Documente Academic

Documente Profesional

Documente Cultură

Major Project Report-Libre

Încărcat de

Leo-Brian V. Valisto0 evaluări0% au considerat acest document util (0 voturi)

186 vizualizări74 paginiMajor Project Report-libre

Titlu original

Major Project Report-libre

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMajor Project Report-libre

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

186 vizualizări74 paginiMajor Project Report-Libre

Încărcat de

Leo-Brian V. ValistoMajor Project Report-libre

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 74

1

PROJECT REPORT SUBMITTED IN PARTIAL FULFILLMENT FOR THE

DEGREE OF

BACHELOR OF TECHNOLOGY

IN

CIVIL ENGINEERING

ON

ANALYSIS AND DESIGN OF THREE STOREY FRAMED

BUILDING

BY

UMER FAROOQ MUZAMIL YOUSUF

ROLL NO 01-CE-2008 ROLL NO 22-CE-2008

Department of civil engineering

Baba Ghulam Shah Badshah University, Rajouri

2

PROJECT REPORT SUBMITTED IN PARTIAL FULFILLMENT FOR THE

DEGREE OF

BACHELOR OF TECHNOLOGY

IN

CIVIL ENGINEERING

ON

ANALYSIS AND DESIGN OF THREE STOREY FRAMED

BUILDING

BY

UMER FAROOQ MUZAMIL YOUSUF

ROLL NO 01-CE-2008 ROLL NO 22-CE-2008

Under the guidance of

MR. VASEEM AHMAD SHAHNAZ

Head of Department of civil engineering

Baba Ghulam Shah Badshah University, Rajouri

3

ACKNOWLEGDGEMENTS

At the outset, I express my deepest thanks to our Lord, the most Gracious,

the most merciful, the cherisher and sustainer of the worlds.

I am thankful to my parents who continuously look after me right from

my birth, provided me with the best facilities that they could provide me and

continuously encouraged me to perform well in my studies and my daily life in

general. All these factors were the favorable conditions that made me to strive

for the better future life. May the almighty forgive me, my parents and all the

believers on the Day of Reckoning

I express my deepest gratitude to my teacher Mr. Mir Aijaz Ahmad who

as a mentor and Asstt. Professor in the Department of Civil Engineering for

his invaluable guidance and inputs. I thank him for allowing me to work on this

project and for his constant help and support throughout my endeavor. I

consider myself fortunate to have worked under his supervision. It was a

matter of great pleasure to have him as a guide in the preparation of this

project report.

I take this great opportunity to express my profound gratitude to HOD

Civil Engineering Mr Vaseem Shahnaz for his superlative flow of ideas and

guidance as well as moving inspirations all throughout the classes. I owe a lot

to him for his kind gesture in serving our teacher. I also thank him for

checking the report before submission.

Umer Farooq Muzamil Yousuf

Roll no. 01-CE-2008 Roll no. 22-CE-2008

4

DEPARTMENT OF CI VI L ENGI NEERI NG

BABA GHULAM SHAH BADSHAH UNI VERSI TY

RAJOURI J&K- 185131 (I NDI A)

CERTIFICATE

This is to certify that this report entitled ANALYSIS AND DESIGN OF

THREE STOREY FRAMED BUILDING submitted by UMER FAROOQ

(01-CE-2008), and MUZAMIL YOUSUF (22-CE-2008) in partial fulfillments

for the requirements for the award of Bachelor of Technology Degree in

Civil Engineering at College of Engineering & Technology, BGSB

University, Rajouri (J&K) is an authentic work carried out by them under

my supervision and guidance.

To the best of my knowledge, the matter embodied in this report has not

been submitted to any other University/Institute for the award of any

Degree or Diploma.

Date:

Mr. Vaseem Ahmad Shahnaz

HOD External Examiner

Department of Civil Engineering

5

CONTENTS

S. No. Description Page No.

1.

Abstract

6

2.

History

7

3.

Introduction

12

4.

Analysis under Vertical loads

15

5.

Design of Slabs

25

6.

Design of Beams

38

7.

Design of Columns

47

8.

Design of Footing

53

9.

Design of Stairs

71

10.

References

74

6

ABSTRACT

Structural design is the primary aspect of civil engineering. The foremost

basic in structural engineering is the design of simple basic components and

members of a building viz., Slabs, Beams, Columns and Footings. In order to

design them, it is important to first obtain the plan of the particular building.

Thereby depending on the suitability; plan layout of beams and the position of

columns are fixed. Thereafter, the vertical loads are calculated namely the

dead load and live load.

Once the loads are obtained, the component takes the load first i.e the slabs

can be designed. Designing of slabs depends upon whether it is a one-way or

a two-way slab, the end conditions and the loading. From the slabs, the loads

are transferred to the beam. The loads coming from the slabs onto the beam

may be trapezoidal or triangular. Depending on this, the beam may be

designed. Thereafter, the loads (mainly shear) from the beams are taken by

the columns. For designing columns, it is necessary to know the moments

they are subjected to. For this purpose, frame analysis is done by Moment

Distribution Method. After this, the designing of columns is taken up

depending on end conditions, moments, eccentricity and if it is a short or

slender column. Most of the columns designed in this mini project were

considered to be axially loaded with uniaxial bending. Finally, the footings are

designed based on the loading from the column and also the soil bearing

capacity value for that particular area. Most importantly, the sections must be

checked for all the four components with regard to strength and serviceability.

7

CHAPTER 1

HISTORY

8

HISTORY

STRUCTURAL ANALYSIS

A structure refers to a system of two or more connected parts use to support

a load. It is an assemblage of two or more basic components connected to

each other so that they serve the user and carry the loads developing due to

the self and super-imposed loads safely without causing any serviceability

failure. Once a preliminary design of a structure is fixed, the structure then

must be analyzed to make sure that it has its required strength and rigidity. To

analyze a structure a structure correctly, certain idealizations are to be made

as to how the members are supported and connected together. The loadings

are supposed to be taken from respective design codes and local

specifications, if any. The forces in the members and the displacements of the

joints are found using the theory of structural analysis.

The whole structural system and its loading conditions might be of complex

nature so to make the analysis simpler, we use certain simplifying

assumptions related to the quality of material, member geometry, nature of

applied loads, their distribution, the type of connections at the joints and the

support conditions. This shall help making the process of structural analysis

simpler to quite an extent.

Methods of structural analysis

When the number of unknown reactions or the number of internal forces

exceeds the number of equilibrium equations available for the purpose of

analysis, the structure is called as a statically indeterminate structure. Most of

the structures designed today are statically indeterminate. This indeterminacy

may develop as a result of added supports or extra members, or by the

general form of the structure.

While analyzing any indeterminate structure, it is essential to satisfy

equilibrium, compatibility, and force-displacement requisites for the structure.

When the reactive forces hold the structure at rest, equilibrium is satisfied and

9

compatibility is said to be satisfied when various segments of a structure fit

together without intentional breaks or overlaps.

Two fundamental methods to analyze the statically indeterminate structures

are discussed below.

Force methods-

Originally developed by James Clerk Maxwell in 1864, later developed by

Otto Mohr and Heinrich Muller-Breslau, the force method was one of the first

methods available for analysis of statically indeterminate structures. As

compatibility is the basis for this method, it is sometimes also called as

compatibility method or the method of consistent displacements. In this

method, equations are formed that satisfy the compatibility and force-

displacement requirements for the given structure in order to determine the

redundant forces. Once these forces are determined, the remaining reactive

forces on the given structure are found out by satisfying the equilibrium

requirements.

Displacement methods-

The displacement method works the opposite way. In these methods, we first

write load-displacement relations for the members of the structure and then

satisfy the equilibrium requirements for the same. In here, the unknowns in

the equations are displacements. Unknown displacements are written in

terms of the loads (i.e. forces) by using the load-displacement relations and

then these equations are solved to determine the displacements. As the

displacements are determined, the loads are found out from the compatibility

and load- displacement equations. Some classical techniques used to apply

the displacement method are discussed.

Slope deflection method-

This method was first devised by Heinrich Manderla and Otto Mohr to study

the secondary stresses in trusses and was further developed by G. A. Maney

extend its application to analyze indeterminate beams and framed structures.

10

The basic assumption of this method is to consider the deformations caused

only by bending moments. Its assumed that the effects of shear force or axial

force deformations are negligible in indeterminate beams or frames.

The fundamental slope-deflection equation expresses the moment at the end

of a member as the superposition of the end moments caused due to the

external loads on the member, while the ends being assumed as restrained,

and the end moments caused by the displacements and actual end rotations.

A structure comprises of several members, slope-deflection equations are

applied to each of the member. Using appropriate equations of equilibrium for

the joints along with the slope-deflection equations of each member we can

obtain a set of simultaneous equations with unknowns as the displacements.

Once we get the values of these unknowns i.e. the displacements we can

easily determine the end moments using the slope-deflection equations.

Moment distribution method-

This method of analyzing beams and multi-storey frames using moment

distribution was introduced by Prof. Hardy Cross in 1930, and is also

sometimes referred to as Hardy Cross method. It is an iterative method in

which one goes on carrying on the cycle to reach to a desired degree of

accuracy. To start off with this method, initially all the joints are temporarily

restrained against rotation and fixed end moments for all the members are

written down. Each joint is then released one by one in succession and the

unbalanced moment is distributed to the ends of the members, meeting at the

same joint, in the ratio of their distribution factors. These distributed moments

are then carried over to the far ends of the joints. Again the joint is temporarily

restrained before moving on to the next joint. Same set of operations are

performed at each joints till all the joints are completed and the results

obtained are up to desired accuracy. The method does not involve solving a

number of simultaneous equations, which may get quite complicated while

applying large structures, and is therefore preferred over the slope-deflection

method.

11

Kanis method-

This method was first developed by Prof. Gasper Kani of Germany in the year

1947. The method is named after him. This is an indirect extension of slope

deflection method. This is an efficient method due to simplicity of moment

distribution. The method offers an iterative scheme for applying slope

deflection method of structural analysis. Whereas the moment distribution

method reduces the number of linear simultaneous equations and such

equations needed are equal to the number of translator displacements, the

number of equations needed is zero in case of the Kanis method. This

method may be considered as a further simplification of moment distribution

method wherein the problems involving sway were attempted in a tabular

form thrice (for double story frames) and two shear coefficients had to be

determined which when inserted in end moments gave us the final end

moments. All this effort can be cut short very considerably by using this

method.

Advantages of Kanis method:

All the computations are carried out in a single line diagram of the

structure.

The effects of joint rotations and sway are considered in each cycle

of iteration. Henceforth, no need to derive and solve the simultaneous

equations. This method thus becomes very effective and easy to use

especially in case of multistory building frames.

The method is self correcting, that is, the error, if any, in a cycle is

corrected automatically in the subsequent cycles. The checking is

easier as only the last cycle is required to be checked.

The convergence is generally fast. It leads to the solutions in just a

few cycles of iterations.

12

CHAPTER 2

INTRODUCTION

13

Introduction

Structural analysis is the backbone of civil engineering. During recent

years, there has been a growing emphasis on using computer aided

softwares and tools to analyze the structures. There has also been

advancement in finite element analysis of structures using Finite

Element Analysis methods or matrix analysis. These developments are

most welcome, as they relieve the engineer of the often lengthy

calculations and procedures required to be followed while large or

complicated structures are analyzed using classical methods. But not

all the time such detailed analysis are necessary to be performed i.e.

sometimes, just approximate analysis could suffice our requirements as

in case of preparing the rough estimates and participating in the

bidding process for a tender. It may even happen that sometimes the

analysis software or tool is not available at hand? Or the worst case,

the computer itself is not available?? Then in such cases, accurate

analysis of such large and complicated structures involving so many

calculations is almost impossible.

Now-a-days, high rise buildings and multi-bay-multi-storey buildings are

very common in metropolitan cities. The analysis of frames of multi-

storeyed buildings proves to be rather cumbersome as the frames have

a large number of joints which are free to move. Even if the commonly

used Moment distribution method is applied to all the joints, the work

involved shall be tremendous. However, with certain assumptions,

applying the substitute analysis methods like substitute frame method,

portal method, cantilever method or factor method, the structures can

be analyzed approximately.

Substitute frame method

By considering any floor of the frame called substitute frame, the

moments can be calculated and results can be obtained in good

14

agreement with the results from rigorous analysis. The moments

carried from floor to floor through columns are very small as compared

to the beam moments; therefore, the moments in one floor have

negligible effect on the moments on the floors above and below.

Therefore, in this method, the analysis of the multi-storeyed frames is

carried out by taking one floor at a time. Each floor is taken with

columns above and below fixed at far ends, and the moments and

shears are calculated in beams and columns.

The method is very effective in analyzing any framed structure under

vertical loadings. This work is focused to check its applicability and

efficacy under the lateral loading conditions

Objectives

To manually analyze the problem frame, using Kanis method under

vertical loading conditions.

To perform the same analysis using standard analysis software

Staad.Pro

Perform substitute frame analysis for the loading cases

Compare the accuracy of the substitute frame analysis with manual

and Staad.Pro analysis and check its validity in lateral loading cases.

Optimize the substitute frame method to further lessen the

calculations so as to get the final results within permissible limit of

errors.

Design the Structural members of the multistory.

15

CHAPTER 3

ANALYSIS UNDER VERTICAL LOADS

16

Approximate analysis of the frame for

vertical loads:

The analysis is made by considering the following assumptions:

1) Beams do not receive axial forces.

2) For any beam a point of contra flexure occurs at a distance of 0.1L

form each end of the span, where L is the span of beam

Dead load on the beams = 25 kN/m

Live load on the beams = 15 kN/m

Span of the beams between AB, EF, IJ, CD, GH, KL = 6.1 m

Span of the beams between BC, FG, JK = 2.1 m

Assume points of contra flexure at 0.1 L from each end i.e. 0.1 x 6.1 = 0.61 m

from each end for the long beams.

Distance between points of contra flexure, L

1

= 6.1 - (2x0.61) = 4.88 m

17

Maximum positive B.M =

25+15

8

x 4.88

2

= 119.1 kN-m

Shear at each point of contra flexure = (15+25)

4.88

2

= 97.6 kN

Maximum negative moment at each end of the beam =

- [97.6 x 0.61+

400.610.61

2

] = - 67 kN

Maximum shear force for a beam occurs at each end of the beam and is

equal to

406.1

2

= 122 kN

Analysis of columns:

Consider the end column AEMN

Axial force in AE = 40 x 3.05 = 122 kN

Axial force in EI = 122+122 = 244 kN

Axial force in IM = 244+122 = 366 kN

Moment at the upper end of column = Moment at the end of beam = 67 kN-m

Assuming equal stiffness for column moment transmitted to each column by a

beam at E or I = 67/2 = 33.5 kN-m

Now consider any interior column.

There will be no moment transmission to the interior column.

Consider the column BFJN

Axial force in BF = 40 x 6.1 = 244 kN,

Axial force in FJ = 244+244 = 488 kN

Axial force in JN = 488+244 =732 Kn

18

Method of substitute frames :

Analysis of multi-storey building frames involves lot of complications and

tedious calculations by using conventional methods. To carry out exact

analysis is a time consuming task. Substitute frame method for analysis

of multistory frame can be handy in approximate and quick analysis. This

method has been applied only for vertical loading conditions.

The method assumes that the moments in the beams of any floor are

influenced by loading on that floor alone. The influence of loading on the

lower or upper floors is ignored altogether.

The process involves the division of multi-storied structure into smaller

frames. These sub frames are known as equivalent frames or substitute

frames.

The sub frames are usually analyzed by the moment distribution method,

using only Two cycle of distribution. It is only necessary to consider the loads

on the two nearest spans on each side of the point .

The substitute frames are formed by the beams at the floor level under

consideration, together with the columns above and below with their far ends

fixed.

19

The distributed B.M are not carried over far ends of the columns in this

process; the moments in the columns are computed at each floor level

independently and retained at that floor irrespective of further analysis.

Assumptions

Slab thickness = 0.15m floor finish thickness = 0.05m

Beam section = 0.35mx0.45m column section = 0.35mx0.35m

Density of concrete used = 25 Kn/m

3

live load for educational building =

3kN/m

2

Clockwise moment positive and vice-versa

Loading-

Slab dead load = 0.15x1x25 = 3.75 kN/m

2

Floor finish = 1.25 kN/m

2

, live load = 3kN/m

2

Beam self weight = 0.35x0.45x25 = 3.9 kN/m

Total vertical load per metre length of beam = (3.75+1.25+3)+3.9 = 12kN/m

Fixed end moments induced

20

M

ab

= M

ef

= M

ij

=M

cd

= M

gh

= M

kl

= -

1266

12

= - 36 kN-m

M

ba

= M

fe

= M

ji

=M

dc

= M

hg

= M

lk

=

1266

12

= 36kN-m

M

bc

= M

fg

= M

jk

= -

1222

12

= - 4kN-m

M

bc

= M

gf

= M

kj

=

1222

12

= 4kN-m

Span

Moment of

inertia (mm

3

)

x10

3

Length

(L)

metres

Relative

stiffness

(K)

Distribution

factors

= K/k

Rotation

Factor =

-(1/2)( K/k)

AB 443 6 73.8 0.34

-0.17

AE 417 3 139 0.65

-0.325

BA 443 6 73.8 0.08

-0.04

BF 417 3 139 0.15

-0.075

BC 1328 2 664 0.75

-0.375

CB 1328 2 664 0.75

-0.375

CG 417 3 139 0.15

-0.075

CD 443 6 73.8 0.08

-0.04

DC 443 6 73.8 0.34

-0.17

DH 417 3 139 0.65

-0.325

EA 417 3 139 0.39

-0.195

EF 443 6 73.8 0.21

-0.105

EI 417 3 139 0.39

-0.195

FE 443 6 73.8 0.07

-0.035

FB 417 3 139 0.14

-0.07

FG 1328 2 664 0.65

-0.325

FJ 417 3 139 0.14

-0.07

GF 1328 2 664 0.65

-0.325

GC 417 3 139 0.14

-0.07

GH 443 6 73.8 0.07

-0.035

GK 417 3 139 0.14

-0.07

HD 417 3 139 0.39

-0.195

HL 417 3 139 0.39

-0.195

HG 443 6 73.8 0.21

-0.105

21

IE 417 3 139 0.48

-0.24

IJ 443 6 73.8 0.25

-0.125

II 313 4 78.3 0.27

-0.135

JI 443 6 73.8 0.08

-0.04

JF 417 3 139 0.14

-0.07

JK 1328 2 664 0.70

-0.35

JJ 313 4 78.3 0.08

-0.04

KJ 1328 2 664 0.70

-0.35

KG 417 3 139 0.14

-0.07

KL 443 6 73.8 0.08

-0.04

KK 313 4 78.3 0.08

-0.04

LH 417 3 139 0.48

-0.24

LL 313 4 78.3 0.27

-0.135

LK 443 6 73.8 0.25

-0.125

Spacing of the frame = 5.4 m

D.L of Slab = 5 kN/m

2

, L.L of Slab = 3 kN/m

2

D.L of floor per meter run of girder = (5 x 5.4) + 8.1 = 35.1 kN/m

L.L of floor per meter run of girder = 3 x 5.4 = 16.2 kN/m

Fixed end moments: The fixed end moments due to dead load and live load

are-

Member D.L per metre

(kN/m)

L.L per metre

(kN/m)

F.E.M due to

D.L (kN-m)

F.E.M due to

D.L+L.L(kN-m)

EF 35.1 16.2 105.3 153.9

FG 35.1 16.2 11.7 17.1

GH 35.1 16.2 105.3 153.9

22

Frame will be analyzed be two cycle moment distribution:

Bending Moment in columns:

Loading: D.L on EFGH, L.L on EF and GH

JOINT E F G H

Column

distribution

factors

Just above floor

Just below floor

0.39

0.39

0.14

0.14

0.14

0.14

0.39

0.39

Horizontal

members

EF FE FG GF GH HG

Distribution

factors

FEM due to D.L

F.E.M due to

total load

Distribution

+carry over

0.21

-153.9

-4.977

0.07 0.65

-11.7

153.9

16.16 -92.43

0.65 0.07

11.7

-153.9

92.43 -16.16

0.21

153.9

4.977

Summation

-158.877 170.06 -104.13 104.13 -170.06 158.87

Distribution to

23

columns

Just above floor

Just below floor

61.95

61.95

9.23

9.23

-9.23

-9.23

61.95

61.95

joints E F G H

Members EF FE FG GF GH HG

Distribution

factors

0.21 0.07 0.65 0.65 0.07 0.21

FEM,s -153.9 153.9 -17.1 17.1 -153.9 153.9

Distribution 32.32 -9.57 -88.92 88.92 -9.57 -32.32

Carry over -4.78 16.16 -49.24 -4.78 -16.16 4.8

Distribution 1.0 -2.31 21.47 25.79 2.77 1.08

Carry over -1.15 0.5 12.89 10.73 0.54 1.38

Distribution 0.24 -0.57 8.25 6.62 0.71 0.28

Total moment -126.3 158.1 -112.7 128.6 -156.5 124.8

24

Members Staad Pro

End moments

Kanis Method

End Moments

Substitute frame

end moments

Kanis Method

Vs

S/ F Method

EF -129.23 -133.37 -126.3 5.5%

FE 156.52 160.43 158.1 1.47%

FG 108.57 -113.51 -112.7 0.7%

GF 120.64 128.6 128.6 0

GH -150.42 -159.76 -156.5 2.08%

HG 127.60 125 124.8 0.2%

The inference made from the table is that in case of vertical loading, the

difference between the Kanis analysis and substitute frame method (S/F

method) is very less.

25

Chapter 4

Design of Slab

26

Design of slab:

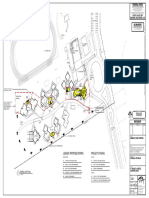

Plan of Ground Floor and First Floor

27

Design of slab: S1 (Two-way slab)

Size of slab = 5.4 m x 6.3 m

Edge conditions = two adjacent edges discontinuous

Materials used = M-20 grade of concrete and Fe-415 HYSD bars

Depth of slab: 6 inch = 152.4mm

Adopt the effective depth (d) = 135mm

Loads:

Self weight of slab = (25 x 0.22) = 5.5 kN/m

2

Imposed load = 3 kN/m

2

Weight of flooring 50 mm thick = (0.05 x 24) = 1.2 kN/m

2

Total working load = w = 9.7 kN/m

2

Therefore design ultimate load = w

u

= (1.5 x 9.7) = 14.55kN/m

2

Ultimate design moments

The moment coefficients for (L

y

/L

x

) = (6.3/5.4) =1.16

Short span moment coefficients:

a) ve moment coefficient =

x

= 0.053

b) +ve moment coefficient =

x

= 0.040

Long span moment coefficients:

a) ve moment coefficient =

y

= 0.042

b) +ve moment coefficient=

y

= 0.035

M

ux

(-ve) = (

x

w

u

L

x

2

) = (0.053 x 14.55 x 5.4

2

) = 22.9 kN-m

M

ux

(+ve)= (

x

w

u

L

x

2

) = (0.040 x 14.55 x 5.4

2

) = 16.97 kN-m

M

uy

(-ve) = (

y

w

u

L

x

2

) = (0.042 x 14.55 x 5.4

2

) = 17.82 kN-m

M

uy

(+ve) = (

y

w

u

L

x

2

) = (0.035 x 14.55 x 5.4

2

) = 14.85 kN-m

V

u

= 0.5 w

u

L

x

= 0.5 x 14.55 x 5.4 = 39.3 kN

28

Check for depth: M

u,lim

= 0.138 f

ck

b d

2

d = (22.9 x 10

6

)/(0.138 x 20 x 1000) = 91mm < 135mm

hence the effective depth selected is sufficient to resist the design ultimate

moment

A

st,min

=(0.12% b d) = 0.0012 x 1000 x 153 = 183.6 mm

2

Reinforcements along short and long span directions

the area of reinforcement is calculated using the relation,

M

u

= 0.87 f

y

A

st

d {1- A

st

f

y

/ b d f

ck

}

Spacing of the selected bars are computed using the relation,

Spacing = S = (Area of 1 bar/ total area) x1000 such that A

st

(provided)

A

st

(min)

In addition, the spacing should be the least Of three times the effective depth

or 300 mm. using 10 mm diameter bars for long span, d = 135 mm & for short

span, d = 125 mm.

The detail of reinforcements provided in the two-way slab is compiled in the

table below:

Location A

st

(required) Spacing of 10 mm bars

1) Short span

a) ve B.M(top of supports)

b) +ve B.M(centre of span)

560 mm

2

403 mm

2

140 mm c/c

190 mm c/c

2) Long span

a) ve B.M (top of supports)

b) +ve B.M(centre of span)

388 mm

2

320 mm

2

200 mm c/c

240 mm c/c

Torsion Reinforcement at corners

Area of torsional steel in each 4 layers = (0.75 x 403) = 302.25 mm

2

29

Distance over which the torsion reinforcement is provided = (1/5 short span) =

(0.2 x 5400) = 1080 mm. Provide 6 mm diameter bars at 75 mm c/c for a

length of 1080 mm at all 4 corners in 4 layers

Design of slab: S2 (Two-way Slab)

Size of slab = 5.4 m x 6.3 m

Edge conditions = one edge discontinuous

Materials used = M-20 grade of concrete and Fe-415 HYSD bars

Depth of slab: 6 inch = 152.4mm

Adopt the effective depth (d) = 135mm

Loads:

Self weight of slab = (25 x 0.22) = 5.5 kN/m

2

Imposed load = 3 kN/m

2

Weight of flooring 50 mm thick = (0.05 x 24) = 1.2 kN/m

2

Total working load = w = 9.7 kN/m

2

Therefore design ultimate load = w

u

= (1.5 x 9.7) = 14.55 kN/m

2

Ultimate design moments

The moment coefficients for (L

y

/L

x

) = (6.3/5.4) =1.16

Short span moment coefficients:

c) ve moment coefficient =

x

= 0.048

d) +ve moment coefficient =

x

= 0.036

Long span moment coefficients:

c) ve moment coefficient =

y

= 0.037

d) +ve moment coefficient=

y

= 0.028

M

ux

(-ve) = (

x

w

u

L

x

2

) = (0.048 x 14.55 x 5.4

2

) = 20.36 kN-m

30

M

ux

(+ve) = (

x

w

u

L

x

2

) = (0.036 x 14.55 x 5.4

2

) = 15.27 kN-m

M

uy

(-ve) = (

y

w

u

L

x

2

) = (0.037 x 14.55 x 5.4

2

) = 15.69 kN-m

M

uy

(+ve) = (

y

w

u

L

x

2

) = (0.028 x 14.55 x 5.4

2

) = 11.88 kN-m

V

u

= 0.5 w

u

L

x

= 0.5 x 14.55 x 5.4 = 39.3 kN

Check for depth:

M

u, lim

= 0.138 f

ck

b d

2

d = (20.36 x 10

6

) / (0.138 x 20 x 1000) = 85.88mm < 135mm

Hence the effective depth selected is sufficient to resist the design ultimate

moment

A

st, min

= (0.12% b d) = 0.0012 x 1000 x 153 = 183.6 mm

2

Reinforcements along short and long span directions

The area of reinforcement is calculated using the relation,

M

u

= 0.87 f

y

A

st

d {1- A

st

f

y

/ b d f

ck

}

Spacing of the selected bars are computed using the relation,

Spacing = S = (Area of 1 bar/ total area) x1000, such that A

st

(provided) A

st

(min)

In addition, the spacing should be the least Of three times the effective depth

or 300 mm. using 10 mm diameter bars for long span, d = 135 mm & for short

span, d = 125 mm.

The detail of reinforcements provided in the two-way slab is compiled in the

table below:

31

Location A

st

(required) Spacing of 10 mm

bars

3) Short span

c) ve B.M(top of supports)

d) +ve B.M(centre of span)

490 mm

2

360 mm

2

160 mm c/c

215 mm c/c

4) Long span

c) ve B.M (top of supports)

d) +ve B.M(centre of span)

340 mm

2

254 mm

2

230 mm c/c

305 mm c/c

Torsion Reinforcement at corners

Area of torsional steel in each 4 layers = (0.75 x 360) = 270 mm

2

Distance over which the torsion reinforcement is provided = (1/5 short span) =

(0.2 x 5400) = 1080 mm. Provide 6 mm diameter bars at 75 mm c/c for a

length of 1080 mm at all 4 corners in 4 layers

(Same for Design of other slabs having same area and end conditions)

Design of slab S3 (One-way Slab)

Size of slab = 5.4 m x 2.1m

Edge conditions = one edge discontinuous

Materials used = M-20 grade of concrete and Fe-415 HYSD bars

Depth of slab: 6 inch = 152.4mm

Adopt the effective depth (d) = 135mm

Loads:

Self weight of slab = (25 x 0.22) = 5.5 kN/m

2

Imposed load = 3 kN/m

2

Weight of flooring 50 mm thick = (0.05 x 24) = 1.2 kN/m

2

32

Total working load = w = 9.7 kN/m

2

Therefore design ultimate load = w

u

= (1.5 x 9.7) = 14.55 kN/m

2

Ultimate design moments

The moment coefficients for (L

y

/L

x

) = (6.3/5.4) =1.16

Short span moment coefficients:

e) ve moment coefficient =

x

= 0.048

f) +ve moment coefficient =

x

= 0.036

Long span moment coefficients:

e) ve moment coefficient =

y

= 0.037

f) +ve moment coefficient=

y

= 0.028

M

ux

(-ve) = (

x

w

u

L

x

2

) = (0.048 x 14.55 x 5.4

2

) = 20.36 kN-m

M

ux

(+ve) = (

x

w

u

L

x

2

) = (0.036 x 14.55 x 5.4

2

) = 15.27 kN-m

M

uy

(-ve) = (

y

w

u

L

x

2

) = (0.037 x 14.55 x 5.4

2

) = 15.69 kN-m

M

uy

(+ve) = (

y

w

u

L

x

2

) = (0.028 x 14.55 x 5.4

2

) = 11.88 kN-m

V

u

= 0.5 w

u

L

x

= 0.5 x 14.55 x 5.4 = 39.3 kN

Check for depth:

M

u, lim

= 0.138 f

ck

b d

2

d = (20.36 x 10

6

) / (0.138 x 20 x 1000) = 85.88mm < 135mm

Hence the effective depth selected is sufficient to resist the design ultimate

moment

A

st, min

= (0.12% b d) = 0.0012 x 1000 x 153 = 183.6 mm

2

Reinforcements along short and long span directions

The area of reinforcement is calculated using the relation,

M

u

= 0.87 f

y

A

st

d {1- A

st

f

y

/ b d f

ck

}

Spacing of the selected bars are computed using the relation,

33

Spacing = S = (Area of 1 bar/ total area) x1000, such that A

st

(provided) A

st

(min)

In addition, the spacing should be the least Of three times the effective depth

or 300 mm. using 10 mm diameter bars for long span, d = 135 mm & for short

span, d = 125 mm.

The detail of reinforcements provided in the two-way slab is compiled in the

table below:

Location A

st

(required) Spacing of 10 mm

bars

5) Short span

a) ve B.M(top of supports)

b) +ve B.M(centre of span)

490 mm

2

360 mm

2

160 mm c/c

215 mm c/c

Long span

c) ve B.M (top of supports)

d) +ve B.M(centre of span)

340 mm

2

254 mm

2

230 mm c/c

305 mm c/c

Torsion Reinforcement at corners

Area of torsional steel in each 4 layers = (0.75 x 360) = 270 mm

2

Distance over which the torsion reinforcement is provided = (1/5 short span) =

(0.2 x 5400) = 1080 mm. Provide 6 mm diameter bars at 75 mm c/c for a

length of 1080 mm at all 4 corners in 4 layers

(Same Design for other slabs having same area and end conditions)

Design of slab: S4 (One-way Slab)

Size of slab = 5.4 m x 2.1 m

Edge conditions = one edges discontinuous

Materials used = M-20 grade of concrete and Fe-415 HYSD bars

34

Depth of slab: 6 inch = 152.4mm

Adopt the effective depth (d) = 135mm

Effective span: The least of

i) (Clear span + eff depth ) = 2.1 + 0.135 = 2.235

ii) (Center to center supports) = 2.1+0.23 = 2.33

Loads:

Self weight of slab = (25 x 0.22) = 5.5 kN/m

2

Imposed load = 3 kN/m

2

Weight of flooring 50 mm thick = (0.05 x 24) = 1.2 kN/m

2

Total working load = w = 9.7 kN/m

2

Therefore design ultimate load = w

u

= (1.5 x 9.7) = 14.55kN/m

2

Ultimate moments and shear forces,

M

u

= (0.125w

u

L

2

) = (0.125x14.55x2.235

2

) =9.09 kN-m

V

u

= (0.5w

u

L) = (0.5 x 14.55 x2.235) = 16.25 KN

Limiting moment of resistance

M

u, lim

= 0.138 f

ck

b d

2

=(0.138x20x1000x 135

2

) = 50 KN-m

M

u

<

M

u, lim.

Section is under reinforced.

Tension

Reinforcements

M

u

= 0.87 f

y

A

st

d {1- A

st

f

y

/ b d f

ck

}

9.09x10

6

=( 0.87x415xA

st

135) {1- A

st

415/1000x135x20}

Solving A

st

= 192 mm

2

> A

st, min

= 160 mm

2

Using 10 mm diameter of bars, the spacing of the selected bars are computed

using the relation,

35

Spacing = S = (Area of 1 bar/ total area) x1000 such that A

st

(provided)

A

st

(min)

S = (1000x78.5 / 193 ) = 400mm

Adopt spacing of 400 with alternative bars are bent up at supports

Distribution bars

A

st

= 0.12 percent = (0.12x1000x155) = 186mm

2

Providing 8mm bars at 270 c/c

Check for shear stress

t

v

= (v

u

/ bxd) = (16.25x10

3

/1000x135) = 0.120 N/mm

2

pt = (100A

st

/ bxd ) =(100x192x0.5 / 1000x135) = 0.142

Permissible shear stress slab (as IS- 456 ) is calculated as

kt

c

= 0.36

N/mm

2

> t

v

Hence slab is safe.

Check for deflection control

(L/d)

max

= (L/d)

basic

x k

t

x k

c

x k

f

For pt = s(100x192 / 1000x135) = 0.33 percent ,k

c

= 1, k

f

= 1.

(L/d)

max

= ( 26x1.4x1x1) = 36.4

(L/d)

provided

= 13.8

Hence deflection criteria is satisfied

Design of slab: S5 (One-way Slab)

Size of slab = 5.4 m x 2.1 m

Edge conditions = No one edges discontinuous

Materials used = M-20 grade of concrete and Fe-415 HYSD bars

Depth of slab: 6 inch = 152.4mm

36

Adopt the effective depth (d) = 135mm

Effective span: The least of

(Clear span + eff. depth) = 2.1 + 0.135 = 2.235

(Center to center supports) = 2.1+0.23 = 2.33

Loads:

Self weight of slab = (25 x 0.22) = 5.5 kN/m

2

Imposed load = 3 kN/m

2

Weight of flooring 50 mm thick = (0.05 x 24) = 1.2 kN/m

2

Total working load = w = 9.7 kN/m

2

Therefore design ultimate load = w

u

= (1.5 x 9.7) = 14.55kN/m

2

Ultimate moments and shear forces,

M

u

= (0.125w

u

L

2

) = (0.125x14.55x2.235

2

) = 9.09 kN-m

V

u

= (0.5w

u

L) = (0.5 x 14.55 x2.235) = 16.25 KN

Limiting moment of resistance

M

u, lim

= 0.138 f

ck

b d

2

= (0.138x20x1000x 135

2

) = 50 KN-m

M

u

<

M

u, lim.

Section is under reinforced.

Tension

Reinforcements

M

u

= 0.87 f

y

A

st

d {1- A

st

f

y

/ b d f

ck

}

9.09x10

6

= ( 0.87x415xA

st

135) {1- A

st

415/1000x135x20}

Solving A

st

= 192 mm

2

> A

st, min

= 160 mm

2

Using 10 mm diameter of bars, the spacing of the selected bars are computed

using the relation,

Spacing = S = (Area of 1 bar/ total area) x1000 such that A

st

(provided)

A

st

(min)

37

S = (1000x78.5 / 193 ) = 400mm

Adopt spacing of 400 with alternative bars are bent up at supports

Distribution bars

A

st

= 0.12 percent = (0.12x1000x155) = 186mm

2

Providing 8mm bars at 270 c/c

Check for shear stress

t

v

= (v

u

/ bxd) = (16.25x10

3

/1000x135) = 0.120 N/mm

2

pt = (100A

st

/ bxd ) =(100x192x0.5 / 1000x135) = 0.142

Permissible shear stress slab (as IS- 456 ) is calculated as

kt

c

= 0.36

N/mm

2

> t

v

Hence slab is safe.

Check for deflection control

(L/d)

max

= (L/d)

basic

x k

t

x k

c

x k

f

For pt = s (100x192 / 1000x135) = 0.33 percent, kc = 1, k

f

= 1.

(L/d)

max

= ( 26x1.4x1x1) = 36

(L/d)

provided

= 13.7

Hence deflection criteria is satisfied.

38

CHAPTER 5

Design of Beams

39

DESIGN OF BEAM B1: 350mm x 450mm (Long beam)

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 6.1 m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 9.18 m

2

Weight of slab on beam = 9.18 x 0.1524 x 25 = 5.7 kN/m

Total weight = 18.6 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -126.3 kN-m

Fixed end moment at another end = 158.1 kN-m

Design end moment at mid span =

= (1.5 x 18.6 x 6.1

2

)/8 (18.6 x 6.1

2

)/2

= 129.76 346.05 = -216.29 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -126.3 1.78 0.563 837

IInd Support 158.1 2.23 0.731 1087

Mid Span -216.29 3.05 0.955 1504

Design for shear reinforcement

Maximum shear force = 56.73 kN

Max steel percentage = 0.955 %

t

c

= 0.62 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 56.73 0.62 x 0.35 x 0.45 = 56.63 kN

Shear resisted by stirrups = 56.63 kN

V

us

/ d = 56.63/425 = 0.13 , Provide 2L-8mm shear stirrups

Provide 2L-8mm dia bars @ 75 mm c/c

40

DESIGN OF BEAM B2: 350mm x 450mm (short beam)

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 2.8 m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 9.18 m

2

Weight of slab on beam = 9.18 x 0.1524 x 25 = 5.7 kN/m

Total weight = 18.6 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -112.7 kN-m

Fixed end moment at another end = 128.6 kN-m

Design end moment at mid span =

= (1.5 x 18.6 x 2.8

2

)/8 (18.6 x 2.8

2

)/2

= 27.34 72.91 = -45.57 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -112.7 1.59 0.493 777

IInd Support 128.6 1.81 0.564 889

Mid Span -45.57 0.64 0.186 293

Design for shear reinforcement

Maximum shear force = 26.04 kN

Max steel percentage = 0.56 %

t

c

= 0.5 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 26.04 0.5 x 0.35 x 0.45 = 25.96 kN

Shear resisted by stirrups = 25.96 kN

V

us

/ d = 25.96/425 = 0.06, Provide 2L-8mm shear stirrups

Provide 2L-8mm dia bars @ 80 mm c/c

41

DESIGN OF BEAM B3: 350mm x 450mm (intermediate beam)

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 5.4m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 7.29 m

2

Weight of slab on beam = 7.29 x 0.1524 x 25 = 5.14 kN/m

Total weight = 18.04 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -112.7 kN-m

Fixed end moment at another end = 128.6 kN-m

Design end moment at mid span =

= (1.5 x 18.04 x 5.4

2

)/8 (18.04 x 5.4

2

)/2

= 98.63 263.02 = -164.39 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -112.7 1.59 0.493 777

IInd Support 128.6 1.81 0.564 889

Mid Span -164.39 2.31 0.758 1194

Design for shear reinforcement

Maximum shear force = 48.71 kN

Max steel percentage = 0.758 %

t

c

= 0.57 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 48.71 0.57 x 0.35 x 0.45 = 48.62 kN

Shear resisted by stirrups = 48.62 kN

V

us

/ d = 48.62/425 = 0.11, Provide 2L-8mm shear stirrups

Provide 2L-8mm dia bars @ 80 mm c/c

42

DESIGN OF BEAM B4: 350mm x 450mm

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 6.1m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 18.38 m

2

Weight of slab on beam = 18.36 x 0.1524 x 25 = 11.46 kN/m

Total weight = 24.36 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -126.3 kN-m

Fixed end moment at another end = 158.1 kN-m

Design end moment at mid span =

= (1.5 x 24.36 x 6.1

2

)/8 (24.36 x 6.1

2

)/2

= 169.95 453.21 = -283.26 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -126.3 1.78 0.493 777

IInd Support 158.1 2.23 0.564 889

Mid Span -283.26 3.99 0.955 1504

Design for shear reinforcement

Maximum shear force = 453.21 kN

Max steel percentage = 0.955 %

t

c

= 0.62 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 453.21 0.62 x 0.35 x 0.45 = 453.11 kN

Shear resisted by stirrups = 453.11 kN

V

us

/ d = 453.11/425 = 1.06, Provide 2L-8mm shear stirrups.

Provide 2L-8mm dia bars @ 80 mm c/c

43

DESIGN OF BEAM B5: 350mm x 450mm

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 6.1m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 18.38 m

2

Weight of slab on beam = 18.36 x 0.1524 x 25 = 11.46 kN/m

Total weight = 24.36 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -126.3 kN-m

Fixed end moment at another end = 158.1 kN-m

Design end moment at mid span =

= (1.5 x 24.36 x 6.1

2

)/8 (24.36 x 6.1

2

)/2

= 169.95 453.21 = -283.26 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -126.3 1.78 0.493 777

IInd Support 158.1 2.23 0.564 889

Mid Span -283.26 3.99 0.955 1504

Design for shear reinforcement

Maximum shear force = 453.21 kN

Max steel percentage = 0.955 %

t

c

= 0.62 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 453.21 0.62 x 0.35 x 0.45 = 453.11 kN

Shear resisted by stirrups = 453.11 kN

V

us

/ d = 453.11/425 = 1.06 , Provide 2L-8mm shear stirrups

Provide 2L-8mm dia bars @ 80 mm c/c

44

DESIGN OF BEAM B6: 350mm x 450mm

Calculation of loads

Self weight of beam = 3.9 kN/m , length of beam = 5.4m

Weight of the 9 wall above Beam = 0.15m x 3 x 20 = 9 KN/m

Area of load control of slab under beam = 14.58 m

2

Weight of slab on beam = 18.36 x 0.1524 x 25 = 10.287 kN/m

Total weight = 23.18 KN/m

f

ck

= 20 N/mm

2

f

y

= 415 N/mm

2

Assuming 25 mm effective cover, b = 350 mm, d = 425 mm

Fixed end moment at one end = -126.3 kN-m

Fixed end moment at another end = 158.1 kN-m

Design end moment at mid span =

= (1.5 x 23.18 x 5.4

2

)/8 (23.18 x 5.4

2

)/2

= 187.76 337.96 = -150.20 kNm

Location M

u

(kNm) M

u

/bd

2

P

t

(%)

From SP-16

Area of

steel mm

2

Ist Support -126.3 1.78 0.493 777

IInd Support 158.1 2.23 0.564 889

Mid Span -150.20 2.12 0.685 1079

Design for shear reinforcement

Maximum shear force = 62.58 kN

Max steel percentage = 0.685 %

t

c

= 0.53 N/mm

2

(I.S-456:2000)

V

us

= V

u

t

c

b d

= 62.58 0.53 x 0.35 x 0.45 = 62.49 kN

Shear resisted by stirrups = 62.49 kN

V

us

/ d = 62.49/425 = 0.14, Provide 2L-8mm shear stirrups

Provide 2L-8mm dia bars @ 80 mm c/c

45

3-D model of Building

3-storey frame in Staad Pro

46

Shear Diagram of beam B1

Deflection profile for beam b1

Reinforcement details for Beam B1 in Staad

47

CHAPTER 6

Design of Columns

48

LOADS

1) Floor height = 10 ft = 3.048 m

2) Weight of 6 thick slab (0.1524m) = 25 x 0.1524 = 3.8 kN/m

2

3) Weight of flooring 50 mm thick = 24 x 0.05 = 1.2 KN/m

2

Total D.L = 5.0kN/m

2

4) Imposed floor loads for class rooms and lecture rooms = 3 KN/m

2

5) Self weight of column (350 mm x 350 mm) of 10 m height

= 0.35

2

x10x25 = 30.6 kN

6) Loads from roof (truss) = 1kN/m

2

7) Load of 9 thick wall(228.6mm) for 10m height

= 0.2286x10x20 = 45.72kN/m

8) For each floor height of 3.048m, loads of 9 wall on the beam

= 0.2286x3.048x20 = 13.93kN/m

9) Wind loads: Design wind pressure is P

x

= 0.6V

x

2

Where P

x

= design wind pressure in N/mm

2

at a height Z and

V

x

= design wind velocity in m/s at a height Z

Column A1

Area under column = 2.7 m x 3.16 m = 8.53 m

2

Total dead weight(weight of slab, flooring, finishes) = 8.53 x 5 = 42.65 kN

For three strorey building, total dead load carried = 42.65 x 3 =128 kN

Weight of 9 thick wall = 45.72(3.16+2.7-0.35) = 251.9 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total dead load = 128+251.9+30.6 =410.5 kN

Live load = 3 x 8.53 x 3 = 76.7 kN

Load from Roof = 1 x 8.5 = 8.5 kN

Grand total: 410.5+76.7+8.53 = 495.73 kN

Loading is same for column A4

Column A2

Area of load = 2.7 x 4.36 = 11.7m

2

Dead load(weight of slab, flooring, finishes) =11.7 x 5 = 58.5 kN

49

For three storey building, DL = 58.5 x 3 = 175.5 kN

Weight of 9 thick wall = 45.72(4.36+2.7-0.35) = 306.78 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 175.5+306.78+30.6 = 512.88 kN

L.L = 3 x 11.7 x 3 = 105.3 kN

Load from roof = 1 x 11.7 = 11.7 kN

Grand total: 629.88 kN

Loading is similar for the column A3

Column B1

Area of load control under column B1 = 5.4 x 3.16 = 17.06m

2

Dead load(weight of slab, flooring, finishes) =17.06 x 5 = 85.3 kN

For three storey building, DL = 85.3 x 3 = 256 kN

Weight of 9 thick wall = 45.72(5.4+3.16-0.35) = 375.36 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 256+375.36+3.6 = 747.26 kN

L.L = 3 x 17.06 x 3 = 153 kN

Load from roof = 1 x 17.06 = 17.06 kN

Grand total: 832.02 kN

Loading is similar for the column B4,C1,C4,D1,D4,E1,E4,F1,F4,G1,G4,H1,H4

Column B2:

Area of load control under column B2 = 5.4 x 4.36 = 23.5m

2

Dead load(weight of slab, flooring, finishes) =23.5 x 5 = 117.5 kN

For three storey building, DL = 117.5 x 3 = 352.5 kN

Weight of 9 thick wall = 45.72(5.4+4.36) = 446.2 kN

Self weight of column (350mm x 350mm) of 10m height =

0.35

2

x 10 x 25 = 30.6 kN

50

Total D.L = 256+375.36+3.6 = 747.26 kN

L.L = 3 x 23.5 x 3 = 211.5 kN

Load from roof = 1 x 23.5 = 23.5 kN

Grand total: 1064.3 kN

Loading is similar for the column B3,C2,C3,E2,D1,D2,E3,F2,F3,G2,G3,H2,H3

Column J1

Area of load control under column J1 = 3.16 x 1.25 = 3.95 m

2

Dead load(weight of slab, flooring, finishes) =3.95 x 5 = 19.75 kN

For three storey building, DL = 19.75 x 3 = 59.25 kN

Weight of 9 thick wall = 45.72(1.25+3.16-0.35) = 185.62 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 59.25+185.62+30.6= 275.47 kN

L.L = 3 x 3.95 x 3 = 35.55 kN

Load from roof = 1 x 3.95 = 3.95 kN

Grand total: 314.97 kN

Loading is similar for the column J4

Column J2

Area of load control under column J2 = 1.25 x 4.36 = 5.45 m

2

Dead load(weight of slab, flooring, finishes) =5.45 x 5 = 27.25 kN

For three storey building, DL = 27.75 x 3 = 83.25 kN

Weight of 9 thick wall = 45.72(4.36+1.25-0.35) = 240.48 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 83.45+240.48+30.6= 354.53 kN

L.L = 3 x 5.45 x 3 = 49.05 kN

Load from roof = 1 x 5.45 = 5.45 kN

Grand total: 409.03 kN

51

Loading is similar for the column J3

Column I2

Area of load control under column I2 = 3.95 x 4.36 = 17.22 m

2

Dead load(weight of slab, flooring, finishes) = 17.22 x 5 = 86.1 kN

For three storey building, DL = 86.1 x 3 = 258.3 kN

Weight of 9 thick wall = 45.72(4.36+3.95) = 379.93 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 258.3+379.93+30.6= 668.83 kN

L.L = 3 x 17.22 x 3 = 154.98 kN

Load from roof = 1 x 17.22 = 17.22 kN

Grand total: 841.03 kN

Loading is similar for the column I3

Column I1

Area of load control under column I2 = 3.325 x 3.05 = 10.14 m

2

Dead load(weight of slab, flooring, finishes) = 10.14 x 5 x 0.1524 = 7.72 kN

For three storey building, DL = 7.72 x 3 = 23.18 kN

Weight of 9 thick wall = 45.72(3.325+3.05) = 291.46 kN

Self weight of column (350mm x 350mm) of 10m height = 0.35

2

x 10 x 25 =

30.6 kN

Total D.L = 152.1+291.46+30.6= 345.24 kN

L.L = 3 x 10.14 x 3 = 91.26 kN

Load from roof = 1 x 10.14 = 10.14 kN

Grand total: 575.56 kN, Loading is similar for the column I4

52

Bending Shear Profile for Column C1

Deflection profile for Column C1

Reinforcement details for column C1

53

Chapter 7

Design of footing

54

Design of footing 1 (F1)

1.) Data

Axial load of column=p= 496KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 496KN

Wt of footing & backfill at 10%= 49.6

Total load = 545.6KN

Area of footing = (545.6/200)

= 2.728m

2

Size of footing =L=B = 2.728 = 1.651m

Adopt 1.7 by 1.7m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(496x1.5/1.7x1.7) = 257KN/m

2

=

0.26 N/mm

2

3.) One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.26x1700)(1000-d)

=442(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x1700xd). = (612d) N

V

u1

< V

c1

442(1000-d) < 612d .

d > 420 mm

55

4.) Two way shear,

Assuming the effective depth of slab 430mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.26[1700

2

-(350+d)

2

]

=597246 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

597246 < (1565.2d + 4.472d

2

).

Solving, d > 230.18 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 425mm, and overall depth = 450mm.

5.) Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(260x0.675x0.5)

=87.75 KNm/m

(M

u

/ bd

2

) = (87.75x10

6

/10

3

x425

2

)

=0.4858

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.140 which is less than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x425/100)

=1062.5mm

2

/m

Using 20mm dia bars,

Spacing of bars is S = (1000x314/1063)

=295.39mm c/c

56

Adopt 20mm dia bars at 290mm centres in both directions

Design of footing 2 (F2)

1. Data

Axial load of column=p= 630KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 630KN

Wt of footing & backfill at 10%= 63

Total load = 693KN

Area of footing = (693/200)

= 3.465m

2

Size of footing =L=B = 3.465 = 1.86m

Adopt 1.9 by 1.9m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(630x1.5/1.9x1.9) = 261.77KN/m

2

=

0.26 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.26x1900)(1000-d)

=498(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x1900xd). = (684d) N

V

u1

< V

c1

57

498(1000-d) < 684d .

d > 421 mm

4. Two way shear,

Assuming the effective depth of slab 430mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.26[1900

2

-(350+d)

2

]

=790079.46N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

790079.46 < (1565.2d + 4.472d

2

).

Solving, d > 280.3 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 425mm, and overall depth = 450mm.

5. Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(0.5x0.75x260)

=97.5 KNm/m

(M

u

/ bd

2

) = (97.5x10

6

/10

3

x425

2

)

=0.539

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.155 which is less than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x425/100)

=1062.5mm

2

/m

Using 20mm dia bars,

58

Spacing of bars is S = (1000x314/1063)

=295.39mm c/c

Adopt 20mm dia bars at 290mm centres in both directions

Design of footing 3 (F3)

1. Data

Axial load of column=p=833KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 833KN

Wt of footing & backfill at 10%= 83.3

Total load = 916.3KN

Area of footing = (916.3/200)

= 4.58m

2

Size of footing =L=B = 4.58 = 2.14m

Adopt 2.2 by 2.2 m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(833x1.5/2.2x2.2) = 258.16KN/m

2

=

0.26 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.26x2200)(1000-d)

=572(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x2200xd). = (792d) N

59

V

u1

< V

c1

572(1000-d) < 792 d .

d > 420 mm

4. Two way shear,

Assuming the effective depth of slab 430mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.26[2200

2

-(350+d)

2

]

=1104246 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

1104246< (1565.2d + 4.472d

2

).

Solving, d >315.82 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 425mm, and overall depth = 450mm.

5. Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(0.5x0.925x260)

=120.25 KNm/m

(M

u

/ bd

2

) = (120.25x10

6

/10

3

x425

2

)

=0.67

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.188 which is less than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x425/100)

=1062.5mm

2

/m

60

Using 20mm dia bars,

Spacing of bars is S = (1000x314/1063)

=295.39mm c/c

Adopt 20mm dia bars at 290mm centres in both directions

Design of footing 4 (F4)

1. Data

Axial load of column=p=1065KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 1065KN

Wt of footing & backfill at 10%=106.5

Total load =1171. KN

Area of footing = (1171.5/200)

= 5.86m

2

Size of footing =L=B = 5.86 = 2.42m

Adopt 2.5 by 2.5m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(1065x1.5/2.5x2.5) = 255.6KN/m

2

=

0.26 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.26x2500)(1000-d)

=650(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

61

V

c1

=(t

c

x2500xd). = (900d) N

V

u1

< V

c1

650(1000-d) < 900d .

d > 420 mm

4. Two way shear,

Assuming the effective depth of slab 420mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.26[2500

2

-(350+d)

2

]

=1470846 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

1470846 < (1565.2d + 4.472d

2

).

Solving, d > 425 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 425mm, and overall depth = 450mm.

5. Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(0.5x1.075x260)

=139.75 KNm/m

(M

u

/ bd

2

) = (140x10

6

/10

3

x425

2

)

=0.78

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.224 which is less than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x425/100)

62

=1062.5mm

2

/m

Using 20mm dia bars,

Spacing of bars is S = (1000x314/1063)

=295.39mm c/c

Adopt 20mm dia bars at 290mm centres in both directions

Design of footing 5 (F5)

1. Data

Axial load of column=p= 315KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 315KN

Wt of footing & backfill at 10%= 31.5

Total load = 346.5KN

Area of footing = (346.5/200)

= 1.73m

2

Size of footing =L=B = 1.73 = 1.316m

Adopt 1.3 by 1.3m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(315x1.5/1.3x1.3) = 279.58KN/m

2

=

0.28 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face

Factored shear force = V

u1

= (0.28x1300)(1000-d)

=364(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

63

One way shear resistance

V

c1

=(t

c

x1300xd). = (468d) N

V

u1

< V

c1

364(1000-d) < 468d .

d > 437.5 mm

4. Two way shear,

Assuming the effective depth of slab 438mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.28[1300

2

-(350+d)

2

]

=299335.65 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

299335.65 < (1565.2d + 4.472d

2

).

Solving, d > 138 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 440mm, and overall depth = 465mm.

5. Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(0.5x0.475x280)

=66.5 KNm/m

(M

u

/ bd

2

) = (66.5x10

6

/10

3

x425

2

)

=0.368

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.102 which is less than 0.25 percent assumed for one- way shear

64

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x425/100)

=1062.5mm

2

/m

Using 20mm dia bars,

Spacing of bars is S = (1000x314/1063)

=295.39mm c/c

Adopt 20mm dia bars at 290mm centres in both directions.

Design of footing 6 (F6)

1. Data

Axial load of column=p= 410KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 410KN

Wt of footing & backfill at 10%= 41

Total load = 451kN

Area of footing = (451/200)

= 2.25m

2

Size of footing =L=B = 2.25 = 1.501m

Adopt 1.5 by 1.5m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(410x1.5/1.5x1.5) = 273.33KN/m

2

=

0.27 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.26x1500)(1000-d)

=390(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

65

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x1500xd). = (540d) N

V

u1

< V

c1

390(1000-d) < 540d .

d > 295.45 mm

4. Two way shear,

Assuming the effective depth of slab 300mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.27[1500

2

-(350+d)

2

]

=493425 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

493425 < (1565.2d + 4.472d

2

).

Solving, d > 200.44 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 200mm, and overall depth = 225mm.

5. Design of reinforcements.

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(273x0.575x0.5)

=78.48 KNm/m

(M

u

/ bd

2

) = (78.48x10

6

/10

3

x425

2

)

=1.55

66

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.477 which is greater than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.477x1000x200/100)

=954 mm

2

/m

Using 16mm dia bars,

Spacing of bars is S = (1000x154/954)

=161.42mm c/c

Adopt 16 mm dia bars at 160mm centres in both directions

Design of footing 7 (F7)

1. Data

Axial load of column=p= 842 KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 842 KN

Wt of footing & backfill at 10%= 84.2

Total load = 926.2KN

Area of footing = (926.2/200)

= 4.631m

2

Size of footing =L=B = 4.631 = 2.151m

Adopt 2.1 by 2.1m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(842x1.5/2.1x2.1) = 286.39KN/m

2

=

0.286 N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

( refer fig 7)

67

Factored shear force = V

u1

= (0.286x2100)(1000-d)

=600(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x2100xd). = (756d) N

V

u1

< V

c1

600(1000-d) < 756d .

d > 442 mm

4. Two way shear,

Assuming the effective depth of slab 442mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.286[2100

2

-(350+d)

2

]

=1081862.5 N

Two way shear resistance is calculated as

V

c2

= k

s

x t

c

[4(350+d)d]

Where k

s

=1, t

c

=0.25 = 1.118 N/mm

2

=1x1.118[1400d+4d

2

]

V

u2

< v

c2

,

1081862.5 < (1565.2d + 4.472d

2

).

Solving, d > 347 mm

Hence, one way shear is more critical,

Adopt eff depth =d = 445mm, and overall depth = 470mm.

5. Design of reinforcements.

68

Ultimate moment at col face is computed as

M

u

=(0.5xbxs.p) =(286x0.675x0.5)

=96.52 KNm/m

(M

u

/ bd

2

) = (96.52x10

6

/10

3

x425

2

)

=0.53

Refer table 2 SP-16, and interpolate the percentage of reinforcement as p

t

=0.152 which is less than 0.25 percent assumed for one- way shear

Therefore, A

st

= (p

t

bd/100) =(0.25x1000x445/100)

=1112.5mm

2

/m

Using 20mm dia bars,

Spacing of bars is S = (1000x314/1113)

=282.12mm c/c

Adopt 20mm dia bars at 280mm centres in both directions

Design of footing 8 (F8)

1. Data

Axial load of colum,P = 576KN

Size of column = 350 x 350 mm

2

Use M20 & fe-415HYSD bars

2.) Size of footing;

Load on column = 576KN

Wt of footing & backfill at 10%= 57.6

Total load = 633.6KN

Area of footing = (633.6/200)

= 3.168m

2

Size of footing =L=B = 3.168 = 1.779m

Adopt 1.8 by 1.8m square footing.

Net soil pressure at ultimate loads with a load factor of 1.5 is given by

Q

u

(576x1.5/1.8x1.8) = 266.6KN/m

2

69

=

0.266N/mm

2

3. One way shear.

The critical section is at a distance d from the column face .

Factored shear force = V

u1

= (0.266x1800) (1000-d)

=478.8(1000-d)

Assuming percentage of reinforcement in the footing pt = 0.25 percent for

M20 grade concrete

Now from IS-456 code permissible shear stress as =t

c

=0.36 N/mm

2

One way shear resistance

V

c1

=(t

c

x1800xd). = (648d) N

V

u1

< V

c1

479(1000-d) < 648d .

d > 425 mm

4. Two way shear,

Assuming the effective depth of slab 430mm and computing the two way

shear resistance at critical section (d/2) from face of column,

We have the relation

V

c2

= 0.266[1800

2

-(350+d)