax: 65-6-222-3280

England

Haynes International, Ltd.

P.O. Box 10

Parkhouse Street

Openshaw

Manchester, M11 2ER

Tel: 44-161-230-7777

Fax: 44-161-223-2412

France

Haynes International, S.A.R.L.

Boite Postale 303

95617 Cergy Pontoise

Cedex, France

Tel: 33-1-34-48-3100

Fax: 33-1-30-37-8022

Eastern Service Center

430 Hayden Station Road

Windsor, Connecticut

06095

Tel: 860-688-7771

800-426-1963

Fax: 860-688-5550

Western Service Center

Stadium Plaza

1520 South Sinclair Street

Anaheim, California 92806

Tel: 714-978-1775

800-531-0285

Fax: 714-978-1743

Properties Data:

The data and information in this publication are based

on work conducted principally by Haynes International, Inc.

and occasionally supplemented by information from the open

literature, and are believed to be reliable. However, Haynes

does not make any warranty or assume any legal liability or

responsibility for its accuracy, completeness, or usefulness,

nor does Haynes represent that its use would not infringe

upon private rights. Any suggestions as to uses and applica-

tions for specific alloys are opinions only and Haynes

International, Inc. makes no warranty of results to be obtained

in any particular situation. For specific concentrations of

elements present in a particular product and a discussion of

the potential health affects thereof, refer to the Material Safety

Data Sheet supplied by Haynes International, Inc.

Bar, Billet, Plate, Sheet, Strip, Coils, Seamless or Welded Pipe & Tubing, Pipe Fittings, Flanges,

Fittings, Welding Wire, and Coated Electrodes

Standard Forms:

STANDARD PRODUCTS

By Brand or Alloy Designation:

061902

North American Service Centers International Service Centers

(All trademarks are owned by Haynes International, Inc.)

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- SMAW PowerpointDocument28 paginiSMAW PowerpointShankar Gurusamy100% (3)

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Document1 paginăM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselÎncă nu există evaluări

- SKF Bearing Installation and MaintenanceDocument146 paginiSKF Bearing Installation and MaintenanceDefinal ChaniagoÎncă nu există evaluări

- Outokumpu Stainless Steel HandbookDocument92 paginiOutokumpu Stainless Steel HandbookcutefrenzyÎncă nu există evaluări

- Einschlaganker Drop in Anchor: Çakma DübelDocument16 paginiEinschlaganker Drop in Anchor: Çakma DübelSuphi YükselÎncă nu există evaluări

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Document108 paginiGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Suphi YükselÎncă nu există evaluări

- EN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadDocument1 paginăEN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadSuphi YükselÎncă nu există evaluări

- Fransız Elektrot Firması Seçim TablosuDocument60 paginiFransız Elektrot Firması Seçim TablosuSuphi Yüksel100% (2)

- Fiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Document1 paginăFiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Suphi YükselÎncă nu există evaluări

- DIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertDocument1 paginăDIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertSuphi YükselÎncă nu există evaluări

- Thread Size Chart for Metric Hex Nuts (M6 to M20Document1 paginăThread Size Chart for Metric Hex Nuts (M6 to M20Suphi YükselÎncă nu există evaluări

- DIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsDocument1 paginăDIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsSuphi YükselÎncă nu există evaluări

- DIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarDocument1 paginăDIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarSuphi YükselÎncă nu există evaluări

- 10512Document1 pagină10512Suphi YükselÎncă nu există evaluări

- DIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Document1 paginăDIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Suphi YükselÎncă nu există evaluări

- DIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Document1 paginăDIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Suphi YükselÎncă nu există evaluări

- P B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinDocument1 paginăP B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselÎncă nu există evaluări

- 34801Document1 pagină34801Suphi YükselÎncă nu există evaluări

- P (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeDocument1 paginăP (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeSuphi YükselÎncă nu există evaluări

- Solutions Guide: The Choice of Master CraftsmenDocument20 paginiSolutions Guide: The Choice of Master CraftsmenSuphi YükselÎncă nu există evaluări

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 paginăMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselÎncă nu există evaluări

- 1665Document1 pagină1665Suphi YükselÎncă nu există evaluări

- Thread Size Chart for Metric Bolts M5 to M16Document1 paginăThread Size Chart for Metric Bolts M5 to M16Suphi YükselÎncă nu există evaluări

- A Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Document1 paginăA Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Suphi YükselÎncă nu există evaluări

- Thread Size Dimensions Chart for M12, M16, M20 BoltsDocument1 paginăThread Size Dimensions Chart for M12, M16, M20 BoltsSuphi YükselÎncă nu există evaluări

- 6921Document1 pagină6921Suphi YükselÎncă nu există evaluări

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 paginăMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselÎncă nu există evaluări

- Mass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadDocument1 paginăMass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadSuphi YükselÎncă nu există evaluări

- Ref. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinDocument1 paginăRef. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinSuphi YükselÎncă nu există evaluări

- Storage Tanks Made of SteelDocument6 paginiStorage Tanks Made of SteelHakan Şahinoğlu100% (1)