Documente Academic

Documente Profesional

Documente Cultură

Fluidiesed Bed

Încărcat de

Saints Burner ChristopherDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fluidiesed Bed

Încărcat de

Saints Burner ChristopherDrepturi de autor:

Formate disponibile

1.

0 TITLE

Fluidized Bed

2.0 OBJECTIVES

-To determine the pressure drop across fluidized bed

-To verify the Carman- Kozeny equation

-To observed the differences between particulate and aggregative fluidization.

3.0 INTRODUCTION

A fluidized-bed reactor (FBR) is a combination of the two most common, packed-bed and

stirred tank, continuous flow reactors. In FBR, the substrate is passed upward through the

immobilized enzyme bed at a high enough velocity to lift the particles. However, the

velocity must not be so high that the enzymes are swept away from the reactor entirely.

This type of reactor is ideal for highly exothermic reaction because it eliminates local hot-

spots, due to its mass and heat transfer characteristics mentioned before.

The increase in FBR use in todays industrial world is due to the inherent advantages of

the technology. FBR perform uniform particle mixing and temperature gradients and

ability to operate reactor in continuous state. On the other hands, FBR does have its draw-

backs, which must take consideration. FBR need to increased reactor vessel size to solve

the expansion of the bed materials in the reactor. The requirement for fluid to suspend the

solid material necessitates that a higher fluid velocity is attained in the reactor. The high

gas velocities present in this style of reactor often result in fine particles becoming

entrained in the fluid. This may continue is an expensive problem even with other

entrainment reducing technologies. The fluid-like behaviors of the fine solid particles with

the bed eventually result in the wear of the reactor vessel. This can require expensive

maintenance and upkeep for the reaction vessel and pipes. If fluidization pressure is

suddenly lost, the surface area of the bed may be suddenly reduced. This can either be an

inconvenience, such as runaway reaction.

Possible solid particle fluid mixture state are: fixed bed, stationary fluidized bed, bottom

feeding and overflow at the free surface of the bed, or vice versa, vertical conveying in

the dense bed, low density vertical and horizontal conveying, downward particle

movement in the dense bed and spouted bed. Dense phase, non-fluidized solid floe, in

which particles move en bloc, with little relative velocity, has been referred to as moving-

bed flow, packed bed flow or slip-stick flow. The voidage is close to the minimum

fluidization value. Vertical down flow is often used with the fluid moving faster than

solids. Upflow of non-fluidized particles is not common. The spouted bed is a combination

of a jet-like upward moving dilute fluidized phase surrounded by a slow downwards

moving bed through which gas percolates upwards. The use of such system is limited to a

few physical operations with large particles. Using some bed expansion and higher flow

rates will give higher mass transfer rates from the liquid to the particles. Clogging and

dead zones will also be avoided and attrition may help in controlling. Depending on

particle size and density, liquid and gas flow rates, the use of recycle and bed geometry,

several mixing patterns may be obtained in which the liquid phase and the solid phase are

mixed or not.

It is most often applied in immobilized-enzyme catalysis where viscous. Particulate

substrates are to be handled. FBR are used for produce gasoline and other fuels, along

with many other chemicals. Many industrials produced polymers are made using FBR

technology, such as rubber, vinyl chloride, polyethylene, styrenes and polypropylene.

Various utilities also use FBRs for coal gasification, nuclear power plants, and water and

waste water treatment setting.

4.0 MATERIAL AND EQUIPMENT

5.0 RESULTS AND CALCULATIONS

Column inner diameter = 46 mm

Carbon Height of the bed (Initial) = 135 mm

Length of tube = 470 mm

The results of the experiment is tabulated as below:

Air Flow Rate

(LPM)

Differential Pressure (mbar)

Air Carbon Acrylic

8 0 1 1

10 0 1 1

12 0 1 1

14 0 1 1

16 0 1 1

18 0 1 1

20 0 1 1

22 0 1 1

24 0 2 1

26 0 2 1

28 0 2 1

30 0 2 1

32 0 2 1

34 0 2 1

36 0 2 1

38 0 2 1

40 0 2 1

42 0 2 1

44 0 2 1

46 0 2 1

48 0 2 1

50 0 2 1

52 0 2 1

54 0 2 1

56 0 2 1

58 0 2 1

60 0 3 1

62 0 3 1

64 0 3 1

66 0 3 1

68 0 3 1

70 0 3 1

72 0 3 1

74 0 3 1

76 0 3 1

78 0 3 1

80 0 3 1

82 0 3 1

84 0 3 1

86 0 3 1

88 0 3 1

90 0 3 1

91.2 0 3 1

Table 1.1 Results of the experiment

To calculate the Fluid Velocity, we will use this equation:

=

32

()

Where,

= Mean velocity of the tube

= Viscosity of the fluid = 1.983 10

kg /m s

= Diameter of the tube (m)

= Length of the tube (m)

= Differential Pressure (Pa)

Thus for carbon grain

Differential

Pressure

(mbar)

Differential

Pressure (Pa)

Mean velocity

(m/s)

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

2 200 14.18976191

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

3 300 21.28464287

The graph of Pressure drop Against Fluid Velocity for Carbon:

y = 1

R = #N/A

0

0.2

0.4

0.6

0.8

1

1.2

0 1 2 3 4 5 6 7 8

P

r

e

s

s

u

r

e

(

m

b

a

r

)

Mean velocity (m/s)

Graph of Pressure Drop Vs Fluid Velocity

For Acrylic

Differential

Pressure

(mbar)

Differential

Pressure (Pa)

Mean velocity

(m/s)

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

1 100 7.094880956

The Graph of Pressure drop against Fluid velocity for Acrylic

y = 1

R = #N/A

0

0.2

0.4

0.6

0.8

1

1.2

0 1 2 3 4 5 6 7 8

P

r

e

s

s

u

r

e

(

m

b

a

r

)

Mean velocity (m/s)

Graph of Pressure Drop Vs Fluid Velocity

By combining both Graphs for both materials:

0

0.5

1

1.5

2

2.5

3

3.5

0 5 10 15 20 25

P

r

e

s

s

u

r

e

D

r

o

p

Mean Fluid Velocity

Graph of Pressure drop Vs Mean Fluid Velocity

Carbon grain Acrylite Linear (Carbon grain)

6.0 DISCUSSION

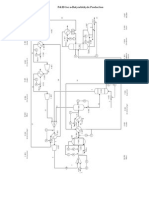

Figure 6.1: Schematic Diagram of Fluidized Bed Unit

Calculation of this experiment is done by using the Carmen-Kozeny equation

which is given below,

where u = mean velocity of the tube

= viscosity of the fluid

dt = diameter of the tube

lt = length of the tube

W

a

t

e

r

C

o

l

u

m

n

A

i

r

C

o

l

u

m

n

dp dp

Digital Water

Flow Meter

Main ON/OFF

Switch

Water Bypass

Valve

Water Flow

Control Valve

Water

Pump

Water

Tank

Digital Air

Flow Meter

Air Flow Control

Valve

Digital Pressure

Drop Meter

(Water Column)

Digital Pressure

Drop Meter (Air

Column)

Based on the equation, pressure drop, P is directly proportional to the velocity, u. The

higher the velocity, the higher the pressure drop or vice versa. In this experiment, carbon

grain and acrylic are being used to test the differential pressure for air system across the

tube. Based on the graphs that we have plotted, they showed a direct relationship between

differential pressure and velocity across the tube. When the differential pressure is

increases, the velocity increases too. The experiment for carbon grain is successful as the

velocity across the tube increases as the differential pressure increases. However, for

acrylic, it is not successful because the pressure remains constant in the whole experiment.

The pressure indicator might encounter some errors during the process.

During the experiment, we can observe that when the air is passing upwards

through the particle at a very low flow rate, which is also at low fluid velocities, the bed

will remain packed and the particles would not move. When the air flow rate is increased

sufficiently, a point will be reached at which the drag force on a particle will be balanced

by the net weight of the particle. The particles are suspended in the upward moving air

and it will move away from one another and this is the point of incipient fluidization at

and beyond which the bed is said to be fluidized.

On the other hand, we also observe that the initial and final height of the test

material in the column before and after experiment is different. This means that there is

some air trapped between the test materials or the test materials are held loosely in the

column or not compressed. When we are testing for acrylic, there are some black particles

which are believed to be carbon grains left in the column. Hence, this might gives us

inaccurate results for this experiment. Besides, the digital flow meter and pressure drop

meter are not sensitive to give small reading of flow rate. This will cause inaccurate result.

There are few precaution steps need to be taken. It is important to open the compressor

valve slowly to avoid excess strong air flow pressure from entering the column. Opening

compressor valve in sudden will trigger the material in the column to burst out from the

air outlet. While changing the test materials from the column, make sure that the column

is perfectly cleaned to avoid any contamination for the next test material.

7.0 CONCLUSION

The experiments shows that the Pressure drop is having a direct proportional relationship

to the air velocity, however it will come constant when it reaches a maxiumum point of

the air velocity. From the experiment, the variation of the pressure drop for carbon grain

is greater than acrylic, this can be explain as the mass of the acrylic and volume of acrylic

is greater than the carbon grain. The Carmen-Kozerny Equation verified.

8.0 REFERENCES

Rhodes, M. (2008). Introduction to particle technology (1st ed.). Chichester, England:

Wiley.

S-ar putea să vă placă și

- Visio Stream Table Part3Document1 paginăVisio Stream Table Part3Saints Burner ChristopherÎncă nu există evaluări

- UEMK4353 Assignment - Mech DesignDocument2 paginiUEMK4353 Assignment - Mech DesignSaints Burner ChristopherÎncă nu există evaluări

- Garbage Enzyme University SarawakDocument6 paginiGarbage Enzyme University SarawakSaints Burner ChristopherÎncă nu există evaluări

- P&IDDocument1 paginăP&IDSaints Burner ChristopherÎncă nu există evaluări

- Industrial Training Report UtarDocument29 paginiIndustrial Training Report UtarSaints Burner Christopher100% (1)

- Visio IndexDocument1 paginăVisio IndexSaints Burner ChristopherÎncă nu există evaluări

- HAZOP TemplateDocument12 paginiHAZOP TemplateSaints Burner ChristopherÎncă nu există evaluări

- Tutorial 5Document7 paginiTutorial 5Saints Burner ChristopherÎncă nu există evaluări

- Foodchapter 1 PDFDocument1 paginăFoodchapter 1 PDFSaints Burner ChristopherÎncă nu există evaluări

- Experiment 1: Batch Reactor: Experiment 1: 6.1. Calibration Curve - Conductivity Vs ConversionDocument2 paginiExperiment 1: Batch Reactor: Experiment 1: 6.1. Calibration Curve - Conductivity Vs ConversionSaints Burner ChristopherÎncă nu există evaluări

- Chemical Reaction Engineering Catalyst ResearchDocument4 paginiChemical Reaction Engineering Catalyst ResearchSaints Burner ChristopherÎncă nu există evaluări

- Assignment 1 (CRE 2)Document1 paginăAssignment 1 (CRE 2)Saints Burner ChristopherÎncă nu există evaluări

- Microsoft Word - Cpci Assignment NewDocument25 paginiMicrosoft Word - Cpci Assignment NewSaints Burner ChristopherÎncă nu există evaluări

- Disc Bowl Flow ChartDocument3 paginiDisc Bowl Flow ChartSaints Burner ChristopherÎncă nu există evaluări

- Introduction For Batch Reactor ExperimentDocument5 paginiIntroduction For Batch Reactor ExperimentSaints Burner Christopher25% (4)

- Gas Absorption Report PDFDocument13 paginiGas Absorption Report PDFSaints Burner Christopher100% (1)

- For Temperature Changes Per TimeDocument1 paginăFor Temperature Changes Per TimeSaints Burner ChristopherÎncă nu există evaluări

- Ni Hao Hi Chi Le Ma? Have You Eaten? Zai Jian Good ByeDocument1 paginăNi Hao Hi Chi Le Ma? Have You Eaten? Zai Jian Good ByeSaints Burner ChristopherÎncă nu există evaluări

- Chapter 3 - Tutorial SolutionDocument8 paginiChapter 3 - Tutorial SolutionSaints Burner ChristopherÎncă nu există evaluări

- Table 10.4 Food Packaging ConsiderationsDocument1 paginăTable 10.4 Food Packaging ConsiderationsSaints Burner ChristopherÎncă nu există evaluări

- French Flash Card 18Document1 paginăFrench Flash Card 18Saints Burner ChristopherÎncă nu există evaluări

- Dow Chemical Company CSTR IssuesDocument7 paginiDow Chemical Company CSTR IssuesSaints Burner ChristopherÎncă nu există evaluări

- For Temperature Changes Per TimeDocument1 paginăFor Temperature Changes Per TimeSaints Burner ChristopherÎncă nu există evaluări

- Liquid phase cis–trans isomerization reactor sizingDocument21 paginiLiquid phase cis–trans isomerization reactor sizingSaints Burner Christopher100% (1)

- Dow Chemical Company CSTR IssuesDocument7 paginiDow Chemical Company CSTR IssuesSaints Burner ChristopherÎncă nu există evaluări

- For Temperature Changes Per TimeDocument1 paginăFor Temperature Changes Per TimeSaints Burner ChristopherÎncă nu există evaluări

- Flash Card FrenchDocument6 paginiFlash Card FrenchSaints Burner ChristopherÎncă nu există evaluări

- Eis AssignmentDocument4 paginiEis AssignmentSaints Burner ChristopherÎncă nu există evaluări

- Chemical Engineering Compulsory SubjectDocument1 paginăChemical Engineering Compulsory SubjectSaints Burner ChristopherÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ztree 2 StataDocument3 paginiZtree 2 StataDaniel Felipe ParraÎncă nu există evaluări

- W6 ReadmeDocument15 paginiW6 ReadmewerewÎncă nu există evaluări

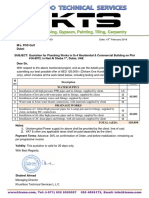

- KTS Quotation Meidan Building Plumbing Works PDFDocument1 paginăKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

- Barangay Profile: (BP DCF No. 1 S. 2022)Document4 paginiBarangay Profile: (BP DCF No. 1 S. 2022)AiMae BaobaoenÎncă nu există evaluări

- DPD Catalog 05 PDFDocument36 paginiDPD Catalog 05 PDFRuth D.Încă nu există evaluări

- 9303 Part 1 Vol 1 PDFDocument99 pagini9303 Part 1 Vol 1 PDFrexthrottleÎncă nu există evaluări

- Icest 2013 02 PDFDocument424 paginiIcest 2013 02 PDFphanduy1310Încă nu există evaluări

- Tu QuestionDocument6 paginiTu QuestionKrishnaa BoraÎncă nu există evaluări

- Right ShipDocument25 paginiRight ShipEmmÎncă nu există evaluări

- Marine Fuel Stability and Compatibility IssuesDocument4 paginiMarine Fuel Stability and Compatibility IssuesRebekah SchmidtÎncă nu există evaluări

- Wind MachinesDocument34 paginiWind Machinesjeswin johnsonÎncă nu există evaluări

- ALFA 4000 - Peru 2 PDFDocument2 paginiALFA 4000 - Peru 2 PDFErick MaderoÎncă nu există evaluări

- Third Party Inspection Report: Industry & Facilities Division Page 1 of 9Document9 paginiThird Party Inspection Report: Industry & Facilities Division Page 1 of 9mustafa nasihÎncă nu există evaluări

- User's Manual: Motherboard AMD Socket AM2Document56 paginiUser's Manual: Motherboard AMD Socket AM2vagnerrock007Încă nu există evaluări

- Trajectory ClusteringDocument58 paginiTrajectory ClusteringPetrick Gonzalez PerezÎncă nu există evaluări

- Palm Tower 3 Coverage ReportDocument61 paginiPalm Tower 3 Coverage ReportHassan DaudÎncă nu există evaluări

- Accidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitDocument4 paginiAccidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitEdouard Francis Dufour DarbellayÎncă nu există evaluări

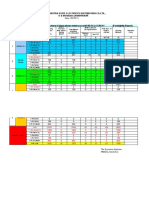

- Estimating and Quantity Surveying Materials for Construction ProjectsDocument3 paginiEstimating and Quantity Surveying Materials for Construction ProjectsAldrin SerranoÎncă nu există evaluări

- IEEEtran HOWTO PDFDocument28 paginiIEEEtran HOWTO PDFMario CruzÎncă nu există evaluări

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocument3 paginiMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornareÎncă nu există evaluări

- System Software Module 3Document109 paginiSystem Software Module 3arunlaldsÎncă nu există evaluări

- KPC Tech Catalog 2010Document84 paginiKPC Tech Catalog 2010Mattia KrumenakerÎncă nu există evaluări

- AST Waveguide Switch 1 1 PDFDocument5 paginiAST Waveguide Switch 1 1 PDFANTONIO MARMOLÎncă nu există evaluări

- SuperStr 14Document1 paginăSuperStr 14Poshan DhunganaÎncă nu există evaluări

- ZQYM Diesel Cummins Series Injector 2023.07Document13 paginiZQYM Diesel Cummins Series Injector 2023.07harbh9355Încă nu există evaluări

- DehumidificationDocument9 paginiDehumidificationRafael Echano AcederaÎncă nu există evaluări

- 1st Term Exam Part 2 - QSDocument10 pagini1st Term Exam Part 2 - QSMark Anthony TajonÎncă nu există evaluări

- Cleaning Krisbow 2013 (Low Res) 2Document12 paginiCleaning Krisbow 2013 (Low Res) 2Andres Agung PerdanaÎncă nu există evaluări

- Nuke 9.0v1 ReleaseNotesDocument32 paginiNuke 9.0v1 ReleaseNotesFlavioÎncă nu există evaluări

- GM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDocument100 paginiGM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDaniel GonzalezÎncă nu există evaluări