Documente Academic

Documente Profesional

Documente Cultură

1953 Lucas Dynamos E3L E3LM E3N

Încărcat de

edelapollo0 evaluări0% au considerat acest document util (0 voturi)

155 vizualizări7 paginiThis document provides workshop instructions for motor cycle generators models E3L, E3LM, and E3N. It discusses the general features and construction of the generators including testing data and output specifications. It also provides details on routine maintenance including lubrication, inspection of brushes and commutator, and servicing procedures for testing and dismantling the generator to locate faults.

Descriere originală:

Motorbike electrics

Titlu original

1953 Lucas Dynamos E3L E3LM E3N[2]

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides workshop instructions for motor cycle generators models E3L, E3LM, and E3N. It discusses the general features and construction of the generators including testing data and output specifications. It also provides details on routine maintenance including lubrication, inspection of brushes and commutator, and servicing procedures for testing and dismantling the generator to locate faults.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

155 vizualizări7 pagini1953 Lucas Dynamos E3L E3LM E3N

Încărcat de

edelapolloThis document provides workshop instructions for motor cycle generators models E3L, E3LM, and E3N. It discusses the general features and construction of the generators including testing data and output specifications. It also provides details on routine maintenance including lubrication, inspection of brushes and commutator, and servicing procedures for testing and dismantling the generator to locate faults.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

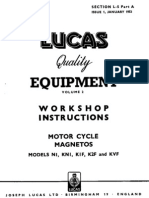

SECTION L-2 Part A

ISSUE 1, J ANUARY 1953

EQUIPMENT

VOL UME 2

W O R K S H O P

I NSTRUCTI ONS

MOTOR CYCLE GENERATORS

MODELS E3L, E3LM and E3N

J O S E P H L U C A S L TD B I R M I N G H A M 1 9 E N G L A N D

Printed in England

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page 1

GENERATORS

MODELS E3L, E3LM and E3N

1. GENERAL

The generator is a shunt-wound t wo pole machine.

arranged to work in conjunction wi t h a regulator unit

(see SECTION L-3) to give an output which is de-

pendent on the state of charge of the batter/ and the

loading of the electrical equipment In use. When the

batter/ is in a low state of charge, the generator

gives a high output, whereas if the battery is fully

charged the generator gives only a trickle charge to

keep the battery in a good condition wi thout over-

charging. In addition, an Increase of output is given

to balance the current taken by the lamps when in use.

Models E3L and E3LM are similar in construction and

both have a 60 watt output. The constructional

difference between the t wo models is in the shape of

the drive-end bearing retaining plate; Model E3L is

designed to fit on to the engine crankcase and Model

E3LM to be the upper portion of the 'Magdyno'.

Model E3N is identical in diameter and construction

to the t wo previously mentioned models, but differs

in overall length and output. The output is 45 watts

and the overall length is

7

/

8

" less than that of Models

E3L and E3LM.

Fig. 1

Various drive-end bearing retaining places

2. TEST DATA

Models

E3L

E3LM

E3N

Cutting In Speed

(generator cold)

1050-1200 r.p.m. at 7 volts

1250-1500 r.p.m. at 7 volts

Output Test

8.5 amps. at 1850-2000 r.p.m.

at 7 volts. *

5 amps at 2100-2300 r.p.m.

at 7 volts.

Field

Resistance

2.8 ohms

3.2 ohms

Brush

Spring

Tension

16-20 oz.

16-20 oz.

* On resistance load of 0.82 ohm.

On resistance load of 1.4 ohms,

OIL SEAL

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page 2

3. ROUTINE MAINTENANCE

(a) Lubrication

No lubrication is necessary as the ball bearings are

packed wi t h H.M.P. grease which will last unti l the

machine is taken down for a general overhaul, when the

bearings should be repacked. Thin lubricating oi l ,

if allowed to reach the bearings, wi l l soften the grease

and eventually cause the bearings to run hot.

(b) Inspection of Commutator and Brushgear

About once every six months remove the cover band

for Inspection of commutator and brushes. The brushes

are held in contact wi t h the commutator by means of

springs. Move each brush to see that It Is free to slide

in its holder; if it sticks, remove it and clean wi th a

cloth moistened wi t h petrol. Care must be taken

to replace the brushes in their original positions,

otherwise they wi l l not ' bed' properly on the com-

mutator. If, after long service, the brushes have

become worn to such an extent that the brush flexible

is exposed on the running face, or If the brushes do

not make good contact wi th the commutator, they

must be replaced by genuine Lucas brushes. The

commutator should be free from any trace of oil or

di rt and should have a highly polished appearance.

Clean a di rty or blackened commutator by pressing a

fine dry cloth against it while the engine is slowly

turned over by means of the kick starter crank. (It

is an advantage to remove the sparking plug before

doing this.) If the commutator is very di rty, moisten

the cloth wi th petrol.

4. SERVICING

(a) Testing in position to locate fault in charging

circuit

In the event of a fault in the charging circuit, adopt

the following procedure to locate the cause of trouble.

(i) Check that the generator and regulator unit are

connected correctly. The generator terminal ' D'

should be connected to the regulator unit terminal

' D' and generator terminal 'F' to regulator unit

terminal 'F'.

(ii) Remove the cables from the generator terminals

'D' and 'F' and connect the t wo terminals wi t h a short

length of wire.

(iii) Start the engine and set to run at normal idling

speed.

(iv) Connect the negative lead of a moving coil volt-

meter, calibrated 010 volts, to one of the generator

terminals and connect the positive lead to a good

earthing point on the generator yoke or engine.

Reverse voltmeter connections on negative earth

machines.

(v) Gradually increase the engine speed, when the

voltmeter reading should rise rapidly and wi thout

fluctuation. Do not allow the voltmeter reading to

rise above 10 volts and do not race the engine In an

attempt to increase the voltage. It is sufficient to run

the generator up to a speed of 1,000 r.p.m. If there is

no reading, check the brush gear, as described in (vi)

below. If there is a low reading of approximately

volt, the field winding may be at fault (see Para. 4 (d).

If there is a reading of approximately 1 to 2 volts,

the armature winding may be at fault (see Para. 4 (e).

(vi) Remove the cover band and examine the brushes

and commutator. Hold back each of the brush springs

and move the brush by pulling gently on its flexible

connector. If the movement is sluggish, remove the

brush from its holder and ease the sides by lightly

polishing on a smooth file. Always replace brushes in

their original positions. If the brushes are worn so

that they do not bear on the commutator, or if the

brush flexible is exposed on the running face, new

brushes must be fi tted.

Fig. 2 Testing brush spring tension

BRUSH

SPRING

BRUSH

COMMUTATOR

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page 3

Test the brush spring tension wi th a spring scale,

The correct tension is 1620 oz. and new springs must

be fitted if the tension Is low.

If the commutator is blackened or di rty, clean It by

holding a petrol moistened cloth against It while the

engine is turned slowly by means of the kick start

(with sparking plug removed).

Re-test the generator as in (v) above. If there is still

no reading on the voltmeter, there is an internal fault

and the complete unit if a spare is available, should

be replaced. Otherwise the unit must be dismantled

(see Para. 4 (b) for internal examination.

(vii) If the generator Is in good order, restore the

original connections. Connect regulator unit terminal

' D' to generator terminal 'D', and regulator terminal

'F' to generator terminal ' F' . Proceed to test the

regulator as described in SECTION L-3 Part A.

(b) To Dismantle

Remove the generator from the motorcycle. To

detach the generator from a Magdyno, unscrew the

hexagon-headed nut from the driving end cover and

slacken the screws securing the band clip.

Proceed to dismantle as follows:

(i) On models E3L and E3N, remove the securing

nut from the drive end of the shaft, and withdraw the

gear wi t h the aid of an extractor. On model E3LM,

bend back the tag on the washer 'B' locking the screw

' A' . Remove this screw, withdraw the gear 'C' from

the shaft wi t h the aid of an extractor and remove

the key(s) ' D' from the shaft.

(ii) Remove the cover band 'H' hold back the brush

springs and lift the brushes from their holders.

(iii) Take out the screw ' J' wi th spring washer, from

the centre of the black moulded end cap 'G'. Draw

the cap away from the end bracket, take off terminal

nuts 'F', and spring washers, and lift the connections

off the terminals.

(iv) Unscrew and remove from the drive end bracket,

the t wo through bolts ' L' securing the drive end

bracket 'N' and commutator end bracket 'Q' to the

yoke 'M'. Hold the nuts ' K' at the commutator end

while unscrewing the bolts, and take care not to

lose the nuts.

(v) Draw the drive end bracket complete wi t h

armature 'E' out of the yoke,

(vi) Remove the nut 'R' and press the armature out

of the drive end bracket by means of a hand press,

When removing the armature from an E3L generator

fitted wi t h a rubber oil seal ' 5' take great care not to

damage the sealing lip.

(vii) Remove the bearing retaining plate 'P' from the

drive end bracket (secured by three screws on E3L

and E3N models, or t wo screws and long threaded bolt

on E3LM models).

Fig. 3 Dismantled view of Model E3LM

SCREWS SECURI NG BEARI NG

RETAI NI NG PLATE

DRI VI NG END BRACKET YOKE COMMUTATOR END BRACKET

SCREW SECURI NG

END CAP

BRUSH

TERMINAL NUTS END CAP

COVER B A ND

BEARI NG

SCREW SECURI NG

DRI VI NG GEAR LOCKI NG

WASHER DRI VI NG

GEAR

KEY

ARMATURE

THROUGH BOLT NUT

BEARI NG

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page 4

(viii) Take out the screw securing the green field coil

lead wi t h the yellow sleeve to commutator end

bracket and remove the end bracket 'Q' withdrawing

the connectors through the slot in the Insulating p|ate.

(ix) Unscrew the three screws securing the insulating

plate to the commutator end bracket and remove the

plate complete wi th brushgear.

(c) Commutator

Examine the commutator. If it is in good condition,

it wi l l be smooth and free from pits or burned spots.

Clean wi th a petrol-moistened cloth. If this is in-

effective, carefully polish wi t h a strip of very fine

glasspaper while rotating the armature. To remedy a

badly worn commutator, mount the armature wi t h

or wi thout the drive end bracket in a lathe, rotate at

high speed and take a light cut wi t h a very sharp tool .

Do not remove more metal than is necessary. Polish

the commutator wi th very fine glasspaper.

the bulb lights, there is an earth between coil and

yoke.

Fig. 5

Generator connections

Fig. 4

Method of undercutting commutator insulation

Undercut the insulation between the segments to a

depth of

1

/

32

" wi th a hacksaw blade ground down until

it is only slightly thicker than the insulation,

(d) Field Coil

Measure the resistance of the field winding by means

of an ohm meter. If this Is not available, connect a

6-volt D.C supply wi t h an ammeter in series across

the coil. The ammeter reading should be approxi-

mately 2.1 amps. for models E3L and E3LM and 1.8

amps for E3N. No reading on the ammeter Indicates

an open circuit in the field winding.

To check for an earthed coll, connect a mains test

lamp between one end of the coil and the yoke. If

In either case, unless a replacement generator Is

available, the field coil must be replaced, but this should

only be attempted if a wheel-operated screwdriver

and pole shoe expander are at hand, the latter being

especially necessary to ensure that there wi l l be no

alrgap between the pole shoe and the inner face

of the yoke.

To replace the field coi l , proceed as fol l ows:-

(i) Unscrew the pole shoe retaining screw(s) (Fig. 6)

by means of the wheel-operated screwdriver.

Fig. 6

Pole shoe expander

EARTHED

BRUSH

INSULATED

BRUSH

LEAD (GREEN)

FI TTED WI TH

YELLOW SLEEVE

FI ELD COI L

LEAD

INSULATOR SEGMENTS INSULATOR

RIGHT WAV WRONG WAY

POLE SHOE RETAINING SCREW

FIELD COIL

POLE SHOE

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page

(ii) Draw the pole shoe and field coll out of the yoke

and lift off the coll.

(iii) Fit the new field coil over the pole shoe and

place it in position inside the yoke. Take care to

ensure that the taping of the field coll Is not trapped

between the pole shoe and the yoke.

(iv) Locate the pole shoe and field coil by lightly

tightening the fixing screw(s), insert the pole shoe

expander, open to its fullest extent and tighten the

screw(s). Remove the expander and give the screw(s)

a final tightening wi th the wheel-operated screwdriver.

Lock the screw(s) in position by caulking, that is, by

tapping some or the metal of the yoke into the slot

in the head of the screw{s).

(e) Armature

The testing of the armature winding requires the use

of a voltdrop test or a growler. If these are not avail-

able, the armature should be checked by substitution.

No attempt should be made to machine the armature

core or to true a distorted armature shaft.

(f) Bearings

Ball bearings are fitted to both the commutator and

drive end brackets. When the bearings become worn

to such an extent that they allow side movement of

the armature shaft, they must be replaced. To replace

the ball bearing at the commutator end, proceed as

follows:

(i) Remove the screw from the end of the armature

shaft and using a calliper type extractor, draw the

bearing off the shaft.

(ii) Wipe out the bearing housing and pack the new

bearing wi t h H.M.P. grease.

(iii) Position the bearing on the end of the shaft and

press it squarely home, applying pressure on the Inner

journal of the bearing.

To replace the ball bearing at the drive end, proceed

as follows;

(i) Remove the bearing retaining plate from the

drive end bracket as previously described.

(ii) Press the bearing out of the end bracket, using

a metal drift locating on the inner journal of the

bearing. Wipe Out the bearing housing and pack the

new bearing wi th H.M.P. grease.

(iv) Position the bearing in its housing and press it

squarely home, applying pressure on the outer journal

of the bearing.

Fig. 8 Removing the ball race

(g) Reassembly

In the main, the reassembly of the generator is a

reversal of the operations described in paragraph 4 (b),

bearing in mind the following points:

(i) The field coil lead fitted wi th the short length of

yellow tubing must be connected together wi t h the

eyelet of the earthed brush to the commutator end

bracket by means of the screw provided.

(ii) The second field coil lead must be connected to

terminal ' F' on the moulded cap,

(iii) The unearthed brush flexible lead must be con-

nected direct to terminal ' D' on the moulded end cap.

(iv) Take care to refit cover band in original position

and make sure that the securing screw, when of

flush-fitting pattern, does not short on brushgear.

(v) On E3L generators wi t h oil seal, ensure that no

damage has been caused to the seal, otherwise replace-

ment must be made. To remove the oil seal from the

bearing retaining plate, use a metal dri ft locating on

the outer edge of the rubber seal. Insert a new seal

using a mandrel to press it squarely home.

Fig. 7 WheeI-operated screwdriver

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

SECTION L-2 Part A Page 6

5. GENERATOR POLARITY

All replacement motor cycle generators are despatched

from the Works suitable for immediate use on positive

earth systems. If the negative terminal of the battery

is earthed on the machine for which the replacement

generator is Intended, it wi l l be necessary to re-

polarize the generator before use to make it suitable

for negative earth.

Similarly, if a generator has been incorrectly connected

on the motorcycle and its polarity has become reversed,

then it must be re-polarized.

To do this, fit the generator to the motor cycle but do

not at this stage connect the cables to the D and F

terminals. Temporarily connect a length of wire to

the battery positive terminal and hold the other end

of this wire in contact wi t h generator terminal F for

a few seconds only. This serves to re-polarize the

generator; the temporary connection can now be

removed and the original cables connected to D and

F terminals.

The practice of closing the cut-out points to reverse

the generator polarity is not recommended as this

method allows a high initial surge of current from the

battery to pass through the armature, which can

damage the windings, insulation, etc., and result in a

decreased service life of the machine.

Generally speaking, the majority of motor-cycles manu-

factured up to and including 1951 had the negative

terminal of the battery connected to the frame. The

majority of machines in current production have the

positive terminal earthed.

Replacing the ball race

Fig. 9

LUCAS WORK SHOP I NST RUCT I ONS

w

w

w

.

a

j

s

-

m

a

t

c

h

l

e

s

s

.

i

n

f

o

S-ar putea să vă placă și

- Rover ManualDocument207 paginiRover Manualkevinkcam100% (11)

- Instructions: 6 Speed Transmission Super KitDocument14 paginiInstructions: 6 Speed Transmission Super KitthailanÎncă nu există evaluări

- Repair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetorDocument5 paginiRepair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetoreducsalÎncă nu există evaluări

- 1971 Chevy Overhaul ManualDocument505 pagini1971 Chevy Overhaul ManualCharlie Moretti100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Jetaway Service GuideDocument185 paginiJetaway Service Guideralleman1Încă nu există evaluări

- Why Mosfets FailDocument2 paginiWhy Mosfets FailkholshÎncă nu există evaluări

- Sioux 7192 PDFDocument22 paginiSioux 7192 PDFJeff LetcherÎncă nu există evaluări

- Singer Model 66 18 Sewing Machine ManualDocument64 paginiSinger Model 66 18 Sewing Machine ManualPrasert BoontharaksaÎncă nu există evaluări

- Manual de Transmisiones Chrysler Años 90 PrincipalmenteDocument188 paginiManual de Transmisiones Chrysler Años 90 PrincipalmenteMarbelmen100% (1)

- Starter: 1991 Mitsubishi MonteroDocument9 paginiStarter: 1991 Mitsubishi MonteroAnimemanuel MuñozÎncă nu există evaluări

- Alternator and RegulatorDocument6 paginiAlternator and Regulatorsonny1234Încă nu există evaluări

- Prestolite Starter MMDocument155 paginiPrestolite Starter MMleather_nun100% (2)

- 1955 Seagrave Model 530-BH ManualsDocument129 pagini1955 Seagrave Model 530-BH Manualsbones333100% (3)

- Volkswagen Taro 2Y 4Y Engine ManualDocument186 paginiVolkswagen Taro 2Y 4Y Engine ManualManos StavrouÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFDocument30 paginiManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFLuis Reinaldo Ramirez Contreras100% (1)

- 1ZSE 5492-161 en Rev 2Document20 pagini1ZSE 5492-161 en Rev 2Elafan100% (1)

- Lucas K1F MagnetoDocument10 paginiLucas K1F MagnetoThunderbird3100% (1)

- PrestoliteStarterAlternatorManual PDFDocument155 paginiPrestoliteStarterAlternatorManual PDFElzo FreitasÎncă nu există evaluări

- 1978 Johnson 175 200 235 HP Outboard Service Manual PDFDocument6 pagini1978 Johnson 175 200 235 HP Outboard Service Manual PDFChrisStainton0% (2)

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsDocument30 paginiManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsRoussel Florez ZuloagaÎncă nu există evaluări

- 8-11... Lobo Service ManualDocument41 pagini8-11... Lobo Service ManualRusonegro100% (1)

- Spindle Belt ReplacementDocument3 paginiSpindle Belt ReplacementAshÎncă nu există evaluări

- Manual For 1215 Kva Rig AlternatorDocument18 paginiManual For 1215 Kva Rig Alternatorprem080910Încă nu există evaluări

- 1953 Lucas Dynamos E3L E3LM E3N PDFDocument7 pagini1953 Lucas Dynamos E3L E3LM E3N PDFepicenterrulezÎncă nu există evaluări

- Moriniservices5 PDFDocument44 paginiMoriniservices5 PDFMoto TOWÎncă nu există evaluări

- K25 8Document17 paginiK25 8mushfiq66Încă nu există evaluări

- W R H Main Manual PDFDocument14 paginiW R H Main Manual PDFjaikolangaraparambilÎncă nu există evaluări

- Master Solenoid Kit: MS KM-175 93Document1 paginăMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliÎncă nu există evaluări

- 07 - Power DrivetrainDocument20 pagini07 - Power DrivetrainVictor RamirezÎncă nu există evaluări

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocument12 paginiInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146Încă nu există evaluări

- Winpower Wisc v-465d EngineDocument5 paginiWinpower Wisc v-465d Engine80sDweebÎncă nu există evaluări

- 804Document259 pagini804juanÎncă nu există evaluări

- AIR-X Circuit Replacement InstructionsDocument9 paginiAIR-X Circuit Replacement InstructionsscabdÎncă nu există evaluări

- Transcriptor Skeleton Turntable Owners ManualDocument20 paginiTranscriptor Skeleton Turntable Owners ManualMatt RichmondÎncă nu există evaluări

- Ounting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Document9 paginiOunting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Chad HuntÎncă nu există evaluări

- Fa125 22Document2 paginiFa125 22Ricardo FavalliÎncă nu există evaluări

- MSD 4151Document8 paginiMSD 4151rxhughesÎncă nu există evaluări

- Valve Adjustment PDFDocument34 paginiValve Adjustment PDFlilo6romeroÎncă nu există evaluări

- Service Manual: VCR Mechanism UnitDocument34 paginiService Manual: VCR Mechanism UnitcobrabrÎncă nu există evaluări

- Windshield Wiper and Washer SystemsDocument22 paginiWindshield Wiper and Washer SystemsChristian MartinezÎncă nu există evaluări

- SpreadersDocument13 paginiSpreadersEdgardo Alfonso Ilabaca Saez100% (1)

- Semi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VDocument2 paginiSemi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VAbu Naufal HanifahÎncă nu există evaluări

- IOM Actuator AutomaxSupernovaDocument4 paginiIOM Actuator AutomaxSupernovaNaser JahangiriÎncă nu există evaluări

- Ac Motor RepairDocument14 paginiAc Motor RepairJohn fredy cuervoÎncă nu există evaluări

- KTA 50 CoolPac 0908-0156Document7 paginiKTA 50 CoolPac 0908-0156Ahmed AbdullahÎncă nu există evaluări

- 1966 Ford Mustang Breaker Points and Condenser Removal and InstallationDocument4 pagini1966 Ford Mustang Breaker Points and Condenser Removal and InstallationOxgardÎncă nu există evaluări

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 paginiWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanÎncă nu există evaluări

- Section 10 - Power Take-OffDocument19 paginiSection 10 - Power Take-OffMiller Andres ArocaÎncă nu există evaluări

- Starting System (2Az-Fe) : InspectionDocument40 paginiStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- Basic Electricity GeneratorDocument5 paginiBasic Electricity GeneratorMerad AmmarÎncă nu există evaluări

- STEERING SYSTEM Volvo 940Document16 paginiSTEERING SYSTEM Volvo 940JaÎncă nu există evaluări

- Engine Electrical SystemDocument14 paginiEngine Electrical SystemMatthew Robert QuinnÎncă nu există evaluări

- Rotating Beam Fatigue Test MachineDocument13 paginiRotating Beam Fatigue Test MachineReÎncă nu există evaluări

- Generator TestsDocument9 paginiGenerator TestspeterÎncă nu există evaluări

- All Engine Manual (OCR)Document580 paginiAll Engine Manual (OCR)Alberto Mansilla Tejeda100% (1)

- JD 2030 Kvačilo PDFDocument7 paginiJD 2030 Kvačilo PDFBranko Mikulinjak100% (1)

- Wiper, Washer & Horn: SectionDocument10 paginiWiper, Washer & Horn: Sectiontomallor101Încă nu există evaluări

- Motorcycle, Solo (Harley-Davidson Model WLA)De la EverandMotorcycle, Solo (Harley-Davidson Model WLA)Încă nu există evaluări

- Vol168 No.03Document40 paginiVol168 No.03edelapolloÎncă nu există evaluări

- Vol168 No.01Document47 paginiVol168 No.01edelapolloÎncă nu există evaluări

- Vol168 No.08Document40 paginiVol168 No.08edelapolloÎncă nu există evaluări

- Vol168 No.20Document40 paginiVol168 No.20edelapolloÎncă nu există evaluări

- Vol168 No.07Document40 paginiVol168 No.07edelapolloÎncă nu există evaluări

- Vol168 No.05Document39 paginiVol168 No.05edelapolloÎncă nu există evaluări

- Vol168 No.17Document36 paginiVol168 No.17edelapolloÎncă nu există evaluări

- Lock Up Your: KEY MENDocument12 paginiLock Up Your: KEY MENedelapolloÎncă nu există evaluări

- Vol168 No.13Document39 paginiVol168 No.13edelapolloÎncă nu există evaluări

- Vol168 No.15Document56 paginiVol168 No.15edelapolloÎncă nu există evaluări

- Spindle OilsDocument1 paginăSpindle OilsedelapolloÎncă nu există evaluări

- Vol168 No.16Document40 paginiVol168 No.16edelapolloÎncă nu există evaluări

- Abstract Honsel Meschede KleinDocument1 paginăAbstract Honsel Meschede KleinedelapolloÎncă nu există evaluări

- Pazon V Boyer: The TriggerDocument12 paginiPazon V Boyer: The TriggeredelapolloÎncă nu există evaluări

- Turnmill: Gantry-Type Multi-Professional Machining CentreDocument2 paginiTurnmill: Gantry-Type Multi-Professional Machining CentreedelapolloÎncă nu există evaluări

- 3 Phase DiagramDocument18 pagini3 Phase DiagramedelapolloÎncă nu există evaluări

- Garlock Bearing Isolator Application Data SheetDocument1 paginăGarlock Bearing Isolator Application Data SheetedelapolloÎncă nu există evaluări

- Trochoidal Milling: Process DescriptionDocument7 paginiTrochoidal Milling: Process DescriptionedelapolloÎncă nu există evaluări

- Hot Work Tool Steel: Z Similar SteelsDocument2 paginiHot Work Tool Steel: Z Similar SteelsedelapolloÎncă nu există evaluări

- Tto Eco+P: Ecodesign Liquid Immersed Hermetic Transformers - Technical Catalogue According To Regulation EU No. 548/2014Document8 paginiTto Eco+P: Ecodesign Liquid Immersed Hermetic Transformers - Technical Catalogue According To Regulation EU No. 548/2014Ivan HandjievÎncă nu există evaluări

- 1600KVA ស្វាយជ្រុំRMU, LVDBDocument4 pagini1600KVA ស្វាយជ្រុំRMU, LVDBmain mydriveÎncă nu există evaluări

- Direct RF Sampling Transceiver Architecture Applied To VHF Radio, Acars and EltsDocument10 paginiDirect RF Sampling Transceiver Architecture Applied To VHF Radio, Acars and EltsjaxÎncă nu există evaluări

- Design of OFDM Transmitter and Receiver For Error Free CommunicationDocument61 paginiDesign of OFDM Transmitter and Receiver For Error Free CommunicationVamshiKrishnaReddyÎncă nu există evaluări

- PanasonicGP31 ChassisDocument16 paginiPanasonicGP31 ChassisLuis RamirezÎncă nu există evaluări

- B.Tech. V-Semester Supplementary Examinations, April-2019 Antennas and Wave PropagationDocument2 paginiB.Tech. V-Semester Supplementary Examinations, April-2019 Antennas and Wave PropagationSarath Chandra VarmaÎncă nu există evaluări

- Iecex PTB 06.0049XDocument7 paginiIecex PTB 06.0049XFrancesco_CÎncă nu există evaluări

- Ficha Tecnica MircomDocument4 paginiFicha Tecnica Mircomcort68Încă nu există evaluări

- E300 Electronic Overload RelayDocument44 paginiE300 Electronic Overload Relayvõ cườngÎncă nu există evaluări

- Analisis en DC Con QucsDocument13 paginiAnalisis en DC Con Qucscayo_sincheÎncă nu există evaluări

- List of Purchase Units and Reference Pages: CautionDocument15 paginiList of Purchase Units and Reference Pages: Cautionmaran.suguÎncă nu există evaluări

- Digital Ic TesterDocument28 paginiDigital Ic TesterChris ManojÎncă nu există evaluări

- Detector de Movimiento LEGRANDDocument4 paginiDetector de Movimiento LEGRANDDeyvi Vasquez PittmanÎncă nu există evaluări

- Cerberus Pyrotronics Strobes 2 4952870316 2Document2 paginiCerberus Pyrotronics Strobes 2 4952870316 2Rafael DantasÎncă nu există evaluări

- Omega Manual FrenchDocument23 paginiOmega Manual FrenchmimiscriÎncă nu există evaluări

- EC60085-DSP and Its Applications Homework-2: Due Date: 14 Sept. 2019Document2 paginiEC60085-DSP and Its Applications Homework-2: Due Date: 14 Sept. 2019harshitÎncă nu există evaluări

- MPI (Slides 8085 Microprocessor)Document20 paginiMPI (Slides 8085 Microprocessor)Rosh_MiÎncă nu există evaluări

- 30W Gan Wide-Band Power Amplifier: RF in VGQ Pin 1 (CUT) RF Out VDQ Pin 2 GND BaseDocument7 pagini30W Gan Wide-Band Power Amplifier: RF in VGQ Pin 1 (CUT) RF Out VDQ Pin 2 GND BaseRajneesh VermaÎncă nu există evaluări

- 80 Channel System For Various Interior Measurement ScenariosDocument2 pagini80 Channel System For Various Interior Measurement ScenariosXVJÎncă nu există evaluări

- Al802Ulada: NAC Power Extender Installation GuideDocument12 paginiAl802Ulada: NAC Power Extender Installation GuideChristine May CagaraÎncă nu există evaluări

- 03 - Sensors - Sensor Input ManagementDocument14 pagini03 - Sensors - Sensor Input ManagementLeca GeorgeÎncă nu există evaluări

- Analysis of Single Switch Step Up DC-DC Converter For Alternative Energy SystemsDocument6 paginiAnalysis of Single Switch Step Up DC-DC Converter For Alternative Energy SystemsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Fault Identification System For Electric Power Transmission Lines Using Artificial Neural NetworksDocument8 paginiFault Identification System For Electric Power Transmission Lines Using Artificial Neural NetworksPeter MbamaluikemÎncă nu există evaluări

- NDE 152 Final MT Review - STUDENT - SP18Document5 paginiNDE 152 Final MT Review - STUDENT - SP18donciriusÎncă nu există evaluări

- Introduction To Test Methodologies: Keysight I3070 In-Circuit Test SystemDocument26 paginiIntroduction To Test Methodologies: Keysight I3070 In-Circuit Test SystemHà LêÎncă nu există evaluări

- 4-2 ECE R13 Syllabus TSSNDocument21 pagini4-2 ECE R13 Syllabus TSSNnagaraniÎncă nu există evaluări

- Half Wave and Full Wave RectifierDocument8 paginiHalf Wave and Full Wave Rectifierbolbo naÎncă nu există evaluări

- LTG CotelDocument56 paginiLTG Cotelvlady callisayaÎncă nu există evaluări