Documente Academic

Documente Profesional

Documente Cultură

RELEASE NOTES FOR MEPDG Version 1.1 - September 2009

Încărcat de

Anonymous vA7MJfmDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RELEASE NOTES FOR MEPDG Version 1.1 - September 2009

Încărcat de

Anonymous vA7MJfmDrepturi de autor:

Formate disponibile

RELEASE NOTES FOR MEPDG Version 1.

1 September 2009

Before installing the MEPDG Version 1.1 make sure to uninstall all previous version of the MEPDG

software. The MEPDG Version 1.1 is able to open and save previous MEPDG project files, but the

current file format is not backwardly compatible with previous versions (Version 1.1 files cannot be

opened in Version 1.0 and earlier).

It is recommended that the MEPDG be installed to the default directory. Long MEPDG project path

and file names can cause the Thermal Cracking module to report no cracking. The use of the default

installation and project directories, keep project path names shorter.

Issues have been reported with using Version 1.100 with certain firewalls and virtual private

networks (VPN). Network firewalls may keep the MEPDG from connecting to the Transportation

Research Boards license server. Adding the MEPDG (dg2k2.exe) to the Allow HTML Connection

list will allow the MEPDG to connect to the server. Cisco VPN software has been reported to cause

problems with MEPDG operation due to memory conflicts.

The following changes and improvements have been made to the MEPDG since the last official

release in April 2007.

Improved reports for AC over JPCP to output reflection cracking prediction properly.

Improved reports for AC over CRCP to output reflection cracking prediction properly.

Improved ICM stability by additional checks on model inputs.

Variable ICM time-step and nodal spacing to better model thin bonded PCC overlays of

existing JPCP.

For AC over JPCP design, changed the method of JPCP damage analysis from a two-layer

equivalent analysis (pavement/base) to a three-layer equivalent analysis (AC/PCC/base).

The three-layer analysis method takes into consideration the stresses at the top and bottom

of the PCC layer, as well as determination of the equivalent temperature gradients through

the asphalt layer.

For bonded JPCP over JPCP design, the original approach utilized an equivalent two- layer

system with several deficiencies, including one input for thermal expansion coefficients for

both layers, the use of equivalent modulus instead of actual modulus for determination of

strength and damage, and there was no conversion from top and bottom stresses of

equivalent systems into stresses on the top and bottom surfaces of the concrete. In the

modified approach, a three-layer analysis (JPCP/JPCP/base) is used that addresses these

issues.

Fixed bug associated with the use of widened lanes. A deficiency in the fatigue damage

algorithm was identified for JPCP in which the proper damage calculation was not

performed over the total range of widening. In the new version of the software, after 6

inches of widening, the critical fatigue location correctly shifts from the outer slab edge of

the widened portion to the inner slab edge near lane-to-lane longitudinal joints.

Users can now modify AC IRI calibration constants.

Joint spalling model: The spalling model included in the MEPDG is an empirical model based

on data collected primarily from the NCHRP 1-19, FHWA RPPR, and FHWA PRS projects.

The time period over which the data was collected on these models does not extend beyond

25 years. Considering that pavement age is a primary variable in this empirical model, the

spalling calculations in this version of the software have been capped at a 25-year value for

projects with design lives greater than 25 years. For projects with design lives less than 25

years, this modification will not have an impact.

Sealant type: Sealant type affects joint spalling predictions. However, the spalling model

behaves exactly the same way for all sealant types (including for the no sealant option) with

the exception of a Preformed sealant. Hence the Sealant Type pull down menu has been

simplified to include only two optionsPreformed and Otheras compared to the four

options previously availableNone, Liquid, Silicone, Preformed.

The default long-term lane-shoulder load transfer efficiency (LTE) has been set to 50

percent for tied joints.

A license check fix allows the MEPDG to utilize the Transportation Research Boards new

content server.

Set minimum PCC layer thickness to 1.5 inches for bonded PCC overlays.

In addition to these significant improvements, several small interface bug reports have been

addressed.

S-ar putea să vă placă și

- Roadside Design Guide 3rd Edition (2006)Document337 paginiRoadside Design Guide 3rd Edition (2006)proudleo196288% (16)

- 2012 Nacto Urban Street Design GuideDocument37 pagini2012 Nacto Urban Street Design Guidearkirovic1994100% (2)

- Notebook Power System Introduction TroubleshootingDocument44 paginiNotebook Power System Introduction TroubleshootingDhruv Gonawala89% (9)

- 012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)Document61 pagini012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)buts101100% (5)

- Parametric Finite Element Model of AIRBUS Engine Pylon With MSC - PatranDocument9 paginiParametric Finite Element Model of AIRBUS Engine Pylon With MSC - Patranventus45Încă nu există evaluări

- CH 5 NOTES - Data Organization and Descriptive StatisticsDocument32 paginiCH 5 NOTES - Data Organization and Descriptive StatisticsMila SmithÎncă nu există evaluări

- StorageTek SL150 Modular Tape Libraries Installation (IDO) Specialist AssessmentDocument13 paginiStorageTek SL150 Modular Tape Libraries Installation (IDO) Specialist AssessmentAl MamunÎncă nu există evaluări

- FAARFIELD 2.0.7 Readme 2021-09-14Document5 paginiFAARFIELD 2.0.7 Readme 2021-09-14Miguel O PÎncă nu există evaluări

- C.R. Siqueira - 3d Transient Simulation of An Intake Manifold CFD - SAE 2006-01-2633Document7 paginiC.R. Siqueira - 3d Transient Simulation of An Intake Manifold CFD - SAE 2006-01-2633Thomas MouraÎncă nu există evaluări

- Optimization of Turbo Machinery Validation Against Experimental ResultsDocument13 paginiOptimization of Turbo Machinery Validation Against Experimental ResultsSrinivasÎncă nu există evaluări

- GMD 2018 42 Manuscript Version4Document23 paginiGMD 2018 42 Manuscript Version4matraguna347Încă nu există evaluări

- Pipe Sim 20091Document24 paginiPipe Sim 20091Yk LokeÎncă nu există evaluări

- Hydraulic Modeling With EPA-NETDocument27 paginiHydraulic Modeling With EPA-NETcasaeanÎncă nu există evaluări

- Numerical Simulation in Automotive Design: G. Lonsdale C&C Research Laboratories, NEC Europe LTD., St. Augustin, GermanyDocument7 paginiNumerical Simulation in Automotive Design: G. Lonsdale C&C Research Laboratories, NEC Europe LTD., St. Augustin, Germanybadboys123Încă nu există evaluări

- WP Flow Simulation Gas MixingDocument5 paginiWP Flow Simulation Gas MixingpengkritikÎncă nu există evaluări

- Version Control System of CAD Documents and PLC PRDocument6 paginiVersion Control System of CAD Documents and PLC PRgeorge stanley paceteÎncă nu există evaluări

- Rapt 550 ManualDocument16 paginiRapt 550 ManualbbwhaleÎncă nu există evaluări

- Loading Methods in PLS-CADDDocument17 paginiLoading Methods in PLS-CADDSimonckloh100% (1)

- PLS-CADD Version7 LoadsDocument4 paginiPLS-CADD Version7 LoadsTerex14253Încă nu există evaluări

- Stochastic Analysis of Thermal Cracking Distress of Asphalt Pavements Using The MEPDG Thermal Cracking ModelDocument9 paginiStochastic Analysis of Thermal Cracking Distress of Asphalt Pavements Using The MEPDG Thermal Cracking ModelAyu Intan NÎncă nu există evaluări

- Advance Process ControlDocument11 paginiAdvance Process Control김형진Încă nu există evaluări

- Computational Fluid Mechanics Simulation and Computation With Gambit and FluentDocument69 paginiComputational Fluid Mechanics Simulation and Computation With Gambit and FluentYush KumarÎncă nu există evaluări

- Txdot Primary Researchers: Rigid Pavement Design and AnalysisDocument4 paginiTxdot Primary Researchers: Rigid Pavement Design and AnalysisDarshan KashiÎncă nu există evaluări

- Integrated Finite Element Analysis and Design of StructuresDocument106 paginiIntegrated Finite Element Analysis and Design of StructuresMatías Pino Yáñez100% (1)

- RAM Structural System CONNECT Edition Update 8 Release 15.08 Release NotesDocument12 paginiRAM Structural System CONNECT Edition Update 8 Release 15.08 Release NotesMosab Abdelhalim Abdelkarim MakkiÎncă nu există evaluări

- Research Results DigestDocument31 paginiResearch Results Digesterika guerreroÎncă nu există evaluări

- Spe 192080 MsDocument14 paginiSpe 192080 Ms9412ttjÎncă nu există evaluări

- CFD in Formula 1Document7 paginiCFD in Formula 1delducaÎncă nu există evaluări

- Vectis Undeunderrhood AirflowDocument14 paginiVectis Undeunderrhood AirflowdineshÎncă nu există evaluări

- Impact of Geometric Scaling On Centrifugal Compressor PerformanceDocument12 paginiImpact of Geometric Scaling On Centrifugal Compressor PerformanceRonald George100% (1)

- Draft DigestDocument31 paginiDraft DigestluisÎncă nu există evaluări

- CFD (Computation Flow Diagram)Document17 paginiCFD (Computation Flow Diagram)Mahesh LohanoÎncă nu există evaluări

- Codinglog - TXT File A Useful Tool When The "Brown Stuff and The Fan Meet"Document3 paginiCodinglog - TXT File A Useful Tool When The "Brown Stuff and The Fan Meet"Alin DanielÎncă nu există evaluări

- FLO-2D Porting Document (PRO Model)Document5 paginiFLO-2D Porting Document (PRO Model)Jason ChupicaÎncă nu există evaluări

- 6 AERMOD Update ThurmanDocument18 pagini6 AERMOD Update ThurmanCesar MenganoÎncă nu există evaluări

- IjesrtDocument8 paginiIjesrtMeko Koko BeboÎncă nu există evaluări

- A Numerical Analysis For The Cooling Module Related To Automobile Air Conditioning SystemDocument10 paginiA Numerical Analysis For The Cooling Module Related To Automobile Air Conditioning SystematosayÎncă nu există evaluări

- Hybrid Parallelization of A Turbomachinery CFD Code: Peformance Enhancements On Multicore ArchitecturesDocument15 paginiHybrid Parallelization of A Turbomachinery CFD Code: Peformance Enhancements On Multicore ArchitecturesSagnik BanikÎncă nu există evaluări

- Read MeDocument5 paginiRead MeKairenÎncă nu există evaluări

- FYP Interim Report - RussellDocument8 paginiFYP Interim Report - Russellrussell_mahmood100% (1)

- New Generation Pipeline Analysis Software PDFDocument17 paginiNew Generation Pipeline Analysis Software PDFmirnori6048Încă nu există evaluări

- Use of CFD Methods For Hullform Ion in A Model BasinDocument11 paginiUse of CFD Methods For Hullform Ion in A Model Basinseckin80Încă nu există evaluări

- External AerodynamicsDocument14 paginiExternal AerodynamicsBharath Dv100% (1)

- MSC/CONSTRUCT - Topology and Shape Optimization of Large Real World Structures Using The Distributed Parallel MSC/NASTRANDocument17 paginiMSC/CONSTRUCT - Topology and Shape Optimization of Large Real World Structures Using The Distributed Parallel MSC/NASTRANJyotsna ReddyÎncă nu există evaluări

- Flaps Simulation: H. Guelzau, TUHH T. Krueger, AIRBUSDocument12 paginiFlaps Simulation: H. Guelzau, TUHH T. Krueger, AIRBUSPrasad KaneÎncă nu există evaluări

- Optimal Size and Cost Analysis of Stand-Alone Hybrid Wind/photovoltaic Power-Generation SystemsDocument62 paginiOptimal Size and Cost Analysis of Stand-Alone Hybrid Wind/photovoltaic Power-Generation Systemsmohammadjm2008100% (1)

- A Direct Assessment Module For Pipeline Integrity Management at GasunieDocument16 paginiA Direct Assessment Module For Pipeline Integrity Management at GasunieSoutik GhoshÎncă nu există evaluări

- Kim Spitler Delahoussaye 02 Pt2Document24 paginiKim Spitler Delahoussaye 02 Pt2marjan 01Încă nu există evaluări

- 01 TRB 2009 Fatigue PaperDocument10 pagini01 TRB 2009 Fatigue PaperEman MousaÎncă nu există evaluări

- Tekla - Eurocode Portal Frame InformationDocument11 paginiTekla - Eurocode Portal Frame InformationMikeÎncă nu există evaluări

- Revision HistoryDocument9 paginiRevision HistoryalexÎncă nu există evaluări

- Mechanistic-Empirical Pavement Design GuideDocument3 paginiMechanistic-Empirical Pavement Design Guidelelu8210Încă nu există evaluări

- Introduction To Computational Fluid Dynamics Lecture 2: CFD IntroductionDocument18 paginiIntroduction To Computational Fluid Dynamics Lecture 2: CFD IntroductionHunter NoVaÎncă nu există evaluări

- CFD Report (Introduction To CFD)Document10 paginiCFD Report (Introduction To CFD)Israel Torres100% (1)

- Coupling 1D and 3D CFD: Myth or Reality: (Fluids & Co, Canada)Document15 paginiCoupling 1D and 3D CFD: Myth or Reality: (Fluids & Co, Canada)Mahfoud AMMOURÎncă nu există evaluări

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe la EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusÎncă nu există evaluări

- High Performance Parallelism Pearls Volume Two: Multicore and Many-core Programming ApproachesDe la EverandHigh Performance Parallelism Pearls Volume Two: Multicore and Many-core Programming ApproachesÎncă nu există evaluări

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesDe la EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesÎncă nu există evaluări

- The Effects of Traffic Structure on Application and Network PerformanceDe la EverandThe Effects of Traffic Structure on Application and Network PerformanceÎncă nu există evaluări

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsDe la EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsÎncă nu există evaluări

- Process System Value and Exergoeconomic Performance of Captive Power PlantsDe la EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsÎncă nu există evaluări

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsDe la EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsÎncă nu există evaluări

- LEARN MPLS FROM SCRATCH PART-A: A Beginner's Guide to Next Level of NetworkingDe la EverandLEARN MPLS FROM SCRATCH PART-A: A Beginner's Guide to Next Level of NetworkingÎncă nu există evaluări

- 2007 3011 Ccid 8 01 00002 PDFDocument12 pagini2007 3011 Ccid 8 01 00002 PDFAnonymous vA7MJfmÎncă nu există evaluări

- Concrete PCI BookDocument23 paginiConcrete PCI BookLorentz MelialaÎncă nu există evaluări

- Pavement Condition Index - City of Olathe PDFDocument1 paginăPavement Condition Index - City of Olathe PDFAnonymous vA7MJfmÎncă nu există evaluări

- Package Granovagg': February 25, 2012Document18 paginiPackage Granovagg': February 25, 2012Anonymous vA7MJfmÎncă nu există evaluări

- Guidance and Tools Support Wider Use of Composite Paving System ConstructionDocument2 paginiGuidance and Tools Support Wider Use of Composite Paving System ConstructionAnonymous vA7MJfmÎncă nu există evaluări

- Options For Using Precast Concrete To Speed ConstructionDocument2 paginiOptions For Using Precast Concrete To Speed ConstructionAnonymous vA7MJfmÎncă nu există evaluări

- Toolbox Resource For Non-Destructive TestingDocument2 paginiToolbox Resource For Non-Destructive TestingAnonymous vA7MJfmÎncă nu există evaluări

- Getting Started With Satellite 6Document54 paginiGetting Started With Satellite 6Sudheer KhanduriÎncă nu există evaluări

- Annual Exam COMPUTER SC Class XIDocument8 paginiAnnual Exam COMPUTER SC Class XIST JOSEPH'S SCHOOLÎncă nu există evaluări

- I Need Free Serial Key of Acrobat Xi Pro - FixyaDocument3 paginiI Need Free Serial Key of Acrobat Xi Pro - FixyaRamesh Gowda33% (3)

- Release Notes - READDocument3 paginiRelease Notes - READHari KurniadiÎncă nu există evaluări

- Binomial DistributionDocument3 paginiBinomial DistributionelminvaldezÎncă nu există evaluări

- Class 8 Art BookDocument17 paginiClass 8 Art BookSrijanÎncă nu există evaluări

- Agenda: - What's A Microcontroller?Document38 paginiAgenda: - What's A Microcontroller?Hoang Dung SonÎncă nu există evaluări

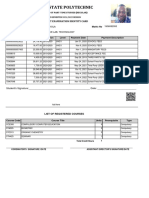

- Lagos State Polytechnic: Student Examination Identity CardDocument1 paginăLagos State Polytechnic: Student Examination Identity CardSunday PeterÎncă nu există evaluări

- Hardware Manual: REJ09B0261-0100Document1.692 paginiHardware Manual: REJ09B0261-0100Ferdinand KlautÎncă nu există evaluări

- Fuzzy SetsDocument3 paginiFuzzy SetsShugal On HaiÎncă nu există evaluări

- Unit 5 - Cyber SecurityDocument9 paginiUnit 5 - Cyber SecurityDraxÎncă nu există evaluări

- Chapter 2 MeasurementsDocument50 paginiChapter 2 MeasurementsMehak SharmaÎncă nu există evaluări

- Verafin CaseDocument3 paginiVerafin CaseMargaret Tariro MunemwaÎncă nu există evaluări

- Excel ExerciseDocument296 paginiExcel ExerciseshubhamÎncă nu există evaluări

- Sorting Out Centrality: An Analysis of The Performance of Four Centrality Models in Real and Simulated NetworksDocument21 paginiSorting Out Centrality: An Analysis of The Performance of Four Centrality Models in Real and Simulated NetworksComplejidady EconomíaÎncă nu există evaluări

- A Business Case For SAP GIS IntegrationDocument7 paginiA Business Case For SAP GIS IntegrationCharles AshmanÎncă nu există evaluări

- Technology and Tourism by Anil SangwanDocument62 paginiTechnology and Tourism by Anil SangwanAkhil V. MadhuÎncă nu există evaluări

- Motorola Cp140Document104 paginiMotorola Cp140Neil BotesÎncă nu există evaluări

- TB6500 ManualDocument11 paginiTB6500 ManualEnrique BautistaÎncă nu există evaluări

- Idoc Error Handling For Everyone: How It WorksDocument2 paginiIdoc Error Handling For Everyone: How It WorksSudheer KumarÎncă nu există evaluări

- Employee Verification FormDocument7 paginiEmployee Verification FormAparna NandaÎncă nu există evaluări

- Management Reporter Integration Guide For Microsoft Dynamics® AX - DynAXDataProvInstGuide - ENUSDocument17 paginiManagement Reporter Integration Guide For Microsoft Dynamics® AX - DynAXDataProvInstGuide - ENUSUmesh PanditÎncă nu există evaluări

- DBMS FileDocument76 paginiDBMS FileJeremy MontgomeryÎncă nu există evaluări

- Rational Root TheoremDocument9 paginiRational Root TheoremAerown John Gonzales TamayoÎncă nu există evaluări

- Book PDF Reliability Maintainability and Risk Practical Methods For Engineers PDF Full ChapterDocument18 paginiBook PDF Reliability Maintainability and Risk Practical Methods For Engineers PDF Full Chaptermary.turner669100% (8)

- Design and Implementation The LLC Resonant TransformerDocument3 paginiDesign and Implementation The LLC Resonant TransformerMathe ZsoltÎncă nu există evaluări