Documente Academic

Documente Profesional

Documente Cultură

L12-Cathodic & Anodic Protection

Încărcat de

Amir KhalidDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

L12-Cathodic & Anodic Protection

Încărcat de

Amir KhalidDrepturi de autor:

Formate disponibile

1

Trethewey & Chamberlain; Ch-16

Fontana; Ch-6

2

The theoretical basis

3

Free corrosion potential E

corr

of iron in

aerated water is in the range of -600 to -

700 mV SSC at pH 7.

Different ways of affecting the condition of

the system at point O are:

Decreasing the pH

Increasing the pH

Apply a more negative potential

Cathodic Protection (CP)

Make the potential more positive

Anodic Protection (AP)

4

CPDesign Considerations

5

The corrosion rate, i

p

, at a given polarization

cathodic to E

corr

(at which the corrosion rate is i

corr

)

is expressed by

K T

Z

T R

F Z

i i

corr p

283

2

5 . 0

) exp(

=

=

=

=

o

q o

6

For a given polarization of -200 mV, we get

corr p

corr p

i i

x

x x x

i i

00027 . 0

283 314 . 8

494 , 96 2 ) 2 . 0 ( 5 . 0

exp

=

|

|

.

|

\

|

=

Therefore, the corrosion rate at -850 mV SSC will be reduced to 0.03%

of the rate of unprotected steel.

At -750 mV SSC, corrosion rate is reduced to 2% of the rate at E

corr

.

Cathodic Protection

The most important of all approaches to corrosion control.

Using an externally applied electric current, corrosion is reduced

(approaching zero).

The mechanism of cathodic protection depends on external current that

polarizes the entire surface to the thermodynamic potential of the

anode.

The surface becomes equipotential (cathode and anode potentials

become equal), and corrosion currents no longer flow.

Or, looked at another way, at a high enough value of external current

density, a net positive current enters the metal at all regions of the

metal surface (including anodic areas); hence, there is no tendency for

metal ions to enter into solution.

Cathodic protection can be applied in practice to protect metals, such

as steel, copper, lead, and brass, against corrosion in all soils and in

almost all aqueous media.

7

Pitting corrosion can be prevented in passive metals, such as the

stainless steels or aluminum.

Cathodic protection can be used effectively to eliminate

stress - corrosion cracking (e.g., of brass, mild steel, stainless steels,

magnesium, aluminum),

corrosion fatigue of most metals (but not fatigue),

intergranular corrosion (e.g., of Duralumin, 188 stainless steel), or

dezincification of brass.

It can be used to avoid SCC of high-strength steels, but not

hydrogen cracking of such steels.

Corrosion above the water line (e.g., of water tanks) is not affected,

because the impressed current cannot reach metal areas that are

out of contact with the electrolyte.

Nor does the protective current extend into electrically screened

areas, such as the interior of water condenser tubes (unless the

auxiliary anode enters the tubes), even though the water box may

be adequately protected.

8

9

Types of CP

Two types:

1) Sacrificial anode CP (SACP)

2) Impressed current CP (ICCP)

10

Example of Sacrificial Anode CPover ground

11

Example of Sacrificial Anode CPover ground

12

Sacrificial anodes

The sacrificial anodes are usually composed of magnesium or magnesium-

based alloys.

Occasionally, zinc or aluminum has been used.

Approximately 10 million pounds of magnesium is annually used for this

purpose.

The open-circuit potential difference between magnesium and steel is about

1 V.

This means that one anode can protect only a limited length of pipeline.

However, this low voltage can have an advantage over higher

impressed voltages in that the danger of overprotection to some portions of

the structure is less; and because the total current per anode is limited, the

danger of stray-current damage to adjoining metal structures is reduced.

Magnesium anode rods have also been placed in steel hot-water tanks to

increase the life of these tanks. The greatest degree of protection is

afforded in hard waters where the conductivity of the water is greater

than in soft waters.

13

Anode Requirements

To provide cathodic protection, a current density

of a few milliamps (mA) is required.

To determine the anodic requirements, it is

necessary to know the energy content of the

anode and its efficiency.

From this data the necessary calculations can

be made to size the anode, determine its

expected life, and determine the number of

anodes required.

The three most common metals used are

magnesium,

zinc, and

Aluminum.

14

15

Principle of impressed current CP

16

17

18

Potentials more negative than -850 mV SSC show even

less metal loss. Why not use -1000 mV SSC, or lower?

There are two reasons:

1) More hydrogen evolution at more negative

potentials. It may cause damage like

hydrogen embrittlement etc.

2) More negative potentials produce high local

concentrations of hydroxyl ions which ,may

cause chalking or damage any barrier

coatings such as paint.

19

Current should be controlled or potential?

Fixing current may cause decrease in current

density if the area is increased by damage in

coating. This may change potential towards

E

corr

.

Area may increase or decrease

Regulating potential can provide required

current density.

20

Sacrificial Anode Design

21

Protection PotentialE

p

It is the least negative potential necessary

to achieve a satisfactory level of

protection.

For steel in aerated seawater, this is

considered to be 800 mV SSC

The anodes connected for protection are

termed as Sacrificial Anodes.

The anodes are usually welded or

mechanically coupled with the structure at

predetermined points.

22

Anodes Material

Usually Zinc, Magnesium & Aluminum

Traditionallyfor steel in seawater; Zinc &

Cast Iron

Using sacrificial anodes on Copper reduced

the consumption, however, fouling was

increased.

C-Sentry __ Zn-alloy with

0.10.5% Al,

0.0250.15% Cd.

Extensively used by marine industry.

23

Sacrificial anodes are supposed to be

dissolving at uniform rate.

Commercially pure zinc corrodes in seawater

forming an impermeable skin which severely

limits its current output.

Fethe most detrimental impurity

Its solubility in Zn is so low (<0.0014%) that any

excess is present as discrete particles.

This forms local galvanic cellsproducing a

coating of insoluble non-conducting Zn-hydroxide

or Zn-carbonate.

Addition of Al is beneficiala less noble Al-Fe

intermetallic is formed which reduces the effect of

local corrosion cells.

24

Addition of Cdreduces the adverse effect of Pb

impurity

Aluminum

undergoes pitting corrosion in seawater because of

cathodic oxide film

Therefore, pure Almost unreliable for use as sacrificial

anodes

Al-alloys containing Zn & Hg or Zn & In

Have much higher electrical power/weight ratios than Zn-

alloys

Magnesium

Too vigorous corrosion rate in seawater

Used in soil or estuarine waters where resistivity is

relatively high to limit effectiveness of Alor Znalloys

25

26

Efficiency of anodes

Magnesium in seawater

E

corr

~ -2.12 V SCE (theoretical)

E

corr

~ -1.7 V SCE (practical)

Theoretically, 1 kg should yield ~ 2200 A h

Practically, 1200 A h

Therefore, efficiency = 5060%

Efficiency for Zn and Al alloys is >90%.

27

Factors that affect current requirements are:

1. The nature of the electrolyte

2. The soil resistivity

3. The degree of aeration

The required current to provide cathodic

protection can vary from 0.5 to 20 mA/ft

2

of bare

surface.

28

29

Benefit of coating

Less anode material is required for a coated

structure

A surface with a fresh coal tar paintwill be well

protected with a current density of 2030 mA/m

2

to accommodate holidays in the coating

A bare steel structure requires >100 mA/m

2

.

30

Few important terminologies

Capacity of an anode

The no. of Ampere-hours supplied by each kg of

the material

Wastage rate

Current output per unit of exposed surface

areaexpresses the rate of loss of metal by

volume or mass

Throwing power

The effective distance between the metal and

the anode

31

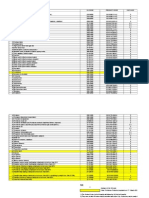

Total weight of anode material required to protect a

structure for its projected life is:

C

L A i

W

av

8760 * * *

=

W= total mass of anode material (kg)

A = area of structure (m

2

)

i

av

= mean current density demand of the structure (A m

-2

)

C = anode capacity (A h kg

-1

)

L = Design life (years)

32

Total weight of anode material must equal or

exceed W

Each individual anode must be able to supply

current for the design lifetime and be able to

meet varying demands.

Current output from an anode will vary

according to its shape.

The anode output I therefore, is dependant

on

The anode shape

The resistivity of environment

The protection potential E

p

(usually ~ -0.8 V SSC)

The anode operating potential E

a

33

I = (E

p

E

a

)/R

a

Where R

a

is the anode resistance (depends on

shape)

Anode life L is then given by

L = (M

a

U)/(I W

w

)

M

a

is the mass of single anode

I is the anode current

W

w

is the waste rate by weight (kg (Ay)

-1

U is the utilization factor which depends on

anode geometry and is the fraction of

material consumed when the remaining

material is no longer able to provide the

required current.

34

35

Anodes distribution

A good protection is achieved with more

anodes, but

It increases cost and weight

Correct protection potential should be

maintained at points of structure most

vulnerable to stress

E.g. welded joints of offshore platform, called

nodes

Danger may be associated with overprotection

and hydrogen embrittlement

Anode-cathode distance is also important

36

37

38

Testing for Completeness of Protection

The preferred method is to take potential

measurements.

Position of reference electrode

as close as possible to the protected structure

avoids and minimizes internal resistance (IR)

drop through the soil.

For buried pipelines, a compromise location is directly over

the buried pipe at the soil surface because cathodic

protection currents flow mostly to the lower surface and are

minimum at the upper surface of the pipe buried a few feet

below the surface.

39

Overpotential of steel structures,

If to a moderate degree, does not cause any problems.

The primary disadvantages are

waste of power and

increased consumption of auxiliary anodes.

hydrogen can be generated at the protected structure,

causes

blistering of organic coatings,

hydrogen embrittlement of the steel, or

hydrogen cracking.

Overprotection of systems with amphoteric

metals (e.g., tin, lead, aluminum, zinc)

will damage the metal by causing increased attack

instead of reduced corrosion.

40

Several ways to check effectiveness of protection.

1. Coupon test. A metal coupon is shaped to conform to the contour of the pipe,

weighed, and attached by a braze-connected cable to the pipe. Both the cable

and the surface between the coupon and the pipe are coated with coal tar. The

coupon is allowed to remain buried for weeks or months, uncovered, cleaned,

and weighed. The weight loss, if any, is an indication as to whether or not the

cathodic protection is complete.

2. Colorimetric test. A piece of absorbent paper soaked in potassium ferricyanide

solution is placed in contact with a cleaned section of the buried pipeline and

the soil replaced. After a relatively short time, the paper is retrieved. A blue

ferrous/ferricyanide reaction indicates incomplete cathodic protection, whereas

an absence of blue on the paper indicates that cathodic protection is complete.

3. Potential measurements. By measuring the potential of the protected

structure, the degree of protection, including overprotection, can be quantitavely

determined. This measurement is the generally accepted criterion and is used

by corrosion engineers. The basis for this determination is the fundamental

concept that cathodic protection is complete when the protected structure is

polarized to the open-circuit anodic potential of the local action cells.

41

S-ar putea să vă placă și

- Lecture Cathodic ProtectionDocument23 paginiLecture Cathodic ProtectionNoman RazaÎncă nu există evaluări

- Anodic ProtectionDocument30 paginiAnodic ProtectionLuis Eduardo PereiraÎncă nu există evaluări

- 11.sacrificial Cathodic ProtrctionDocument5 pagini11.sacrificial Cathodic ProtrctionChayon MondalÎncă nu există evaluări

- Presentation - Painting, Coating & Corrosion Protection - Beca - Cathodic ProtectionDocument56 paginiPresentation - Painting, Coating & Corrosion Protection - Beca - Cathodic Protectionzinha_al100% (1)

- Cathodic Protection en - WikipediaDocument8 paginiCathodic Protection en - WikipediaPRABHU SHANKAR MÎncă nu există evaluări

- Anodic ProtectionDocument50 paginiAnodic ProtectionEngr Arfan Ali DhamrahoÎncă nu există evaluări

- Design of Cp1.PDF-3Document12 paginiDesign of Cp1.PDF-3Diwakar NigamÎncă nu există evaluări

- Cathodic Protection Training GuideDocument71 paginiCathodic Protection Training Guideahmed100% (1)

- Cathodic Protection - Calc.Document6 paginiCathodic Protection - Calc.EngFaisal Alrai100% (2)

- Cathodic Protection Wrap PipeDocument23 paginiCathodic Protection Wrap PipeyogacruiseÎncă nu există evaluări

- Cathodic Protection - PresentationDocument24 paginiCathodic Protection - Presentationatripathi2009Încă nu există evaluări

- Cathodic Protection SystemDocument27 paginiCathodic Protection SystemSandeep GuptaÎncă nu există evaluări

- Cathodic Protection Process of CorrosionDocument14 paginiCathodic Protection Process of CorrosionAdelÎncă nu există evaluări

- Calculation of CPCXXDocument2 paginiCalculation of CPCXXAdis Kawe100% (1)

- CP System DesignDocument8 paginiCP System Designvchui34Încă nu există evaluări

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 paginiCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- What Is CorrosionDocument4 paginiWhat Is CorrosionOsransyah Os100% (1)

- Impressed Current Cathodic Protection Design For Eleme Petrochemical 6 and 8'' Pipeline PDFDocument16 paginiImpressed Current Cathodic Protection Design For Eleme Petrochemical 6 and 8'' Pipeline PDFobuseÎncă nu există evaluări

- Cathodic protection design examplesDocument26 paginiCathodic protection design examplesmspd2003Încă nu există evaluări

- Lecture on corrosion types and controlDocument43 paginiLecture on corrosion types and controlTEZ ANALYSIS AND STORIESÎncă nu există evaluări

- Design and calculation permanent CP systemDocument14 paginiDesign and calculation permanent CP systemVIETLHÎncă nu există evaluări

- Cathodic Protection DesignDocument34 paginiCathodic Protection Designsouheil boussaid100% (2)

- Design & Calculation Cathodic Protection Impressed Cureent SystemDocument107 paginiDesign & Calculation Cathodic Protection Impressed Cureent Systemmtuanlatoi9704Încă nu există evaluări

- Corrosion LibraryDocument73 paginiCorrosion Libraryuyus72Încă nu există evaluări

- Nace Standard On Cathodic Protection - Google SearchDocument2 paginiNace Standard On Cathodic Protection - Google SearchankiÎncă nu există evaluări

- Cathodic Protection DesignDocument30 paginiCathodic Protection Designmtuanlatoi9704Încă nu există evaluări

- Cathodic ProtectionDocument68 paginiCathodic Protectionsjaveeds2003Încă nu există evaluări

- CorrosionDocument65 paginiCorrosionSurendra Kamal100% (9)

- AC Mit PowerTool Quick Guide PrciDocument23 paginiAC Mit PowerTool Quick Guide PrciJoe BlagÎncă nu există evaluări

- P Cathodic ProtectionDocument118 paginiP Cathodic Protectiondian astuti100% (5)

- Design of ICCP For Steel Immersed in Freshwater (Thesis)Document107 paginiDesign of ICCP For Steel Immersed in Freshwater (Thesis)VCÎncă nu există evaluări

- Cathodic Protection CourseDocument545 paginiCathodic Protection Coursekirubha_karan2000100% (2)

- Design Aspects of Cathodic ProtectionDocument24 paginiDesign Aspects of Cathodic ProtectionRahul AdityaÎncă nu există evaluări

- Cathodic Protection - Rev 1Document162 paginiCathodic Protection - Rev 1Mohammed almarhabiÎncă nu există evaluări

- Water Line Stray Current ControlDocument18 paginiWater Line Stray Current ControlVinzoKeiÎncă nu există evaluări

- Cathodic Protection For Steel Water Storage Tanks Pocket Field GuideDocument15 paginiCathodic Protection For Steel Water Storage Tanks Pocket Field GuideBilel YoussefiÎncă nu există evaluări

- Tanks CP System CalculationDocument1 paginăTanks CP System CalculationkakoullisgÎncă nu există evaluări

- Cpmonitoringeffectiveness (CP Bullet)Document47 paginiCpmonitoringeffectiveness (CP Bullet)thongpvgasÎncă nu există evaluări

- IES - Cathodic Protection Basic PresentationDocument81 paginiIES - Cathodic Protection Basic PresentationAmit HasanÎncă nu există evaluări

- Cathode Protection Bullets & TanksDocument53 paginiCathode Protection Bullets & TanksGanga DharÎncă nu există evaluări

- Anode Calculation TemplateDocument1 paginăAnode Calculation TemplateFian Ardiyana100% (1)

- A Simple View of Corrosion Causes and PreventionDocument19 paginiA Simple View of Corrosion Causes and Preventiongopal singhÎncă nu există evaluări

- DC and AC InterferenceDocument40 paginiDC and AC InterferenceREJI JOY ThoppilÎncă nu există evaluări

- ACVG TheoryDocument49 paginiACVG TheorynuvanÎncă nu există evaluări

- WIS5 ConsumablesDocument29 paginiWIS5 ConsumablesMNur SarhanÎncă nu există evaluări

- Cathodic Protection Report - EKFLRDocument19 paginiCathodic Protection Report - EKFLReke23100% (1)

- Cathodic Protection PDFDocument24 paginiCathodic Protection PDFJorge Luis Clavijo Iturri50% (2)

- Cathodic Protection Design for Steel Fuel Oil LinesDocument99 paginiCathodic Protection Design for Steel Fuel Oil LinesAhmed Abdel Hafez67% (3)

- Cathodic Protection Design Using Ceramic AnodesDocument132 paginiCathodic Protection Design Using Ceramic Anodesadeoye_okunoyeÎncă nu există evaluări

- Cathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeDocument7 paginiCathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeFa HedaiatÎncă nu există evaluări

- Cathodic Protection Design Analysis for SOF GSBDocument12 paginiCathodic Protection Design Analysis for SOF GSBBosko Ginz JadibataÎncă nu există evaluări

- Stray Current CorrosionDocument21 paginiStray Current CorrosionPaolo Mogollon AcostaÎncă nu există evaluări

- Case Study-Corrosion ProtectionDocument25 paginiCase Study-Corrosion ProtectionAjeng Fadillah100% (1)

- Cathodic ProtectionDocument34 paginiCathodic Protectiongharsallah mounaÎncă nu există evaluări

- 1986-0040-EL-SPE05-0001 RA Specification For Cathodic Protection SystemDocument12 pagini1986-0040-EL-SPE05-0001 RA Specification For Cathodic Protection Systemjmohammadreza100% (1)

- Cathodic protection A Complete Guide - 2019 EditionDe la EverandCathodic protection A Complete Guide - 2019 EditionÎncă nu există evaluări

- Overview of Cathodic Protection in 40 CharactersDocument36 paginiOverview of Cathodic Protection in 40 CharactersrampokalaÎncă nu există evaluări

- Cathodic Protection PresentationDocument38 paginiCathodic Protection PresentationSHAHUL HAMEED100% (2)

- Cathodic Protection of Pipes (CPDocument25 paginiCathodic Protection of Pipes (CPnimish ugemugeÎncă nu există evaluări

- Cathodic Protection TechniqueDocument7 paginiCathodic Protection TechniquefayasÎncă nu există evaluări

- Zno Nano Composite Poster 1Document1 paginăZno Nano Composite Poster 1Amir KhalidÎncă nu există evaluări

- Assignment SEMDocument1 paginăAssignment SEMAmir KhalidÎncă nu există evaluări

- Heat Exchanger Corrosion from Untreated WaterDocument45 paginiHeat Exchanger Corrosion from Untreated WaterAmir KhalidÎncă nu există evaluări

- The SI systemDocument2 paginiThe SI systemAmir KhalidÎncă nu există evaluări

- Fixed Bed Gasifiers TypesDocument1 paginăFixed Bed Gasifiers TypesAmir KhalidÎncă nu există evaluări

- Caustic SodaDocument15 paginiCaustic SodaAmir KhalidÎncă nu există evaluări

- Bromine Literature ReviewDocument78 paginiBromine Literature ReviewChakuli100% (2)

- Stoichiometry Handout 6.1Document5 paginiStoichiometry Handout 6.1Vanesa DimasacupanÎncă nu există evaluări

- Cleaner CompositionsDocument10 paginiCleaner Compositionsyilmaz_uuurÎncă nu există evaluări

- Complete List of Licensable ChemicalsDocument14 paginiComplete List of Licensable ChemicalsLukmannÎncă nu există evaluări

- B.Sc I yr CHEMISTRY SYLLABUS SEMESTER IDocument30 paginiB.Sc I yr CHEMISTRY SYLLABUS SEMESTER ITitikshaÎncă nu există evaluări

- Groundwater Quality Status Using Water Quality Index in Amalner Town MaharashtraDocument5 paginiGroundwater Quality Status Using Water Quality Index in Amalner Town Maharashtrasunaina agarwalÎncă nu există evaluări

- UnfinishedDocument8 paginiUnfinishedDaniel TorralbaÎncă nu există evaluări

- GALabsite - EXERCISE 4Document4 paginiGALabsite - EXERCISE 4EggÎncă nu există evaluări

- Oreas 402Document2 paginiOreas 402flysch_ukÎncă nu există evaluări

- TDS Pattex Repair Extreme 031223Document2 paginiTDS Pattex Repair Extreme 031223jfmanÎncă nu există evaluări

- Production of Citric Acid by Aspergillus nigerDocument9 paginiProduction of Citric Acid by Aspergillus nigerNikitaÎncă nu există evaluări

- Topic 1 - Introduction To Plumbing Module 1-DEFINITIONDocument85 paginiTopic 1 - Introduction To Plumbing Module 1-DEFINITIONJersey PerlasÎncă nu există evaluări

- Introduction To Organic ChemistryDocument92 paginiIntroduction To Organic ChemistryAmmaarah PatelÎncă nu există evaluări

- Pre FormulationDocument13 paginiPre FormulationCm MouliÎncă nu există evaluări

- Objectives: - Describe - Identify - Describe - CalculateDocument29 paginiObjectives: - Describe - Identify - Describe - CalculateJanaÎncă nu există evaluări

- Mccabe SolutionDocument66 paginiMccabe SolutionSuhailÎncă nu există evaluări

- Dr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane CoatingDocument4 paginiDr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane Coatingkkundan52Încă nu există evaluări

- Amdry - Activated Diffusion Braze AlloysDocument6 paginiAmdry - Activated Diffusion Braze AlloysJ. BangjakÎncă nu există evaluări

- Cryogenic Piping Stress AnalysisDocument6 paginiCryogenic Piping Stress AnalysismasilamaniÎncă nu există evaluări

- Wan Noor Afifah BT Wan YusoffDocument33 paginiWan Noor Afifah BT Wan YusoffThilagavathyÎncă nu există evaluări

- Environmental Impact Assessment of Balakot Hydropower ProjectDocument428 paginiEnvironmental Impact Assessment of Balakot Hydropower ProjectArslan HaiderÎncă nu există evaluări

- Methods of extraction: Pyrometallurgy Techniques (Stage 2Document22 paginiMethods of extraction: Pyrometallurgy Techniques (Stage 2Oluwasegun OkajareÎncă nu există evaluări

- JM 72052 Olefin Product ListDocument2 paginiJM 72052 Olefin Product Listricko4001Încă nu există evaluări

- Study On Fusion Characteristics of Biomass AshDocument9 paginiStudy On Fusion Characteristics of Biomass AshPrakash WarrierÎncă nu există evaluări

- Explosion Proof ATEX LiftsDocument12 paginiExplosion Proof ATEX LiftshtpshareÎncă nu există evaluări

- Catalog FEEL by THM AgencyDocument68 paginiCatalog FEEL by THM Agencykartika lestariÎncă nu există evaluări

- Phys Sci Classifying Elements ComicDocument4 paginiPhys Sci Classifying Elements Comicapi-253632941Încă nu există evaluări

- United States Patent (10) Patent No.: US 6,773,818 B2: Cretekos Et Al. (45) Date of Patent: Aug. 10, 2004Document10 paginiUnited States Patent (10) Patent No.: US 6,773,818 B2: Cretekos Et Al. (45) Date of Patent: Aug. 10, 2004Arif QA AresÎncă nu există evaluări

- Decomposition of Sodium ChlorateDocument3 paginiDecomposition of Sodium Chlorateعبد القادر حدادÎncă nu există evaluări