Documente Academic

Documente Profesional

Documente Cultură

Pipe Thickness Calculation

Încărcat de

Lokman HakimDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Thickness Calculation

Încărcat de

Lokman HakimDrepturi de autor:

Formate disponibile

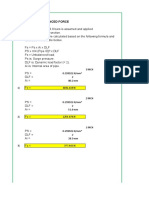

Job No. Sheet No. 1 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

Design Parameter :-

DESIGN DISCHARGE, Qd =

GROSS HEAD, hg =

GRAVITY, g =

WATER DENSITY, = kg/m

PIPELINE LENGTH, Lp =

PIPELINE INTERNAL DIAMETER, D =

PIPE FLOW AREA, Af =

FLOW VELOCITY, Va =

PARAMETER ko ( Coal-tar coated), k0 =

Calculating the losses from the water intake and along the pipe/penstock length.

FRICTION COEFFICIENT,

= x ^

= x ^ =

m

m/s

0.010 k0 0.314

1.800

7257.000

9.810

m/s

m

m

m

m/s

1.500

2.593

2.545

6.600

237.000

D

0.010 1.500 0.314 0.009

1000

Penstock Design

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

Bob

= x ^ =

Losses In Penstock Line

Head Loss @ Trash Rack,htr

Assume Approach Velocity, V =

Thickness of bar, s =

Spacing of bars, b =

Angle of inclination from horizontal, =

Oblique flow angle, =

Coefficient (Table I/23) =

Factor Bar Section, =

Trash Rack Losses, htr

= s ^ V sin

b 2g

= ^ sin = m

0.010 1.500 0.314 0.009

3.600

2.420

1.800

3.000

8.000

50.000

m/s

(4/3)

180

deg

deg

mm

mm

60.000

30.000

2.420 8.00

50.00

3.000

2(9.81)

0.084 60

180

(4/3)

Job No. Sheet No. 2 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

Head Loss @ Fine Screen, hf

Sreen Size 6 x 50 @25 mm c/c

Water Flow, Q =

Thickness of bar, s =

Spacing of bars, b =

Width of Opening =

No. of Bar =

Length of Opening =

Height of Opening =

Effective Length =

Velocity, V =

Angle of inclination from horizontal, =

Oblique flow angle, =

Coefficient (Table I/23) =

Factor Bar Section, =

Fine Screen Losses, hf

Bob

6.000

6.600

2.420

1.000

0.000

90.000

no.

Penstock Design

19.000

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

deg

0.101

13.038

5.000

7.519

m

m

m

mm

mm

m/s

396

7.500

deg

m/s

m

= s ^ V sin

b 2g

= ^ sin = m

Head Loss @ Bifurcation,hbf

Discharge Ratio =

Qm/Qb Ratio =

Acute 30 deg. Angle

Loss Coefficient, m (Table I/93)

=

Loss Coefficient, b (Table I/93) =

Bifurcation Losses, hbf

= Va + Va

2g 2g

= + = m

2 x 2 x

Head Loss @ Reducer, hr

Losses Coefficient, =

= Va = = m

(4/3)

0.000 2.593

0.000

180

2.420 6.00 (4/3) 0.101 90

2(9.81) 180 19.00

0.44

0

1

0.5

m b

0.151

0.050

0.440 2.593

9.810 9.810

0.017 2.593 0.050

2g 2 x 9.810

Job No. Sheet No. 3 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

Head Loss @ Valve

No. of Air valve =

No. of Scour valve =

Losses Coefficient, Kv (Butterfly) =

Total Losses Coefficient =

= Va = = m

2g 2 x

Head Loss @ Entrance

Losses Coefficient, =

= Va = = m

2g 2 x

Head Loss Along Penstock Line

0.500 2.593

9.810

Penstock Design

0.600

7.200 2.593 2.468

0.171

Bob

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

6.000

6.000

9.810

0.500

7.200

= Lp x Va

D 2g

= x = m

2 x

Head Loss In Bend (Horizontal and Vertical)

Total Losses Coefficient, b

=

= Va = = m

2g 2 x

Total Head Loss

a) TRASH RACK m

b) FINE SCREEN m

c) ENTRANCE LOSS TO PENSTOCK m

d) PENSTOCK FRICTION HEAD LOSSES m

e) BEND LOSSES IN PENSTOCK (HORIZONTAL & VERTICAL) m

f) HEAD LOSS TO BIFURCATION m

g) HEAD LOSS AT REDUCER m

h) HEAD LOSS AT VALVES m

TOTAL HEAD LOSS (a+b+c+d+e+f+g+h) m

NET HEAD = GROSS HEAD - TOTAL HEAD LOSS

=

=

0.171

0.000

0.084

=

=

=

=

=

=

=

17.546

2.468

0.017

0.151

1.604

13.051

1.800

b

4.680 2.593 1.604

9.810

9.810

13.051

0.009 2.593 7257

4.680

NET HEAD = GROSS HEAD - TOTAL HEAD LOSS

= - = m 237.000 17.546 219.454

Job No. Sheet No. 4 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

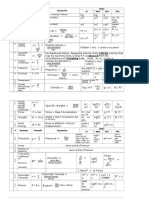

Preliminary Thickness

Assuming the percentage (%) of increase in net head due surge pressure = %

Surge pressure = x = m

Total pressure head = Static pressure head + Surge pressure

= + = m

Nominal thickness ( CP 2010 : Part 2 : 1970 : 2.2.2.2)

t = + corrosion allowance

where ; a = design factor ( CP 2010 : Part 2 : 1970 : 2.2.2.3)

D = outside diameter, in (mm)

E = joint factor given in ( CP 2010 : Part 2 : 1970 : Table 5)

fy = specified minimum yield stress, in (MN/m)

p = internal design pressure, in (MN/m)

Bob

21.945 258.945

p D

Penstock Design

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

2 a fy e

237.00

10

219.454 0.100 21.945

t = design thickness, in (mm)

Internal design pressure, P = g H

= x x

= MN/m

t = x + = mm

2 x x x 1

take penstock wall thickness as mm thick.

Checking Surge Pressure Created Using 20mm Thickness

Calculating the thickness for the most critical section of length in the penstock

The pressure wave speed c (m/s) depends on the elasticity of the water and pipe material

according to the formula:

where

k = bulk modulus of water 2.1x10^9 N/m2

E = modulus of elasticity of pipe material 210x10^9 N/m2

t = wall thickness (mm)

20.0

0.6 275

2.54 1800

258.945

2.54

1000.000 9.810

14.856 1.00

t = wall thickness (mm)

Job No. Sheet No. 5 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

The time taken for the pressure wave to reach the valve on its return, after sudden closure

is known as the critical time:

T= 2L/c

Summarising the data,

Gross Head: m

Rated Discharge: m

Internal Pipe Diameter: m

Total Pipe Length: m

Closure Time: s

Estimating in a first approach at 20 mm wall thickness to compute the wave speed c :

c = /

1 + x

x

= m/s

Penstock Design Bob

1.800

7257.000

20

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

237.000

6.600

90

1051.315

2.1E+09 1000

2.1E+09 1800

2.1E+11

Critical time, T = 2L/c

= 2 x = s

10T = 10 x

= s

The closure time (90s) is bigger than the critical time s but smaller than 10 times its

value s, the Allievi formula can be applied.

Allievi formula may compute the maximum overpressure:

where P0 is the hydrostatic pressure due to the head and:

where:

V0 = water velocity in m/s

L = total penstock length (m)

P0 = gross hydrostatic pressure (m)

t = closing time (s)

The total pressure experienced by the penstock is P = P0 + P

The water velocity in the pipe is:

V = 4 x 6.6 = m/s 2.593

7257.000

1051.31

13.806

13.806

138.056

13.81

138.1

V = 4 x 6.6 = m/s

x 1.8

2.593

Job No. Sheet No. 6 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

N would be computed from a net head in the pipe of = m

N = x =

x x

and therefore;

p = +

= m; m

Total pressure head = m

Check back the wall thickness of penstock by using new head pressure, h = m

Internal design pressure, P = g H

Penstock Design

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

0.009

Bob

9.810 219.454 90

2.593 7257

219.454

0.009

22.376 -20.306

219.454 0.009

2

0.009

4

259.376

259.376

= x x

= MN/m

t = x + = mm

2 x x x 1

the penstock wall thickness of mm thick is sufficient for this design.

Checking Max. Head Pressure For Difference Penstock Wall Thickness

Using earlier formulation to find nominal thickness

t = + 1mm (corrosion allowance) -------------- 1

t = + 1 -------------- 2

H = -------------- 3

Using 8mm penstock wall thickness + 1mm corrosion allowance

H = 2 x ( 8 - 1 ) x x E+ 6 x 1

x x 1816

0.75 275

2 (t -1)a fy e

g D

1000

p D

2 a fy e

g H D

2 a fy e

2.54

2.54 1840 1.00

1000.000 9.810 259.376

12.350

0.75 275

20.0

9.810 x x

= m

1816

162.083

1000 9.810

Job No. Sheet No. 7 Rev.

Project Tittle:

Member/Location:

PERUNDING ZAR S/B Drg. Ref.

Job Title : Made by : Date : Remark

Table below shows the max head pressure for every thickness given.

16.208

18.503

20.793

23.078

25.358

27.633

29.904

32.169

34.429

36.684

38.934

41.180

43.420

17 366.839

20 434.201

18 389.342

19 411.796

14 299.035

15 321.686

16 344.287

10

11 230.784

12 253.585

13 276.335

THE DEVELOPMENT OF 10 MW SMALL HYDRO POWER PLANT

UNDER SREP PROGRAMME AT SUNGAI BROOKE, GUA

MUSANG, KELANTAN.

Penstock Wall Thickness (mm) + 1mm corrosion allowance Max. Head Pressure (m)

162.083 8

185.034

Penstock Design Bob

9

207.934

16.208

23.078

29.904

36.684

38.934

43.420

Penstock Wall Thickness (mm) + 1mm corrosion allowance Max. Head Pressure (m)

8 162.083

11 230.784

20 434.201

14 299.035

17 366.839

18 389.342

S-ar putea să vă placă și

- Sample Calculation Drainage Design (Road Side Drain)Document3 paginiSample Calculation Drainage Design (Road Side Drain)Lokman Hakim100% (4)

- Thrust Block CalculationsDocument5 paginiThrust Block CalculationsNiño Erick Castañares86% (7)

- Drainage Design Report For Perbadanan PutrajayaDocument21 paginiDrainage Design Report For Perbadanan PutrajayaLokman Hakim100% (1)

- Irrigation Chapter 1Document73 paginiIrrigation Chapter 1Kliff Orge100% (3)

- Manual of Information: RIFE Hydraulic RamDocument19 paginiManual of Information: RIFE Hydraulic RamSean100% (1)

- Ms Pipe DesignDocument6 paginiMs Pipe DesignMathiTwadCÎncă nu există evaluări

- Installation - Minimum Straight Section Between Curves - ADocument2 paginiInstallation - Minimum Straight Section Between Curves - AKumar Pandravada100% (1)

- Plate CalculationDocument7 paginiPlate CalculationminhthanhmosÎncă nu există evaluări

- Slug Force Calculation - MEA LINESDocument2 paginiSlug Force Calculation - MEA LINESKinjalShah100% (2)

- Pipe Thickness Calculation For Internal PressureDocument12 paginiPipe Thickness Calculation For Internal PressurefsijestÎncă nu există evaluări

- Crude Oil Characterization and PVT Studies On Prudhoe BayDocument14 paginiCrude Oil Characterization and PVT Studies On Prudhoe BayRuth Abello100% (2)

- Drainage System Calculation MASMADocument11 paginiDrainage System Calculation MASMAAsyraf Malik100% (4)

- Chris Mills 2020Document17 paginiChris Mills 2020AminÎncă nu există evaluări

- Pressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Document5 paginiPressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Y.Ebadi100% (2)

- Master CalculationDocument9 paginiMaster CalculationRANA1575100% (2)

- Thickness CalculationsDocument6 paginiThickness Calculationsvijayunity100% (1)

- Pipe Section Technical PapersDocument8 paginiPipe Section Technical PapersFerdie TolosaÎncă nu există evaluări

- Surge Shaft Design (First Edition) : SGI October 2005Document61 paginiSurge Shaft Design (First Edition) : SGI October 2005octatheweel100% (1)

- Minimum Radius Pipe Bending-R1Document4 paginiMinimum Radius Pipe Bending-R1AdvisÎncă nu există evaluări

- CALCULATION Characteristic Pump2Document16 paginiCALCULATION Characteristic Pump2Ahlan Haryo PambudiÎncă nu există evaluări

- Penstock CaalculationDocument3 paginiPenstock CaalculationGertjan DuniceriÎncă nu există evaluări

- Mitered BendsDocument1 paginăMitered BendsTsouki TsoukiÎncă nu există evaluări

- Basic Calculations PDFDocument1 paginăBasic Calculations PDFSanthosh Kumar100% (1)

- Steel Pipe Design CriteriaDocument3 paginiSteel Pipe Design CriteriaAnonymous 3kDy7eÎncă nu există evaluări

- Steel Structure ST 37Document11 paginiSteel Structure ST 37aliÎncă nu există evaluări

- Design of DesandersDocument5 paginiDesign of Desandersguildkey0% (1)

- Inspection of PenstockDocument9 paginiInspection of PenstockDangol RupeshÎncă nu există evaluări

- Stress ChecklistDocument2 paginiStress ChecklistNixonÎncă nu există evaluări

- Hydrodynamic Calculation Gate Valve (Through Conduit)Document25 paginiHydrodynamic Calculation Gate Valve (Through Conduit)Eng-CalculationsÎncă nu există evaluări

- Bifurcation Design PDFDocument51 paginiBifurcation Design PDFMadhav BaralÎncă nu există evaluări

- Buoyancy CalculationDocument2 paginiBuoyancy CalculationHerruSetiawanÎncă nu există evaluări

- PenstockDocument7 paginiPenstockmodest_dhuÎncă nu există evaluări

- Surge Analysis and The Wave Plan Method IntroDocument22 paginiSurge Analysis and The Wave Plan Method IntroVivek100% (2)

- Pipe Line CalculationDocument14 paginiPipe Line Calculationsamirbendre1Încă nu există evaluări

- GC11 Pipe Thickness CalcDocument1 paginăGC11 Pipe Thickness CalcsrinivasanÎncă nu există evaluări

- Total Length Calcs For Pipes Valves and Fittings RevADocument9 paginiTotal Length Calcs For Pipes Valves and Fittings RevAlutfi awnÎncă nu există evaluări

- Virtual Anchor Length - KBRDocument22 paginiVirtual Anchor Length - KBRSammar Adhikari100% (2)

- 8 Penstock BFV and AccessoriesDocument6 pagini8 Penstock BFV and Accessoriespavankumar001Încă nu există evaluări

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 paginiAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLOÎncă nu există evaluări

- Town Water Supply - Pump, Pumping Main: Delivery PipeDocument2 paginiTown Water Supply - Pump, Pumping Main: Delivery PipeJohn BandaÎncă nu există evaluări

- Penstock Surge ConsiderationDocument29 paginiPenstock Surge ConsiderationoctatheweelÎncă nu există evaluări

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 paginiHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadÎncă nu există evaluări

- Surge AnalysisDocument2 paginiSurge AnalysisPraveen ChaudharyÎncă nu există evaluări

- Pumps: Pacifico Ortaliza Pme 828Document32 paginiPumps: Pacifico Ortaliza Pme 828Angel Silva VicenteÎncă nu există evaluări

- Inputs Required For FIV & AIV StudyDocument1 paginăInputs Required For FIV & AIV StudyRonak MotaÎncă nu există evaluări

- Penstock Thickness Cacl.Document44 paginiPenstock Thickness Cacl.Anonymous sfkedkymÎncă nu există evaluări

- 10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleDocument1 pagină10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleKrishna KnsÎncă nu există evaluări

- Coarse Screen Calculation V2Document2 paginiCoarse Screen Calculation V2WAN CHAND0% (1)

- Surge ForceDocument2 paginiSurge ForceJ A S JASÎncă nu există evaluări

- DESIGNING HYDRAULIC AIR Chamber in Water Sys PipelineDocument7 paginiDESIGNING HYDRAULIC AIR Chamber in Water Sys PipelinesaishankarlÎncă nu există evaluări

- Total Length Calcs For Pipes Valves and FittingsDocument6 paginiTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinÎncă nu există evaluări

- Computation of Penstock Pipe For Pinacanauan, Scheme BDocument6 paginiComputation of Penstock Pipe For Pinacanauan, Scheme BAziz ul HakeemÎncă nu există evaluări

- Design of Power PipeDocument1 paginăDesign of Power PipebalashardaÎncă nu există evaluări

- Penstock Water Hammer CalculationDocument2 paginiPenstock Water Hammer CalculationChris Angelo G CaadlawonÎncă nu există evaluări

- Surge Tank Thoma and Svee CriteriaDocument79 paginiSurge Tank Thoma and Svee CriteriaManikandanÎncă nu există evaluări

- Application of Bellows Expansion Joints in Piping SystemDocument5 paginiApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Încă nu există evaluări

- MasterSeries 850 Specification SheetDocument2 paginiMasterSeries 850 Specification SheetFEBCOÎncă nu există evaluări

- Wall Thickness Calculations As Per ASME B31 3 PDFDocument2 paginiWall Thickness Calculations As Per ASME B31 3 PDFAnonymous cyKuQKÎncă nu există evaluări

- Me 2204 Fluid Mechanics and Machinery LiDocument8 paginiMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanÎncă nu există evaluări

- Penstock Thickness CaclDocument44 paginiPenstock Thickness CaclAnonymous sfkedkym100% (1)

- SIF ExcelDocument3 paginiSIF ExcelaravindhcamÎncă nu există evaluări

- Weir Drawing SectionDocument1 paginăWeir Drawing SectionAziz ul HakeemÎncă nu există evaluări

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDocument3 paginiCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanÎncă nu există evaluări

- New Cut Length CalculatorDocument30 paginiNew Cut Length CalculatorsmdriyazbashaÎncă nu există evaluări

- Design Water TankDocument83 paginiDesign Water TankHemant Sonawadekar100% (2)

- BeamDocument20 paginiBeamrajivkishore62100% (1)

- Astm E1300 - 140414 - OfficeDocument285 paginiAstm E1300 - 140414 - OfficeklynchelleÎncă nu există evaluări

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesDe la Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesÎncă nu există evaluări

- Iem-Pi (1) Item 12 (Excel)Document4 paginiIem-Pi (1) Item 12 (Excel)Lokman HakimÎncă nu există evaluări

- DDJR Form ExampleDocument1 paginăDDJR Form ExampleLokman HakimÎncă nu există evaluări

- Cover Example For LLM DDJRDocument1 paginăCover Example For LLM DDJRLokman HakimÎncă nu există evaluări

- Typical Trafic Managment Plan Location Plan For JKR WorkDocument1 paginăTypical Trafic Managment Plan Location Plan For JKR WorkLokman Hakim100% (1)

- Riprap GuideDocument87 paginiRiprap Guidezeregis100% (5)

- Choosing Cylinders ValvesDocument6 paginiChoosing Cylinders ValvesLokman HakimÎncă nu există evaluări

- Chemical CleaningDocument56 paginiChemical CleaningRathinamalÎncă nu există evaluări

- Design of An Airfoil by Mathematical Modelling Using DatabaseDocument8 paginiDesign of An Airfoil by Mathematical Modelling Using DatabaseNetherlands PressÎncă nu există evaluări

- Experiment 1: HYDROSTASTIC: Mapua Institute of Technology at Laguna Academic Year 2021 - 2022Document5 paginiExperiment 1: HYDROSTASTIC: Mapua Institute of Technology at Laguna Academic Year 2021 - 2022Dyas FerÎncă nu există evaluări

- Human Excreta DisposalDocument36 paginiHuman Excreta DisposalRiJade BibianoÎncă nu există evaluări

- Maverick Technical Manual 2Document120 paginiMaverick Technical Manual 2Doug RowserÎncă nu există evaluări

- Me320 1Document9 paginiMe320 1Krishna AnandÎncă nu există evaluări

- Newtons Law of Viscosity Chapter 1 BSLDocument29 paginiNewtons Law of Viscosity Chapter 1 BSLJannine Joyce BergonioÎncă nu există evaluări

- 2 - Pitot TubeDocument16 pagini2 - Pitot TubeHassan El SayedÎncă nu există evaluări

- Albao Assignment 3Document5 paginiAlbao Assignment 3Shaun Patrick AlbaoÎncă nu există evaluări

- ES 15 Lecture 3 Hydrostatic Forces On Plane SurfacesDocument18 paginiES 15 Lecture 3 Hydrostatic Forces On Plane SurfacesMark Christian Zabaldica PortezaÎncă nu există evaluări

- PE-D-ROPJD124227008-IN-DAS-003-05-E - Flow Counter - DatasheetsDocument2 paginiPE-D-ROPJD124227008-IN-DAS-003-05-E - Flow Counter - Datasheetstravel for photoÎncă nu există evaluări

- Reverse EngineeringDocument3 paginiReverse EngineeringRahul SureshÎncă nu există evaluări

- Properties of Fluids: Lecture - 1Document40 paginiProperties of Fluids: Lecture - 1Nawaz441Încă nu există evaluări

- ADA476496Document27 paginiADA476496Augusto PenessiÎncă nu există evaluări

- Computer-Aided Thermofluid Analyses Usin PDFDocument184 paginiComputer-Aided Thermofluid Analyses Usin PDFJuan JerezÎncă nu există evaluări

- Steam Bench: ObjectiveDocument6 paginiSteam Bench: Objectiveحسين عمريÎncă nu există evaluări

- Fluid Mechanics Lab Report 1 AliDocument10 paginiFluid Mechanics Lab Report 1 AliAli ArshadÎncă nu există evaluări

- Air Receiver TankDocument4 paginiAir Receiver TankHudaFiHayyatÎncă nu există evaluări

- Bernuili EquationDocument15 paginiBernuili EquationHaitham AliÎncă nu există evaluări

- Applied Mathematical Modelling: C.D. Argyropoulos, N.C. MarkatosDocument40 paginiApplied Mathematical Modelling: C.D. Argyropoulos, N.C. MarkatoskaranbeeshmÎncă nu există evaluări

- Chapter 2-B Well Performance AnalysisDocument33 paginiChapter 2-B Well Performance AnalysisT CÎncă nu există evaluări

- Bombas Sumergibles KSBDocument92 paginiBombas Sumergibles KSBArturPÎncă nu există evaluări

- Basic Hydrogeology: Ground Water, Aquifers & Confining BedsDocument10 paginiBasic Hydrogeology: Ground Water, Aquifers & Confining BedsAndi FirdausÎncă nu există evaluări

- University Septic Tanks TextDocument68 paginiUniversity Septic Tanks Textdkm455Încă nu există evaluări