Documente Academic

Documente Profesional

Documente Cultură

Fastener Design Manual, Part Two

Încărcat de

HibozoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fastener Design Manual, Part Two

Încărcat de

HibozoDrepturi de autor:

Formate disponibile

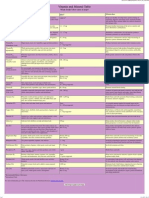

Figure 12.

Types of

Belleville washers. (a)

smooth; (b) serrated

Figure 13.

Combinations of

Belleville washers. (a)

series; (b) parallel; (c)

parallel-series

Figure 14. Helical

spring washers.

Figure 15. Tooth

lockwashers. (a) at;

(b) countersunk

Figure 16.

Self-aligning washer.

The Engineer's Companion

Home Ethics Failures Fasteners Innovation On Jobs Licensing PID Tuning Quality Rhetoric About Ron What Engineers Are

Fastener Design Manual, Part Two

Rich Barrett

Washers

Belleville Washers

Belleville washers (Figure 12) are conical washers used more for maintaining a uniform tension

load on a bolt than for locking. If they are not completely flattened out, they serve as a spring in

the bolt joint. However, unless they have serrated surfaces, they have no significant locking

capability. These surfaces, on the other hand, will damage the mating surfaces under them.

These washers can be stacked in combinations as shown in Figure 13 to either increase the

total spring length (Figure 13(a) and (c)) or increase the spring constant (Figure 13(b)).

Lockwashers

The typical helical spring washer shown in Figure 14 is made of

slightly trapezoidal wire formed into a helix of one coil so that the

free height is approximately twice the thickness of the washer

cross section. Lockwashers are usually made of hardened carbon

steel, but they are also available in aluminum, silicon, bronze,

phosphor-bronze alloy, stainless steel, and K-Monel.

The lockwasher serves as a spring while the bolt is being

tightened. However, the washer is normally flat when the bolt is

fully torqued. At this time it is equivalent to a solid flat washer, and its locking ability is

nonexistent. In summary, a lockwasher of this type is useless for locking.

Tooth (or Star) Lockwashers

Tooth lockwashers (Figure 15) are used with screws and nuts for

some spring action but mostly for locking action. The teeth are

formed in a twisted configuration with sharp edges. One edge

bites into the bolthead (or nut) while the other edge bites into the

mating surface.

Although this washer does provide some locking action, it

damages the mating surfaces. These scratches can cause

crack formation in highly stressed fasteners, in mating

parts, or both, as well as decreased corrosion resistance.

Self-Aligning Washers

A self-aligning washer is used

with a mating nut that has conical

faces as shown in Figure 16.

Because there is both a weight

penalty and a severe cost penalty

for using this nut, it should be used only as a last resort. Maintaining parallel mating surfaces

within acceptable limits (two feet, per SAE Handbook (ref. 4)) is normally the better alternative.

Inserts

An insert is a special type of device that is threaded on inside diameter and locked with threads or protrusions on outside

diameter in a drilled, molded, or tapped hole. It is used to provide a strong, wear-resistant tapped hole in a soft material

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

1 of 9 08.03.2014 18:03

Figure 17. Wire

thread insert

installation.

Figure 18. Wire

thread insert types.

(a) free running; (b)

locking

Figure 19.

Self-tapping inserts.

(a) Slotted; (b) Nylok

Figure 20. Speedsert.

Figure 21. Keensert.

(e.g. plastics, nonferrous metals), as well as to repair stripped threads in a tapped hole.

The aerospace industry uses inserts in tapped holes in soft materials in order to take

advantage of weight savings provided by small high-strength fasteners. The bigger external

thread of the insert (nominally 1/8 in. bigger in diameter than the internal thread) gives, for

example, a 10-32 bolt in an equivalent 5/16-18 nut.

In general, there are two types of inserts: those that are threaded externally, and those that

are locked by some method other than threads (knurls, serrated surfaces, grooves, or

interference fit). Within the threaded inserts there are three types: the wire thread, the

self-tapping, and the solid bushing.

Threaded Inserts

Wire thread. The wire thread type of insert (Heli-coil 10) (a) is a

precision coil of diamond-shaped CRES wire that forms both

external and internal threads as shown in Figure 17. The coil is

made slightly oversize so that it will have an interference fit in the

tapped hole. In addition, this insert is available with a deformed coil (Figure 18) for additional

locking. The tang is broken off at the notch after installation.

The wire thread insert is the most popular type for repair of a tapped hole with stripped threads,

since it requires the least amount of hole enlargement. However, the solid bushing insert is

preferred if space permits.

Self-tapping. Most of the self-tapping inserts are the solid bushing

type made with a tapered external thread similar to a self-tapping

screw (Figure 19). There are several different locking

combinations, such as the Nylok plug (Figure 19(b)) or the thread-forming Speedsert

deformed thread (Figure 20). An additional advantage of the thread-forming insert is that it

generates no cutting chips, since it does not cut the threads. It can only be used, however,

in softer materials. [Rexnord Specialty Fasteners Division, Torrance, California.]

Solid bushing. Solid bushing inserts have conventional threads

both internally and externally. A popular type is the Keensert

[Rexnord] shown in Figure 21. The locking keys are driven in after

the insert is in place. Another manufacturer uses a two-prong ring for locking. These inserts are

also available with distorted external thread or Nylok plugs for locking.

Nonthreaded Inserts

Plastic expandable. The most familiar of the nonthreaded inserts

is the plastic expandable type shown in figure 22. This insert has

barbs on the outside and longitudinal slits that allow it to expand

outward as the threaded fastener is installed, pushing the barbs

into the wall of the drilled hole. (See ref. 5.)

Molded in place. This type of insert (Figure 23) is knurled or

seffated to resist both pullout and rotation. It is commonly used

with ceramics, rubber, and plastics, since it can develop higher resistance to both pullout

and rotation in these materials than self-tapping or conventionally threaded inserts. (See

ref. 5.)

Ultrasonic. Ultrasonic inserts (Figure 24) have grooves in various

directions to give them locking strength. They are installed in a

prepared hole by pushing them in while they are being

ultrasonically vibrated. The ultrasonic vibration melts the wall of the hole locally so that the insert

grooves are "welded" in place. Since the area melted is small, these inserts do not have the

holding power of those that are molded in place. Ultrasonic inserts are limited to use in

thermoplastics. (See ref. 5.)

Threads

Types of Threads Since complete information on most threads can be found in the ANSI

standards (ref. 6), the SAE Handbook (ref. 4), and the National Institute of Standards and

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

2 of 9 08.03.2014 18:03

Figure 22. Plastic

expandable insert.

Figure 23. Molded

in-place insert.

Figure 24. Ultrasonic

inserts.

Technology Handbook H-28 (ref. 7) no thread standards will be

included here. The goal here is to explain the common thread

types, along with their advantages and disadvantages. The

common thread types are unified national coarse (UNC), unified

national fine (UNF), unified national extra fine (UNEF), UNJC,

UNJF, UNR, UNK, and constant-pitch threads.

Unified national coarse. UNC is the most commonly used thread

on general-purpose fasteners. Coarse threads are deeper than

fine threads and are easier to assemble without cross threading.

The manufacturing tolerances can be larger than for finer threads,

allowing for higher plating tolerances. UNC threads are normally

easier to remove when corroded, owing to their sloppy fit.

However, a UNC fastener can be procured with a class 3 (tighter)

fit if needed (classes to be covered later).

Unified national fine. UNF thread has a larger minor diameter than

UNC thread, which gives UNF fasteners slightly higher

load-carrying and better torque-locking capabilities than UNC

fasteners of the same identical material and outside diameter. The fine threads have tighter

manufacturing tolerances than UNC threads, and the smaller lead angle allows for finer tension adjustment. UNF threads

are the most widely used threads in the aerospace industry.

Unified national extra fine. UNEF is a still finer type of thread than UNF and is common to the aerospace field. This thread

is particularly advantageous for tapped holes in hard materials and for thin threaded walls, as well as for tapped holes in

thin materials.

UNJC and UNJF threads. "J" threads are made in both external and internal forms. The external thread has a much

larger root radius than the corresponding UNC, UNR, UNK, or UNF threads. This radius is mandatory and its inspection is

required, whereas no root radius is required on UNC, UNF, or UNEF threads. Since the larger root radius increases the

minor diameter, a UNJF or UNJC fastener has a larger net tensile area than a corresponding UNF or UNC fastener. This

root radius also gives a smaller stress concentration factor in the threaded section. Therefore, high-strength (180 ksi or

more) bolts usually have "J" threads.

UNR threads. The UNR external thread is a rolled UN thread in all respects except that the root radius must be rounded.

However, the root radius and the minor diameter are not checked or toleranced. There is no internal UNR thread.

UNK threads. The UNK external thread is similar to UNR, except that the root radius and the minor diameter are

toleranced and inspected. There is no internal UNK thread.

According to a survey of manufacturers conducted by the Industrial Fasteners Institute, nearly all manufacturers of

externally threaded fasteners make UNR rolled threads rather than plain UN. The only exception is for ground or cut

threads.

Constant-pitch threads. These threads offer a selection of pitches that can be matched with various diameters to fit a

particular design. This is a common practice for bolts of 1-in. diameter and above, with pitches of 8, 12, or 16 threads per

inch being the most common.

A graphical and tabular explanation Of UN, UNR, UNK, and UNJ threads is given on page M-6 of reference 8. A copy

(Figure 25) is enclosed here for reference. According to the Industrial Fasteners Institute, "[the following] is not a screw

thread standard, should not be used as a working sheet, and should only refer the reader to the proper ANSI Standards

document wherein the full thread details on working data are contained."

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

3 of 9 08.03.2014 18:03

Figure 25. Explanation of UN, UNR, UNK, and UNJ threads. Reprinted with permission of Industrial Fasteners Institute.

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

4 of 9 08.03.2014 18:03

Classes of Threads

Thread classes are distinguished from each other by the amounts of tolerance and allowance. The designations run from

IA to 3A and IB to 3B for external and internal threads, respectively. A class I is a looser fitting, general-purpose thread; a

class 3 is the aerospace standard thread, and has a tighter tolerance. (The individual tolerances and sizes for the various

classes are given in the SAE Handbook (ref 4).)

Forming of Threads

Threads may be cut, hot rolled, or cold rolled. The most common manufacturing method is to cold form both the head and

the threads for bolts up to one inch in diameter. For bolts of larger diameter and high-strength smaller bolts, the heads are

hot forged. The threads are still cold rolled until the bolt size prohibits the material displacement necessary to form the

threads (up to a constant pitch of eight threads per inch). Threads are cut only at assembly with taps and dies or by lathe

cutting.

Cold rolling has the additional advantage of increasing the strength of the bolt threads through the high compressive

surface stresses, similar to the effects of shot peening. This process makes the threads more resistant to fatigue

cracking.

Fatigue-Resistant Bolts

If a bolt is cycled in tension, it will normally break near the end of the threaded portion because this is the area of

maximum stress concentration. In order to lessen the stress concentration factor, the bolt shank can be machined down

to the root diameter of the threads. Then it will survive tensile cyclic loading much longer than a standard bolt with the

shank diameter equal to the thread outside diameter.

Fatigue (Cyclic) Loading of Bolts

Figure 26. Fatigue loading of bolts. (a) bolted flanges with external load; (b) free body with no external load; (c) free body

with external load

The bolted joint in Figure 26 (from ref. 9) is preloaded with an initial load Fi, which equals the clamping load FC before the

external load FE is applied. The equation (from ref. 11) for this assembly is

FB = Fi + FE KB / (KB + KC)

where FB is the total bolt load. In this equation KB is the spring constant of the bolt and KC is the spring constant of the

clamped faces. To see the effects of the relative spring constants, let R = KC / KB. Then (from ref. 10)

FB = Fi + FE / (1 + R)

In a normal clamped joint KC is much larger than KB (R = 5.0 for steel bolt and flanges), so that the bolt load does not

increase much as the initial external load is applied. (Note that the bolt load does not increase significantly until FE

exceeds Fi.)

A series of triangular diagrams (Figure 27, from ref. 11) can be used to clarify the effect of externally applied loads.

Triangle OAB is identical in all four diagrams. The slope of OA represents the bolt stiffness; the slope of AB represents

the joint stiffness (joint is stiffer than bolt by ratio OC/CB.) In Figure 27(a) the externally applied load FE (a) does not load

the bolt to its yield point. In Figure 27 (b) the bolt is loaded by FE (b) to its yield point, with the corresponding decrease in

clamping load to FCL. In Figure 27 (c) the external load (c) has caused the bolt to take a permanent elongation such that

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

5 of 9 08.03.2014 18:03

the clamping force will be less than Fi when FE (c) is removed. In Figure 27 (d) the joint has completely separated on its

way to bolt failure. Note that the flatter the slope of OA (or the larger the ratio OC/OB becomes), the smaller the effect Fi

has on bolt load. Therefore, using more small-diameter fasteners rather than a few large-diameter fasteners will give a

more fatigue-resistant joint. Referring to Figure 27 (a), note that the cyclic (alternating) load is that portion above Fi. This

is the alternating load (stress) to be used on a stress-versus-load-cycles diagram of the bolt material to predict the fatigue

life of the bolts. Note that an initial preload Fi near the bolt yields minimizes cyclic loading.

Figure 27. Bolt external loading.

Thermal Cyclic Loading of Bolts

If the bolt and joint are of different materials, an operating temperature higher or lower than the installation temperature

can cause problems. Differential contraction can cause the joint to unload (or separate); differential expansion can cause

overloading of the fasteners. In these cases it is common practice to use conical washers (see washer section of this

manual) to give additional adjustments in fastener and joint loading.

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

6 of 9 08.03.2014 18:03

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

7 of 9 08.03.2014 18:03

Table 4. Coefficients of static and sliding friction.

On coefficients of static and sliding friction (from reference 12)

Campbell, Trans. ASME, 1939. 1.

Clarke, Lincoln, and Sterrett, Proc. API, 1935. 2.

Beare and Bowden, Phil. Trans. Roy. Soc., 1985. 3.

Dokos, Trans. ASME, 1946. 4.

Boyd and Robertson, Trans. ASME, 1945. 5.

Sachs, zeit f. angew. Math. And Mech., 1924. 6.

Honda and Yamada, Jour. I of M, 1925. 7.

Tomlinson, Phil. Mag., 1929. 8.

Morin, Acad. Roy. des Sciences, 1838. 9.

Claypoole, Trans. ASME, 1943. 10.

Tabor, Jour. Applied Phys., 1945. 11.

Eyssen, General Discussion on Lubrication, ASME, 1937. 12.

Brazier and Holland-Bowyer, General Discussion on Lubrication,

ASME, 1937.

13.

Burwell, Jour. SAE, 1942. 14.

Oleic acid a.

Atlantic spindle oil (light mineral) b.

Castor oil c.

Lard oil d.

Atlantic spindle oil plus 2% oleic

acid

e.

Medium mineral oil f.

Medium mineral oil plus 0.5% oleic

acid

g.

Stearic acid h.

Grease (zinc oxide base) i.

Graphite j.

Turbine oil plus 1% graphite k.

Turbine oil plus 1% stearic acid l.

Turbine oil (medium mineral) m.

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

8 of 9 08.03.2014 18:03

Stanton, "Friction", Longmans. 15.

Ernst and Merchant, Conference on Friction and Surface Finish, MIT,

1940.

16.

Gongwer, Conference on Friction and Surface Finish, MIT, 1940. 17.

Hardy and Bircumshaw, Proc. Roy. Soc., 1925. 18.

Hardy and Hardy, Phil. Mag., 1919. 19.

Bowden and Young, Proc. Roy. Soc., 1951. 20.

Hardy and Doubleday, Proc. Roy. Soc., 1923. 21.

Bowden and Tabor, "The Friction and Lubrication of Solids," Oxford. 22.

Shooter, Research, 4, 1951. 23.

Olive oil n.

o.

Palmitic acid p.

Ricinoleic acid q.

Dry soap r.

Lard s.

Water t.

Rape oil u.

3-in-1 Oil v.

Octyl alcohol w.

Triolein x.

1% lauric acid in paraffin oil y.

Fastener Torque

Determining the proper torque for a fastener is the biggest problem in fastener installation. Some of the many variables

causing problems are

The coefficient of friction between mating threads 1.

The coefficient of friction between the bolthead (or nut) and its mating surface 2.

The effect of bolt coatings and lubricants on the friction coefficients 3.

The percentage of bolt tensile strength to be used for preload 4.

Once agreement is reached on item 4, how to accurately determine this value 5.

Relative spring rates of the structure and the bolts 6.

Interaction formulas to be used for combining simultaneous shear and tension loads on a bolt (should friction loads due

to bolt clamping action be included in the interaction calculations?)

7.

Whether "running torque" for a locking device should be added to the normal torque 8.

Go back to part one.

The conscientious, effective engineer is a virtuous engineer. -- Samuel Florman, The Civilized Engineer

The Engineer's Companion is Copyright 1995-present by Ron Graham -- Last updated 11/14/2008 20:38:20

rongraham01@gmail.com

The Engineer's Companion/Fastener Design Manu... http://www.designnotes.com/companion/manual-2...

9 of 9 08.03.2014 18:03

S-ar putea să vă placă și

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Roller Chain GuideDocument5 paginiRoller Chain GuidechikoopandaÎncă nu există evaluări

- Plate Girder Behaviour and DesignDocument48 paginiPlate Girder Behaviour and DesignayingbaÎncă nu există evaluări

- Bracing ConnectionDocument16 paginiBracing ConnectionMa N U VenusÎncă nu există evaluări

- Motorreductores BaldorDocument52 paginiMotorreductores BaldorADRIAN MENDEZ RICARIOÎncă nu există evaluări

- Rotary Feeders: PrecisionDocument8 paginiRotary Feeders: PrecisionrheriÎncă nu există evaluări

- Dodge Saf Pillow BlocksDocument6 paginiDodge Saf Pillow BlocksjvalkenburgÎncă nu există evaluări

- Expansion Joints How To Select and Maintain ThemDocument6 paginiExpansion Joints How To Select and Maintain ThemSeungmin PaekÎncă nu există evaluări

- Renold Conveyor Section4 0508Document41 paginiRenold Conveyor Section4 0508deep200Încă nu există evaluări

- Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ®Document26 paginiInstallation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ®Carlos RiosÎncă nu există evaluări

- CATALOGO BROWING Form - 9242E REDUCTORES PDFDocument254 paginiCATALOGO BROWING Form - 9242E REDUCTORES PDFAndres Byke SepulvedaÎncă nu există evaluări

- Lorbrand Idler CatalogueDocument88 paginiLorbrand Idler CatalogueJakesÎncă nu există evaluări

- ISO General Purpose Metric Screw ThreadsDocument19 paginiISO General Purpose Metric Screw ThreadsMiguel VillalobosÎncă nu există evaluări

- Bolted Beam Column ConnectionsDocument16 paginiBolted Beam Column Connectionslael00Încă nu există evaluări

- Fine Material Washer SPLT1047ENPR 01Document6 paginiFine Material Washer SPLT1047ENPR 01NarvaxisÎncă nu există evaluări

- E1102m PDFDocument283 paginiE1102m PDFBhawani Singh RajawatÎncă nu există evaluări

- Bossard Taptite Self Tapping Screw CatalogueDocument10 paginiBossard Taptite Self Tapping Screw CataloguepmlmkpÎncă nu există evaluări

- S-Wall™ Sidewall Conveyor Belting: Technical ManualDocument44 paginiS-Wall™ Sidewall Conveyor Belting: Technical ManualVasant HiremathÎncă nu există evaluări

- Bucket Elevators, Bucket Conveyors and MoreDocument22 paginiBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguÎncă nu există evaluări

- Totime BTA DRILLDocument5 paginiTotime BTA DRILLTOTIME (DEREK HIROSAKA)Încă nu există evaluări

- V Groove WheelDocument3 paginiV Groove Wheelthirumalg1981Încă nu există evaluări

- International Standard: Plain Bearings - Multilayer Materials For Thin-Walled Plain BearingsDocument12 paginiInternational Standard: Plain Bearings - Multilayer Materials For Thin-Walled Plain BearingsabramÎncă nu există evaluări

- Fasteners, Powers Screws, ConnectionsDocument27 paginiFasteners, Powers Screws, ConnectionsTîwäRî RãJêêvÎncă nu există evaluări

- Self-Tapping Screws How To ChooseDocument3 paginiSelf-Tapping Screws How To ChooseoarmstroÎncă nu există evaluări

- Technical Notehowmanythreads PDFDocument4 paginiTechnical Notehowmanythreads PDFGatyo GatevÎncă nu există evaluări

- Idlers: TRF Limited TRF LimitedDocument10 paginiIdlers: TRF Limited TRF LimitedAjit SarukÎncă nu există evaluări

- Piping Flexibility - Thermal Expansion in PipingDocument6 paginiPiping Flexibility - Thermal Expansion in PipingMohamed Al-OdatÎncă nu există evaluări

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 paginiTechnical Information: Radial Play (Internal Clearance) in Ball Bearingsluisbmwm6Încă nu există evaluări

- Optimization of CNC End Milling Process Parameters For Aluminium 6061 Alloy Using Carbide Tool Material by Design of ExperimentsDocument7 paginiOptimization of CNC End Milling Process Parameters For Aluminium 6061 Alloy Using Carbide Tool Material by Design of ExperimentsIJIRSTÎncă nu există evaluări

- Sidewall Splicing MechanicalDocument11 paginiSidewall Splicing MechanicalTamer EmamÎncă nu există evaluări

- Design Guide, Spring, Pin, Coiled, SPIROLDocument24 paginiDesign Guide, Spring, Pin, Coiled, SPIROLDerekÎncă nu există evaluări

- Precise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityDocument13 paginiPrecise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityShamik ChowdhuryÎncă nu există evaluări

- L11 Mechanical FastenersDocument91 paginiL11 Mechanical FastenersSHADES 4 ALLÎncă nu există evaluări

- Leadscrews Ballscrews Splines Cten PAG126Document240 paginiLeadscrews Ballscrews Splines Cten PAG126lucian lunaÎncă nu există evaluări

- Ball Screw CalculatorDocument60 paginiBall Screw Calculatorمنير بوزيدÎncă nu există evaluări

- Chapter 5 - Shaft DesignDocument0 paginiChapter 5 - Shaft DesignwanpudinÎncă nu există evaluări

- Solidworks 2003 ManualDocument95 paginiSolidworks 2003 ManualPhạm Văn ĐảngÎncă nu există evaluări

- ToolingDocument12 paginiToolingPuneet SharmaÎncă nu există evaluări

- Flexible Couplings: ElflexDocument8 paginiFlexible Couplings: ElflexSUNIL TVÎncă nu există evaluări

- Plain Bearings With ELGOTEX: Available Bearing SizesDocument2 paginiPlain Bearings With ELGOTEX: Available Bearing SizesMarian DunareanuÎncă nu există evaluări

- Expansion Joints:: Where, When and HowDocument4 paginiExpansion Joints:: Where, When and Howdnl_vicarsÎncă nu există evaluări

- Deep Hole SolutionsDocument28 paginiDeep Hole SolutionsyatinbhatÎncă nu există evaluări

- Sae J1392 2001Document10 paginiSae J1392 2001henrychtÎncă nu există evaluări

- Anchor BoltsDocument24 paginiAnchor BoltsJose Jesus Chagolla LopezÎncă nu există evaluări

- SKF Locknut Shaft Details InchDocument6 paginiSKF Locknut Shaft Details InchKOMATSU SHOVELÎncă nu există evaluări

- Mesys ManualDocument269 paginiMesys ManualFernandoHernándezÎncă nu există evaluări

- Shrink Disc MAVDocument36 paginiShrink Disc MAVTim kuÎncă nu există evaluări

- Design of RivetsDocument20 paginiDesign of RivetsRavishanker BaligaÎncă nu există evaluări

- Pop Nut PDFDocument48 paginiPop Nut PDFJavier A. ValenzuelaÎncă nu există evaluări

- Router Table Fence PlansDocument9 paginiRouter Table Fence PlansAfonso PraganaÎncă nu există evaluări

- Worldwide Engineering Standards: Polypropylene Expanded Bead FoamDocument5 paginiWorldwide Engineering Standards: Polypropylene Expanded Bead FoamLucas MlbÎncă nu există evaluări

- STI 463 ModelDocument1 paginăSTI 463 Modelਗਗਨ ਜੋਤÎncă nu există evaluări

- Alluminio TeoriaDocument91 paginiAlluminio TeoriaxypangioÎncă nu există evaluări

- CA3000BDocument756 paginiCA3000BAlejandro Hernandez100% (2)

- Warner Ball ScrewsDocument45 paginiWarner Ball ScrewssaddlemanÎncă nu există evaluări

- Threaded Fasteners For PlasticsDocument32 paginiThreaded Fasteners For PlasticsStefano BarbieriÎncă nu există evaluări

- Fastener Design Manual - Part TwoDocument9 paginiFastener Design Manual - Part TwoNikolaAvÎncă nu există evaluări

- L - 9 Ah - SSBLF I (6.5)Document7 paginiL - 9 Ah - SSBLF I (6.5)Arjun SharmaÎncă nu există evaluări

- Topic 1 Design of FastenersDocument15 paginiTopic 1 Design of FastenersSimon DavidÎncă nu există evaluări

- Service.: The 2.7-Litre V6 BiturboDocument72 paginiService.: The 2.7-Litre V6 BiturboHibozoÎncă nu există evaluări

- By Wikibooks Contributors: FromDocument84 paginiBy Wikibooks Contributors: FromHibozoÎncă nu există evaluări

- Catalogo Hommel KellerDocument52 paginiCatalogo Hommel KellerHibozoÎncă nu există evaluări

- Vitamin and Mineral TABLEDocument1 paginăVitamin and Mineral TABLEHibozoÎncă nu există evaluări

- TATA Product Range 10 - UpdateDocument67 paginiTATA Product Range 10 - UpdateKrishnadas GouravÎncă nu există evaluări

- Tata Steel - Designers Manual (India)Document39 paginiTata Steel - Designers Manual (India)Rohit Rangnekar100% (3)

- Steel Construction - Education SectorDocument24 paginiSteel Construction - Education Sectorhgor100% (1)

- Cost Comparison Steel vs. ConcreteDocument20 paginiCost Comparison Steel vs. ConcreteHibozo82% (17)

- Basic Training Manual Xsteel 6.0Document195 paginiBasic Training Manual Xsteel 6.0Hibozo100% (1)

- CorusDocument11 paginiCorusHibozoÎncă nu există evaluări

- Technical ManualDocument72 paginiTechnical ManualHibozoÎncă nu există evaluări

- First Principles of Mechanical and Engineering Drawing PDFDocument190 paginiFirst Principles of Mechanical and Engineering Drawing PDFimed100% (1)

- En 10025Document16 paginiEn 10025Sorin Radu100% (1)

- Product CatalogueDocument2 paginiProduct CatalogueHibozoÎncă nu există evaluări

- Facility Design GuidelinesDocument440 paginiFacility Design GuidelinesWalid Abou HassanÎncă nu există evaluări

- Jbase Locking MecanismeDocument33 paginiJbase Locking MecanismeMamat AdoumaÎncă nu există evaluări

- Gas Reservoir Engineering Application ToolkitDocument20 paginiGas Reservoir Engineering Application Toolkitnishant41288100% (1)

- 2006-2011 Yaris OEM Cruise Control DIY 20110315Document34 pagini2006-2011 Yaris OEM Cruise Control DIY 20110315juanÎncă nu există evaluări

- Integrating Security Into The IoT Strategy in The New Converged EnvironmentDocument20 paginiIntegrating Security Into The IoT Strategy in The New Converged EnvironmentSuriya RojsuriyaÎncă nu există evaluări

- An Acknowledgement LetterDocument1 paginăAn Acknowledgement LetterGovindan PerumalÎncă nu există evaluări

- Optical Wireless Communications For Beyond 5G Networks and IoT - Unit 6 - Week 3Document1 paginăOptical Wireless Communications For Beyond 5G Networks and IoT - Unit 6 - Week 3Sarika JainÎncă nu există evaluări

- List of Mobile Phones Supported OTG Function PDFDocument7 paginiList of Mobile Phones Supported OTG Function PDFCarlos Manuel De Los Santos PerezÎncă nu există evaluări

- VNP28N04 E DatasheetzDocument11 paginiVNP28N04 E Datasheetzwawans6762Încă nu există evaluări

- AN5116-02 Technical ManualDocument72 paginiAN5116-02 Technical ManualValdinei Quaresma0% (1)

- Stilo Servo Electric PDFDocument7 paginiStilo Servo Electric PDFManu Alex100% (1)

- Personal Particulars: Thanuja ParamanandanDocument4 paginiPersonal Particulars: Thanuja ParamanandanThanujaÎncă nu există evaluări

- K725-2016 Course OutlineDocument10 paginiK725-2016 Course Outlinemelissa_infusionÎncă nu există evaluări

- Precision Bias: Every Astm Test Method Requires A AND Section. What Is It? How Do I Create One? Read OnDocument4 paginiPrecision Bias: Every Astm Test Method Requires A AND Section. What Is It? How Do I Create One? Read Onjrlr65Încă nu există evaluări

- Industrial Report On InfosysDocument14 paginiIndustrial Report On InfosysMitesh ChauhanÎncă nu există evaluări

- This XML File Does Not Appear To Have Any Style Information Associated With It. The Document Tree Is Shown BelowDocument7 paginiThis XML File Does Not Appear To Have Any Style Information Associated With It. The Document Tree Is Shown BelowSpit FireÎncă nu există evaluări

- Desain Layout Mobil Toko Laundry SepatuDocument7 paginiDesain Layout Mobil Toko Laundry SepatuKlinikrifdaÎncă nu există evaluări

- Data Sufficiency Number SystemDocument2 paginiData Sufficiency Number Systemsagar283Încă nu există evaluări

- Power Plant Manual 1Document8 paginiPower Plant Manual 1Khoirul WaladÎncă nu există evaluări

- Datatables Velzon - Admin Dashboard TemplateDocument2 paginiDatatables Velzon - Admin Dashboard Templateganeshvittanala33Încă nu există evaluări

- MCA 2020 - List of Applicants Shortlisted For Interview (F) - 30 May 2020Document21 paginiMCA 2020 - List of Applicants Shortlisted For Interview (F) - 30 May 2020shatabdi mukherjeeÎncă nu există evaluări

- Introduction Information Systems Foundation (Information Systems Foundation IS201)Document22 paginiIntroduction Information Systems Foundation (Information Systems Foundation IS201)binsalweÎncă nu există evaluări

- Spatial AnalysisDocument91 paginiSpatial Analysischiradzulu83% (6)

- Social Dimensions of ComputerisationDocument6 paginiSocial Dimensions of Computerisationgourav rathore100% (1)

- Regus Lakeview - Meeting Room Price ListDocument1 paginăRegus Lakeview - Meeting Room Price ListJayaraj TÎncă nu există evaluări

- Compiler Lab VivaDocument6 paginiCompiler Lab VivaGaurav SharmaÎncă nu există evaluări

- Teachers Voices From Argentine ClassroomsDocument69 paginiTeachers Voices From Argentine ClassroomsEmanuel AlvarezÎncă nu există evaluări

- Module 1 Keyword ResearchDocument29 paginiModule 1 Keyword Researchalfian gunadiÎncă nu există evaluări

- JNTU Old Question Papers 2007Document8 paginiJNTU Old Question Papers 2007Srinivasa Rao GÎncă nu există evaluări

- Parent QuestionnaireDocument2 paginiParent QuestionnaireJoaquinÎncă nu există evaluări