Documente Academic

Documente Profesional

Documente Cultură

QC Tower Erection

Încărcat de

Anonymous ExWAN2xjFJDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QC Tower Erection

Încărcat de

Anonymous ExWAN2xjFJDrepturi de autor:

Formate disponibile

1 Tower Erection 1. Materials 1.

Visual checking Structural Drawing / Approved 100% of item Surveillance Review Received Cum Damage

i. Bottom Assembling Tower schedule/BOM & members at stores Report (RCDR) / Factory

ii. Top Assembling As per Tech. Spec. Inspection Report (FAT)

2. Cleanliness & Galvanizing S-OHL-T (Rev 1,2005) Random Checking

With Elcometer Surveillance Review

2.Erection of 1.Sequence of As per Approved Drawings 100% at each Surveillance Review Approved tower Schedule.

Towers Assembles erection S-OHL-T (Rev 1,2005) location by SE Check list for erection of

Technical Specifications/ each location

Method statement

2.Check for completeness As per Approved Drawings 100% at each Surveillance Review Check list for erection/

Technical Specifications location by SE/ Tower Check report

Foremen of each location

3.Tightening of nuts and As per Approved Drawings 100% at each Surveillance Review Check list for erection

bolts Technical Specifications location by SE/

Foremen

As per Approved Drawings 100% at each Surveillance Review Statistical checking for

Technical Specifications location by SE/ tightening of bolts

Foremen/Surveyor

3. Tower footing resistance TFR at locations As ADWEA Tech. Specifications 100% at each Surveillance Review Check list for Tower Footing

(TFR) S-EARTH-GROUND location by SE Resistance of each location

( REV. 3- 2005)

Legend :

Witness: Representative from to Client/Consultant as well as person's from third party / KEC in whose presence inspection and test carried out in Construction/ Production period to determine and prove that the product is

satisfactory and acceptable for further Course.

Review:Verification of Documents and procedures by Client /Consultant/KEC to ascertain whether the information given is correct and worth acceptable for approval.

Surveillance:During Construction/ Production period Client/Consultant as well as person's from third party / KEC need to check the measurement/ Quantum of work to allow further Course.

PM-Project Manager, SE-Site Engineer

Approved By-

Project Manager

Ramesh Babu

CHECK/TESTING

REF.DOCUMENTS STAGE WISE INSPECTION

SUB-ACTIVITIES (ITEMS

TO BE CHECKED)

DOCUMENT

SHEET REV.

SR.

NO.

QUALITY CONTROL

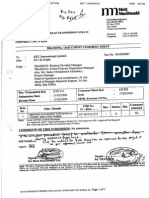

INSPECTION TEST PLAN FOR TOWER ERECTION

SHEET NUMBER

ISSUE NUMBER

DATE

BY M/s KEC

BY M/s

LAHMEYER

BY M/s

TRANSCO

QC RECORDS

CONTRACT NO. N- 6445:- 400kV OHL CONNECTION TO NEW 400/132/33 KV AJMAN GRID STATION

DESCRIPTION OF

ACTIVITY

0

12.08.2010

Review of

Inspection and Test

reports furnished

by the supplier

REMARK

1 OF 1

CONTRACT NO. N- 6445:- 400kV OHL CONNECTION TO NEW 400/132/33 KV AJMAN GRID STATION

KEC/QC/TE/766

0

S.No Observation

Setting period of foundation is allowed for at least 14 days

as per Spec. Back filling is O.K

1 Yes/No

CHECK LIST FOR TOWER ERECTION

Name of the Line : Location No:

Approved Drg DTS No: Drg No :

Date : Type Of Tower :

Item Checked Result

2

All tested tools, plants and safety equipment are available at

site and in working condition

Yes/No

Shutdown of Power Line, if required, is arranged

Client Consultant Contractor

Yes/No 4

Required no of safety Helmets, Safety Belts & Safety Shoes

are being used.

Yes/No 5

All Tower members, Nuts/Bolts are available at site without

any damage, bent or rusting

Yes/No 3

First section is completely fitted with all bracing members

and all plane diagonals are placed in proper position.

Yes/No 6

All Nuts/Bolts, Flat/Spring washers are provided as per

approved drawings.

Yes/No 7

Subsequent section are erected, only after ensuring that

previous section is erected completely with all bracing

members.

Yes/No 9

Any undue stress, bending or damage of member during

erection noticed.

Yes/No 10

Any filling of holes or cutting of members during erection

observed

Yes/No 11

Any heavy hammering of bolt casuing damage of threads

noticed.

Yes/No 12

Tightening is done progressively from top to bottom +

Tightness checked by torque wrench.

Yes/No 13

All bolts at the same level are tightened as per Specification Yes/No 15

Slipping/running over Nuts/Bolts are replaced by new ones. 16

8

All horizontal Bolt heads are facing inside and vertical bolt

heads are facing upwards

Yes/No

Details of missing member , nut bolts etc 17

Yes/No

Threaded portion of bolts projcected out side of nut is not

less than 3mm

14

LAHMEYER

INTERNATIONAL

QC Format-8 Page 3 of 4

Ohm

KEC TRANSCO

Client Representative Contractor Representative

Name

Signature

Date

Consultant Representative

Name

Signature

Date

Signature

Name

Date

Lahmeyer International

Yes/No a)

Yes/No 18

Yes/No

Yes/No

b)

c)

d)

All left over holes are filled with correct size of Bolts/nuts.

All the following tower accessories are fixed as per specification/approved drawing.

Number Plate

Certificate :

Tower Accessories 19

Zinc Rich (90%) cold galvanizing paint applied over tack

welding.

Yes/No

Tower Erection is completed in all respects and footing resistance is within permissible

limits.

Tack welding is done as per specification using Standard

quality of welding rods

Danger Plate

Phase plate

Aviation signals/paints as per specification using Standard

quality of welding rods.

Tower footing resistance 22

Yes/No 20

21

Yes/No

Remarks

QC Format-8 Page 4 of 4

S-ar putea să vă placă și

- ScafoldingDocument5 paginiScafoldingMehmet ErsayınÎncă nu există evaluări

- ITP-001 Steelwork Fabrication Rev ADocument5 paginiITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Brochure A35g A40g t4f en 22 20050840 DDocument20 paginiBrochure A35g A40g t4f en 22 20050840 DRengga PratamaÎncă nu există evaluări

- Masterlist - SubstationDocument16 paginiMasterlist - SubstationIzwan ShihabuddinÎncă nu există evaluări

- 109 Substation Pre - Energization Checklist - Energization1Document10 pagini109 Substation Pre - Energization Checklist - Energization1Akhileshkumar Pandey75% (4)

- Work Method of Stringing ConductorsDocument5 paginiWork Method of Stringing ConductorsJatmiko Purwo Saputro50% (2)

- Risk Assessment Tower Erection WorkDocument4 paginiRisk Assessment Tower Erection WorkAnonymous ExWAN2xjFJ83% (6)

- Risk Assessment Tower Erection WorkDocument4 paginiRisk Assessment Tower Erection WorkAnonymous ExWAN2xjFJ83% (6)

- B777 ChecklistDocument2 paginiB777 ChecklistMarkus Schütz100% (1)

- Safety and Health Checklist For Monitoring Transmission Line Construction WorksDocument6 paginiSafety and Health Checklist For Monitoring Transmission Line Construction WorksWinstone Audi100% (3)

- Erection Tower Method StatementDocument23 paginiErection Tower Method StatementJatmiko Purwo Saputro100% (2)

- Method Statement For Transmission Line Lanco PDFDocument37 paginiMethod Statement For Transmission Line Lanco PDFAmar WadoodÎncă nu există evaluări

- Qcs 2010 Part 8.06 Metal WorksDocument10 paginiQcs 2010 Part 8.06 Metal WorksRotsapNayrbÎncă nu există evaluări

- HG Power Transmission Sdn. BHD.: Method StatementDocument6 paginiHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanÎncă nu există evaluări

- TOR For Route-Geo - Calaca-Dasma500Document48 paginiTOR For Route-Geo - Calaca-Dasma500Faty BercasioÎncă nu există evaluări

- EotDocument16 paginiEotMayuresh GoregaonkarÎncă nu există evaluări

- StringingDocument12 paginiStringingsid_3150% (2)

- Method Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneDocument14 paginiMethod Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneFAYIZÎncă nu există evaluări

- Fortune Engineering PLC Bole International Airport Expansion Project Cable Tray and Cable Supporting System Installation ProposalDocument10 paginiFortune Engineering PLC Bole International Airport Expansion Project Cable Tray and Cable Supporting System Installation ProposalNova Smart Items100% (1)

- Method Statement Tower Erection - 2014Document16 paginiMethod Statement Tower Erection - 2014Nivesh Agarwal67% (3)

- Lesson 3 Extrusion Blow MoldingDocument34 paginiLesson 3 Extrusion Blow MoldingAnonymous ExWAN2xjFJÎncă nu există evaluări

- Power Grid Corporation of India Limited Construction ManagementDocument8 paginiPower Grid Corporation of India Limited Construction ManagementRahul RanjanÎncă nu există evaluări

- Ms For ShotcreteDocument12 paginiMs For ShotcreteAnonymous ExWAN2xjFJ100% (1)

- Towers ErectionDocument60 paginiTowers Erectionshoaib100% (1)

- Methodstatement and RiskAssessmentDocument13 paginiMethodstatement and RiskAssessmentAnonymous ExWAN2xjFJ100% (1)

- N-11038 - Method Statement For Cleaning, Welding and Painting of Steel Angles & Casings-OldDocument20 paginiN-11038 - Method Statement For Cleaning, Welding and Painting of Steel Angles & Casings-OldAnonymous ExWAN2xjFJÎncă nu există evaluări

- Method Statement For Erection WorksDocument7 paginiMethod Statement For Erection WorksCobbinah Mark0% (1)

- Ohl TestDocument5 paginiOhl TestAnonymous ExWAN2xjFJÎncă nu există evaluări

- Tower ErectionDocument13 paginiTower ErectionTechne PhobosÎncă nu există evaluări

- OSHAD-SF - TG - Process of Risk Management v3.0 EnglishDocument20 paginiOSHAD-SF - TG - Process of Risk Management v3.0 EnglishAnonymous ExWAN2xjFJ50% (2)

- Method of Statement and JSA For Live Line Crosssing in PXIDocument8 paginiMethod of Statement and JSA For Live Line Crosssing in PXITwin BullsÎncă nu există evaluări

- 33attachment B Technical ReportDocument52 pagini33attachment B Technical ReportAnonymous ExWAN2xjFJ0% (1)

- NSC-400-CE-3110-MOS-02-A-Method Statement For 69kV Transmission Pole ErectionDocument18 paginiNSC-400-CE-3110-MOS-02-A-Method Statement For 69kV Transmission Pole ErectionElisco Pher SalmasanÎncă nu există evaluări

- 15-II.5. Tower ErectionDocument8 pagini15-II.5. Tower Erectionashok10577100% (3)

- Safety Audit Checklist - Stringing ActivityDocument3 paginiSafety Audit Checklist - Stringing ActivitysAuRaBhÎncă nu există evaluări

- QA&QC Earthing SystemDocument6 paginiQA&QC Earthing SystemMuhammadZahirKhanÎncă nu există evaluări

- Tower Erection ChecklistDocument72 paginiTower Erection ChecklistPravin HireÎncă nu există evaluări

- Method Statement Transformer InstallationDocument2 paginiMethod Statement Transformer Installationphilipyong93% (14)

- Method Statement - Installation of Transformers and E-House Rev 01Document13 paginiMethod Statement - Installation of Transformers and E-House Rev 01amakiri Tamunoimama100% (1)

- Substation MethodologyDocument64 paginiSubstation Methodologycools_nag100% (4)

- Conductor StringingDocument0 paginiConductor Stringingoaktree2009Încă nu există evaluări

- Methodology High MastDocument12 paginiMethodology High MastAmis VenturesÎncă nu există evaluări

- Conductor Installation Manual-MegatroDocument5 paginiConductor Installation Manual-MegatromanafÎncă nu există evaluări

- Main Tools and Equipments For Tower ErectionDocument3 paginiMain Tools and Equipments For Tower ErectionFunk Macole100% (10)

- 6.method Statement Steel Erection and CladdingDocument4 pagini6.method Statement Steel Erection and Claddingشاز إياسÎncă nu există evaluări

- 01 A Tower Material 220kv Line ZebraDocument15 pagini01 A Tower Material 220kv Line ZebraVaibhav JainÎncă nu există evaluări

- FEWA WOODEN POLE and OHL PDFDocument56 paginiFEWA WOODEN POLE and OHL PDFscribdgineerÎncă nu există evaluări

- V1 001 PDFDocument20 paginiV1 001 PDFG100% (2)

- MS FoundationDocument12 paginiMS FoundationNabil MazelanÎncă nu există evaluări

- Method of Statement For Foundation of P5, P11 69kvDocument8 paginiMethod of Statement For Foundation of P5, P11 69kvTwin Bulls100% (2)

- Inspection Request Form For Post-Tensioning WorkDocument2 paginiInspection Request Form For Post-Tensioning WorkWr ArÎncă nu există evaluări

- Risk Assessment For Rectification of AwlDocument4 paginiRisk Assessment For Rectification of AwlAnonymous ExWAN2xjFJÎncă nu există evaluări

- Inspection Test PlanDocument3 paginiInspection Test Planfabin100% (3)

- Cooling Tower 3DTrasar ManualDocument90 paginiCooling Tower 3DTrasar ManualArevaLemaÎncă nu există evaluări

- POUR CARD and Foundation FormatsDocument16 paginiPOUR CARD and Foundation Formatsshanmugam.s100% (1)

- Method Statement For Cabling WorksDocument8 paginiMethod Statement For Cabling WorksAnonymous ExWAN2xjFJ100% (1)

- Template For Table of Contents of RPMS PortfolioDocument4 paginiTemplate For Table of Contents of RPMS PortfolioGener Toledo100% (4)

- Checklist For Design Basis Report For Civil & Structural WorkDocument2 paginiChecklist For Design Basis Report For Civil & Structural WorkRupesh KhandekarÎncă nu există evaluări

- Pilot Trenching MOSDocument6 paginiPilot Trenching MOSshah1980Încă nu există evaluări

- Al-Bader 13213.8KV SubstationDocument18 paginiAl-Bader 13213.8KV SubstationfarhanyazdaniÎncă nu există evaluări

- Transmission LineDocument4 paginiTransmission Linewalidlol0% (1)

- Work Method Statement For X-A T#31 To 34Document8 paginiWork Method Statement For X-A T#31 To 34Twin Bulls100% (1)

- Methodstatement of Stringing Activity Near Live AreaDocument5 paginiMethodstatement of Stringing Activity Near Live AreaSujit Kumar pahiÎncă nu există evaluări

- Humed Method Statement For Mono-Poles InstallationDocument3 paginiHumed Method Statement For Mono-Poles InstallationUtibe EkongÎncă nu există evaluări

- Pe12 3067 Doc q900 Project Hse Plan r0Document16 paginiPe12 3067 Doc q900 Project Hse Plan r0morgojoyoÎncă nu există evaluări

- Installation Method StatementDocument6 paginiInstallation Method StatementgururajÎncă nu există evaluări

- S TR Ohl Surv (Rev.0 2010)Document6 paginiS TR Ohl Surv (Rev.0 2010)bogdanÎncă nu există evaluări

- Method Statement For Installation of Cable Tray or TrunkingDocument1 paginăMethod Statement For Installation of Cable Tray or TrunkingIliyanPetrovÎncă nu există evaluări

- Form Inspection Premob - Quarterly (1) - 2Document26 paginiForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniÎncă nu există evaluări

- Erection Methodology PresentationDocument34 paginiErection Methodology PresentationCyril BayugaÎncă nu există evaluări

- Solidworks Report of Light PoleDocument12 paginiSolidworks Report of Light PoleThahir ShahÎncă nu există evaluări

- 1 Compliance Statement CABLE TRAYDocument3 pagini1 Compliance Statement CABLE TRAYvtalexÎncă nu există evaluări

- Method Statement For Cable Tray Manual Lifting and InstallationDocument5 paginiMethod Statement For Cable Tray Manual Lifting and InstallationVeronica De Jesus100% (1)

- StringingDocument5 paginiStringingsrinu240000100% (1)

- Whosit Construction Company: Letter of TransmittalDocument1 paginăWhosit Construction Company: Letter of Transmittalmarzuki0202Încă nu există evaluări

- Look Up MethodsDocument1 paginăLook Up MethodsAnonymous ExWAN2xjFJÎncă nu există evaluări

- P6-Importable Fields1Document7 paginiP6-Importable Fields1Anonymous ExWAN2xjFJÎncă nu există evaluări

- Pile Design - 2A-20 - 1 LOCDocument8 paginiPile Design - 2A-20 - 1 LOCAnonymous ExWAN2xjFJÎncă nu există evaluări

- Presentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarDocument70 paginiPresentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarAnonymous ExWAN2xjFJ100% (1)

- AC TransmissionDocument42 paginiAC TransmissionIcha MoniceÎncă nu există evaluări

- Signature Not Verified: S A M E A S 'M'Document34 paginiSignature Not Verified: S A M E A S 'M'Anonymous ExWAN2xjFJÎncă nu există evaluări

- Suspension ClampsDocument15 paginiSuspension ClampsAbhinav SinhaÎncă nu există evaluări

- Updating The Current ScheduleDocument4 paginiUpdating The Current ScheduleAnonymous ExWAN2xjFJÎncă nu există evaluări

- Construction Method StatementDocument13 paginiConstruction Method StatementAnonymous ExWAN2xjFJÎncă nu există evaluări

- Gin Pole ErectionDocument10 paginiGin Pole ErectionAnonymous ExWAN2xjFJÎncă nu există evaluări

- Reviewer NG Water UkinamDocument3 paginiReviewer NG Water UkinamMl KrishaÎncă nu există evaluări

- Resume EeeeDocument4 paginiResume EeeeWhilmark Tican MucaÎncă nu există evaluări

- Dr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inDocument4 paginiDr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inshamalac2004Încă nu există evaluări

- Poiseuille Lab ExperimentDocument7 paginiPoiseuille Lab ExperimentArjun SinghÎncă nu există evaluări

- DataDocument4 paginiDataQuế SươngÎncă nu există evaluări

- Jinko 570 Mono Facial Jkm570m-7rl4-VDocument2 paginiJinko 570 Mono Facial Jkm570m-7rl4-VShahneela AnsariÎncă nu există evaluări

- 2501 Solid Drawn Copper Tubes For General Engineering PurposesDocument8 pagini2501 Solid Drawn Copper Tubes For General Engineering PurposesKaushik SenguptaÎncă nu există evaluări

- ECSS E ST 50 03C (31july2008)Document43 paginiECSS E ST 50 03C (31july2008)jsadachiÎncă nu există evaluări

- Alexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Document5 paginiAlexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Mahmoud EltawabÎncă nu există evaluări

- Getting Started With ATV310: DangerDocument4 paginiGetting Started With ATV310: DangerAdnan Naeem MalikÎncă nu există evaluări

- Slide Akuntansi ManahemenDocument10 paginiSlide Akuntansi ManahemenHandaru Edit Sasongko0% (1)

- Electricalprep Com Transformers More 5Document16 paginiElectricalprep Com Transformers More 5gokulchandruÎncă nu există evaluări

- LIVING IN THE IT ERA (Introduction)Document9 paginiLIVING IN THE IT ERA (Introduction)johnnyboy.galvanÎncă nu există evaluări

- GautierDocument164 paginiGautierDimitar NedkovÎncă nu există evaluări

- Toshiba NB520 Compal LA-6859PDocument38 paginiToshiba NB520 Compal LA-6859Pash thonÎncă nu există evaluări

- Lynx ROMdisassemblyDocument156 paginiLynx ROMdisassemblyMark LoomisÎncă nu există evaluări

- Eurotherm 2604 PDFDocument2 paginiEurotherm 2604 PDFLorena100% (1)

- Toshiba Multi Split and Single Split Systems BrochureDocument32 paginiToshiba Multi Split and Single Split Systems Brochurethanhlong2005Încă nu există evaluări

- The Impact of Greed On Academic Medicine and Patient CareDocument5 paginiThe Impact of Greed On Academic Medicine and Patient CareBhawana Prashant AgrawalÎncă nu există evaluări

- Seguridad en Reactores de Investigación PDFDocument152 paginiSeguridad en Reactores de Investigación PDFJorge PáezÎncă nu există evaluări

- Manas Lahon: Areas of Interests EducationDocument2 paginiManas Lahon: Areas of Interests EducationmanaslahonÎncă nu există evaluări

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Document4 pagini2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensÎncă nu există evaluări

- VbeltDocument7 paginiVbeltMinaBasconÎncă nu există evaluări

- 2537 - York YCAS 690Document11 pagini2537 - York YCAS 690Md JamilÎncă nu există evaluări