Documente Academic

Documente Profesional

Documente Cultură

Reading and Adjusting Ring and Pinion Tooth Patterns

Încărcat de

Paul Roth0 evaluări0% au considerat acest document util (0 voturi)

168 vizualizări4 paginiHow to properly set up rear end gears.

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentHow to properly set up rear end gears.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

168 vizualizări4 paginiReading and Adjusting Ring and Pinion Tooth Patterns

Încărcat de

Paul RothHow to properly set up rear end gears.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

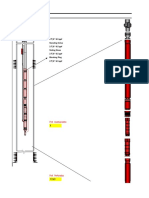

5/4/2C- Reading and Adjusting the

Ring & Pinion Tooth Pattern

The gear pattern is the final check of a

proper installation. It takes a bit of an "eye" to

read them properl y, but with just a littl e practi ce

and coaching, everyone can learn to do it.

1) Tooth Nomenclature. Terms for describing specific areas

of the gear teeth.

~ ~ I

(Outo:r rnd) Co..'\St

Face ( 1 ...... I..a. KI)

End view 01 tooLh rrom ~ I

(Out er encf)

Coast

Rank (Kuul)

Drive

Drive

(r.nnVl""ll)

Randy Sez

Reading Gear Patterns on New Gears

The only part of the pattern that helps me set pinion depth correctly is the contact position

between the face and f lank. If the pattern appears to be toward the heel or toe, I pay li ttle or

no attent ion. Whil e making adjustments, the pattern may also change toward the heel or toe,

but in most cases this aspect of the pattern ca nnot be put into an ideal posit ion. Even if it does-

n't seem intuitive or reasonable, I am onl y concerned with the pattern position between the

face and flank. I have fou nd that housing alignment and the exact posit ion of the pini on bore

during manufacture affects the heel to toe pattern and cannot be altered without machi ne

work. Bottom li ne: a contact pattern that is centered from face to fl ank a lways ind icates a cor-

rect pinion depth, even if a centered heel-to-toe pattern cannot be obta ined.

2) The first step is to cover both sides of three or four teeth on opposite sides of the ring gear with marking compound.

Randy Sez

Reading PaUerns on Used Gears

Pay the most attent ion to the pattern on

the coast side of the ring gear when set -

ling up used gearsets. Thi s area pro-

vides the best indicator because it is

usua ll y worn less. The reverse wi ll be

true on standa rd cut ring gears used on

front axles, so use the drive side for

reading the pattern.

3) Rotate the ring gear in both directions over the painted areas using the pinion yoke to spin it. Supply some drag on the ring

gear while doing it. This will help give you a nice clear pattern like this one. The pattern on the drive side is most important to

read on rear axles, but if a standard CuI ring gear is used up front read the coast side. On reverse cut gears up front, read the

drive side. Thi s is an acceptable pattern, but look at the following figures for more info on reading pa!!erns.

Acceptable Patterns

Hcd

Tur.

II ....... "

4) These are all acceptable patterns. You want to see pa!!erns that have soft edges to them. In general, pattern movements can

be summarized this way:

1) Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the toe.

The coast pattern will move deeper toward the tooth flank and slightly toward the heel.

2) Moving the pinion away from the carrier will move the drive pa!!ern toward the face and slightly to the heel. The coast side

will move toward the face and to the toe.

Pinion is Too Close

lIcd

~

~

5

5) These patterns show a pinion thai is too close to the carrier. In this case you wou ld remove shim thickness. How much thick-

ness \0 remove is a guesstimate, but it's generall y recommended to do it in .OOS-inch increments.

Pinion is Too Far Away

~ ~

Ilt'lI'J

Hocl

Hocl

~

6

6) These show patterns indicating the pinion is too far away from the carrier. In this case, you would add thickness in .005-

inch increments until the correct pattern is obtained.

S-ar putea să vă placă și

- Reading and Adjusting Ring and Pinion Tooth Patterns PDFDocument4 paginiReading and Adjusting Ring and Pinion Tooth Patterns PDFMohammed gÎncă nu există evaluări

- Sumo 3d Build LogDocument5 paginiSumo 3d Build LogbennetjeÎncă nu există evaluări

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsDe la EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsÎncă nu există evaluări

- Artcl Mortise and Tenon JointsDocument12 paginiArtcl Mortise and Tenon Jointsreader_jim100% (1)

- Easy Money Origami Ebook: Fun-to-Fold Dollar Art! (Online Video Demos)De la EverandEasy Money Origami Ebook: Fun-to-Fold Dollar Art! (Online Video Demos)Încă nu există evaluări

- Quaring A ACE AR: Drawing BelowDocument7 paginiQuaring A ACE AR: Drawing BelowHORSEAMYSAM1Încă nu există evaluări

- 5' X 8' Single Axle TrailerDocument34 pagini5' X 8' Single Axle Trailertony9waldronÎncă nu există evaluări

- Art Deco Rose Quilt Pattern: A quick & easy quilting projectDe la EverandArt Deco Rose Quilt Pattern: A quick & easy quilting projectÎncă nu există evaluări

- 2 Pier AlignmentDocument27 pagini2 Pier AlignmentemadsabriÎncă nu există evaluări

- The String Method of Wheel AlignmentDocument5 paginiThe String Method of Wheel Alignmentrb4069100% (1)

- Врезка шейки скрипкиDocument24 paginiВрезка шейки скрипкисвященник Евгений КукушкинÎncă nu există evaluări

- Dana Ring and Pinion PatternDocument2 paginiDana Ring and Pinion PatternMohammed gÎncă nu există evaluări

- Layout Guides: PART 3: Hypoid Gear TeethDocument4 paginiLayout Guides: PART 3: Hypoid Gear TeethEren KayaÎncă nu există evaluări

- Rear Axle PatternDocument4 paginiRear Axle PatternRocker-Arm PinedaÎncă nu există evaluări

- ChippendaleLeg FWW0135Document7 paginiChippendaleLeg FWW0135TAANGTAWAN007100% (1)

- Leeboard Strut InstallDocument3 paginiLeeboard Strut InstallJennifer HuffmanÎncă nu există evaluări

- Bump Steer by Longacre RacingDocument5 paginiBump Steer by Longacre RacingFotis FotopoulosÎncă nu există evaluări

- Suzuki 4x4 - Information - Bump SteerDocument5 paginiSuzuki 4x4 - Information - Bump SteerShine And MoreÎncă nu există evaluări

- SM Setup Guide and Chassis Tuning TipsDocument9 paginiSM Setup Guide and Chassis Tuning TipsrendaoÎncă nu există evaluări

- Mael FinalsDocument9 paginiMael FinalsAtzu YuÎncă nu există evaluări

- Layoutguides 0106Document5 paginiLayoutguides 0106Rashpal DhanotaÎncă nu există evaluări

- Yukon Dana Ring & Pinion InstallationDocument16 paginiYukon Dana Ring & Pinion InstallationCAP History Library100% (13)

- Voicing The Vertical PianoDocument6 paginiVoicing The Vertical PianoJoaquim MorenoÎncă nu există evaluări

- The Wheel and Tyre Bible FinalDocument10 paginiThe Wheel and Tyre Bible FinalDaksh DhingraÎncă nu există evaluări

- Tail-Vise InstructionsDocument22 paginiTail-Vise InstructionsIulian MihaiÎncă nu există evaluări

- RodSmith Build-It! KitsDocument1 paginăRodSmith Build-It! KitsCamil BwoyÎncă nu există evaluări

- A Rotary Sine Bar For The LatheDocument2 paginiA Rotary Sine Bar For The LatheTheodor EikeÎncă nu există evaluări

- Planuri GyrocopterDocument21 paginiPlanuri GyrocopterDRAGOS BILGAÎncă nu există evaluări

- DMM - 2 R19 - UNIT-4 (Ref-2)Document39 paginiDMM - 2 R19 - UNIT-4 (Ref-2)PavaniÎncă nu există evaluări

- Construction of A Longworth ChuckDocument10 paginiConstruction of A Longworth ChuckshopsmithmodÎncă nu există evaluări

- Bikes: Suspension System: Wheel Truing & Spoke Tension ....... 2Document7 paginiBikes: Suspension System: Wheel Truing & Spoke Tension ....... 2kriskee13Încă nu există evaluări

- Строгание грифа 2Document20 paginiСтрогание грифа 2священник Евгений КукушкинÎncă nu există evaluări

- BRT Flags Assembly InstructionsDocument3 paginiBRT Flags Assembly Instructionsakraba1Încă nu există evaluări

- (Backward Engine Girocopter) : Electric Pusher GyrocopterDocument25 pagini(Backward Engine Girocopter) : Electric Pusher GyrocopterИгорь МакаровÎncă nu există evaluări

- Building Model BoatsDocument12 paginiBuilding Model BoatsPegasus08100% (1)

- Shais 168 BDocument3 paginiShais 168 BIrwan OktonyrizalÎncă nu există evaluări

- B87A14A3 3rdlec - SurveyingDocument11 paginiB87A14A3 3rdlec - SurveyingJulyana IsnainiÎncă nu există evaluări

- Basic Cornhole Instructions PDFDocument8 paginiBasic Cornhole Instructions PDFpappy1865Încă nu există evaluări

- Service Information Letter: Trunnion Adjustment - Double Barrels OnlyDocument7 paginiService Information Letter: Trunnion Adjustment - Double Barrels OnlyjustincliftonÎncă nu există evaluări

- Mount A Model Aircraft Wing To A FuselageDocument7 paginiMount A Model Aircraft Wing To A FuselageDeepak Kumar BhagatÎncă nu există evaluări

- Spring Grinding Guide: Page 1 of 13Document13 paginiSpring Grinding Guide: Page 1 of 13fatinÎncă nu există evaluări

- Benchcrafted Moxon ViseDocument12 paginiBenchcrafted Moxon VisexlotoxÎncă nu există evaluări

- Bow Head RepairDocument16 paginiBow Head RepairMario ViolaÎncă nu există evaluări

- PakCanoe Assembly 2016Document6 paginiPakCanoe Assembly 2016macbeni1969Încă nu există evaluări

- Building A Sawbench PDFDocument33 paginiBuilding A Sawbench PDFОлег Одземок100% (1)

- Rebuilding A Spoked Wheel For The Royal Enfield BulletDocument18 paginiRebuilding A Spoked Wheel For The Royal Enfield BulletSrikanth Sridharan100% (1)

- Wing Installation Section VDocument36 paginiWing Installation Section Vmohamed sidkyÎncă nu există evaluări

- Building and Truing A Spoked Wheel: Before You StartDocument2 paginiBuilding and Truing A Spoked Wheel: Before You StartManuel Ćulibrk100% (1)

- ProjectDocument6 paginiProjectchandraprakash koraviÎncă nu există evaluări

- Building The Fairchild Ranger: by Paul W. LindbergDocument4 paginiBuilding The Fairchild Ranger: by Paul W. LindbergBrunno VasquesÎncă nu există evaluări

- Cargo Twin Build GuideDocument8 paginiCargo Twin Build GuidePaulo PereiraÎncă nu există evaluări

- FrogDocument10 paginiFrogbnh2Încă nu există evaluări

- Testing Lathe For AccuracyDocument4 paginiTesting Lathe For AccuracyArnieT100% (1)

- Construção Les PaulDocument6 paginiConstrução Les PaulMarcelo M. MachadoÎncă nu există evaluări

- Bicycle Pannier Bag Instructions and PatternDocument26 paginiBicycle Pannier Bag Instructions and PatternNatalia ZalazarÎncă nu există evaluări

- How To Rig Rowing BoatsDocument9 paginiHow To Rig Rowing Boatsben_elgarwhite100% (1)

- 1990 Ford Truck Emmisions ManualDocument1.365 pagini1990 Ford Truck Emmisions ManualPaul Roth100% (4)

- Rear End Girdle InstructionsDocument1 paginăRear End Girdle InstructionsPaul RothÎncă nu există evaluări

- Eula - NVIDIA Software: License of Customer UseDocument3 paginiEula - NVIDIA Software: License of Customer UseJonathan TanÎncă nu există evaluări

- EULADocument2 paginiEULAMike DixonÎncă nu există evaluări

- NEC NEAX2000 IVS Command ManualDocument473 paginiNEC NEAX2000 IVS Command ManualPaul RothÎncă nu există evaluări

- S. No. Unit: (Ch. 23 Item 7)Document4 paginiS. No. Unit: (Ch. 23 Item 7)Muhammad Abdul Wajid RaiÎncă nu există evaluări

- Jhamsikhel Apartment - Structural - ReportDocument48 paginiJhamsikhel Apartment - Structural - ReportNishan GajurelÎncă nu există evaluări

- 13 - NM Electrical Stimulation in NeurorehabilitationDocument29 pagini13 - NM Electrical Stimulation in NeurorehabilitationvladÎncă nu există evaluări

- Science 6 Week 2Document3 paginiScience 6 Week 2Ma. Jennifer MapanooÎncă nu există evaluări

- INFA3227 Esquema 01-MAR-2021Document9 paginiINFA3227 Esquema 01-MAR-2021sasgarisÎncă nu există evaluări

- IMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicDocument10 paginiIMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicatommotaÎncă nu există evaluări

- Risk Assesment-Rebar Loading & UnloadingDocument1 paginăRisk Assesment-Rebar Loading & Unloadingmainraj rajÎncă nu există evaluări

- Hydroboration Oxidation or (1R) (+) Alpha PineneDocument4 paginiHydroboration Oxidation or (1R) (+) Alpha Pinenewilso279100% (1)

- Computer Science With Java by Sumita Arora Pdf. TutorialDocument3 paginiComputer Science With Java by Sumita Arora Pdf. TutorialSouryadeep MazumderÎncă nu există evaluări

- Loadsand Load PathsDocument34 paginiLoadsand Load PathsAnonymous pD2ymRUgu0% (1)

- Fighting To Win - Tank in Australian ArmyDocument38 paginiFighting To Win - Tank in Australian ArmyLeo Purdy100% (1)

- NJ Res Chapter10Document10 paginiNJ Res Chapter10Anonymous bVFHovÎncă nu există evaluări

- Steam Turbine Centrifugal Liquid Chillers: Installation InstructionsDocument34 paginiSteam Turbine Centrifugal Liquid Chillers: Installation Instructionsh1234bÎncă nu există evaluări

- Network AssignmentDocument4 paginiNetwork AssignmentOsamah ElaiwahÎncă nu există evaluări

- NEBB TAB Technician ProgramDocument2 paginiNEBB TAB Technician Programmoelsaied569Încă nu există evaluări

- Charpy Impact TestDocument3 paginiCharpy Impact TestRamana IkkurthiÎncă nu există evaluări

- GLR EstimateDocument2 paginiGLR EstimateanbujeÎncă nu există evaluări

- CM-510.9 Crane ChecklistDocument2 paginiCM-510.9 Crane ChecklistHSE HerygintingÎncă nu există evaluări

- Proiectarea Asistata de Calculator Pentru Avionica: Elemente de Limbaj C - II Aplicatii de Calcul ComplexeDocument21 paginiProiectarea Asistata de Calculator Pentru Avionica: Elemente de Limbaj C - II Aplicatii de Calcul ComplexeAna BaumÎncă nu există evaluări

- Elegant InteriorsDocument38 paginiElegant Interiorsalka dsouzaÎncă nu există evaluări

- Optical Disc PackagingDocument30 paginiOptical Disc Packagingsameeksha_maury8933Încă nu există evaluări

- Refrigeration Orrifice Selection Chart PDFDocument2 paginiRefrigeration Orrifice Selection Chart PDFMacSpares100% (1)

- C1107Document4 paginiC1107Pankaj PaulÎncă nu există evaluări

- Ludwig Eduard BoltzmannDocument10 paginiLudwig Eduard BoltzmannMarkoÎncă nu există evaluări

- BMW E46 RearlightDocument4 paginiBMW E46 RearlightLiviu CasuneanuÎncă nu există evaluări

- Fruit Recognition Deep LearningDocument53 paginiFruit Recognition Deep Learningsaran20099Încă nu există evaluări

- TNCS EarthingDocument3 paginiTNCS Earthingjoan benwari100% (1)

- Soil Test Report KolhapurDocument35 paginiSoil Test Report Kolhapuryedida viswanadhÎncă nu există evaluări

- Welding PDFDocument6 paginiWelding PDFNavneet ChaubeyÎncă nu există evaluări

- MODELS LS400/LS500: Operation and Parts ManualDocument150 paginiMODELS LS400/LS500: Operation and Parts ManualManolo CaballeroÎncă nu există evaluări

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDe la EverandArizona, Utah & New Mexico: A Guide to the State & National ParksEvaluare: 4 din 5 stele4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe la EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensÎncă nu există evaluări

- The Bahamas a Taste of the Islands ExcerptDe la EverandThe Bahamas a Taste of the Islands ExcerptEvaluare: 4 din 5 stele4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDe la EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoEvaluare: 5 din 5 stele5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDe la EverandNew York & New Jersey: A Guide to the State & National ParksÎncă nu există evaluări

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDe la EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptEvaluare: 5 din 5 stele5/5 (1)