Documente Academic

Documente Profesional

Documente Cultură

Battery Charging

Încărcat de

jprice23020 evaluări0% au considerat acest document util (0 voturi)

115 vizualizări10 paginiBattery Charging

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBattery Charging

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

115 vizualizări10 paginiBattery Charging

Încărcat de

jprice2302Battery Charging

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 10

The battery information contained in this publication is intended for a professional technicians.

Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Battery Charging

NOTE

Before charging a battery, read the Battery Safety Information under the Resources dropdown.

Batteries in good condition, but somewhat discharged, may not provide enough energy to crank the engine.

These batteries may need to be charged. Fully charged batteries are a must to insure accurate results when you

are troubleshooting problems in the starting system or the charging system. You need to know how to properly

charge batteries to conduct such tests. Fully charged batteries are also required to meet fleet service needs. In

such cases, group charging with either a series a parallel charger saves time and insures a ready supply of

good batteries.

Generally, a fully charged battery will have an open circuit voltage of at least 12.6 volts, while a discharged

battery will have an open circuit voltage of 12.0 volts or less. More specifically, discharged maintenance-free

batteries will show a dark eye (if so equipped), while discharged filler cap batteries will have average

hydrometer readings below 1.230.

To effectively diagnose and repair problems on electrical systems, you will need to know about:

Charging maintenance-free batteries

Charging filler cap batteries

Charging AGM batteries

Group charging with series chargers

Group charging with parallel chargers.

Factors Affecting Charging

Whether you are charging maintenance-free batteries or filler cap batteries, the charging rate will be affected by:

Battery Size or Capacity - A discharged 110 minute reserve capacity rated battery needs more charging

time than a discharged 80 minute reserve capacity rated battery.

Electrolyte Temperature - A cold battery takes longer to charge than a warm battery; about two hours longer

at 0F than at 80F. The initial charging current will be low, then increase as the battery warms. Never

attempt to charge a frozen battery.

State-of-Charge - A completely discharged battery needs twice the amp hours as a half-charged battery to

become fully charged. The initial charging current will be low; the electrolyte is mostly water. The current will

increase as the electrolyte acid content increases.

Battery Age and Condition - An older battery in severe service will need up to 50% more amp hours of

charging than a newer battery.

Charger Capacity - A charger that can supply only 5 amps will take much longer than one that supplies 30

amps.

Charging ACDelco Filler Cap Batteries

A dry-charge battery has charged plates but contains no electrolyte. These batteries can be stored for long periods but

must be filled and charged prior to service.

A wet-charge battery has charged plates and is filled with electrolyte. These batteries lose their charge in storage and

must be periodically recharged.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

NOTE

Leave dry-charge batteries in their original shipping cartons; store at 60F or higher. Periodic recharging is needed on

wet-charge batteries, especially when storage is above 60F. Store these in cool areas.

The state of charge on filler cap batteries must be checked by measuring the strength of the electrolyte. Specific

gravity (exact weight) of the electrolyte provides a measure of its strength. Pure water is lighter than the correct

mixture of acid and water. A hydrometer is used to measure the specific gravity of the electrolyte in each battery cell.

These readings, adjusted for the temperature of the electrolyte, are used to determine the batterys state of charge.

CAUTION

All lead-acid batteries generate hydrogen gas, which is highly explosive. If ignited by a flame or spark, the

gas may explode violently. When working near batteries, always wear safety glasses, remove watches or

jewelry, and avoid causing sparks with tools. If splashed with acid, immediately flush area with water and

seek medical attention.

Charging Procedure

Service bulletins are available for specific battery charging procedures. Fast charging is only recommended if

using a smart charger, which provides constant voltage/variable current. Other fast charging methods may

shorten battery life. General guidelines for charging ACDelco filler cap batteries are given here.

NOTE

During charging, leave flame arrester vent caps in place. Remove sealed caps and place a cloth over the vent

holes to allow gassing.

1. When charging or testing sealed-terminal (nonpost type) batteries, use terminal adapters (ST-1201)

when the batteries are removed from the vehicle. Connect charger clamps to battery studs/nuts when

the batteries are in vehicle.

2. The battery terminal voltage does not exceed 15 volts, the electrolyte doesnt spew from the vent holes,

or the battery does not feel excessively hot (>125F). The charging current may need to be reduced or

temporarily stopped to prevent damage to the battery.

3. The battery is fully charged when, after two hours of charging at a low rate, all cells are gassing freely

and no change in the electrolytes specific gravity is noted. Specific gravity should be at least 1.230.

Batteries may function, even with specific gravity below 1.230

Emergency boost charging must be followed by full charging

4. Battery charging requires a charge current (in amperes) for a period of time (in hours).

5. The time required for a proper charge will vary according to:

Battery size or capacity

Electrolyte temperature

State of charge

Battery age or condition

Charger capacity.

NOTE

After charging has been completed, add water to adjust the electrolyte level in each cell to the bottom of the split ring.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Charging ACDelco Maintenance-Free Batteries

The Adapter Kit (ST-1201) is available from ACDelco. It is recommended that this adapter kit, or equivalent, be used

in charging sealed-terminal batteries when they are out of the vehicle.

When the sealed-terminal battery is in the vehicle, connect the chargers leads to the studs/nuts at the batterys

terminals. Post-type batteries need no adapters.

The following basic rules apply to most ACDelco battery charging situations:

1. Charge rates between 3 and 50 amperes are generally satisfactory for any Maintenance-Free Battery as long

as spewing of electrolyte does not occur or the battery does not feel excessively hot (>125F [>52C]). If

spewing occurs or temperature exceeds 125F, the charging rate must be temporarily halted to permit

cooling.

Battery temperature can be estimated by touching or feeling the battery case.

If equipped with a hydrometer, the battery is sufficiently charged when the green dot in the built-in hydrometer

is visible. No further charging is required. Shake or tilt the battery at hourly intervals during charging to mix

the electrolyte and see if the green dot appears.

If the battery is not equipped with a hydrometer, use an automatic taper-rate (decreasing current) charger.

Charge the battery in a well-ventilated area. Wear protective eyewear and clothing, and keep sparks and

flames away from charging batteries. Charge the battery until the charger operation indicates the battery is

fully charged (refer to charger manufacturers instructions).

The time required for a charge will vary because:

Size of Battery - A completely discharged large heavy-duty battery requires more than twice the recharging as a

completely discharged small passenger car battery.

Temperature - A longer time will be needed to charge any battery at 0F than at 80F. When a fast charger is

connected to a cold battery, the current accepted by the battery will be very low at first, then in time, the battery will

accept a higher rate as the battery warms.

State-of-Charge - A completely discharged battery requires more than twice as much charge as an onehalf-charged

battery. Because the electrolyte is nearly pure water and a poor conductor in a completely discharged battery, the

current accepted is very low at first. Later, as the charging current causes the electrolyte acid content to increase, the

charging current will likewise increase.

Charger Capacity - A charger which can supply only 5 amperes will require a much longer period of charging than a

charger that can supply 30 amperes or more.

Water never needs to be added to maintenance-free batteries. The battery cover is sealed and has no filler caps.

Small vent holes allow any gases produced to escape. Special battery plates minimize gassing at normal charging

currents and also limit the possibly of overcharge damage.

NOTE

Do not tilt a maintenance-free battery beyond a 45 angle in any direction. This would allow electrolyte to leak from the

vent holes.

CAUTION

All lead acid batteries generate hydrogen gas which is highly explosive. If ignited by a flame or spark, the gas may

explode violently. When working near batteries, always wear safety glasses, remove watches or jewelry, and avoid

causing sparks with tools. If splashed with acid, immediately flush skin or eyes with water and seek medical attention.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Charging AGM Batteries

The ACDelco AGM Battery may be charged by most commercially available battery chargers if the charging process

is properly monitored. The guideline is to charge the battery as fast as possible, but to avoid causing its built-in valve

to open and allow too much of the internal gases to escape.

Good Practices

Use a modern, taper-rate charger to charge the AGM Battery. These chargers are sometimes referred to as

automatic, and feature a decreasing current as the battery approaches full charge. When the charger operation

indicates that the battery is fully charged (refer to charger manufacturers instructions), remove the battery from

charge. Laboratory tests have shown that AGM batteries respond very well to such chargers.

To charge the battery:

1. Use an automatic taper-rate (decreasing current) charger. Charge the battery in a well-ventilated area. Wear

protective eyewear and clothing, and keep sparks and flames away from charging batteries.

2. When charging the battery in the vehicle, be sure the ignition switch is turned to OFF. This will help prevent

accidental damage to vehicle components and avoid current drains that would prevent efficient battery

charging.

3. Be sure a good connection is available to the battery terminals. If the battery is being charged in the vehicle

with the battery cables still attached, clean away any dirt or corrosion from the connecting surfaces.

When the battery is being charged out of the vehicle or without the battery cables attached, side terminal

batteries must have suitable adapters installed in the terminals, such as ACDelco catalog no. ST-1201. Wire

brush the terminal face and the contact area of the adapter before installing the adapter. Never use bolts or

combinations of bolts, nuts, and washers as adapters since they may introduce resistances into the charging

circuit and cause slower or incomplete recharge. Also, use of other commercially available side terminal

adapters should be limited to those adapters that directly contact the current-carrying face of the terminal.

4. Be sure the charger is turned OFF or disconnected from the power source.

5. Connect the positive charger cable to the battery positive terminal, then the negative charger cable to the

negative battery terminal.

6. Turn the charger ON, or connect it to the power source.

7. Charge the battery until the charger operation indicates the battery is fully charged (refer to charger

manufacturers instructions).

8. Turn OFF the charger or disconnect its power source.

9. Disconnect the charger cable from the negative battery terminal, and then disconnect the charger cable form

the positive battery terminal.

Using Other Charging Methods

Some older charging equipment may not offer the automatic, self-limiting features available on more recent chargers.

However, AGM batteries can be successfully charged with such equipment by proper monitoring.

If a constant-current charger must be used, either directly or in a series hookup, it is recommended that the charge

rate be limited to 10 amperes or less.

Do not allow the battery to be constantly charged at 3 amperes for more than 10 hours, or at 10 amperes for

more than 5 hours. When these time limits have been reached, stop the charge and allow the battery to rest

overnight. Resume the charge the next day.

The charging voltage will increase as the battery nears full charge. Check the charging voltage across the

individual batterys terminals every 30 minutes, and remove the battery from charge when the voltage

reaches 15 volts. When the charging voltage across a battery reaches 15 volts at a constant current rate of 3

to 10 amperes, the battery state of charge will be at 90 to 95%.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

If parallel charging must be used, monitor the charging voltage.

When the voltage reaches 15 volts, maintain the voltage at 15 volts and monitor the current flow into each

battery every 30 minutes.

The current flow will decrease as the battery nears full charge. When the current into an individual battery

falls below 10 amperes at 15 volts, the battery will be at a 90% state of charge or more and charging of that

battery should be stopped.

The features of automatic, self-adjusting chargers may result in conditions which at times appear to exceed the above

recommendations. Following these guidelines when using older equipment will prevent situations that could

inadvertently shorten the battery life.

Charging Voyager Deep Cycle Marine/RV Battery

The ACDelco Voyager Marine/RV Battery is a deep cycle battery that will give hours of electrical power in recreational

vehicle and boating applications. The battery is an energy storage reservoir. When energy is removed from the battery

it must be put back by recharging. The amount of energy to be put back depends on how much was taken out. The

time it will take depends on the ampere output of the charger used.

The typical ACDelco Voyager Battery may have a built-in state-of-charge indicator to show how much energy is left in

the battery. A green or red colored ball may be visible in the indicator, or no ball may be visible causing the indicator

to appear dark. The indicator is also used to determine how long the battery should be recharged as follows.

Important points for good battery performance and life:

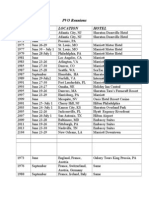

Figure 4-22, Battery Recharge Table

1. Recharge battery after each use.

2. Use a taper-type charger. For best results, a 10-15 amp taper-type charger is recommended to recharge

ACDelco Voyager models. Taper chargers help avoid overcharge by reducing the charge rate as the battery

nears full charge. Follow instructions provided with the charger.

3. Determine the charging time that will be required. Check the built-in indicator and charge the battery for at

least the number of hours shown in Figure 4-19. If the green ball is not visible in the indicator after charging,

tap lightly on top to dislodge trapped air bubbles that might keep the ball from floating into view. If the green

ball is still not visible, continue charging until it appears.

NOTE

A more definite charging time can be set if an accurate voltmeter is available for reading open circuit voltage.

4. Do not leave the battery connected to a battery charger after the battery is fully charged.

5. Batteries charge more efficiently at 60 to 80F.

6. Keep battery in a cool place when storing for long periods (make sure battery is fully chargeda discharged

batterys electrolyte can freeze).

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Multi-Battery Charging

Two different types of charges can be used for group charging batteries:

Current-Limiting (constant current or series chargers)

Voltage-Limiting (constant voltage or parallel chargers).

With series chargers, the batteries are connected so that each battery receives the same amount of charging current.

With parallel chargers, the batteries are connected so that the charging current is divided and each battery receives

only the charging current it can accept at the chargers voltage. As such, the charging procedures are different.

No matter which type of charger is used, the procedures outlined here must be closely followed to prevent under-

charging or overcharging and battery damage on the charging rack. Be aware that the batteries may vary in age,

capacity or size, state of charge, and type.

NOTE

The recommended group charging procedures are for batteries with electrolyte and plates at normal room

temperatures (55F to 85F). Extremely cold batteries will accept very little charging current and must be warmed

before charging.

Group Charging with Series Chargers

Series charging is not recommended. If series charging is used, monitor batteries hourly for spewing, gassing, and

case temperature above 125F or charging voltage above 16 volts. If this occurs, remove batteries and load test. A

four-step process can be followed, using a series or current-limiting charger. Differences in group charging

maintenance-free batteries and filler cap batteries are noted:

1. Visually inspect all batteries for cracked covers or cases. Replace damaged batteries.

Maintenance-Free Batteries: If so equipped, check the built-in hydrometer. If the color is green, the

battery should not be charged and can be load tested. If the eye is dark, proceed with charging. If the eye

is clear or yellow, the battery must be replaced.

If the batteries are not equipped with a hydrometer, use an automatic taper-rate (decreasing current)

charger. Charge the batteries in a well-ventilated area. Wear protective eyewear and clothing, and keep

sparks and flames away from charging batteries. Charge the batteries until the charger operation

indicates the batteries are fully charged (refer to charger manufacturers instructions).

Filler Cap Batteries: Check each cell with a hydrometer. If the reading is 1.230 or more, the battery

should not be charged and can be load tested. If the reading is below 1.230, continue with the charging

procedure. If the electrolyte level is low, add just enough water for taking readings and then proceed with

charging, if needed. After charging, fill each cell to the split ring.

2. Connect batteries to charger, as shown in Figure 4-20. Do not exceed the chargers voltage capabilities by

connecting too many batteries. Make sure all connections are clean and tight. Set the charging rate within a 5

to 10-amp range and maintain this charging rate throughout the procedure.

3. After two or three hours of charging, check the batteries:

Maintenance-Free Batteries: If so equipped, regularly check the hydrometer for a green dot. Shake

or tilt batteries at hourly intervals to see if green dot stays visible. Also, check the battery terminal

voltage with a voltmeter. During charging (both hydrometer and non-hydrometer), if the voltage is 16

volts (or more), remove the battery for load testing. After removal, adjust the charger control to

maintain the previously set charging rate.

Filler Cap Batteries: Take hydrometer readings at hourly intervals. Correct readings to 80F (27C).

Remove any battery from being charged when there is no increase in specific gravity after three

successive hourly readings. Any battery that gets too hot (>125F), or gases excessively, should be

removed for load testing. After removing any battery, adjust the charger control to maintain the

previously set charging rate.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

4. After charging, all batteries should be load tested; that procedure is described earlier in this section and

also in Service Bulletin 1B-115 (for filler cap batteries) and in Service Bulletin 1B-116 (for maintenance-

free batteries). Remove surface charge, if necessary; that procedure is also described earlier in this

chapter.

Figure 4-23, Series Charging

Group Charging with Parallel Chargers

A four-step process can be followed, using a parallel or voltage-limiting charger. Differences in charging maintenance-

free batteries and filler cap batteries are noted:

1. Visually inspect all batteries for cracked covers or cases. Replace damaged batteries.

Maintenance-Free Batteries: Check the built-in hydrometer. If the color is green, the battery should not be

charged and can be load tested. If the eye is dark, proceed with charging. If the eye is clear or yellow, the

battery must be replaced.

If the batteries are not equipped with a hydrometer, use an automatic taper-rate (decreasing current)

charger. Charge the batteries in a well-ventilated area. Wear protective eyewear and clothing, and keep

sparks and flames away from charging batteries. Charge the batteries until the charger operation

indicates the batteries are fully charged (refer to charger manufacturers instructions).

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Filler Cap Batteries: Check each cell with a hydrometer. If the reading is 1.230 or more, the battery

should not be charged and can be load tested. If the reading is below 1.230, continue with the charging

procedure. If the electrolyte level is low, add just enough water for taking readings and then proceed with

charging, if needed. After charging, fill each cell to the split ring.

2. Connect batteries and voltmeter to charger, as shown in Figure 4-21. Make sure all connections are clean

and tight. Set the charging voltage to 15 volts or less for filler cap and AGM batteries and 16 volts or less for

maintenance-free batteries. The charger may not reach this initially, but as the batteries become charged and

accept less current, the voltage will rise. The ammeter on the charger will indicate the total current flow to the

batteries. But the current divides, so the ammeter reading is not a measure of each batterys charging

current. Do not exceed the chargers voltage capabilities by connecting too many batteries, always follow the

chargers instructions.

3. After two or three hours of charging, check the batteries:

Maintenance-Free Batteries: If so equipped, regularly check the eye for a green dot. Stop charging

when the eye stays green. Any battery that gets too hot (>125F), or gases excessively, should be

removed from the charger and tested. Continue charging the remaining batteries, since they received

little charging current. As batteries are removed, make sure you adjust the charging voltage to 16

volts or less on the remaining batteries (both hydrometer and non-hydrometer).

Filler Cap Batteries: Take hydrometer readings at hourly intervals. Correct readings to 80F (27C).

Remove any battery from being charged when there is no increase in specific gravity after three

successive hourly readings. Any battery that gets too hot (>125F), or gases excessively, should be

removed for load testing. Most of the charging current was likely going to that battery, with the

remaining batteries receiving little, so continue charging the other batteries.

4. After charging, all batteries should be load tested; that procedure is described earlier in this section and also

in Service Bulletin 1B-115 (for filler cap batteries) and in Service Bulletin 1B-116 (for maintenance-free

batteries). Remove surface charge, if necessary; that procedure is also described earlier in this chapter.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Alternate Method for Determining Charge Time

If an accurate voltmeter is available, the required time for charging can be determined more closely. Depending on

actual battery state-of-charge, this may be more or less than the minimum time determined from the built-in indicator.

IMPORTANT

Do not measure open circuit voltage right after recharging the battery. Surface charge may cause a false higher voltage

reading. Measure only after battery has been standing with no electrical loads for 24 hours or more.

Determine the hours of charging that will be required. Use an accurate voltmeter to measure the open circuit voltage,

then use Figure 4-22 to determine how long to charge the battery.

Example: If the open circuit voltage is 12.1 volts, find 12.1 volts on the left side of the chart. If a taper charger rated at

10 amps is used, go horizontally across the chart until the line for the 10 amp charger is reached (follow dotted line).

From this point, read the required hours of charge directly below on the bottom line (17 hours).

The battery will be fully charged at the end of the time shown in Figure 4-22. The green ball should be visible in the

built-in indicator. If not, tap the indicator lightly on top to dislodge any trapped air bubbles that might keep the ball from

floating into view.

The battery information contained in this publication is intended for a professional technicians. Please do no attempt any of the maintenance/repair

procedures if you are not licensed or appropriately trained. Do not distribute or share the digital or printed material, including pdf versions of the

content. Also, do not provide a link to this material to another website or email address. This material may be protected under copyright and

trademark laws.

Figure 4-25, Hours of Charge

Charging Voltage and Charging Rates

Similarly, Figure 3-7 shows the charging voltages and charging rates for warm and cold batteries. The curves shown

assume generator output is sufficient to provide the voltage and current required.

For a fully charged battery, the charging rate should be reasonably low to protect the battery from overcharging and

overheating. This low charging rate does indeed occur at the regulator limit when the battery is cold (see Figure 3-7).

However, when the battery is hot, the charging rate is significantly higher. This occurs because battery resistance

decreases at high temperatures which increases charging current flow.

While the high rate of charge on a fully charged battery is generally undesirable, no damage occurs as long as the

condition is not present for long periods of time. Applying a high rate of charge to a partially charged battery is

desirable because the battery should be recharged to full capacity in the shortest amount of time.

Because temperature does have such a dramatic effect on battery operation, some charging systems designed for

extreme hot or cold are equipped with regulators that automatically adjust voltage settings with the temperature. The

regulator allows a higher voltage setting during cold weather and a lower voltage setting during hot weather.

Figure 3-7, Charging Rates for Hot and Cold Batteries

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Dec2013 Zip 9776475 TD Technical+Specifications+of+11KV+3000KVA+Diesel+Power+Generator+SetDocument30 paginiDec2013 Zip 9776475 TD Technical+Specifications+of+11KV+3000KVA+Diesel+Power+Generator+SetBalamurugan ArumugamÎncă nu există evaluări

- Mitsubishi S16R PTADocument67 paginiMitsubishi S16R PTABrizmotors100% (13)

- Commissioning Manual (Rev 4, 10-6-06) Tp60Document321 paginiCommissioning Manual (Rev 4, 10-6-06) Tp60Ismar Adrian100% (4)

- Honda Monkey z50j Workshop ManualDocument276 paginiHonda Monkey z50j Workshop ManualKeith Romanowski100% (3)

- Audi Q7 Elec SysDocument60 paginiAudi Q7 Elec SysJazon Alves100% (8)

- IGCSE Physics Revision NotesDocument34 paginiIGCSE Physics Revision NotesCoolman Poon88% (17)

- 1104d-E44ta sbl@96.5kw (Tpd1575e1)Document10 pagini1104d-E44ta sbl@96.5kw (Tpd1575e1)pricopdaniel50% (2)

- Cathodic ProtectionDocument40 paginiCathodic Protectionjadav parixeet100% (1)

- Pergolizzi PDFDocument22 paginiPergolizzi PDFaftetÎncă nu există evaluări

- License Plate ScrewsDocument1 paginăLicense Plate Screwsjprice2302Încă nu există evaluări

- June/July 2014 Bulk SpecialsDocument1 paginăJune/July 2014 Bulk Specialsjprice2302Încă nu există evaluări

- June 2014 Tool SpecialsDocument1 paginăJune 2014 Tool Specialsjprice2302Încă nu există evaluări

- June 2014 Tool SpecialsDocument1 paginăJune 2014 Tool Specialsjprice2302Încă nu există evaluări

- June 2014 Tool SpecialsDocument1 paginăJune 2014 Tool Specialsjprice2302Încă nu există evaluări

- Battery TestingDocument8 paginiBattery Testingjprice2302Încă nu există evaluări

- June 2014 Tool SpecialsDocument1 paginăJune 2014 Tool Specialsjprice2302Încă nu există evaluări

- June 2014 Tool SpecialsDocument1 paginăJune 2014 Tool Specialsjprice2302Încă nu există evaluări

- PVO Reunions HeldDocument2 paginiPVO Reunions Heldjprice2302Încă nu există evaluări

- Charging AGM BatteriesDocument1 paginăCharging AGM Batteriesjprice2302Încă nu există evaluări

- Summer Freon PricingDocument1 paginăSummer Freon Pricingjprice2302Încă nu există evaluări

- PVO Reunions HeldDocument2 paginiPVO Reunions Heldjprice2302Încă nu există evaluări

- Jerrica ProfileDocument3 paginiJerrica Profilejprice2302Încă nu există evaluări

- Board MembersDocument1 paginăBoard Membersjprice2302Încă nu există evaluări

- Contact InformationDocument1 paginăContact Informationjprice2302Încă nu există evaluări

- 5-14 Miller Spring Event FlyerDocument2 pagini5-14 Miller Spring Event Flyerjprice2302Încă nu există evaluări

- Cse PDFDocument233 paginiCse PDFyavuzkeles1982Încă nu există evaluări

- Super Capacitor BatteryDocument2 paginiSuper Capacitor Batterybuditux100% (1)

- Manuale NanoVIP3 Rel. 1.5 en (UK)Document76 paginiManuale NanoVIP3 Rel. 1.5 en (UK)ECÎncă nu există evaluări

- Nikon Eclipse 50i-55i-Instruction-Manual - M317E 03.12.CF.1Document85 paginiNikon Eclipse 50i-55i-Instruction-Manual - M317E 03.12.CF.1luroguita-1Încă nu există evaluări

- Katalog EneloopDocument16 paginiKatalog Eneloopdemo1967Încă nu există evaluări

- SK600III Instruction ManualDocument30 paginiSK600III Instruction ManualrinconcesarÎncă nu există evaluări

- Sweepers CatalogDocument56 paginiSweepers CatalogNewVersion_FacilityManagementÎncă nu există evaluări

- Presario 1825Document155 paginiPresario 1825Douglas LaingÎncă nu există evaluări

- INSTRUCTION MANUAL FOR MODEL ASSEMBLYDocument34 paginiINSTRUCTION MANUAL FOR MODEL ASSEMBLYcaller10023Încă nu există evaluări

- Ventilator Mindray Syno Vent E3Document2 paginiVentilator Mindray Syno Vent E3erika100% (1)

- Cygnus 2 Manual V617ADocument32 paginiCygnus 2 Manual V617AGleison PrateadoÎncă nu există evaluări

- Fm/Am Compact Disc Player: CDX-GT330 CDX-GT230 CDX-GT33W CDX-GT130Document56 paginiFm/Am Compact Disc Player: CDX-GT330 CDX-GT230 CDX-GT33W CDX-GT130mttw010Încă nu există evaluări

- Owner's Manual: Digital CameraDocument164 paginiOwner's Manual: Digital CameraalelendoÎncă nu există evaluări

- The Forever Rechargeable VARIABLE Super Capacitor Battery !!!Document17 paginiThe Forever Rechargeable VARIABLE Super Capacitor Battery !!!Praveen240679Încă nu există evaluări

- Canada's Renewable Energy Storage LeaderDocument15 paginiCanada's Renewable Energy Storage LeadermukundÎncă nu există evaluări

- Gd555-3a Pen00178-01 OpmDocument269 paginiGd555-3a Pen00178-01 OpmRaul E. Soli100% (4)

- Building The Solid-State Battery FactoryDocument19 paginiBuilding The Solid-State Battery FactoryDesign TeamÎncă nu există evaluări

- Internal Resistance ExplainedDocument7 paginiInternal Resistance ExplainedDyna MoÎncă nu există evaluări

- Om Vib 101Document2 paginiOm Vib 101danvicÎncă nu există evaluări

- Service Manual of MS9V-0912HRDN1-QC2 PDFDocument0 paginiService Manual of MS9V-0912HRDN1-QC2 PDFFerenc SchmidtÎncă nu există evaluări

- GoalZero YETI 400 SOLAR GENERATOR User GuideDocument2 paginiGoalZero YETI 400 SOLAR GENERATOR User GuideSteven AlmerothÎncă nu există evaluări