Documente Academic

Documente Profesional

Documente Cultură

A Cooperative Multi Robot Control Using Ad Hoc Wireless Network

Încărcat de

Jafar SadiqDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Cooperative Multi Robot Control Using Ad Hoc Wireless Network

Încărcat de

Jafar SadiqDrepturi de autor:

Formate disponibile

AbstractIn this paper, a Cooperative Multi-robot for Carrying

Targets (CMCT) algorithm is proposed. The multi-robot team

consists of three robots, one is a supervisor and the others are

workers for carrying boxes in a store of 100100 m

2

. Each robot has

a self recharging mechanism. The CMCT minimizes robots worked

time for carrying many boxes during day by working in parallel. That

is, the supervisor detects the required variables in the same time

another robots work with previous variables. It works with

straightforward mechanical models by using simple cosine laws. It

detects the robots shortest path for reaching the target position

avoiding obstacles by using a proposed CMCT path planning

(CMCT-PP) algorithm. It prevents the collision between robots

during moving. The robots interact in an ad hoc wireless network.

Simulation results show that the proposed system that consists of

CMCT algorithm and its accomplished CMCT-PP algorithm

achieves a high improvement in time and distance while performing

the required tasks over the already existed algorithms.

KeywordsAd hoc network, Computer vision based positioning,

Dynamic collision avoidance, Multi-robot, Path planning algorithms,

Self recharging.

I. INTRODUCTION

ODAY robot systems are becoming more and more

significant in various aspects of human life, for example

in industrial, commercial and scientific applications. A key

driving forces in the development of robotic systems is their

potential for reducing the need for human presence. As a

result of scientific achievements and industrial development,

the number of robots being used in industrial projects is

increased. Autonomous robots performing a common task not

achievable by a single robot must coordinate their actions in

order to success [1].

While all fields of robots have progressively based on rapid

advances in computing and information systems. The field of

distributed and cooperative robots has been catalyzed in

particular by new networks and communications technologies.

In robotics context, the linkage of information systems

through ad hoc network facilitates interactions that quickly

scale from two robots shaking hands to a swarm of multi

robots demonstrating cooperative behaviors. Mobile ad hoc

networks are a collection of mobile nodes or terminals that

Eng. Amira A. Elsonbaty is with Alzarka Higher Institute for

Administration and Computer Sciences.

Dr. Rawya Y. Rizk* is with Electrical Engineering Dept., Suez Canal

University (*Corresponding author; e-mail: r.rizk@ scuegypt.edu.eg).

Dr. Mohamed S. Elksas is with the Computers & Systems Engineering

Dept., Mansoura University, Egypt.

Prof. Mofreh M. Salem is with the Computers & Systems Engineering

Dept., Mansoura University, Egypt.

cannot rely on centralized or organized connectivity. These

networks have no base stations, no xed routers and no

centralized administration. All nodes may move randomly and

are connecting dynamically to each other. Therefore all nodes

are operating as routers and need to be capable of discovering

and maintaining routes to every other node in the network and

to propagate packets accordingly.

This paper presents team of three robots work together

without collision. They have self recharging mechanism,

where their batteries are recharged periodically according to

the total worked time passed from the previous charge. The

paper focuses on the interactions and the constraints among

robots to detect the position of boxes. The robots

communicate through an ad hoc network.

The rest of the paper is organized as follows. Section II

presents the related work. Section III introduces the proposed

cooperative multi-robot for carrying targets. Section IV

presents the proposed path planning algorithm. Section V

introduces the simulation results. Finally, Section VI presents

the main conclusion and the future work.

II. RELATED WORK

Several multi-robot systems have been proposed. Most

research efforts on multi-robots have focused on multi-robot

control, path planning for robot navigation in a dynamic

environment, or the communication among robots.

The Cooperative Multi-robot Observation of Multiple

Moving Targets (CMOMMT) was proposed in [2]. It is a

cooperative team of autonomous sensor-based robots for the

observation of multiple moving targets. It focuses primarily on

developing the on-line distributed control strategies that allow

the robot team to attempt to minimize the total time. In [3],

team of robots assists firefighters by searching and inspection

of the building was used. A robust ad hoc communications

between firefighters was used. Distributed In-Network Task

Allocation (DINTA) was designed in [4] to solve the online

multi-robot task allocation problem. DINTA combined the

benefits of a sensor network with the mobility and

functionality of robots. In [5], some problems that are

expected to happen in dynamic modeling of a multiple-

degree-of-freedom robot arm were studied. The model can be

derived by calculating the kinetic energy and potential energy

of the links and the joints. A dynamic model combining the

dynamics of both robot arm and platform were developed.

Networked robot system called MiNT is designed to

support high fidelity wireless network emulation [6]. The

communications among these robots are through wireless

LAN interfaces. MiNT has self-charging mechanism, and

computer vision-based robot positioning system. In [7], the

A Cooperative Multi-Robot Control Using

Ad Hoc Wireless Network

Amira Elsonbaty, Rawya Rizk, Mohamed Elksas, and Mofreh Salem

T

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

861

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

drawbacks of wireless networking were overcomed by

developing a communication system based on optical fiber

links, with high bandwidth and converters at both ends. A

method to evaluate control and coordination strategies for

group of wireless networked robots was proposed in [8]. An

integrated robot and network simulation tool was developed to

allow investigation of the behavior of robot controllers

combined with detailed communication models embedded in a

virtual environment.

Hierarchical Path Finding A* (HPA*) for reducing problem

complexity in path finding on grid based maps was proposed

in [9]. It abstracted a map into linked local clusters, at the

local level. The optimal distances for crossing each cluster

were computed and cached. The global level, clusters were

traversed in a single big step. Small clusters are grouped

together to form larger clusters. Computing crossing distances

for a large cluster used distances computed for the smaller

contained clusters. A dynamic path finding algorithm for a

vehicle-based automated material handling system (AMHS)

was discussed in [10]. Distance between nodes, node

penalties, number of vehicles queued and historical data from

the AMHS was used to calculate the total cost of a path. It

discussed how to effectively utilize such data in critical

situations to improve overall AMHS performance. The

accuracy of position estimation for groups of mobile robots

performing cooperative localization was studied in [11].

Analytical expressions for the upper bound on their expected

positioning uncertainty were provided by using relative

position measurement graph (RPMG).

III. THE PROPOSED COOPERATIVE MULTI-ROBOT FOR

CARRYING TARGETS

Several multi-robot systems have many attractive features,

but most of them have problems of which the crucial one and

how to control effectively a group of robots. Number of multi-

robot systems work with complex mechanical models.

Various systems have complex equipments for building

robot's body. Some robot groups have environment including

obstacles, which move with low-quality motion planning

algorithm. Some systems need the human role to recharge

robot's battery or for another task. In a multi-robot system,

robots interact with each other by a network that may be

affected with wired cables and limited bandwidth.

The Cooperative Multi-robot for Carrying Targets (CMCT)

is proposed as a combination between centralized and

distributed control. It overcomes some drawbacks founded in

the other approaches by supporting the following features:

- It works with straightforward mechanical models (model of

moving robot, model of manipulator, and model of color

camera) by using simple cosine lows.

- It detects the robot's shortest path for reaching the target

position avoiding obstacles by using a proposed path

planning algorithm.

- It minimizes robot's worked time for carrying many

boxes during day by working in parallel. That is, the

supervisor detects the required variables in the same time

another robots work with previous variables.

- It prevents the collision between robots during moving.

- It provides a good interaction between the team of robot

using ad hoc wireless network.

A. Working Space Environment

Working space is a store with area 100 100 m

2

. Objects

are boxes. Load threshold is measured according to the size of

the motor of robot. Robot's worked time threshold is the

threshold of battery used (6 hours) as in [12]. Traveled

distance threshold is greater than twice the work width of the

robot, or less than approximately ten times the work width of

the robot, according to the velocity of the robot [13].

B. Components of the Proposed System

The proposed system includes three robots as shown in Fig.

1. First and second robots are Worker 1 and Worker 2. Each

consists of arm (2-links as serial manipulator), hand, four

conventional wheels (rolling robot), platform, timer to

calculate the total worked time and counter to calculate the

total traveled distance. The third robot (Supervisor) consists of

rolling robot with four conventional wheels and two color

cameras to detect around. The three robots share in two

charging stations. Ad hoc wireless network is used to

communicate between the three robots.

Worker1 Worker2

Supervisor

Wireless

Network

Maps the environment, controls

the coordinates positions,

checks the charged battery level,

and finds path of moving robots.

Carry the boxes

Charging

Station 1

Charging

Station 2

Fig. 1 The components of the proposed CMCT work space

C. Assistance Mechanisms

Assistance Mechanisms use in CMCT algorithm are; self

recharging mechanism, static path planning algorithm for

navigation, computer vision based positioning system,

dynamic collision avoidance algorithm, and NS_2 network

simulator. Each item is explained in the following:

Self Recharging Mechanism:

Self recharging mechanism is designed to determine the

recharge time for each robot. Typically charging a robots

battery is a manual process that requires the administrator to

physically take the robot to a charging station [14]. The

proposed CMCT supports automatic recharging of robot

battery when it becomes low. Fig. 2 shows the charging

station. It has an AC power plug and an infrared (IR) beacon.

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

862

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

The robot's IR sensors perform the beacon detection. When

the capacity of the robots battery drops below a certain

threshold, it starts looking for any beacon signal emitted by a

docking station. It uses this signal to home into the docking

station and recharge its battery. A timer is used to compute the

total work time of each robot. If this time reaches a certain

threshold, the robot seeks for a charging station to recharge its

battery.

Robot

IR

sensors

Charging Station

IR

beacon

Fig. 2 Self charging station

For sharing a charging station, the robots need to share the

station efficiently as shown in Fig. 3. If the robot reaches the

station while there is another robot recharging its battery, it

will take one of two decisions. First, it waits few seconds.

Second, it seeks another charging station.

Charging station occupied

Seek another station

Wait until another

robot finish

Robot

Seek the charging station

when its battery low

Restart the robot's loop

After

few

seconds

Decision 2 Decision1

Fig. 3 Sharing a charging station

Static Path Planning Algorithm for Navigation:

The aim of path planning is to decide which route to take

[15]. The supervisor robot needs to compute the path for each

robot with static environment. Then it sends the corresponding

movement commands to the robots at the proper moment. The

supervisor takes the current position and the target destination

of a robot, then checks if there is a direct path between the

worker robot and the box. If such paths do not exist, the

algorithm identifies the obstacle closest to the source position

and detects the best moving path for robots. There are

different algorithms for solving the path planning problem

based on an environment map for mobile robots [16] such as

Roadmap algorithm, Cell Decomposition algorithm, and

Potential Field algorithm. A* is a well known algorithm for

finding path planning for mobile robots. In this paper, a

comparison between A* algorithm and the proposed CMCT

algorithm is carried out.

A Computer Vision Based Positioning System:

A Computer vision based positioning system tracks the

position of each robot for collision free robot movement [17].

The robot positioning system in CMCT is necessary to

maintain the location and orientation information of each

robot. One simple way to track the position of a mobile robot

is to use its static path planning with respect to a fixed

direction, send position coordinates to a mobile robot from

supervisor, and process by mechanical model to get results.

Dynamic Collision Avoidance Algorithm:

If any two robots are closer than a threshold distance,

including when they already collide with each other, the

supervisor stops both of them, computes a new path for each

of them if necessary, and moves them on their new path.

NS_2 Network Simulator:

NS_2 is a discrete event simulator written in C++. It

supports TCP, routing algorithm, queuing algorithms, and

multicast protocols over wired and wireless (local and

satellite) networks. It is freely distributed and all source code

is available [18]. Wireless NS_2 protocols support ad hoc

routing and mobile IP and is used in wireless and satellite

networking. The simulator (NS), the network animator (nam),

visualizing ns output, and nam editor are the components of

NS_2.

C. The Proposed CMCT Algorithm

The flow chart of the proposed CMCT algorithm is shown

in Fig. 4. The following considerations are assumed: TDIS(i)

is the robot's worked time, where i is the robot number (i= 1,2

or 3). TDS is the robot's worked time threshold. DIS is the

distance between two robots. Ds is the nearest distance

between two robots to avoid collision. B is a box. The

Coordinates of the initial position of a box are Xs and Ys. The

coordinates of the target position of a box are Xf and Yf. NoB

is the number of boxes in the store. N is the variable for

determining the number of boxes carried. W is the Box's

weight. Ws is the load threshold. R1, R2 are worker robots,

and R3 is the supervisor robot.

In the work space environment:

1) First the operator checks the supervisor's battery level. If

the level is high (not reached battery threshold value),

then it begins the work. Else (the supervisor's battery

level is low), then it automatically seeks the nearest

charging station and recharges its battery.

2) The supervisor measures the battery level for the two

worker robots.

If the battery level for any robot is low (it is equal to

the battery threshold value), then the robot with the

low battery automatically seeks the nearest charging

station by applying the self recharging mechanism.

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

863

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

Else (Each of the batteries of the two robots is less

than battery threshold value), the supervisor does the

following steps:

3) It detects worker robots positions, initial boxs position,

target boxs position and obstacles positions by making

map of the environment.

4) It measures the weight of the box by a load sensor

connected at the end effectors of the robot arm.

If the weight of the box is smaller than or equal to a

load threshold, it will be carried by one worker and

the supervisor detects another boxs variables to the

other worker to carry it.

Else (it's weight larger than load threshold), it will be

carried by the two workers.

5) If the supervisor's battery level becomes low, it

automatically seeks the nearest charging station,

recharges its battery, and repeats the Step 1.

Yes

No

Yes No

Yes

No Yes

STOP

Read

Xs,Xf,Ys,Yf,W

If

W<=WS

- Determine R1 and R2 path

- R1and R2 carry box to Xf, Yf

- Determine R1 or R2 path

- R1or R2 carries box to Xf, Yf

If

N<NO

If TDIS(1)

.OR.

TDIS(2)=TDS

Automatically seek the

nearest charging station

and recharge its battery

No

N=N+1

START

Read TDIS (3),TDS, NOB

N=0

If

TDIS(3)

=TDS

Read TDIS (1),

TDIS (2)

Automatically seeks

the nearest charging

station and recharge

its battery

Read

TDIS (3)

Fig. 4 The flow chart of the proposed CMCT algorithm

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

864

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

D. Kinematics Models Mechanical

This section presents the kinematics models mechanical for

moving robot, manipulator, and color camera.

Moving robot: Aanalysis one wheel

It is assumed that 1: Angle for first start position with

origin (wheel), 2: Angle for first stop position with origin

(wheel), (X1,Y1): Start coordination, (X2,Y2): Target

coordination. Ex: Error signal for X, Ey: Error signal for Y,

Cx: Moving Step for X, Cy: Moving Step for Y, X

m

: in-

between point from (X1, X2) and Y

m

: in-between point from

(Y1, Y2). The Position coordinate of one wheel for moving

robot is shown in Fig. 5.

X1

Y1

? 1

Initial

X2

Y2

Target

Y

X

Up

-Y

Down

+Y

Right

+X

Left

-X

? 2

Fig. 5 Position coordinates of one wheel for a moving robot

i. The angle for start and stop position

Tan (1)= Y1/ X1, 1= ArcTan (Y1/ X1) (1)

Tan (2)= Y2/ X2, 2= ArcTan (Y2/ X2) (2)

ii. The error signal for x and y

Ex= Abs (X2-X1), Ey= Abs (Y2-Y1) (3)

E=

2 2

Ey Ex + (4)

iii. The moving step in direction x and y

Cx =

Abs (X2 X1)

10

(5)

Cy =

Abs (Y2 Y1)

10

(6)

iv. The value of Xm, Ym for different directions

Right (+X): X

m

= X1 + Cx , Y

m

=Y1 (7)

Left (-X): X

m

= X1- Cx, Y

m

=Y1 (8)

Up (-Y): X

m

= X1, Y

m

=Y1-Cy (9)

Down (+Y): X

m

=X1, Y

m

=Y1+Cy (10)

Manipulator

The 2-links that are serial manipulator is shown in Fig. 6

[19]. The following parameters are assumed in the analysis:

1

is the angle for joint_1of manipulator.

2

is the angle for

joint_2 of manipulator.

1 =180-

2

. L

1

is the segment_1

length of manipulator. L

2

is the segment_2 length of

manipulator. X and Y are coordinates of end effector point.

2 2 2 2

1 2 1 2 2

X Y L L 2L L Cos(180 ) + = + (11)

2 2 2 2

1 2

2

1 2

X Y L L

Cos( )

2L L

+

= (12)

2 2 2 2

1 2

2

1 2

X Y L L

ArcCos

2L L

+

=

(13)

1 2 2

2 2 2 2

2

Sin( ) Sin(180 ) Sin( )

L

X Y X Y

= =

+ +

(14)

2 2

1

2 2

L Sin( ) y

ArcSin[ ] ArcTan[2 ]

x

X Y

= +

+

(15)

Fig. 6 End effectors coordinates of a manipulator

Model for two color cameras

Two color cameras making map for around environment by

using a high-level computer language (Visual Basic). Any

video capture device is automatically detected and used to

capture robot video making the robot vision system. The video

from the color camera is sent to the computer from the mobile

robot through the instruction: (VideoOCX1.start) which starts

the video communication links.

IV. PATH PLANNING ALGORITHMS

This section presents the proposed CMCT path planning

(CMCT-PP) algorithm and introduces a comparison between

the proposed algorithm and the A* algorithm.

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

865

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

A. A* Algorithm

A* is a best-first, graph search algorithm that finds the

least-cost path from a given initial node to one goal node (out

of one or more possible goals) [9]. The algorithm traverses

various paths from start to goal. For each node x traversed, it

maintains 3 values:

g(x): the actual shortest distance traveled from the initial

node to the current node.

h(x): the estimated (or "heuristic") distance from the

current node to the goal node.

f(x): the sum of g(x) and h(x).

The Algorithm

Starting with the initial node;

1. The algorithm maintains a priority queue of nodes to be

traversed, known as the open set.

2. The lower f(x) for a given node x, the higher its priority.

3. At each step of the algorithm, the node with the lowest f(x)

value is removed from the queue, the f and h values of its

neighbors are updated accordingly.

4. These neighbors are added to the queue.

5. The algorithm continues until the goal node has a lower f

value than any node in the queue (or until the queue is

empty).

B. The Proposed CMCT Path Planning Algorithm

In the proposed CMCT-PP algorithm, the work space area

is assumed 100100 m

2

. To determine the shortest path for

moving robot from source to target position, the work space is

divided into cells each cell has area (1010 m

2

). The

following parameters are assumed: Xs and Ys are the initial

position coordinates for moving. Xf and Yf are the target

position coordinates for moving. Xm1 is the new X position

for path1, Ym1 is the new Y position for Path 1, Xm2 is the

new X position for Path 2, Ym2 is the new Y position for Path

2, Xm3 is the new X position for Path 3 and Ym3 is the new

Y position for Path 3. Cx is the X moving step and Cy is the

Y moving step. D1 is the length of Path 1, D2 is the length of

Path 2 and D3 is the length of Path 3. Dt is the total distance.

The proposed CMCT-PP algorithm is shown in Fig. 7.

T

P1

P2 P3

D1

D2

P1: Path1

P2: Path2

P3:Path3

S: initial position

T: Target position

Fig. 7 The proposed CMCT-PP algorithm

The Algorithm

1. The Supervisor reads the coordinates, Xs, Ys, Xf, Yf, D1,

D2.

2. Cx =

Abs (Xs Xf )

10

, Cy =

Abs (Ys Yf )

10

.

3. Dt =0.

4. Xm1= Xm2= Xm3= Xs,

Ym1= Ym2= Ym3= Ys.

5. Check the available paths (Path 1, Path 2, Path 3) by the

following steps

Path 1: Xm1= Xm1+Cx, Ym1=Ym1

D1=

2 2

(Xf Xm1 Cx) (Yf Ym1) +

Path 2: Xm2= Xm2+Cx, Ym2=Ym2+Cy.

D2 =

2 2

(Xf Xm2 Cx) (Yf Ym2 Cy) +

Path 3 Xm3= Xm3, Ym3=Ym3+Cy.

D3 =

2 2

(Xf Xm3) (Yf Ym3 Cy) +

If (D1>D2.and.D1>D3) Then draw line between

(Xs,Ys) and (Xm1,Ym1), Xs=Xm1, Ys=Xm1,

Dt=Dt+D1, Go to 6.

Else if (D2>D1.and.D2>D3) Then draw line between

(Xs,Ys) and (Xm2,Ym2), Xs=Xm2, Ys=Xm2,

Dt=Dt+D2, Go to 6.

Else draw line between (Xs,Ys) and (Xm3,Ym3),

Xs=Xm3, Ys=Xm3, Dt=Dt+D3.

6. If ( (Xs=Xf) .And. (Ys=Yf)) Then print Dt, go to 7.

Else Go to 4.

7. Stop.

V. SIMULATION RESULTS

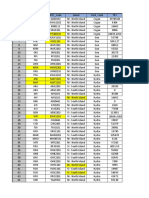

A. The Proposed CMCT-PP Algorithm

The comparison between CMCT-PP and A* algorithms is

centered around the following criteria: the total time required

for carried out a certain task, the distance that expresses the

path length to reach the required position, the accuracy of

position and the processing needs. Figs. 8-11 present the

comparison between CMCT-PP and A* algorithms.

Fig. 8 shows the required time versus the number of

performed tasks in the case of the absence of obstacles. The

time increases with the increase of the number of tasks. It is

clear that, the proposed algorithm achieves the required tasks

at lower time than the A* algorithm. The time saving in the

CMCT-PP algorithm reaches about 100% (At 4 tasks, the time

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

866

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

of the proposed algorithm is 7 s as opposed to 14 s in the A*

algorithm). Fig. 9 presents the total distance of the two

algorithms against the number of performed tasks without

obstacles. It is shown that, the CMCT-PP algorithm find

shorter path to reach the required positions than the A*

algorithm. The distance of the CMCT-PP is about half the

distance of the A* algorithm.

Figs. 10 and 11 present the time and the distance of the two

algorithms in the case of the presence of obstacles. They

confirm the above results. It is shown that, both the time and

the distance of the two algorithms increases in the case of

obstacles.

Another comparison metrics such as complexity and

accuracy prove the efficiency of the proposed CMCT-PP

algorithm. The CMCT-PP algorithm is simpler than A* since

it doesn't need memory. A* algorithm needs memory terms to

save open list and close list. The CMCT-PP algorithm can

obtain the accurate total distance while A* algorithm does not

guarantee the accurate total distance.

B. The Proposed CMCT Algorithm

The comparison between the proposed CMCT algorithm

and the CMOMMT algorithm [2] is presented. The

CMOMMT algorithm works with variable number of robots

and speeds and without supervisor. The CMCT algorithm

works with fixed number of robots (three robots), fixed speed

for the two worker robots and the supervisor. In the

simulation, the variable number of robots, speeds, and

obstacles in both algorithms are ignored (i.e., the same

environment is assumed for the two algorithms).

Fig. 12 shows time versus distance in the proposed CMCT

and the CMOMMT algorithms using the CMCT-PP

algorithm. It is clear that, CMCT saves more time than

CMOMMT since that CMOMMT is a distributive control

algorithm, while the robots in CMCT work in parallel. Thus,

while the two worker robots move toward their targets, the

supervisor robot detects the new variables for the new tasks.

Fig. 13 presents the comparison between CMCT and

CMOMMT in the case of using A* path planning algorithm. It

is shown that, the time of the two algorithms increase than in

the case of using CMCT-PP. The proposed CMCT always

achieves better time than the CMOMMT algorithm.

VI. CONCLUSION

This paper studies the performance of cooperative multi-

robot team, focusing on the mobile robot navigations. Ad Hoc

wireless network is used for communication between a group

of robots over the range of a store. In this paper, a new

algorithm called CMCT is proposed. It is based on self

recharging mechanism. An accomplished path planning

algorithm (CMCT-PP) is also proposed for use with the

CMCT algorithm. The comparison between CMCT-PP

algorithm and the well known path planning algorithm (A*)

proves the efficiency of the proposed algorithm. It is shown

that, CMCT-PP achieves a 100% improvement of time and

distance than A*. In addition it has less processing needs and

provides more accurate total distance. Another comparison

between CMCT and the already existed cooperative algorithm

(CMOMMT) shows that, CMCT improves the performance of

the cooperative multi-robot team.

0

2

4

6

8

10

12

14

16

1 2 3 4

Number of Tasks

T

i

m

e

(

s

)

CMCT-PP

A*

Fig. 8 Time versus the number of performed tasks in both A* and

CMCT-PP algorithms without obstacles

0

10

20

30

40

50

60

70

80

1 2 3 4

Number of Tasks

D

i

s

t

a

n

c

e

(

m

)

CMCT-PP

A*

Fig. 9 Distance against the number of performed tasks in A* and

CMCT-PP algorithms without obstacles

0

5

10

15

20

25

1 2 3 4

Number of Tasks

T

i

m

e

(

s

)

CMCT-PP

A*

Fig. 10 Time versus the number of performed tasks in both A* and

CMCT-PP algorithms with obstacles

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

867

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

0

20

40

60

80

100

120

1 2 3 4

Number of Tasks

D

i

s

t

a

n

c

e

(

m

)

CMCT-PP

A*

Fig. 11 Distance against the number of performed tasks in A* and

CMCT-PP algorithms with obstacles

0

2

4

6

8

10

12

14

16

18

10 20 30 50 70

Di stance (m)

T

i

m

e

(

s

)

CMCT

CMOMMT

Fig. 12 Time versus distance in the CMCT and the CMOMMT

algorithms using CMCT-PP algorithm

0

5

10

15

20

25

30

1 2 3 4 5

Di stance (m)

T

i

m

e

(

s

)

CMCT

CMOMMT

Fig. 13 Time versus distance in the CMCT and the CMOMMT

algorithms using A* path planning algorithm

REFERENCES

[1] T. Zheng, R. Li, W. Guo, and L. Yang, Multi-robot Cooperative Task

Processing in Great Environment, in Proc. of IEEE Conference on

Robotics, Automation and Mechatronics, pp. 1113-1117, September

2008.

[2] L. Parker, "Distributed algorithms for multi-robot observation of

multiple moving targets," Autonomous Robots Journal, vol.12, pp. 231

255, 2002.

[3] Larp Euron, "Ad-hoc network communication infrastructure for multi-

robot systems in disaster scenarios," in Proc. of Robotics for Risky

Intervention and Environmental Surveillance - Benicssim, 2008.

[4] M. J. Johnson, K. Intlekofer, H. Jung, and J. M. Bradshaw, et. al, "

Coordinated operations in mixed teams of humans and robots,"

International Journal of Robotics Research 2, pp. 431-447, no. 5,6, 2006.

[5] J. Wang "Investigation of a mobile manipulator over wired/wireless

control System, in Proc of SkimaInternational conference on software

knowledge information management and applications, 2006.

[6] T. Chiueh, R. Krishnan, P. De, and J. Chiang, "A networked robot

system for wireless network emulation", in Proc. of the 4th International

Conference on Mobile Systems, Applications, and Services, Uppsala,

Sweden, pp. 124-137, 2006.

[7] A. Birk, and C. Condea "Mobile robot communication without the

drawbacks of wireless networking" Springer, vol. 4020, pp. 585 592,

2006.

[8] A. R. Wagner, and R.C. Arkin, Internalized plans for communication

sensitive robot team behaviors, in Proc. of. IEEE Int. Conference on

Intelligent Robotics and Systems, pp 2480-2487, 2003.

[9] A. Botea, M. Mller, and J. Schaeffer "Near optimal hierarchical path-

finding", Journal of Game Development, vol. 1, issue 1, pp. 7-28, 2004.

[10] M. Fukunari, S. Rajanna, R. J. Gaskins, and M. E. Sparrow "Data-based

node penalties in a path-finding algorithm in an automated material

handling system, in Proc. of the 34th conference on Winter simulation,

California, pp1383-1386, 2002.

[11] A. I. Mourikis, and S. I. Roumeliotis, "Performance analysis of

Multirobot cooperative localization," IEEE Transactions on Robotics,

vol. 22, issue 4, pp. 666-681, 2006.

[12] S. Oh., A. Zelinsky, and K. Taylor, "Autonomous battery recharging for

indoor mobile robots," in Proc. of Australian Conference on Robotics

and Automation (ACRA 2000), pp. 1-6, 2000.

[13] J. L. Jones, and P. R. Mass "Method and system for multi mode coverage

for an autonomous robot," Citation of provisional application, Jones, US

Patent 7, Google Patents, 2007.

[14] K. kouzoubov, and D. Austin, "Autonomous recharging for mobile

robotics," in Proc. of Australasian Conference on robotics and

automation Auckland, pp. 27-29, 2002.

[15] J. Chen., and L. Ren, "Path planning protocol for collaborative multi-

robot systems " in Proc. of IEEE International Symposium,

Computational Intelligence in Robotics and Automation, pp.721726,

June 2005.

[16] B. Graf, J. Wandosell, and C. Schaeffer, "Flexible path planning for

nonholonomic mobile robots," in Proc. of the Fourth European

Workshop on Advanced Mobile Robots, 2001.

[17] S. Jantz, Keith, and L Doty, "Visual perception based behaviors for a

small autonomous mobile robot," in Proc. of Florida Conference on

Recent Advances in Robotics, Florida, 2000.

[18] http://www.isi.edu/nsnam/ns,10/2008.

[19] Y. Yong, and G. Kamal, "Puma 560 software client's report", Advanced

Robotics , vol. 14, issue 22, no. 6, pp. 515-536, 2000

.

World Academy of Science, Engineering and Technology

Vol:3 2009-06-20

868

I

n

t

e

r

n

a

t

i

o

n

a

l

S

c

i

e

n

c

e

I

n

d

e

x

V

o

l

:

3

,

N

o

:

6

,

2

0

0

9

w

a

s

e

t

.

o

r

g

/

P

u

b

l

i

c

a

t

i

o

n

/

2

7

1

8

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Daily SunnahDocument234 paginiDaily SunnahJafar SadiqÎncă nu există evaluări

- Synchronous Buck Converter LAB-2: Power Electronics (ECEN405)Document5 paginiSynchronous Buck Converter LAB-2: Power Electronics (ECEN405)Jafar SadiqÎncă nu există evaluări

- OR SS3 20190805 - OffersDocument3 paginiOR SS3 20190805 - OffersJafar SadiqÎncă nu există evaluări

- SOP - Essay GuidelinesDocument2 paginiSOP - Essay GuidelinesJafar SadiqÎncă nu există evaluări

- Risk 1: Inherent Schedule Flaws: The Top Five Software Project RisksDocument4 paginiRisk 1: Inherent Schedule Flaws: The Top Five Software Project RisksJafar Sadiq100% (1)

- Campus To Corporate - Issue 3 - Batch 2Document16 paginiCampus To Corporate - Issue 3 - Batch 2Jafar SadiqÎncă nu există evaluări

- NI-North Island Site DataDocument60 paginiNI-North Island Site DataJafar SadiqÎncă nu există evaluări

- Design a PWM Wave Generator and Vary the Duty CycleDocument7 paginiDesign a PWM Wave Generator and Vary the Duty CycleJafar SadiqÎncă nu există evaluări

- Abcde Fghiÿ Bfihf: FFQRRST Z (Q/) ) Z (Q/) )Document3 paginiAbcde Fghiÿ Bfihf: FFQRRST Z (Q/) ) Z (Q/) )Jafar SadiqÎncă nu există evaluări

- Assignment-1: Power System AnalysisDocument6 paginiAssignment-1: Power System AnalysisJafar SadiqÎncă nu există evaluări

- SI NZ Power Station DataDocument490 paginiSI NZ Power Station DataJafar SadiqÎncă nu există evaluări

- SI NZ Power Station DataDocument490 paginiSI NZ Power Station DataJafar SadiqÎncă nu există evaluări

- Campus To Corporate - Issue 2 Batch 2 PDFDocument6 paginiCampus To Corporate - Issue 2 Batch 2 PDFJafar SadiqÎncă nu există evaluări

- Feerule GudgaonDocument55 paginiFeerule GudgaonJafar SadiqÎncă nu există evaluări

- AP Transco Sub Engineer Question Paper SET-ADocument16 paginiAP Transco Sub Engineer Question Paper SET-AVanitha Pillai KÎncă nu există evaluări

- Campus To Corporate - Issue 1 Batch 2Document5 paginiCampus To Corporate - Issue 1 Batch 2Jafar SadiqÎncă nu există evaluări

- Bowling Skills 2011 PDFDocument27 paginiBowling Skills 2011 PDFJafar SadiqÎncă nu există evaluări

- Campus To Corporate - Issue 2 Batch 2 PDFDocument6 paginiCampus To Corporate - Issue 2 Batch 2 PDFJafar SadiqÎncă nu există evaluări

- Direct Recording: B.Vineeth. B130942EEDocument5 paginiDirect Recording: B.Vineeth. B130942EEJafar SadiqÎncă nu există evaluări

- Abstract PDFDocument1 paginăAbstract PDFJafar SadiqÎncă nu există evaluări

- Welcome: Lets Gear Up For An Amazing Project !!!!!!Document13 paginiWelcome: Lets Gear Up For An Amazing Project !!!!!!Jafar SadiqÎncă nu există evaluări

- OperationalDocument4 paginiOperationalJafar SadiqÎncă nu există evaluări

- Lesson7 SteamPowerPlantDocument33 paginiLesson7 SteamPowerPlantJafar SadiqÎncă nu există evaluări

- Department of Electronics and CommunicationDocument1 paginăDepartment of Electronics and CommunicationJafar SadiqÎncă nu există evaluări

- Cocubes Exambrochure PDFDocument4 paginiCocubes Exambrochure PDFJafar SadiqÎncă nu există evaluări

- Speed Control of DC Motor Using DTMFDocument1 paginăSpeed Control of DC Motor Using DTMFJafar SadiqÎncă nu există evaluări

- 15 Jun 1996 Male GEN No: Communication Address GATE Exam DetailsDocument1 pagină15 Jun 1996 Male GEN No: Communication Address GATE Exam DetailsJafar SadiqÎncă nu există evaluări

- Repor Mid Semt PDFDocument34 paginiRepor Mid Semt PDFJafar SadiqÎncă nu există evaluări

- Business Analyst Interview Questions and Answers PDFDocument5 paginiBusiness Analyst Interview Questions and Answers PDFPraveen GY75% (4)

- Section I - Switchgear & Substation ApparatusDocument194 paginiSection I - Switchgear & Substation Apparatushardeep08Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Robot Arm Tutorial GuideDocument16 paginiRobot Arm Tutorial Guidejulfo05100% (1)

- Motion Planning For Smooth Pickup of Moving ObjectsDocument8 paginiMotion Planning For Smooth Pickup of Moving ObjectsVatsalÎncă nu există evaluări

- Model-Based and Machine Learning-Based High-Level Controller For Autonomous Vehicle Navigation: Lane Centering and Obstacles AvoidanceDocument14 paginiModel-Based and Machine Learning-Based High-Level Controller For Autonomous Vehicle Navigation: Lane Centering and Obstacles AvoidanceIAES International Journal of Robotics and AutomationÎncă nu există evaluări

- Mobile Robot Path Planning in Dynamic Environments Through Globally Guided Reinforcement LearningDocument8 paginiMobile Robot Path Planning in Dynamic Environments Through Globally Guided Reinforcement LearningVarun AgarwalÎncă nu există evaluări

- SlamDocument11 paginiSlamulisesÎncă nu există evaluări

- Mobile Robot Navigation and Obstacle AvoidanceDocument13 paginiMobile Robot Navigation and Obstacle AvoidanceSummer TriangleÎncă nu există evaluări

- C4B - Mobile Robotics: Paul Michael NewmanDocument18 paginiC4B - Mobile Robotics: Paul Michael NewmanMaría De Los Ángeles Pérez GómezÎncă nu există evaluări

- Low-Altitude Navigation For Multi-Rotor Drones in Urban AreasDocument16 paginiLow-Altitude Navigation For Multi-Rotor Drones in Urban AreasAdeeba AliÎncă nu există evaluări

- Full body obstacle collision avoidance methodDocument11 paginiFull body obstacle collision avoidance methodArsh UppalÎncă nu există evaluări

- Versatile Robot Simulation FrameworkDocument6 paginiVersatile Robot Simulation FrameworkRODNEY KEVIN CHACHA PASTASÎncă nu există evaluări

- Thesis BibiliographyDocument6 paginiThesis BibiliographySozharajan BÎncă nu există evaluări

- Robot Arm TutorialDocument16 paginiRobot Arm TutorialFarshad yazdi100% (4)

- Mscthesis AmirAlJawahiri 4225074Document86 paginiMscthesis AmirAlJawahiri 4225074Veerabhadrayya KatapurmathÎncă nu există evaluări

- A ROSPlan-based Multi-Robot Navigation SystemDocument6 paginiA ROSPlan-based Multi-Robot Navigation SystemDannilo MirandaÎncă nu există evaluări

- Snake Robots Full ReportDocument13 paginiSnake Robots Full ReportTreesa ArchnanaÎncă nu există evaluări

- A Behavioral Planning Framework For Autonomous DrivingDocument7 paginiA Behavioral Planning Framework For Autonomous DrivingAnand PrakashÎncă nu există evaluări

- Iacopo Gentilini's Tangent Bug Path Planning AlgorithmDocument4 paginiIacopo Gentilini's Tangent Bug Path Planning AlgorithmervauluÎncă nu există evaluări

- Dynamic resource reservation prevents collisions and deadlocks for multiple AGVsDocument12 paginiDynamic resource reservation prevents collisions and deadlocks for multiple AGVsIchiware StoreÎncă nu există evaluări

- Sanjeev Sharma CVDocument2 paginiSanjeev Sharma CVGabriel Reid100% (1)

- Mrinal Kalakrishnan: CHOMP Motion PlannerDocument15 paginiMrinal Kalakrishnan: CHOMP Motion PlannerWillow GarageÎncă nu există evaluări

- Simulation of AGVs in MATLABDocument67 paginiSimulation of AGVs in MATLABChâuTrungTínÎncă nu există evaluări

- Navigational Strategies of Mobile Robots: A Review: Dayal R. ParhiDocument21 paginiNavigational Strategies of Mobile Robots: A Review: Dayal R. ParhiSMITH CAMILO QUEVEDOÎncă nu există evaluări

- A Survey On Vision Based UAV NavigationDocument13 paginiA Survey On Vision Based UAV NavigationchandrakanthatsÎncă nu există evaluări

- Line-of-Sight Guidance For Path Following of Marine VehiclesDocument29 paginiLine-of-Sight Guidance For Path Following of Marine Vehiclesartist-bossÎncă nu există evaluări

- Research About RoboticsDocument3 paginiResearch About RoboticsAhmed MalikÎncă nu există evaluări

- Udacity - Flying NDDocument6 paginiUdacity - Flying NDRishi BhalodiaÎncă nu există evaluări

- Bachelor Thesis: Coverage and Partitioning Techniques of A Multi-Obstacle EnvironmentDocument76 paginiBachelor Thesis: Coverage and Partitioning Techniques of A Multi-Obstacle Environmentdco123Încă nu există evaluări

- Portfolio: Jaineel Ashok Desai M.S. in Mechanical Engineering, USCDocument32 paginiPortfolio: Jaineel Ashok Desai M.S. in Mechanical Engineering, USCJaineel DesaiÎncă nu există evaluări

- Path Planning and Trajectory Planning Algorithms: A General OverviewDocument33 paginiPath Planning and Trajectory Planning Algorithms: A General OverviewKEEP CALM studiosÎncă nu există evaluări